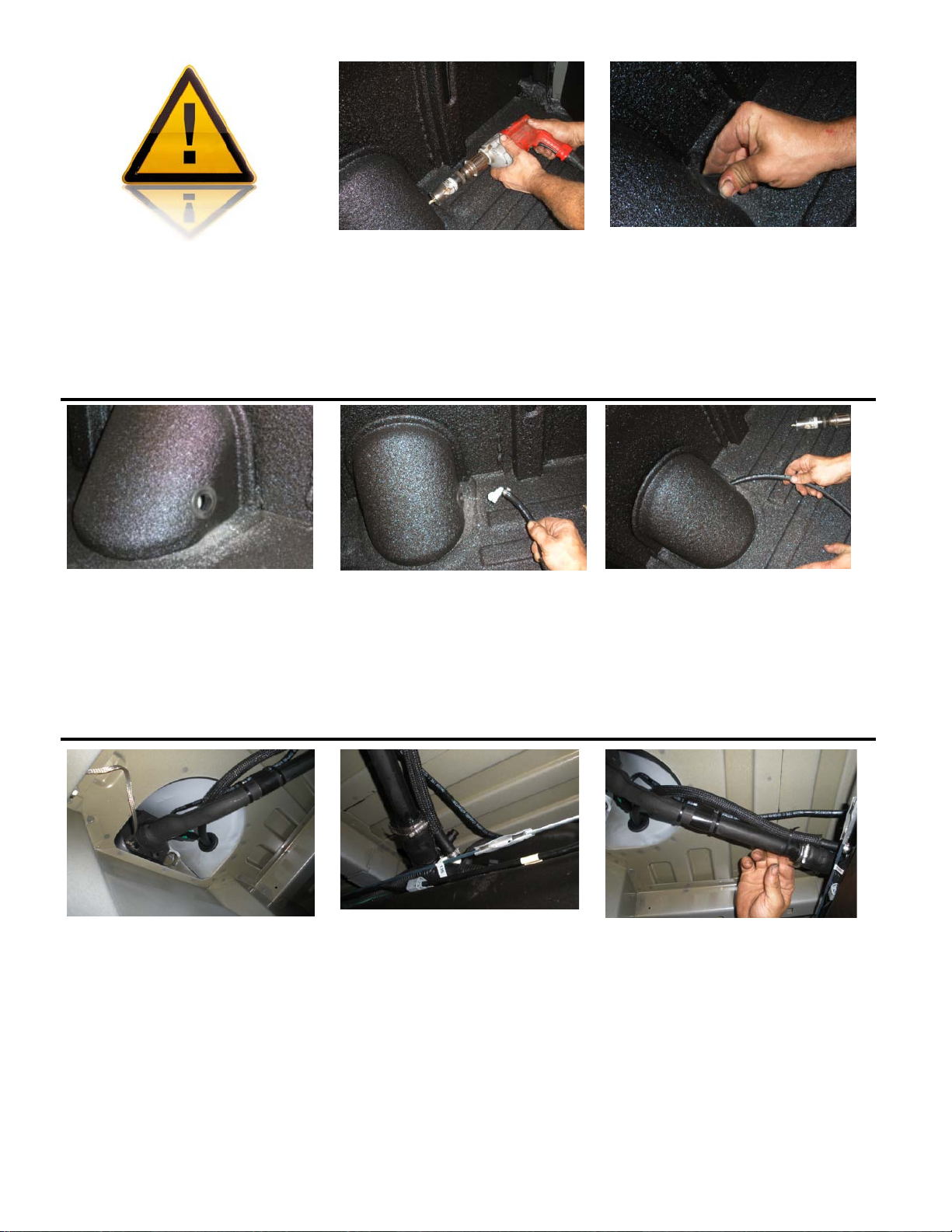

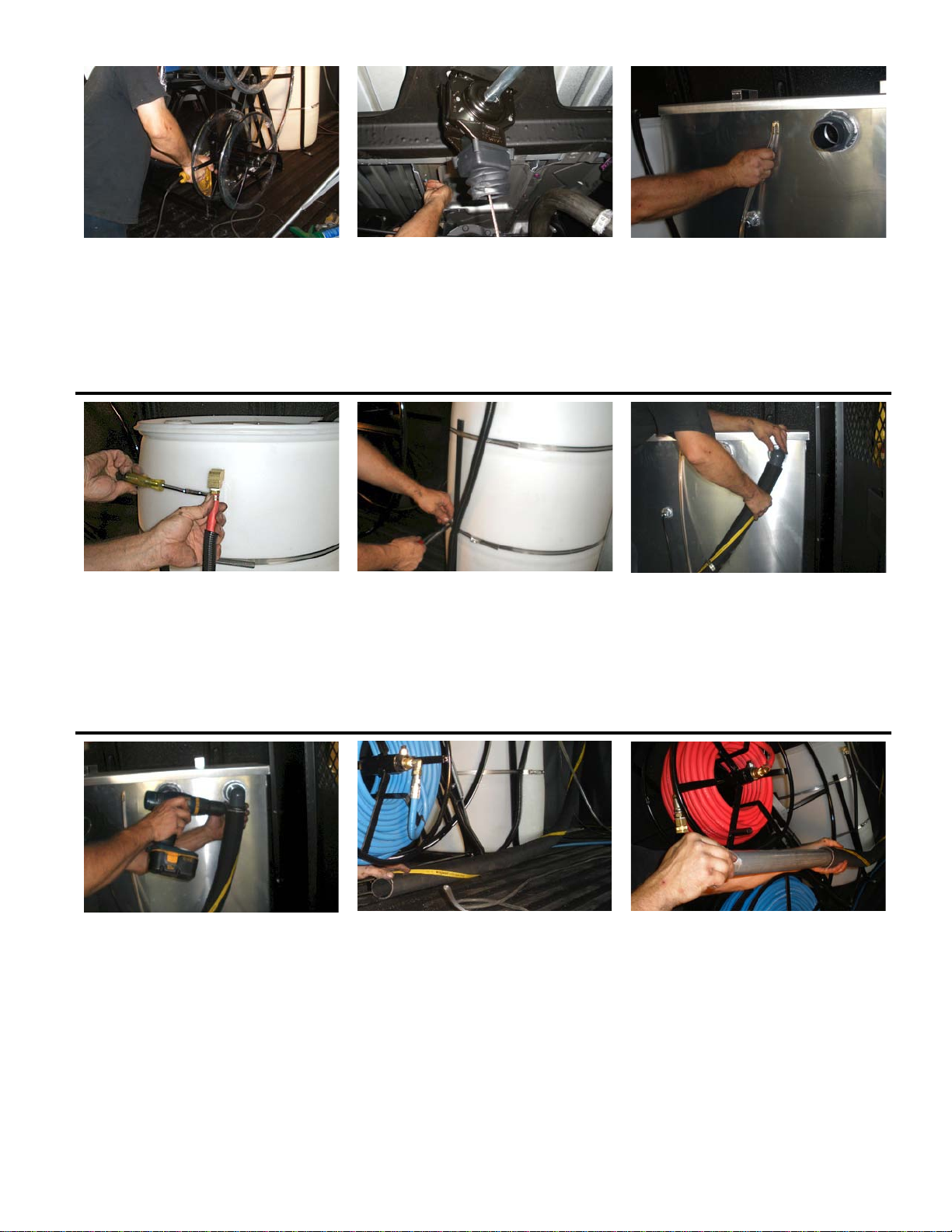

Locate the two tank support legs

and set them on the floor of the

van near the fresh water tank.

