TBEI CRYSTEEL DEUCE User manual

1644259E (406159) 2020-09-301

DEUCE

CRYSTEEL’S

Website: www.TBEI.com

E-mail: [email protected]

Web Site E-Mail Phone (507) 726-2728

THIS MANUAL MUST BE INCLUDED WITH THE VEHICLE

AFTER COMPLETING THE INSTALLATION.

1644259E (406159) 2020-09-3021644259E (406159) 2020-09-303

DATE PURCHASED ____________________________________________________________________

HOIST SERIAL NUMBER ______________________________________________________________

CYLINDER SERIAL NUMBER ________________________________________________________

DEALER ____________________________________________________________________

ADDRESS ____________________________________________________________________

PHONE ____________________________________________________________________

FOREWORD

The Deuce is a dual purpose dump body capable of dumping to the rear or to the left (driver’s) side. The

left side is a `dump through’ side, hinged at the top and latched at the bottom. The right side folds down for

easy loading and unloading of pallets or other materials. The tailgate is a `quick-drop’ design allowing the

tailgate to be folded down or hinged at the top.

This manual contains the information needed for the proper installation and operation of Crysteel’s Deuce

body and hoist. With proper installation, use, and regular maintenance, the Deuce will give many years of

trouble free service.

When ordering parts, be sure to give serial number of the body, hoist, and cylinder. The serial number of the

body is found stamped into the front of the body near the trip lever. The serial number of the hoist is stamped

into the cylinder mounting plate. The serial number of the cylinder is stamped on the barrel of the cylinder

near the base. For future reference, copy these numbers NOW in the space provided above. Order parts by

number and description as given in the parts listing in this manual.

1. Engage PTO from cab and adjust engine speed to fast idle.

2. The hoist should raise when the hoist control lever is pulled back, hold when the lever is in

the center detent, and lower when the lever is pushed forward.

3. To raise the hoist, pull the control lever back. To hold the body in a raised position, place the

control lever in its center detent position. To lower the hoist, push the control lever forward.

4. ALWAYS return the hoist control lever to its center detent position after each use.

5. DO NOT LEAVE THE PTO IN GEAR WHILE TRANSPORTING. THIS CAN CAUSE

SEVERE DAMAGE TO THE PTO OR HYDRAULIC PUMP.

6. Toraisethebodyprop,raisethebody,shutoallpower,raisetheproparmtoafreestand-

ing position. Lower the body slowly using the manual override control in the hydraulic cabinet

until the body prop bracket contacts the prop arm saddle.

7. To lower the body prop, raise the body, lower the prop arm to its storage position. Lower the

body.

8. Thehydraulicsystemshouldbedrained,ushedandrelledwithproperhydraulicuidat

regular intervals. CAUTION: NEVER use hydraulic BRAKE FLUID in the hydraulic system.

OPERATIONANDUSE

SOMEDO’SANDDON’TS FOR SAFEANDLONGSERVICE

1. Usetheproperhydraulicuid.KEEPITCLEAN.Remembertochangeitregularly.

2. Lubricateallgreasettingsevery100cyclesoreverytwomonths.Infrequentorinsucient

lubrication will cause hoist failure and possibly injury or death.

3. ALWAYS carefully block up the body, using the body prop, before working under it.

4. Do not “race” the engine when unloading.

5. Do not load the hoist beyond its capacity.

6. DO NOT tamper with the hydraulic relief valve. This will void the warranty. It can cause

severe damage to the hoist and cylinder.

7. Never leave the PTO in gear while transporting. It could ruin the hydraulic pump, the PTO

or the transmission.

