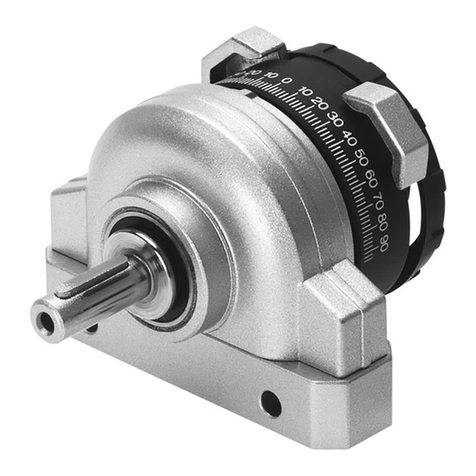

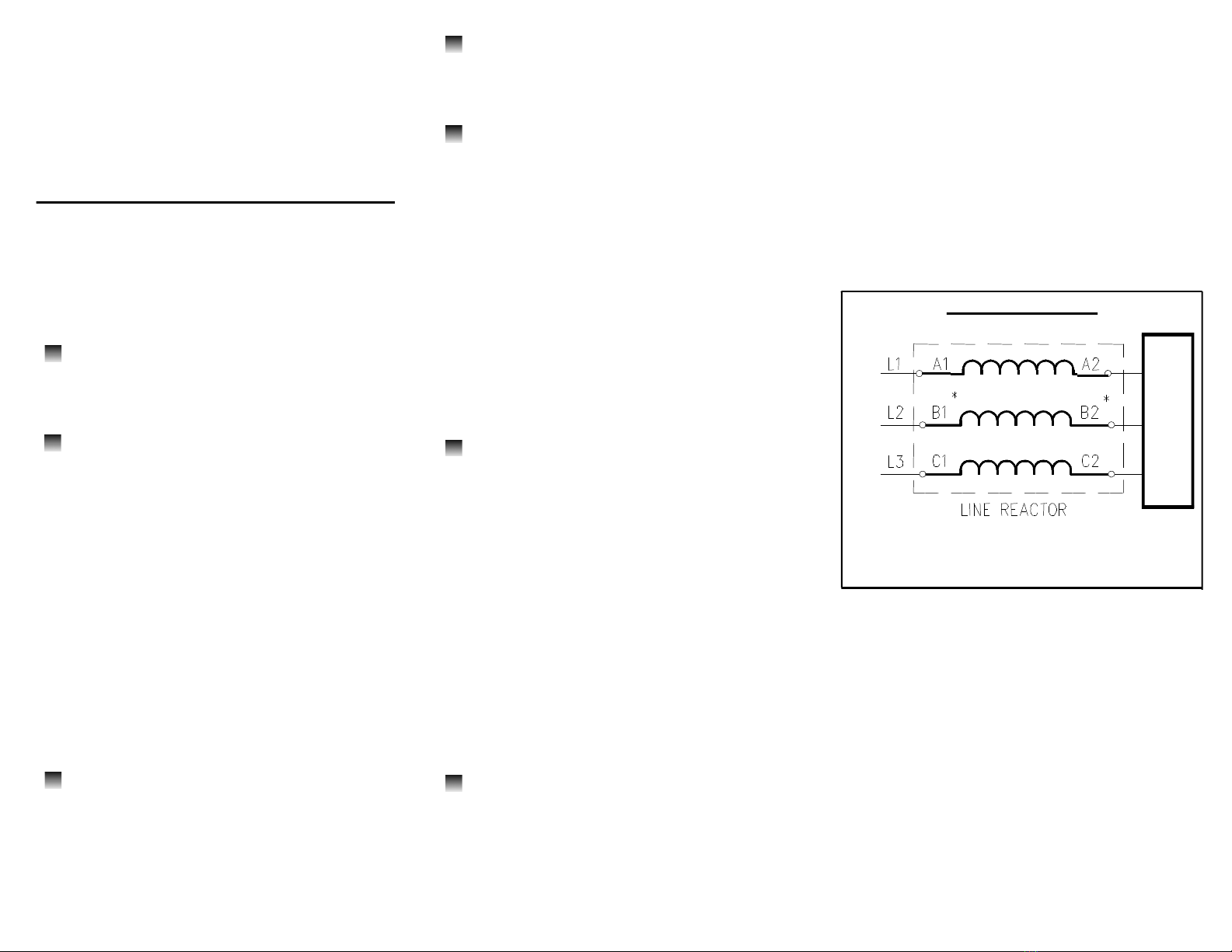

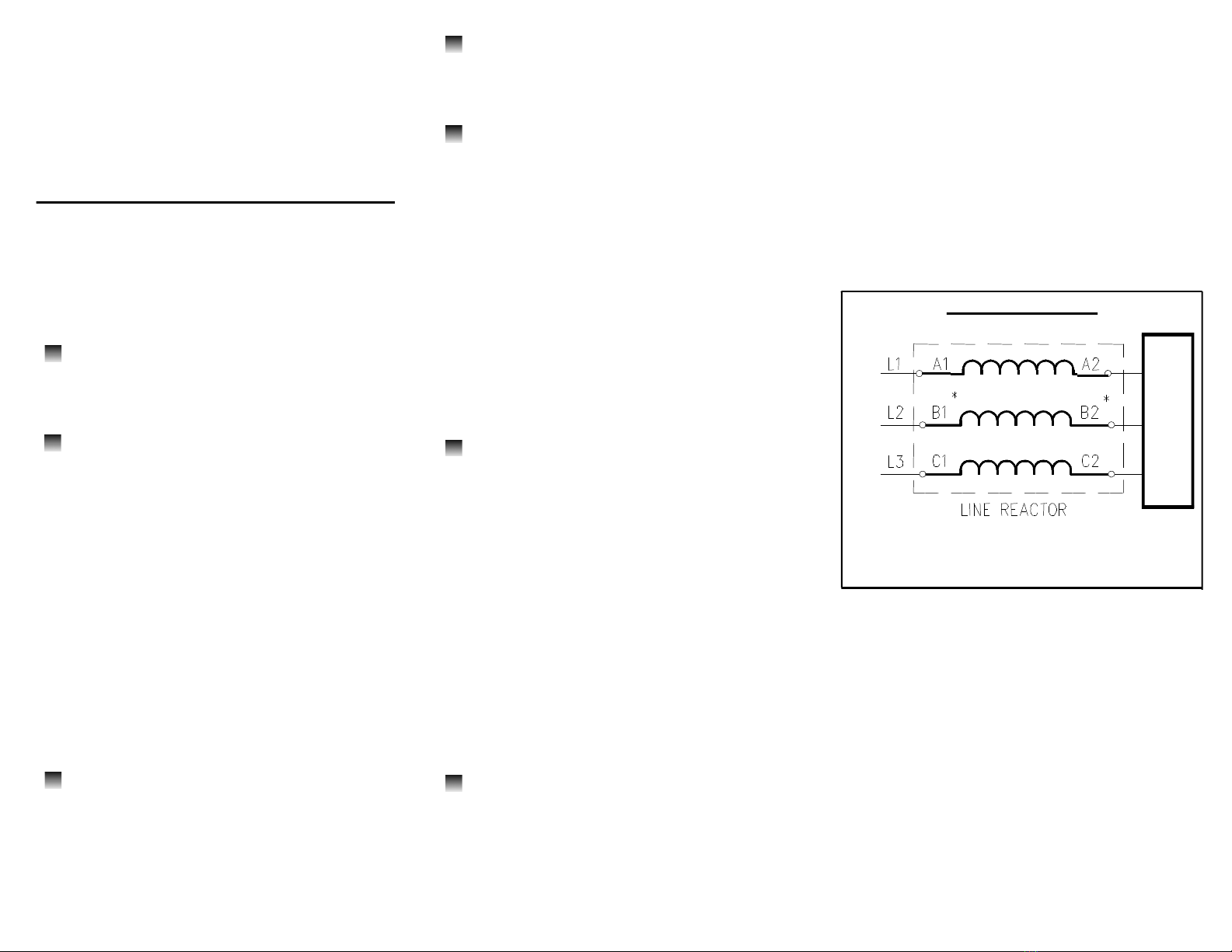

Field WiringInformation

Below is the typical wiring diagram for the 3-phase

reactor applied to the front end of the Variable

Frequency Drive (VFD).

Single-phase applications are acceptable, howev-

er, it is important to size the unit based on the sin-

gle phase Full Load Amperage of the VFD. The

input and output connections should be on termi-

nals A and C to ensure proper performance.

Product Specifications

WiringDiagram

LOAD

LINE

*Forsingle-phaseapplications,usecoils

AandC.IsolateterminalsB1andB2.

u3-Phase, 600 Volt Class

uUL Recognized; File E-116124

uCE Marked

uCSA Approved

uCurrent rated device

u200% rated current for 3 minutes

uAmbient Temperature: 40° C

uPatented Bobbin Construction on

units smaller than 110 amps

uDistributed Gap Technology

TCI recommends that these reactors

be wired as close to the front end of the VFD

as possible.

In standard 40° C ambient or less

installations, a clearance of 3 inches on all

sides of the reactors and its enclosure is

recommended for assisting in heat

dissipation and ample wire bending space.

This is a general guideline for typical

applications. If the reactor is being installed

next to a heat sensitive instrument or control

device, we recommend reviewing specific

requirements or heat limitations. Line reac-

tor heat loss information is available in the

standard TCI product literature or on the web

at Trans-Coil website.

These reactors are designed to be

floor-mounted, or wall-mounted. Large

open-style devices should be panel

mounted by incorporating a bracket that