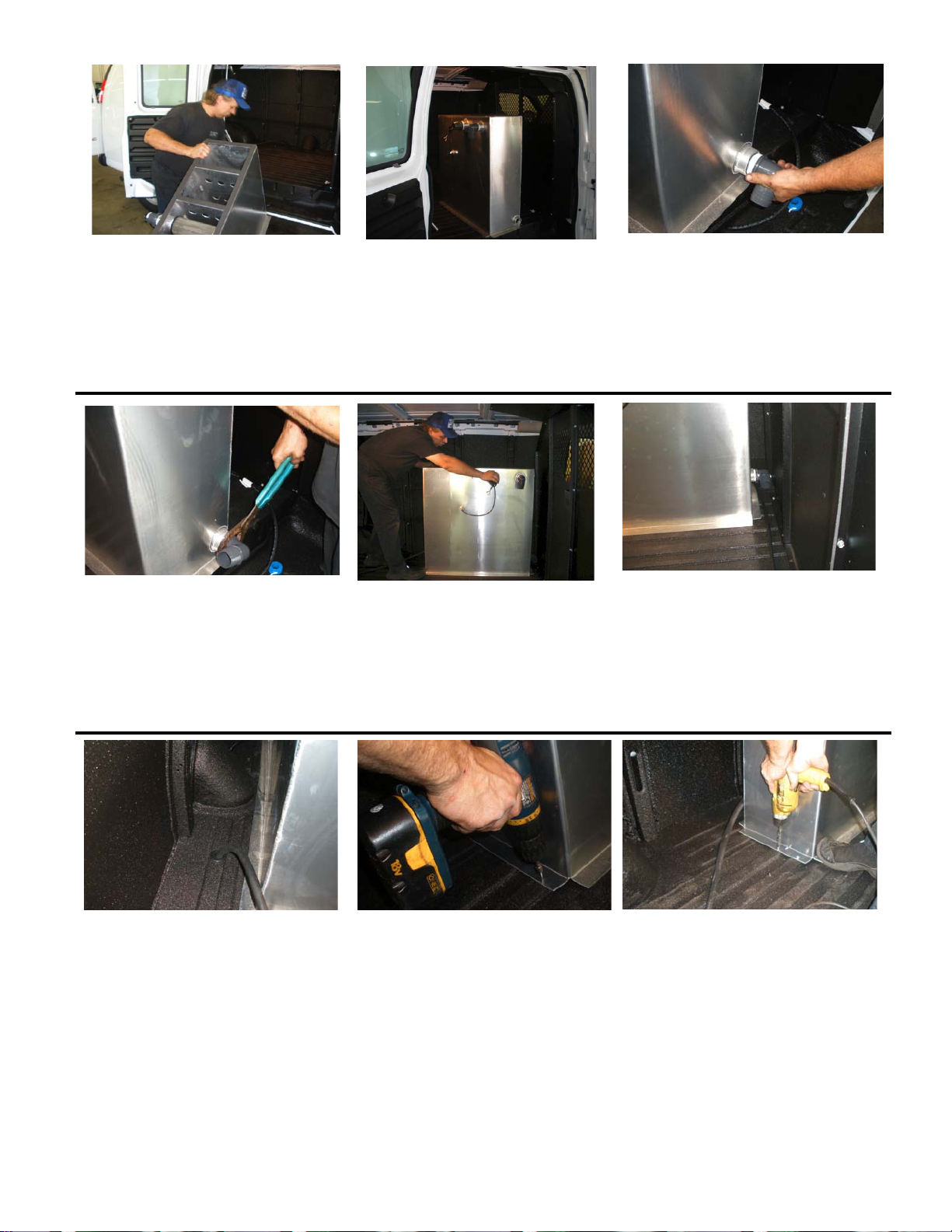

Slip strapping clamps around

the top portion of the fresh water

tank. Leave them loose.

Stand tank support legs into the

approximate position against

fresh water tank.

Slide straps down over the

support legs.