8. Checkallboltsandttingsregularly.Keepthemtight.Seetableonpage4fortorquevalues.

9. Alwaysoperatehoistonarmandlevelsurface.

10. Always make sure area around truck is clear and safe for hoist operation and dumping.

1644259E (406159) 2020-09-3041644259E (406159) 2020-09-305

TABLE OF CONTENTS

FOREWORD 2

SOME DO’S AND DON’TS FOR SAFE AND LONG SERVICE 3

OPERATION AND USE 3

LOCATE DEUCE BODY / HOIST / SUBFRAME 6

LOCATE MOUNTING PLATES 7

DRILL TRUCK FRAME 7

WELD MOUNTING PLATES TO SUBFRAME 7

WELD SUBFRAME TO TRUCK FRAME AT REAR 7

SELECT REAR DUMPING POSITION 8

HYDRAULIC SYSTEMS 9

INSTALL GEAR PUMP 9

INSTALL RESERVOIR / VALVE 9

INSTALL HOIST CONTROL 10

INSTALL HOSES - GEAR PUMP 11

ADD HYDRAULIC FLUID - GEAR PUMP 11

ELECTRIC POWER UNIT MOUNTING - GENERAL 12

INSTALL HOSES - ELECTRIC SINGLE-ACTING 13

INSTALL HOSES - ELECTRIC DOUBLE-ACTING 13

ADD HYDRAULIC OIL - ELECTRIC POWER UNIT 13

INSTALL GREASE ZERKS AND LUBRICATE 14

INSTALL LIGHTS, REFLECTORS AND DECALS 16

CHECK HINGE LATCH ADJUSTMENT 18

DEUCE HOIST PARTS 19

DEUCE SUBFRAME PARTS 20

CYLINDER PARTS 24

SPECIFICATIONS 25

CAPACITY 25

INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

It is a good idea to look through these installation instructions before beginning to mount the hoist and

hydraulic system.

When welding, protect the truck’s electrical, air and brake systems by disconnecting, removing or cover-

ing. Tighten all nuts and bolts to a consistent level. Use the following table for torque values.

Size Grade 2 Torque Grade 5 Torque Grade 8 Torque

1/4-20 3-4 lb-ft 6-7 lb-ft 10-11 lb-ft

1/4-28 4-5 lb-ft 8-9 lb-ft 11-12 lb-ft

5/16-18 8-9 lb-ft 14-15 lb-ft 21-22 lb-ft

5/16-24 9-10 lb-ft 15-16 lb-ft 21-22 lb-ft

3/8-16 17-18 lb-ft 24-26 lb-ft 37-40 lb-ft

3/8-24 19-20 lb-ft 28-30 lb-ft 40-43 lb-ft

1/2-13 38-42 lb-ft 60-65 lb-ft 90-100 lb-ft

1/2-20 43-47 lb-ft 70-75 lb-ft 95-105 lb-ft

5/8-11 75-80 lb-ft 122-130 lb-ft 180-190 lb-ft

5/8-18 85-90 lb-ft 145-150 lb-ft 200-210 lb-ft

3/4-10 132-140 lb-ft 220-230 lb-ft 315-330 lb-ft

3/4-16 152-160 lb-ft 250-260 lb-ft 355-370 lb-ft

Thefollowingabbreviationsareusedindescribinghydraulicttings.

ORBM O-Ring Boss - Male Thread

NPTM Pipe - Male Thread

NPTF Pipe - Female Thread

JICM JIC 37° - Male Thread

JICF JIC 37° - Female Thread

1644259E (406159) 2020-09-3061644259E (406159) 2020-09-307

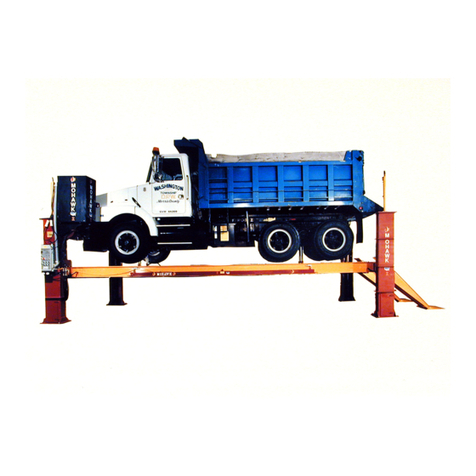

LOCATE DEUCE BODY / HOIST / SUBFRAME

Before placing the Deuce body/hoist/subframe on the truck, measure the length of the truck frame behind the

rearaxle.ThemaximumtruckframelengththatwillnotaecttheoperationoftheDeuceis471/2inches,

assuming a cab clearance of 3 inches. The minimum truck frame length for supporting the Deuce subframe

is 40 1/2 inches, assuming a cab clearance of 3 inches. If the truck frame is longer than 47 1/2 inches, mark

thetruckframeatthepreferredlengthof43inchesandcutito.SeeFigure1.

If the frame cannot be shortened to 47 1/2 inches, the cab clearance can be increased by moving the Deuce

body/hoist/subframeback.HOWEVER,thiswillaectweightdistribution.

