1Safety.........................................................................................................................................4

1.1 Residual risks....................................................................................................................................4

1.2 Information and obligations for the operator .....................................................................................6

1.3 Impermissible operating conditions...................................................................................................6

1.4 Emissions..........................................................................................................................................6

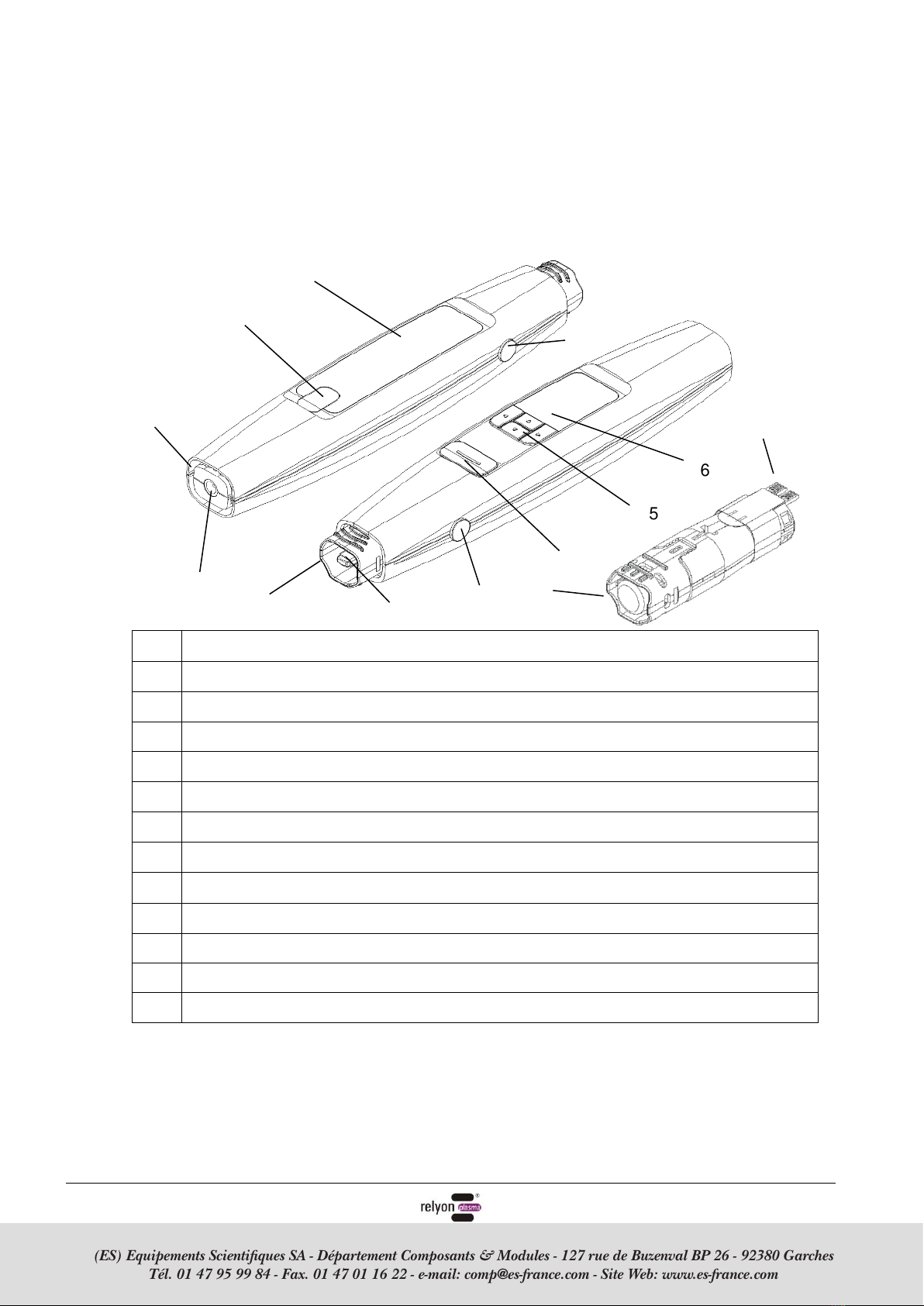

2Description of device................................................................................................................7

2.1 Intended use .....................................................................................................................................7

2.2 Scope of delivery...............................................................................................................................7

