Wired LCC Throttles

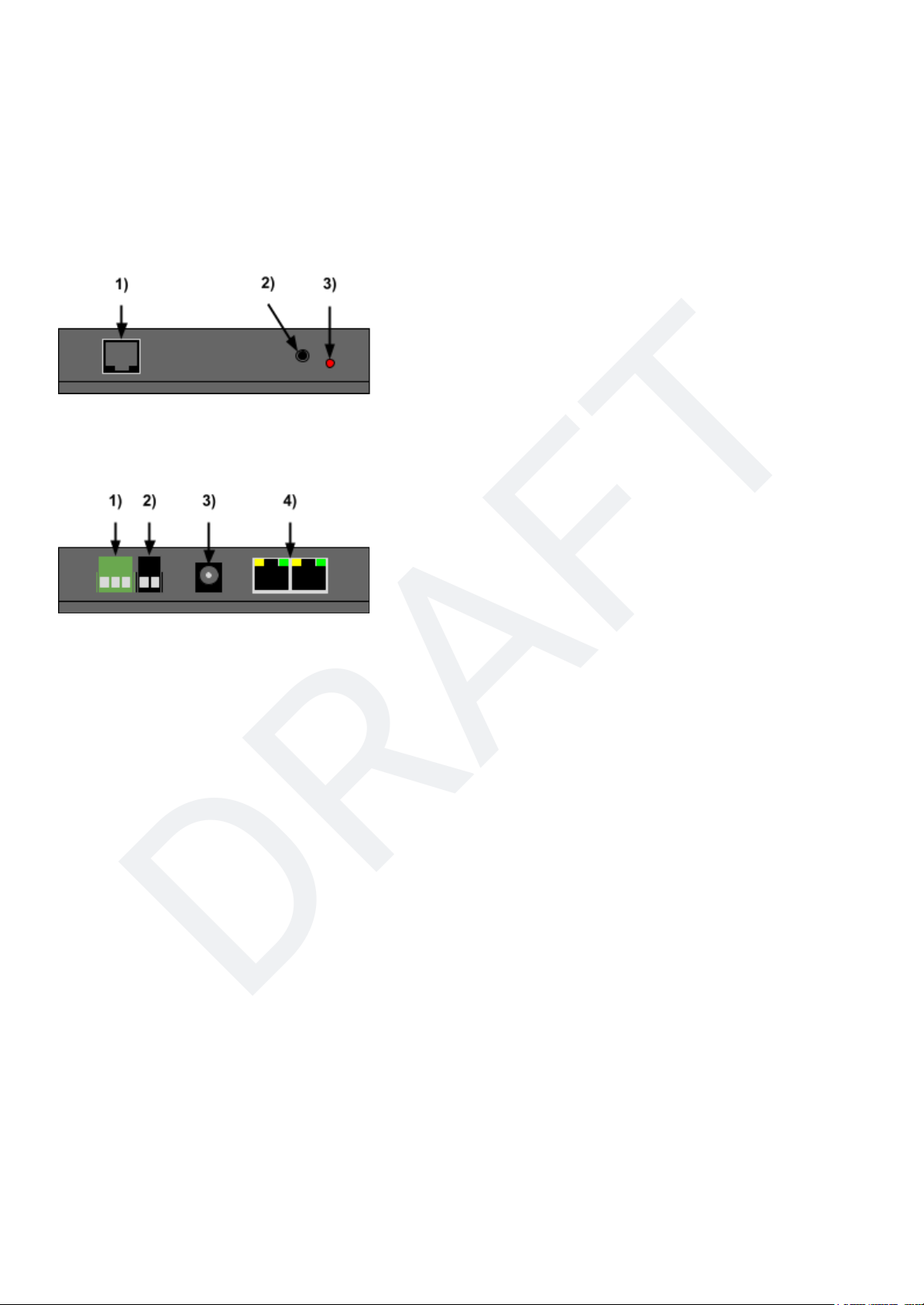

TCS T-50 wired throttles, and/or LT-50 handhelds can be connected directly to the CS-105 through the

on-board dual-RJ-45 LCC header, and/or through add-on LCC fascia panels also available from TCS. If you

connect a T-50 directly to the CS-105 without any other connections on the LCC bus, you must plug a LCC

terminator into the other open port.

Additional LCC throttles, including those controlled by a computer program such as JMRI, can be

connected to and operate trains on the CS-105 through the use of a LCC transceiver such as the LCC

Buffer-USB or LCC-LocoNet Gateway devices available from RR-CirKits Inc.

3.1.2 WiThrottle™ and Engine Driver

WiThrottle™ and Engine Driver throttles can be connected to the CS-105 by using the WiThrottle Protocol

server in JMRI or by using the WFD-30/31 modules from WiFiTrax connected through the Auxiliary

connector in NCE/Ramtraxx/SystemOne Cab Bus mode.

3.1.3 Autodiscovery

The CS-105 uses a standard protocol called mDNS in order for throttles to automatically connect to it when

placed on the same network. Using this protocol, the CS-105 broadcasts its existence over the WiFi

network so that the throttles know how to find and connect to it.

Some networks and WiFi routers block or do not support mDNS packets. In this rare case, it may become

necessary to configure the CS-105 to use a static IP address and manually configure each throttle to

connect using this IP address. More information about this procedure can be found on the TCS website.

3.2 NCE, Ramtraxx, SystemOne Support

NCE, Ramtraxx, and SystemOne throttles are supported by this system through the Auxiliary Cab Bus

port. More information can be found on the TCS Wiki at https://docs.tcsdcc.com/wiki/Cab_Bus.While every

effort has been made to provide a seamless user experience compared to these throttles on their original

system(s), a few features have been added in order to enhance the user experience further. Most of these

added features are only available on NCE, Ramtraxx, and SystemOne Cabs with a 2x16 character LCD.

The Auxiliary Cab Bus in NCE mode also supports the WifiTrax WFD-30/31 WiFi bridge, and the ISE

ProtoThrottle base station (NCE-compatible model).

!!WARNING!! Cab address 1is reserved and should not be used.

3.2.1 NCE Wireless

The NCE wireless system is fully supported. Because of some intrinsic properties of the NCE wireless

system, the behavior of throttles running wirelessly will differ as follows:

1. The EXPN button on NCE cabs is reserved for wireless setup. The EXPN button will not work as

described in the section(s) below. To use the EXPN button as described below, on a wireless cab,

plug the cab in such that it is not using wireless.

2. Normally, when the Horn/Whistle button is pressed, the appropriately assigned function status is

changed to active on the LCD for the duration during which the Horn/Whistle button is held down.

Because the NCE wireless system provides less communications bandwidth than when running

wired, this feature is disabled in wireless mode. This helps to improve overall NCE wireless

performance.

© 2022 Train Control Systems Page 10 of 49