The Deuce body, hoist and subframe come pre-assembled. Place the body/hoist/subframe on the truck with

a minimum of 3 inches of cab clearance. See Figure 1.

NOTE:Ifthetruckframehasrivetsinthetopange,addspacersbetweenthetruckframeandsubframe,

or counter sink the rivet heads into the subframe by drilling holes in the subframe. Do not remove the rivet

heads!

CAUTION: BE CAREFUL OF BRAKE LINES, WIRING, ETC. INSIDE THE

TRUCK FRAME WHEN DRILLING THE TRUCK FRAME.

LOCATEMOUNTINGPLATES

The Deuce subframe must be attached to the truck frame at six locations, four mounting plates, two on each

side, and two welds at the very rear of the truck. The rear mounting plates must be located within 5 inches

of the rear crossmember of the subframe. The front mounting plates must be located behind the front cross-

member of the subframe and within 2 inches of the crossmember. See Figures 2 and 3.

Clamp the mounting plates to the truck frame and to the subrame as shown in Figures 2 and 3. If desired,

locate the plates to use existing holes in the truck frame. Mark the mounting plates for drilling. Repeat this

for the other side. If using existing holes larger than 11/16”, use an appropriate sized bolt.

FIG. 2 FIG. 3

FRONT

REAR

DRILLTRUCKFRAME

WELDMOUNTINGPLATESTOSUBFRAME

WELDSUBFRAMETOTRUCKFRAMEATREAR

Drill 21/32” holes in the mounting plates and the truck frame. Bolt the mounting plates in place using 5/8 x

2capscrews(grade8),atwashersandhexlocknuts,tighteningto180-190lb-ft.

Make sure the body/hoist/subframe assembly is correctly located, centered on and square with the truck

frame. Continuously weld the mounting plates to the subframe.

After the mounting plates have been installed, weld the rear crossmember of the subframe directly to the end

ofthetruckframe.OnFordtrucks,pleaserefertotheframesectioninFord’s“QualiedVehicleModier

UniqueGuidelinesandRequirements”document(www.eet.ford.com/truckbbas/non-html/qpg/2004/f-se-

riesguidelines04.pdf). On GM trucks, please refer to the chassis section in their “Best Practices Manual”

(www.gmuptter.com/publicat/introduction.pdf).DONOTweldthesubframetothetruckframeinanyoth-

er location. ONLY at the rear!

1644259E (406159) 2020-09-3081644259E (406159) 2020-09-309

SELECTREARDUMPINGPOSITION

The rest of the installation will need to have the body raised. Before raising the body, make sure the dumping

direction selector handle is in the ‘REAR’ dumping position. See Figure 4. Using an overhead hoist, raise

the body. Once the body is raised, use the hoist prop to hold it up or securely block the body in the raised

position.

To use the hoist prop, raise the body, raise the prop arm and pin it in its raised position and slowly lower the

body to rest on the hoist prop. The hoist prop is located on the passenger side of the Deuce and is mounted

on the Deuce hoist frame. See Figure 5.

DO NOT WORK UNDER A RAISED BODY UNLESS THE BODY IS SECURELY

BLOCKED OR PROPPED IN THE RAISED POSITION.

FIG. 5

HOISTPROP

PROPPIN

INSTALLGEARPUMP

ThegearpumphasanSAE`A’mountingconguration,an11-toothsplinedshaftandatwo-boltmounting

ange,andisassembledforcounterclockwiserotation.Note:ThispumpwillmountdirectlytoChelsea’s

output type `AD’ or Muncie’s output type `T’. Crysteel Manufacturing recommends a PTO ratio of 100-

120%. This assures a minimum pump operating speed of 600 RPM. CHECK THE ROTATION OF THE

PTO! If it is opposite of the engine, then the pump can be used as it is. If the PTO rotation is the same as

the engine, then the pump will need to be reversed. (See instructions included with the pump.) Bolt the gear

pumptothePTOoutputangeusing3/8x1”capscrewsandlockwashers.

INSTALLRESERVOIR/VALVE

HYDRAULICSYSTEMS

CrysteeloersthreedierenthydraulicsystemsforusewiththeDeuce.Mountinginstructionscanbefound

on the pages shown:

The reservoir/valve assembly is intended to be mounted just behind the cab, between the longbeams of the

body with the control valve to the back side of the reservoir. See Figure 6. Bolt the reservoir/valve assembly

tothismountingbracketusing3/8x1”capscrews,atwashersandhexlocknuts.