Strap support legs to tank using

two strap clamps. Tighten

securely

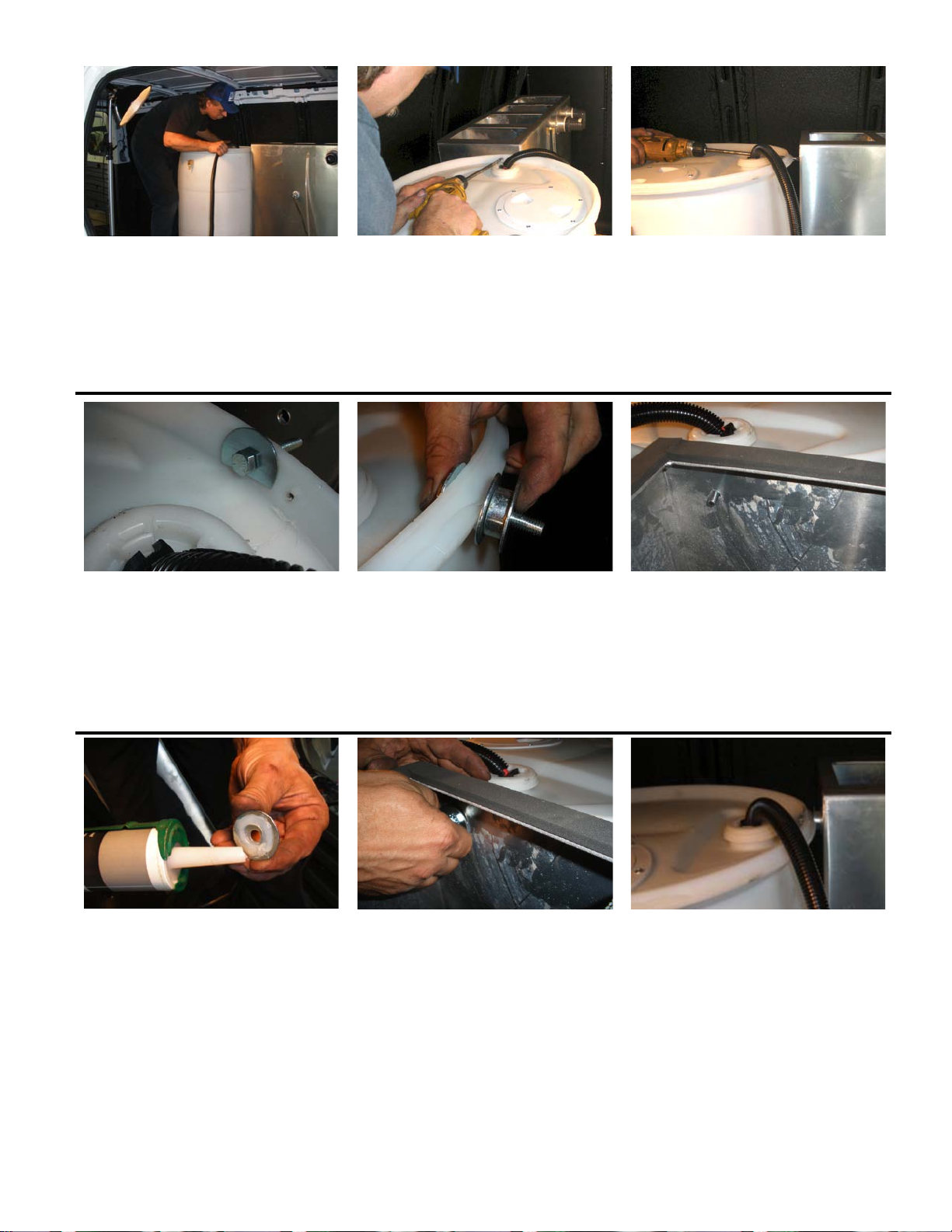

Drill 3/8” holes in floor of van

to bolt tank support legs down.

Check below van before drilling.

Drop a 5/16”x2” bolt with a flat

washer through each hole. From

below, install a fender washer and

a locknut on each bolt.

