TDS EJ-640 Operating manual

EJ-640 Maintenance Guide

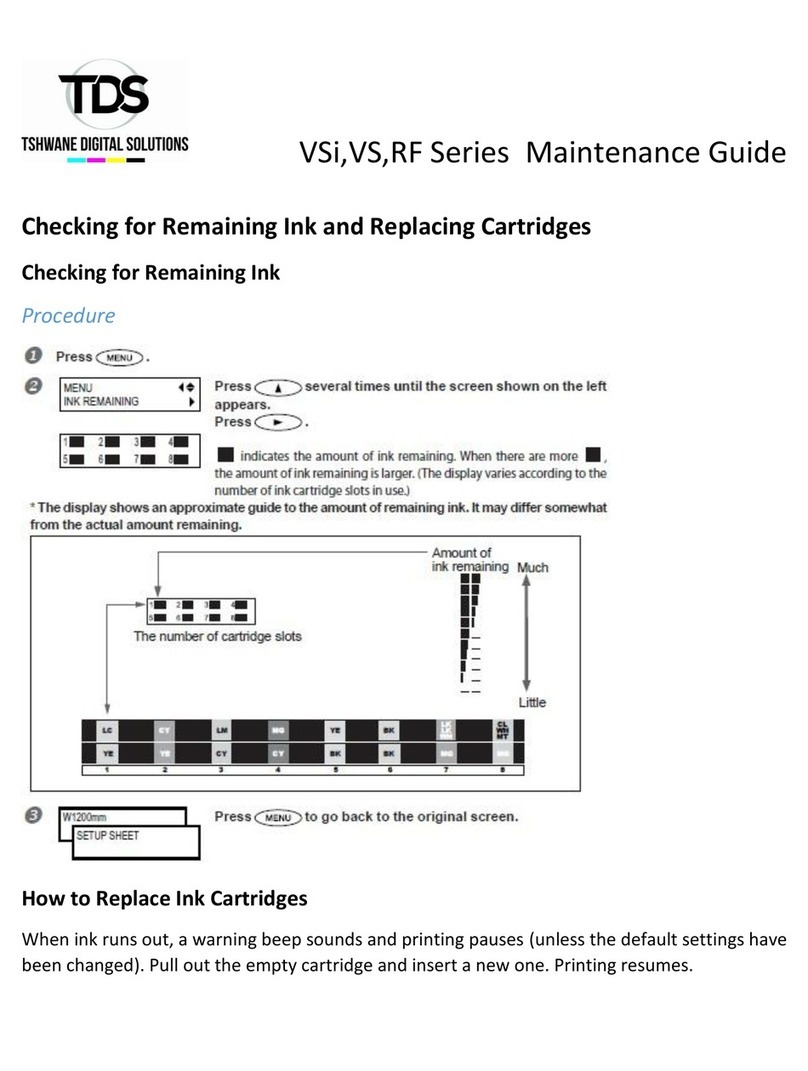

How to Replace Ink Cartridges

Out-of-ink Warnings

If using 4 Colors (CMYK)

If one ink cartridge of the same color runs out, the machine continues printing using the other

ink cartridge. When all ink cartridges of the same color run out, printing pauses and a warning

beep sounds.

If using 7 Colors (CMYKLcLmLk)

When an ink cartridge runs out, printing pauses (unless the factory default settings have been

changed), and a warning beep sounds.

EJ-640 Maintenance Guide

Note: You can check the approximate amount of ink remaining on the screen so as to replace

ink cartridges before they run out.

How to Replace Ink Cartridges

When ink runs out, a warning beep sounds and printing pauses (unless the factory default

settings have been changed.) Pull out the empty cartridge and insert a new one. Printing

resumes.

EJ-640 Maintenance Guide

Note: Never store ink, cleaning liquid, or discharged fluid in any of the following locations.

-Any location exposed to an open flame.

-Any location where high temperatures may occur.

-Near bleach or any other such oxidizing agent or explosive material.

-Any location within reach of children.

Doing so may lead to fire. Accidental ingestion by children may pose a health hazard.

Maintenance That Should Be Performed Daily

Disposing of Discharged Fluid

Procedure

EJ-640 Maintenance Guide

Note: Before you detach the drain bottle, be sure to wait for the screen to display “EMPTY

DRAIN BOTTLE.”

Failing to do so may cause discharged fluid to flow out of the machine and spill onto your hands or the floor and cause a

stain.

