2

Contents

1Safety instructions.......................................................................................4

1.1 General.....................................................................................................4

1.2 Safety actions prior to working on the platform lift.................................4

1.2.1 Only with work in the lift shaft ..........................................................5

1.3 Risk of crushing.......................................................................................7

1.4 Frequency converter.................................................................................7

1.5 Action to be taken in the event of an electrical accident..........................7

2Operating instructions................................................................................8

2.1 Operation of the platform lift...................................................................8

2.1.1 Control panel......................................................................................8

2.2 Emergency situation.................................................................................9

2.2.1 Emergency signal and telephone........................................................9

2.2.2 Manual lowering or raising ..............................................................10

2.2.3 Emergency opening of doors from the inside and outside of the lift

shaft ..................................................................................................10

3Design and configuration..........................................................................12

3.1 Configuration.........................................................................................12

3.2 Platform lift shaft and shaft walls ..........................................................16

3.2.1 Shield wall dismounting and mounting............................................17

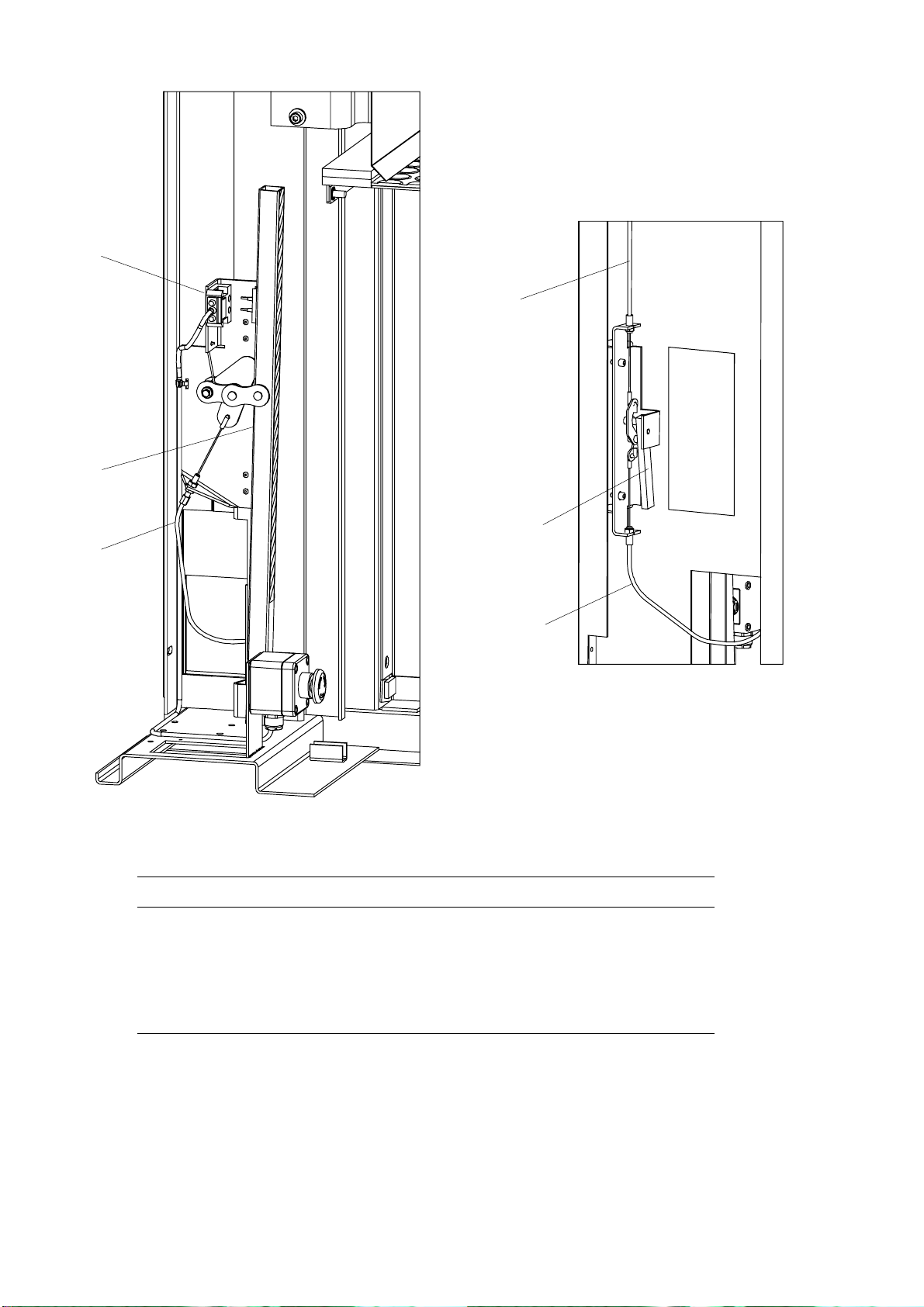

Doors and gates...............................................................................................18

