tbs electronics PD-120 User manual

www.trianglebiomedical.com

INNOVATIONS FOR SCIENCE™

Be certain to read this manual thoroughly

before proceeding with unpacking and installation.

TRIANGLE BIOMEDICAL SCIENCES, INC.

3014 CROASDAILE DRIVE • DURHAM, NORTH CAROLINA 27705-2507 • USA • 919.384.9393 • FAX 919.384.9595 • E-MAIL: [email protected]

Paraffin Dispenser

Catalog # PD-120, PD-220

Operator’s Manual

Version 1.5, May 2006

www.trianglebiomedical.com

INNOVATIONS FOR SCIENCE™

TABLE OF CONTENTS

Topic Page

Warranty card Insert A

Introduction 1

Symbols and conventions 2

Overview and specifications 3

Instructions 5

Precautions and maintenance 8

Regulatory Compliance 8

Error codes 9

Troubleshooting 11

Contact information 12

1

INTRODUCTION

Congratulations on your decision to purchase a TBS®6.25-Gallon Paraffin Dispenser.

Your instrument is designed to meet the large volume requirements of today's histology

laboratory by offering the convenience of having 6.25 gallons of molten paraffin

available at all times. While one low-wattage heating element remains on continuously

to prevent clogging within the spout, two other higher wattage elements are

microprocessor-controlled to maintain 1°C temperature accuracy within the paraffin

reservoir. A sensor positioned on the outside cylinder wall detects temperature

changes precipitated by the introduction of solid paraffin pellets. A complex software

algorithm immediately responds by increasing the temperature of heaters at the bottom

of the cylinder and/or surrounding the cylinder wall. As the pellets melt and the

temperature approaches the set point, the software cycles both elements on or off as

required to maintain the set point. A safety overheat protector device (88°C) is

appropriately positioned to provide additional security.

2

SYMBOLS AND CONVENTIONS

Important Notice

Refer to documentation before operation

Hot Surface

3

OVERVIEW AND SPECIFICATIONS

TBS®Paraffin Dispenser (PD)