would act as a shelf to support the reactor

and/or enclosure. When installing an open

style device in an existing control cabinet,

drive cabinet, motor control center, or other

large enclosure, the reactor should be

mounted in the lower half of the cabinet to

prevent hot spots or pockets of heat.

Locating the reactor in the lower half of the

cabinet typically allows better thermal

dissipation and heat convection.

The KLR/KDR input line reactor

should be located as close to the drive as

possible to have the greatest success in

both protecting the VFD as well as mitigating

line harmonics. We recommend this be 10

feet of cable or less.

KLR/KDRLineReactor

InstallationInstruction

INPUT

RecommendationsandConsiderations

When installing the KLR/KDR Line Reactors

on the INPUT side of the Variable

Frequency Drive (VFD), please use the

following guidelines when wiring the unit:

The KLR/KDR Line Reactor is a 3-

phase device and should be wired in series

and positioned on the input side of the VFD.

All Terminal Block connectors will be

marked. A1, B1, and C1 are the input

terminals where the 3 phases of incoming

power are to be wired. As a result, A2, B2,

and C2 are the output terminals. Units with

copper bus or ring lug terminals are not

marked. In these cases, either the upper

terminals or the lower terminals can be used

as the input terminals, as long as the selec-

tion is consistent. For example, if an upper

terminal is selected as the input, all upper

terminals must be input terminals. Wiring

from the output terminals should connect to

the input of the VFD.

Refer to NEC wiring practices for

appropriate wire sizes for your application.