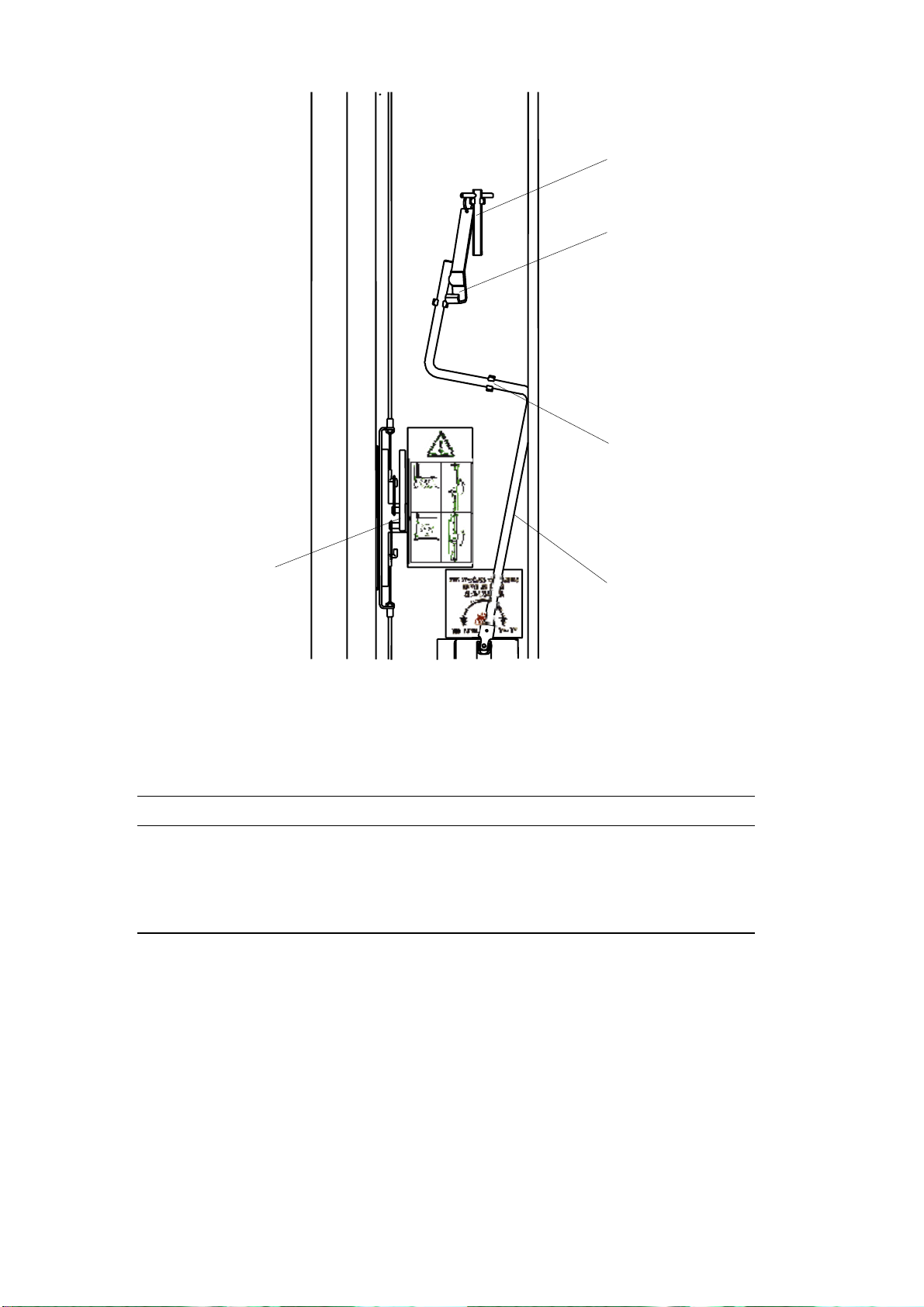

3.2.2 Key locking ......................................................................................19

3.2.3 Automatic door power opener..........................................................20

3.3 Overload protection................................................................................20

3.4 Lighting..................................................................................................20

3.5 Finish......................................................................................................21

3.6 Electrical compartment ..........................................................................21

3.7 Control system .......................................................................................23

4Fault finding ..............................................................................................25

4.1 Fault indications.....................................................................................26

4.2 Fault tracing the CAN-Bus system ........................................................26

5Jumper settings on the circuit card.........................................................30

5.1 Landing level setting (Service mode) ....................................................30

5.2 Jumper placement on the door node on the node card...........................31

5.3 Jumper placement for school locking ....................................................33

6Maintenance ..............................................................................................34

6.1 General...................................................................................................34

6.2 Machinery ..............................................................................................34

6.2.1 Lubrication .......................................................................................34

6.2.2 Visual inspection of drive nut...........................................................35

6.2.3 Drive unit..........................................................................................36

6.3 Shaft.......................................................................................................37

6.4 Electrical compartment ..........................................................................39

6.5 Platform lift............................................................................................39

6.6 Replacing the EPROM...........................................................................40

6.7 Identifying the EPROM .........................................................................41

7Code compliance .......................................................................................42

7.1 Directive and Standards .........................................................................42

7.2 Marking..................................................................................................42