4 GPM Gear Pump with Remote Reservoir/Valve Pages 8 to 10

Electric Pump-Single Acting Pages 11 & 12

Electric Pump-Double Acting Pages 11 & 12

1644259E (406159) 2020-09-3010 1644259E (406159) 2020-09-3011

INSTALLHOISTCONTROL

Mount the Hoist Control decal on the pedestal taking care to align the holes for the PTO cable and indicator

light. Temporarily assemble the valve control head to the pedestal using 5/16 x 2 1/2 machine screws and hex

nuts.Placethisassemblyontheoorofthecab.Thepedestalandvalvecontrolshouldangleforward.This

makes it convenient for the operator to pull the hoist control lever back to raise the hoist. Make sure there is

enoughroomtooperatethevalvecontrolandgearshiftleverandtoadjusttheseat.Checkbelowtheoor

forobstructionsandcablerouting.Relocatethevalvecontrolifnecessary.Marktheoorusingthepedestal

as a template and drill 11/32” holes for the mounting screws and a 3/4” hole for the control cable. Assemble

the control cable to the valve control head and assemble the valve control head and cover to the pedestal us-

ing5/16x21/2machinescrewsandhexlocknuts.Insertthecontrolcablethroughtheholeintheoorand

mountthepedestaltotheoorusing5/16x1/2hexheadcapscrews,clampingplate(undertheoor)and

hex lock nuts. Make sure the valve control lever is in its center detent position. Keep the control cable away

from hot exhaust pipes and rotating drive shafts. The control cable should not have any sharp bends or kinks

in it (these will make the control harder to operate).

Install the 3/4” hex jam nut onto the valve end of the control cable and turn it past the threads. Insert the end

of the cable through the bonnet clamp. Install the bonnet onto the control cable and turn it past the threads

also. Install the 1/4” hex jam nut and terminal eye on the core rod of the cable; lock the terminal eye to the

core rod of the cable using the hex jam nut. Place the terminal eye in the slot of the valve spool; insert the

short pin through the valve spool and terminal eye and secure it in place with the `E’ ring. Thread the bonnet

ontotheendofthecablesoitrmlytouchestheendofthevalve.(Donotover-orunder-tightenthebon-

net as either would move the valve spool out of its neutral position.) Remove two cap screws from opposite

corners of the seal retainer plate. Slide the bonnet clamp onto the bonnet and secure it to the valve using the

1/4x11/4capscrews,lockwashersandatwashers.Lockthebonnettothecableusingthe3/4”hexjam

nut. (See Fig. 7.)

Study Fig. 8 very carefully before connecting hoses. Install a 90_ street elbow and a 3/4” hose barb in the

suction port on the bottom of the reservoir. Install a 1 1/16 ORB x 3/4” hose barb in the suction port of the

pump and install a 3/4” ID suction hose. Secure the suction hose in place using hose clamps. Install a 1 1/16

ORB x 3/8 NPT adapter and a 3/8 NPT 90_ swivel adapter in the `IN’ port of the control valve and a 7/8

ORB x 3/8 NPT adapter in the pressure port of the pump. Connect a 72” long 3/8” hose between the pump

and the valve.

Install 90_ adapters in the work ports of the control valve and straight adapters in the ports on the cylinder.

Connect the shorter 3/8” hose from the `B’ port on the control valve to the base end port on the cylinder;

connect the longer 3/8” hose from the `A’ port to the rod end port. This will raise the hoist when the control

lever is pulled back and lower it when pushed forward.

INSTALLHOSES-GEARPUMP

NOTE: The `A’ port is the `power-down’ port and has a pressure of only 500-1000 PSI; the `B’ port has full

system pressure.

ADD HYDRAULIC FLUID - GEAR PUMP

UseanISO32gradehydraulicuidwhichcontainscorrosionandoxidationinhibitorsandafoamdepres-

sant.ThisisapproximatelytheequivalentofSAE10Worlighterweightoil.Initiallyllthereservoirwith

10quartsofhydraulicuid.DONOTOVERFILLTHERESERVOIR!