4

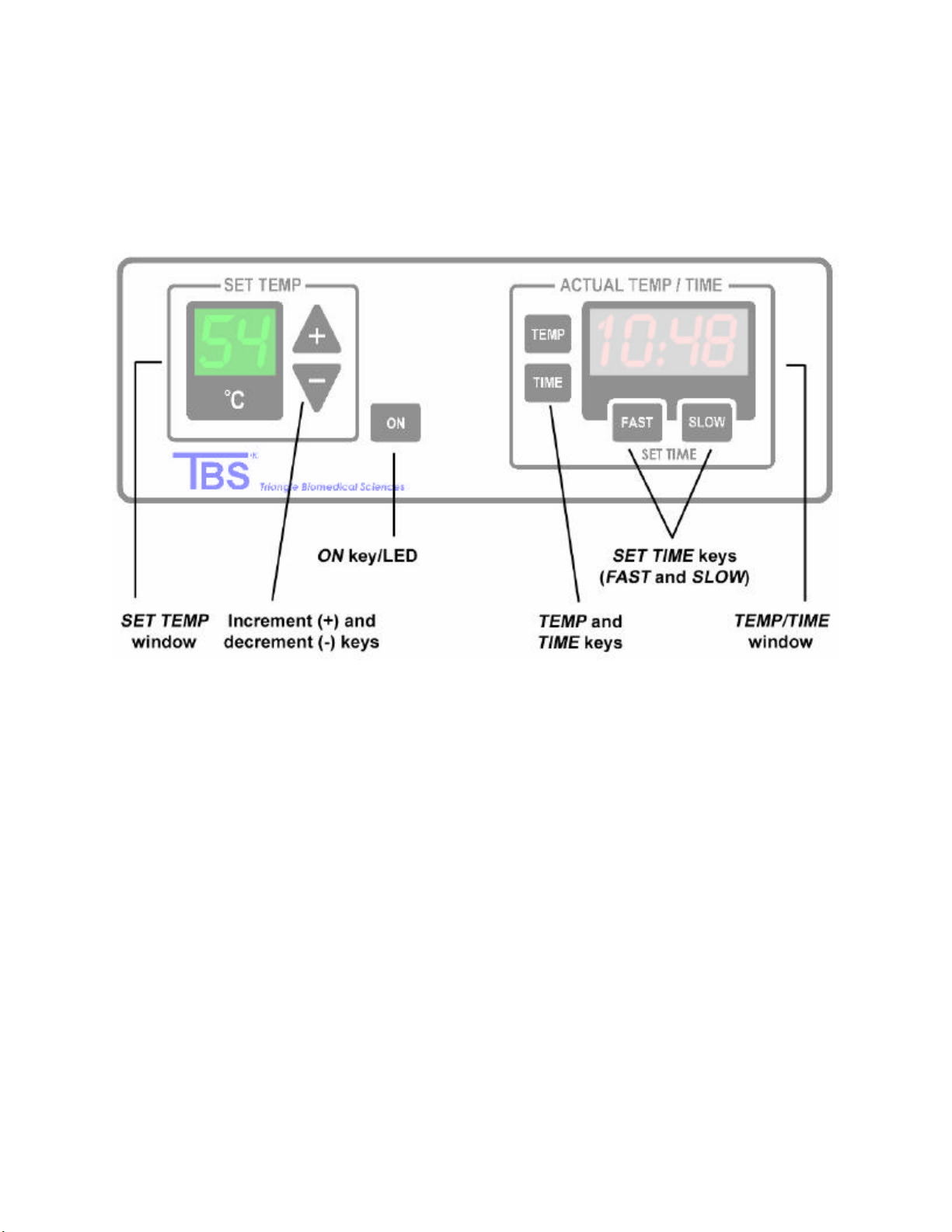

PD Control Panel

Specifications

Dimensions

Height 21.5" (546.1mm)

Width 14" (355.6mm)

Depth 16" (406.4mm)

Voltage

120V AC ±10% 50/60Hz single phase

Current

4.5 amps

Power

540 watts

Default temperature setting

55°C

Maximum temperature

60°C

Heat output

1885 BTU/hr (typical)

Weight

Unit 20.2 lbs (9.072 kg)

Shipping 28 lbs (12.7 kg)

5

INSTRUCTIONS

1. Remove the equipment from the shipping carton carefully. Save the shipping

carton and all packing material until proper operation of the equipment is

confirmed. Immediately notify the carrier if there is any visible damage to the

carton or its contents. Failure to do so may limit your ability to obtain

compensation for damage.

NOTE: The inner chamber of your instrument has been treated with an oil-based

protectant. Please clean the chamber thoroughly with alcohol before filling to avoid

the contamination of paraffin.

2. Connect the power cable to the unit and into a properly grounded 120V outlet.

NOTE: If your unit was shipped outside of the U.S., check the label on the rear of

the instrument for the electrical requirements.

3. Switch the ON/OFF switch at the rear of the unit to the ON position.

4. Immediately upon turning the unit on, the SET TEMP and TIME/TEMP windows

will display 8888 for approximately 4 seconds. The unit will then display PASS or

FAIL in the TEMP/TIME window for 4 seconds. If PASS appears, 06:00 will

appear in the red LED window and flash until set, while the SET TEMP window will

display the factory preset temperature of 55°C.

NOTE: If FAIL appears in the TEMP/TIME window, the SET TEMP LED will be

blank and the beeper will continue to sound. Press any switch to discontinue the

beeping. Although the water bath may appear to function normally, the FAIL

message indicates that the software has found a problem with the unit, and the

unit should be returned for service. Phone our customer service department

immediately for further instructions.

5. Press the ON key to initiate the paraffin reservoir heaters. The small red LED

indicator will light up.

6. You may now set the clock by pressing the SET TIME FAST or SET TIME SLOW

keys. Press the TEMP key to the left of the TEMP/TIME display if you prefer

continuous monitoring of the bath temperature.

7. To increase or decrease the preset reservoir temperature, press and hold the

increment (up arrow) key or the decrement (down arrow) key until the desired

6

temperature is displayed in the SET TEMP window. The maximum operating

temperature is 60°C.

8. Leave the TEMP/TIME display in the TIME mode for continuous monitoring as a

clock, or press the TEMP key to view the actual paraffin temperature. It is not

necessary to unplug the paraffin dispenser while not in use for short periods of

time, as this will cause any user-defined time clock and chamber temperature set

points to be lost.

7

PRECAUTIONS AND MAINTENANCE

•When initially melting a full reservoir of solid paraffin pellets, please allow

approximately 3 hours. For laboratories that are constantly replenishing large

amounts of paraffin, we recommend that you keep your unit set at 62°C to 65°C.

Your meltdown time will be significantly decreased.

•The Paraffin Dispenser is designed to run continuously to maintain large

volumes of molten paraffin; however, any power surge or disruption will activate

the safety cut-off switch, shutting the unit off. TBS recommends that the unit be

connected to a surge protector or some form of uninterrupted power source to

ensure against such disruptions.

•Occasionally check the filter located in the bottom of the paraffin well, as particle

buildup may interfere with the flow volume. The spigot can be removed and

cleaned in the event that clogging does occur. Simply loosen the knurled knob at

the front of the spigot (IMPORTANT: please ensure that the reservoir is empty)

and use forced air to clean the valve. Avoid probing the spigot valve with sharp

objects, as they may puncture the seal.

•A spare 6.3 amp fuse is provided in the fuse holder located in the power entry

module in the rear of the unit.