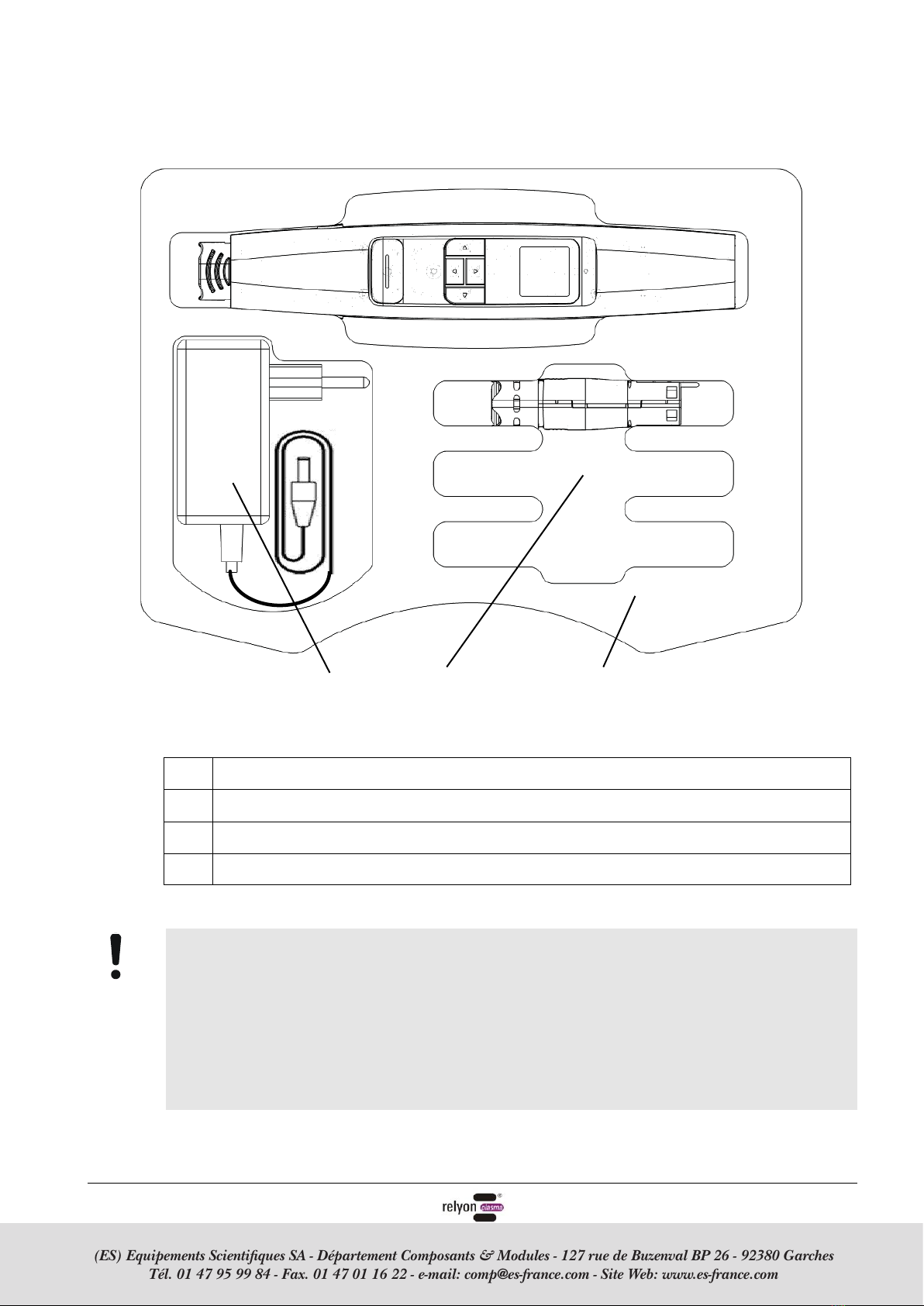

2.3 Description of device.........................................................................................................................8

3Technical data.........................................................................................................................10

4Transport / storage .................................................................................................................10

5Installation...............................................................................................................................10

6Special note on the operation of the plasma process..........................................................11

6.1 General description .........................................................................................................................11

6.2 Carrying out surface treatment .......................................................................................................12

6.3 Measures to take after the surface treatment .................................................................................12

7Operation.................................................................................................................................13

7.1 Inserting / removing the module......................................................................................................13

7.2 Installation .......................................................................................................................................14

7.3 User menu.......................................................................................................................................16

7.4 Process tools...................................................................................................................................18

7.5 Working with module „Standard“.....................................................................................................19

7.6 Working with module „Nearfield“.....................................................................................................19

7.7 Working with other modules............................................................................................................19

8Taking out of service ..............................................................................................................20

9Maintenance............................................................................................................................20

9.1 Cleaning ..........................................................................................................................................20

9.2 Replacing a module ........................................................................................................................20

10 Troubleshooting .....................................................................................................................21

11 Environment............................................................................................................................22

11.1 Disposal ..........................................................................................................................................22

12 Conformity / standards...........................................................................................................22

12.1 CE ...................................................................................................................................................22

12.2 Product standards ...........................................................................................................................22

12.3 Licenses ..........................................................................................................................................22

13 Spare parts..............................................................................................................................23

(ES) Equipements Scientifiques SA - Département Composants & Modules - 127 rue de Buzenval BP 26 - 92380 Garches

Tél. 01 47 95 99 84 - Fax. 01 47 01 16 22 - e-mail: [email protected] - Site Web: www.es-france.com