KEEP THE OIL CLEAN! USE CLEAN CONTAINERS, FUNNELS AND OTHER

EQUIPMENT!

With normal use and working conditions the hydraulic oil should be changed annually. The breather cap

should be cleaned every time the hydraulic oil is changed. With heavy use or very dusty working conditions

the hydraulic oil should be changed more often.

NOTE: If the pump does not pump oil, pressurize the reservoir and engage the pump with the engine at slow

idle. Once the pump is working, release the pressure and install the breather cap.

1644259E (406159) 2020-09-3012 1644259E (406159) 2020-09-3013

ELECTRICPOWERUNITMOUNTING-GENERAL

The electric power unit is intended to be mounted just behind the cab, between the longbeams of the body.

(The same place as the reservoir/valve assembly, as shown in Figure 6.) Bolt the double-acting power unit

withthemotortowardsthepassenger’ssidetothebracketprovidedusingthe3/8x1capscrewsandat

washers. Bolt the single-acting power unit with the motor towards the driver’s side to the bracket provided

usingthe3/8x1capscrews,atwashersandhexlocknuts.Insertthe3x5rubberpadundertheendofthe

tank and clamp the tank to the mounting bracket with the 33” long cable tie.

FIG. 9

TO FRONT OF

TRUCK

SUBFRAME

SINGLE-ACTING

POWER UNIT

DOUBLE-ACTING

POWER UNIT

RESERVOIR

MOUNTING

BRACKET

RUBBER PAD

TIE STRAP

RUBBER PAD

For rated performance, the voltage at the power unit must be a minimum of 12VDC. This should be measured

between the large terminal of the start solenoid (where the battery cable is connected) and the power unit

base, where it is bolted to the mounting bracket. NOTE: Grounding of the power unit is just as important as

the installation of the positive battery cable. It is easier to get a good ground by using a second battery cable.

Connect the large terminal on the motor start solenoid to the positive terminal on the battery with a #0 gauge

battery cable. Connect the negative terminal on the battery to the grounding hole on the power unit with a

#0 gauge battery cable. See Figure 7. Check the voltage between the large terminal on the start solenoid and

the power unit base.

Locate the control in the cab and route the cable out of

the cab through a hole in the back of the cab. Connect

the control to the electric power unit using the 3- or 4-pin

connector set.

After completing the wiring, install the motor start

switch cover over the start switch and secure with a tie

strap.

Fig. 10

Connect Ground Cable

Connect Power Cable

Connect Ground Cable

Connect Power Cable

Double-Acting

Power Unit

Single-Acting

Power Unit

Start Switch

Cover

Fig. 8

INSTALL HOSES - ELECTRIC SINGLE-ACTING

Install a 3/8 NPT x 3/4-16 JIC straight adapter in the power port on the electric power unit, install a 3/4 JIC

x 3/4 JIC 90° swivel adapter to this adpater and install a 1/4 NPT x 3/4-16 JIC male elbow in the port on the

angled face of the reservoir.

Connect the shorter 3/8” hose from the power port on the electric power unit to the base end port on the

cylinder; connect the longer 3/8” hose from the reservoir port to the rod end port. See Figure 8 for port iden-

tication.Thiswillraisethehoistwhenthe`UP’buttonispushedandloweritwhenthe`DOWN’buttonis

pushed.

INSTALL HOSES - ELECTRIC DOUBLE-ACTING

Install 9/16 ORB x 3/4 JIC 90³ swivel adapters in both work ports on the electric power unit. If needed,

for good hose routing, install 3/4 JIC x 3/4 JIC 90³ swivel adapters to both of these adapters. Connect the

shorter3/8IDhosewith3/4JICttingsfromthe`C1’portontheelectricpowerunittothebaseendporton

thecylinder.Connectthelonger3/8”IDhosewith3/4JICttingsfromthe`C2’porttotherodendport.

SeeFigure8forportidentication.

NOTE: The `C2’ port is the power down port and has only 500 psi maximum pressure.

ADD HYDRAULIC OIL - ELECTRIC POWER UNIT

UseanISO32gradehydraulicuidwhichcontainscorrosionandoxidationinhibitorsandafoamdepres-

sant. This is approximately the equivalent of SAE 10W or lighter weight oil. Dexron automatic transmis-

sionuidcanbeusedintheelectricpowerunits.Fillthehydraulicreservoirusingthefollowingtable.