8

REGULATORY COMPLIANCE

The PD-120/220 has been tested by a registered independent body to rigorous

international quality and safety standards, and has been found to be in compliance with

the following regulations and specifications:

UL 61010A

CSA 1010-1

CE EN/IEC EN61010-1, Safety

EN61000-3-2, Harmonic Distortion

EN55011, Emissions

EN61326, Immunity

EN61000-3-3, Voltage Fluctuation/Flicker

9

ERROR CODES

An error condition exists when the beeper sounds an alarm and the SET TIME LED

display flashes an error code. The error code indicates one of the specific problems as

described below:

Error code Problem

E0 General system failure

E1 Sensor #1: Temperature over 70°C

E2 Sensor #2: Temperature over 72°C

10

TROUBLESHOOTING

Problem Probable cause Solution

Unit has no LED display. •No power from main.

•Blown fuse.

•P3 disconnected.

•Connect cord plug to main.

Switch unit on.

•Replace with correct fuse rating.

If problem persists, consult

qualified personnel.

•Reconnect P3.

No response or audible beep

when keypad is depressed.

•Defective keypad.

•Microprocessor lockup

(power surge).

•Replace keypad (call TBS).

•Switch unit off, wait 3 seconds,

switch back on.

Solid block of paraffin not

melting, but will dispense some

liquid paraffin.

•Set temp too low.

•Defective band heater.

•Defective solid state relay

(K2).

•Increase set temp to 65°C.

•Check resistance value for

approx. 55Ωat P4 pin 4 & 1.

•Replace heater (call TBS).

Paraffin not melting. No liquid

wax dispensing, no increase in

temperature.

•Keypad LED not lit.

•Disconnected P4.

•Defective controller board

and/or firmware.

•Press the ON switch.

•Reconnect P4.

•Replace controller board (call

TBS).

Paraffin completely melted.

Actual and set temp agree

but unit will not dispense wax.

•Defective spigot heater.

•Defective solid state relay

(K4).

•Check resistance value for

approximately 1200Ωat P3 pin

2 and P4 pin 6.

•Replace controller board relay

(call TBS).

Paraffin completely melted.

Actual and set temp agree

but unit will not dispense wax,

and spigot is hot to the touch.

•Foreign objects block spigot

or drain. •Remove foreign object.

Spigot leaks at the handle. •Defective seat cup. •Replace seat cup.

Spigot drips. •Foreign debris not allowing

closure.

•Seat cup not fully seated.

•Switch unit off and remove the

spigot handle to expose silicone

seat cup. Clean cup thoroughly

and reinstall.

•Remove seat cup and reinstall,

ensuring proper seal.

Slow or limited temperature

increase; spigot is hot to the

touch, but paraffin does not

flow.

•Defective bottom heater.

•Open safety over heat

protector (thermostat).

•Defective solid state relay(

K1).

•Check resistance value of the

bottom heater approx. 51Ωat

P4 pins 2 and 3.

•Replace thermostat.

•Replace relay.

E1 error code, temp display

reads HI but paraffin reservoir

not overheating.

•Defective bottom

temperature sensor.

•Sensor disconnected P2.

•Defective controller board.

•Replace sensor (call TBS).

•Reconnect P2.

•Replace controller (call TBS).

11

Problem Probable cause Solution

E1 error code; temp display

reads HI but there is an

indication of the paraffin

overheating.

•Defective K1 (solid state

relay) shorted.

•Defective temperature

sensor or sensor wiring.

•Defective controller board.

•Out of calibration.

•Call TBS for replacement.

•Call TBS for replacement.

•Call TBS for replacement.

•Call TBS for calibration

procedure.

E2 error code display reads HI

but there is no indication of

overheating.

•Defective band temperature

sensor.

•P2 disconnected.

•Controller board failure.

•Call TBS for replacement.

•Reconnect P2.

•Call TBS for replacement.

E2 error code display reads HI

but there are indications that

the paraffin is overheating.

•Defective band temperature

sensor.

•Solid state relay K2 shorted.

•Controller board defective.

•Out of calibration.

•Call TBS for replacement.

•Call TBS for replacement.

•Call TBS for replacement.

•Call TBS for calibration

procedure.

12

CONTACT INFORMATION

Customer service

(919) 384-9393

Fax

(919) 384-9595

Mailing address

Triangle Biomedical Sciences, Inc.

3014 Croasdaile Drive

Durham, NC 27705 U.S.A.

Sales and product information

Customer service questions

All other inquiries

Please visit us at

http://www.trianglebiomedical.com

This manual suits for next models

1

Table of contents

Popular Dispenser manuals by other brands

MARMON

MARMON Prince Castle Silver King SKMCD1P/C1 Operation manual

Brookstone

Brookstone Hands-Free Soap Dispenser instruction manual

Sanela

Sanela SLZN 59ES quick start guide

Gourmet Dispensing

Gourmet Dispensing D300 quick start guide

Cornelius

Cornelius VIPER (E) 2 FLAVOR installation manual

ASI

ASI EZFILL 0391 Series Installation and maintenance guide