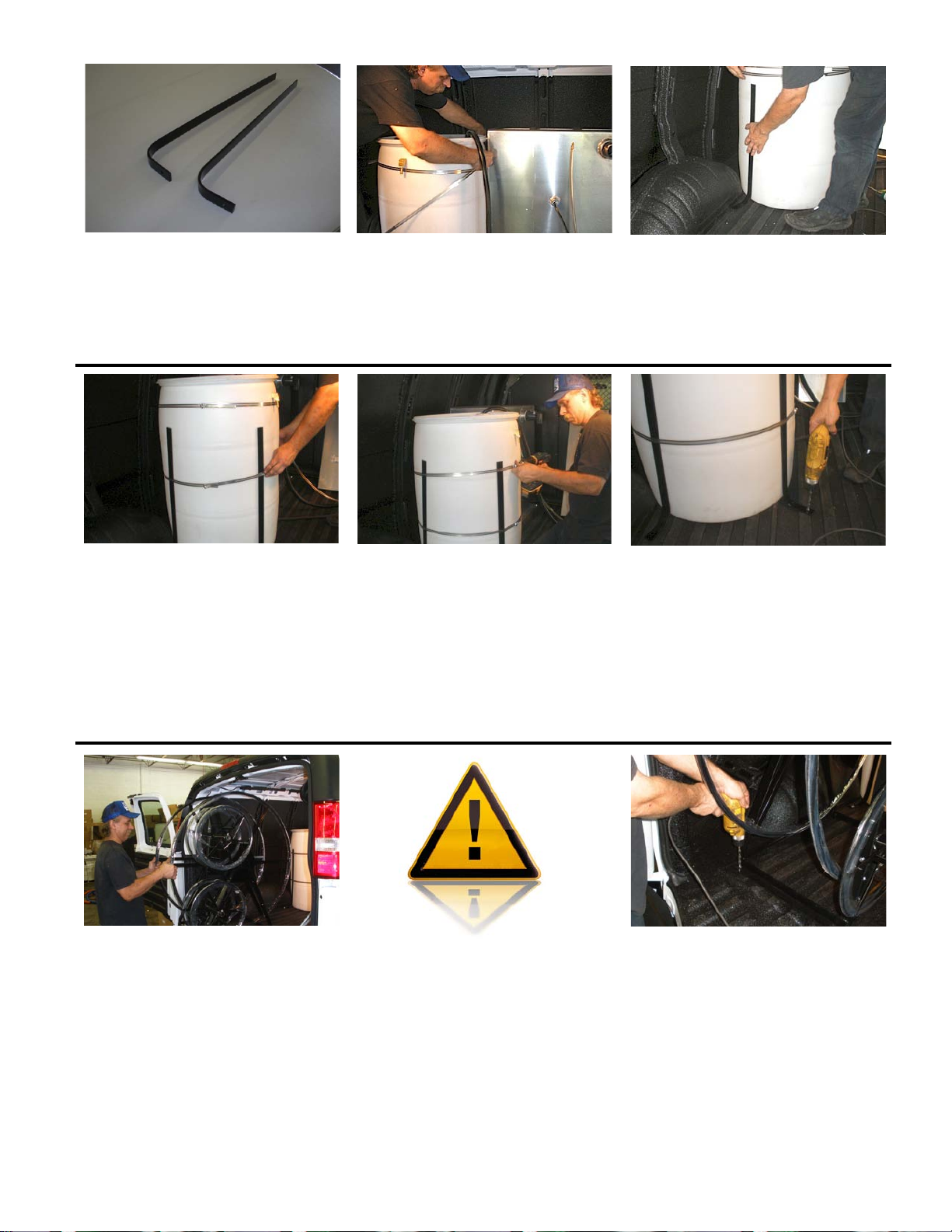

Determine which side the reels

will go on, and set into place.

Generally, it is best to set the

reels as close as possible to the

wheel well, and as close to the

doors as possible. Check to make

sure the doors will close before

WARNING: Check below van to

make sure that you will not do

any damage when drilling the

holes for mounting the reels.

It is recommended that you take

down the spare tire to prevent

damage and make this

procedure easier.

Drill four 3/8” holes through base

of reels and floor of van.

8