Initial Fill

Electric - Single-Acting 10 Qts

Electric - Double-Acting 7 Qts

1644259E (406159) 2020-09-3014 1644259E (406159) 2020-09-3015

INSTALLGREASEZERKSANDLUBRICATE

Lubricateallttingsatregularintervals,atleastevery150

cyclesoreverytwomonths.Thegreasettingsarelocated

as follows:

HOIST

A. Lower Crosstube ......................... 2ttings

B. Upper Crosstube.......................... 1ttings

C. Cylinder Base Pivot Tube ........... 1tting

NOTE: The crosshead, center hinge and body pivot are

equipped with composite bearings which do not need

lubrication.

FIG.11

B

C

A

BODYPIVOT

CROSSHEAD

CENTER

HINGE

BODY

F. Trip Lever - Side Pivot.................1tting

G. Trip Lever - Rear Pivot ................2ttings

H. Side Shaft Pivot............................3ttings

(dump through side)

I. Side Hook Pivot ..........................2ttings

(dump through side)

J. Tailgate Upper Hinge ...................2ttings

K. Rear Latch Cross Shaft ................2ttings

L. Side Hinge Pivot .........................3ttings

(fold down side)

M. Side Shaft Pivot ...........................4ttings

(fold down side)

N. Side Hinge Pivot ..........................2ttings

(dump thru side)

SUBFRAME

O. Side Hinge....................................1tting

P. Rear Hinge ...................................1tting

Q. Left/Rear Hinge ...........................2ttings

R. Side Hinge Saddle........................1tting

S. Rear Hinge Saddle .......................1tting

T. Hinge Control Shaft .....................3ttings

U. Side Latch Control Shaft..............2ttings

V Hoist Pivot ...................................1tting

1644259E (406159) 2020-09-3016 1644259E (406159) 2020-09-3017

INSTALLLIGHTS,REFLECTORSANDDECALS

Install the wiring harness on the body. Anchor the wiring harness to the wire hangers on the body and the

subframe. Be sure to leave a 20 inch long loop between the anchor point on the body and the anchor point

on the subframe to allow for the body to be dumped to the side and the rear without damaging the wiring

harness. There should be some slack in the 20 inch loop when the body is fully raised. Raise the body fully

to the side and check the wiring harness. Raise the body fully to the rear and check the wiring harness again.

Splice the free end of the wiring harness into the marker and ground circuits in the truck wiring.

Insert marker lights into rubber grommets, connect the plugs on the wiring harness to the marker lights and

mount the rubber grommets in the holes provided in the rear pillars and the rear rubrail.

Mounttheamberreectorsnearthefrontonthesides.Mounttheredreectorsneartherearonthesides

and on the tailgate near the sides. Slip the rubber hand grip over the end of the latch control lever. MOUNT

DECALSINTHEPROPERPLACES.SeeFigure15fordecalidenticationandplacement.

Tie Strap Wiring Harness

to Wire Hangers

20 Inch Loop Between

Tie Straps

FIG. 14

FIG. 15

1644259E (406159) 2020-09-3018 1644259E (406159) 2020-09-3019

CHECK HINGE LATCH ADJUSTMENT

The hinge selector linkage is designed to snap ‘over-center’ when the hinge selector handle is moved to se-

lect either the `REAR’ or `SIDE’ dumping direction. The handle moves through a 90_ arc. as shown on the

operation decal. To provide the `over-center snap’ feel, the hooks must contact the hinge pins.

To increase the `over-center’ snap, shorten the tie rods.

DEUCEHOISTPARTS

ITEM DESCRIPTION PART NO. QTY

1. Assy Frame - Deuce 1623837 (150372) 1

2. Assy Cylinder - Deuce 1623615 (148184) 1

3. Cap Screw 3/4-10 x 4 Gr 8 Hex Head 1642961 (401237) 2

4. Hex Lock Nut 3/4-10 1642957 (401226) 2

5. Cap Screw 1/2-13 x 3 1/4 Gr 8 Hex Head 1643433 (403076) 1

6. Hex Lock Nut 1/2-13 1642984 (401316) 1

7. Grease Zerk 1/8 NPT 1645187 (407986) 4

8. Cap Screw 1/2-13 x 4 1/2 Gr 8 Hex Head 1642718 (400135) 1

9. Collar Hoist Mount Tube 1634640 (276171) 1

10. Cap Screw 1/2-13 x 2 3/4 Gr 8 Hex Head 1643730 (404426) 1

11. Pin Upper Pivot 1634031 (272328) 1

12. Roll Pin 1/4 x 3 1642757 (400220) 1

13. Assy Body Prop 1626274 (175199) 1

14. Pin Cotterless 3/8 x 2 1/2 1642759 (400227) 1

1

10

98

6

5

4

3

2

7

6

6

11

12

13

14

1644259E (406159) 2020-09-3020 1644259E (406159) 2020-09-3021

DEUCESUBFRAMEPARTS

ITEM DESCRIPTION PART NO. QTY

1. Assy Hinge Pad 1624748 (156190) 2

2. Rod End Ball 3/8 Male 1636656 (284447) 1

3. Rod End Ball 3/8 Female 1644449 (406640) 1

4. Hex Nut 3/8-24 1643146 (401865) 2

5. Assy Trip Rod - Side 1624750 (156192) 1

6. Grease Zerk 1/8 NPT 1645187 (407986) 6

7. End Yoke 1/2 x 3 w/Lock Pin 1644209 (406039) 2

8. Assy Trip Rod - Rear - 9’ 1624692 (155787) 1

Assy Trip Rod - Rear - 11’ 1624827 (156671) 1

9. Clevis Pin 1/2 x 1.421 1642754 (400215) 2

10. Rue Ring 1/2 1644210 (406040) 2

11. Interlock Cover 1636658 (284449) 1

12. Screw Self-Tapping 5/16-18 x 3/4 1642708 (400112) 4

13. Extension Spring 3/4 x 4 1/2 1644148 (405883) 1

14. Assy Subframe - 9’ Deuce (includes items 2 thru 13) 1625638 (164090) 1

Assy Subframe - 11’ Deuce (includes items 2 thru 13) 1625620 (163709) 1

41

42

27

28

29

31

30

32

34

39

33

36

38

43

35

37

40

16 17

15

18

20

19

21

25

26

2317

18

20

24

21

44

45

46

47

HYDRAULIC SYSTEM PARTS

1644259E (406159) 2020-09-3022 1644259E (406159) 2020-09-3023

ITEM DESCRIPTION PART NO. QTY.

1. Reservoir/Valve Carton 15 Qt 3250 PSI (includes items 2 through 10) 1622192 1

2. Breather Cap 1644723 1

3. Reservoir Weldment 15 Qt 1622166 1

4. Hex Jam Nut 7/8-14 1643196 1

5. Cone Washer 7/8 1643197 1

6. O-Ring .755 ID x .097 CS 1643198 1

7. Control Valve 12 GPM 3250 PSI -8 Port 1643398 1

9. Cap Screw 1/4-20 x 1 3/4 Gr 5 1643058 1

10. Pipe Plug 3/4 Magnetic 1642794 1

11. Adapter 7/8 ORBM x 3/8 NPTF 90° 1642954 1

12. Hose 3/4 JIC x 54” SF/SF 4000 PSI 1644005 1

Hose 3/4 JIC x 66” SF/SF 4000 PSI 1643505 1

Hose 3/4 JIC x 78” SF/SF 4000 PSI 1643804 1

13. Adapter 9/16 ORBM x 3/4 JICM 1643375 2

14. Hose 3/4 JIC x 72” SF/SF 4000 PSI 1643804 1

Hose 3/4 JIC x 96” SF/SF 4000 PSI 1644245 1

15. Adapter 3/4 ORBM x 3/4 JICM 90° 1643357 2

16. Adapter 3/4 JICM x 3/4 JICM 90° 1643545 1

17. Adapter 9/16 ORBM x 3/4 JICM 1643375 1

18. Breather Cap, Splash Resistant 1644498 1

19. Adapter 3/4 JICM x 1/4 NPTM 90° 1643374 1

20. Cable Tie - 33” 1643817 1

21. Rubber Pad 1/4 x 3 x 5 1643881 1

22. Push-Button Control - SA 78” 1200093 1

23. Electric Power Unit - SA 1200094 1

24. Electric Power Unit - DA 2219241 1

25. Keeper, Pistol Grip 2296415 1

26. Control Station W/Cord, 4 Wire DA Pistol 2296414 1

27. Hose 3/8 NPT x 72” RM/RM 4000 PSI 1643014 1

28. Adapter 7/8 ORM x 3/8 NPTF 1642813 1

29. Gear Pump 4 GPM - 9 Tooth 1644648 1

Gear Pump 4 GPM -11 Tooth 1644649 1

30. Hose Barb 1 1/16 ORBM x 3/4 1643228 1

31. Hose Clamp #24 1643011 2

32. Suction Hose 3/4 ID x 72” 1643805 1

33. Hose Barb 3/4 NPTM x 3/4 1643017 1

34. Pipe Elbow 3/4 Street 1643226 1

35. Valve Connection Kit - Prince 4100 1643467 1

36. Clamp Plate, Pedestal 1631026 1

37. Cable, Valve Control - 96” 1643210 1

Cable, Valve Control - 72” 1643209 1

Cable, Valve Control - 84” 1643332 1

Cable, Valve Control - 120” 1643211 1

Cable, Valve Control - 144” 1643212 1

ITEM DESCRIPTION PART NO. QTY.

Cable, Valve Control - 180” 1643213 1

38. Machine Screw 5/16-18 x 1/2 1643329 2

39. Hex Lock Nut 5/16-18 1642962 5

40. Pedestal Bracket, Short - RVC 1630850 1

41. Pedestal Channel, Short - RVC 1630851 1

42. Machine Screw 5/16-18 x 2 1/2 1643233 3

43. Remove Valve Control w/ Center Detent (RVC) 1643208 1

44. Cover Solenoid Service 1644330 1

45. Screw Cap 3/8 X 1 NC G5 1642714 4

46. Washer Flat 3/8 1642732 4

47. Nut Hex Lock 3/8 - 16 1643177 4

NOTES

1644259E (406159) 2020-09-3024 1644259E (406159) 2020-09-3025

CYLINDERPARTS

1

2

3

4

5

6

7

8

9

10

11

12

19

17

16

15

14

13

18

No. Description Item No. Qty

1. Assy Shaft 1623617 (148186) 1

2. Cap Ring 1414737 1

3. Set Screw, Nylon Tip - 1/4” 1642724 (400149) 1

4. Wiper 2.000 ID 1642878 (400913) 1

5. Shaft Seal 2.000 ID 1642765 (400253) 1

6. Cylinder Head 5.500 OD - 2.000 ID 1634982 (278721) 1

7. O-Ring 5.000 ID x .275 CS 1642779 (400276) 2

8. O-Ring 1.500 ID x .070 CS 1642767 (400255) 1

9. Cylinder Piston 5.500 OD 1629802 (205139) 1

10. Piston Seal 5.500 OD x 1/4 CS 1642780 (400277) 1

11. Hex Jam Nut 1 1/2-12 1642995 (401370) 1

12. Assy Cylinder Tube 1623616 (148185) 1

13. Plug 9/16 ORB 1642793 (400404) 1

14. O-Ring 7/16 1642907 (401017) 1

15. Ball - 3/8 1642679 (400013) 1

16. Bypass Valve Pin 1642894 (400979) 1

17. Bypass Valve Body 1642893 (400978) 1

18. Bypass Valve Kit 1621569 (105185) 1

19. Seal Kit 1621641 (107961) 1

SPECIFICATIONS

Hoist Model Cylinder Bore Cylinder Stroke Cylinder Shaft Operating Pressure

DEUCE 5 1/2” 12 1/8” 2” 3250 PSI

CAPACITY

Body Length Overhang Dump Angle

Rear

Capacity to

Rear

Dump Angle

Side

Capacity to

Side

9’ 9” 46° 10.9 Tons 55° 9.6 Tons

11’ 9” 46° 8.6 Tons 55° 9.6 Tons

NOTES

1644259E (406159) 2020-09-3026

CRYSTEEL MANUFACTURING, INC.

CRYSTEEL MANUFACTURING’S

5YEARCUSTOMERSATISFACTIONPLEDGE

& WARRANTY

Crysteel oers the most comprehensive warranty in the truck equip-

ment industry. Crysteel warrants each product against defects in mate-

rial and workmanship for 60 months from the in-service date.

For the full Customer Satisfaction Pledge and Warranty information,

please visit our website.

http://www.crysteel.com

Other TBEI Lifting System manuals