EJ-640 Maintenance Guide

Store discharged fluid in a location not exposed to direct sunlight.

When temporarily storing discharged fluid in the included drain bottle, keep the drain bottle

out of direct sunlight. Otherwise the discharged fluid may harden, the waste bottle may

become unusable, or the waste bottle may be deteriorated, the discharge fluid may leak.

Dispose of discharged fluid properly, in accordance with the laws in affect in your locale.

Discharged fluid is flammable and contains toxic ingredients. Never attempt to incinerate

discharged fluid or discard it with ordinary trash. Also, do not dispose of it in sewer systems,

rivers, or streams. Doing so may have an adverse impact on the environment.

If It Is Not Possible to Check the Amount of Discharged Fluid in the Drain Bottle.

Sometimes, ink affixes to the inside of the drain bottle, which makes it difficult to check the

amount of discharged fluid. In this situation, clean the inside of the drain bottle.

Cleaning method A

Scrape the inside of the drain bottle clean using one of the included cleaning sticks. Dispose

of used cleaning sticks. They cannot be used for any other cleaning. If this method is not

effective, perform cleaning method B, shown below.

Cleaning method B (when cleaning method A is not effective)

EJ-640 Maintenance Guide

Cleaning

Note: Never use solvent such as gasoline, alcohol, or thinner to perform cleaning.

Doing so may cause fire.

Note: Before attempting cleaning, switch off the sub power and wait until the platen and

dryer cool (approximately 30 minutes). Sudden movement of the machine may cause injury,

or hot components may cause burns.

Wipe away any ink or grime on the media path and any other areas as part of the daily

cleaning procedure. Pinch rollers, grit rollers, and the platen are particularly prone to the

buildup of grime. Clean by wiping with a cloth moistened with neutral detergent diluted

with water wrung dry.

EJ-640 Maintenance Guide

Care and Maintenance of the Print Heads

Care of the print heads is essential to ensuring optimal printing at all times. There are

maintenance tasks that should be performed daily and those that should be performed

periodically.

Daily Care and Maintenance

-Printing tests and normal cleaning.

We recommend performing a printing test and normal cleaning before day-to-day operation.

EJ-640 Maintenance Guide

Periodic Care and Maintenance

-Medium cleaning/powerful cleaning.

Perform medium cleaning or powerful cleaning when problems such as dot drop-out are

not corrected after performing normal cleaning.

-Manual cleaning

Perform manual cleaning periodically according to your frequency of use.

-Refreshing subtanks (REFRESH SUBTANKS)

Perform this procedure once every six months. (This procedure is effective when light

choke cleaning does not resolve uneven color issues.)

Care and Maintenance When Uneven Color Occurs

-Light choke cleaning

Perform this cleaning when printed colors are unstable or uneven, e.g. when color density

is inconsistent, even if the same data is printed with the same settings.

-Refresh subtanks (REFRESH SUBTANKS)

Use this procedure when light choke cleaning does not resolve uneven color issues. (Note

that it is necessary to perform this procedure once every six months regardless of whether

or not there are problems with uneven colors.)

Note: The print heads are components that ware out. Periodic replacement is required,

with the frequency of replacement depending on use.

When Normal Cleaning Is Not Effective

Medium Cleaning

When problems such as dot drop-out are not resolved by normal cleaning, perform the

more forceful “medium cleaning”to remove clogging from the print heads.

Procedure

EJ-640 Maintenance Guide

EJ-640 Maintenance Guide

Powerful Cleaning’

Procedure

When powerful cleaning is not effective

If problems such as dot drop-out persist even after you have performed powerful cleaning

several times, perform “manual cleaning.”Such cleaning can be effective when carried

out periodically, according to the frequency of use.

If Colors Are Uneven

Light Choke Cleaning

Perform this cleaning when printed colors are unstable or uneven, e.g. when color density

is inconsistent, even if the same data is printed out with the same settings. This will

stabilize the output colors by agitating the ink.

EJ-640 Maintenance Guide

Procedure

If uneven color issues are not resolved by light choke cleaning, refresh the subtanks.

Maintenance That Should Be Performed Once a Month or More

EJ-640 Maintenance Guide

When Manual Cleaning Becomes Necessary

Perform Manual Cleaning Once a Month or More

To keep the stable output condition at all times, perform cleaning once a month or more.

Manual cleaning takes approximately 10 minutes.

Manual Cleaning Is Recommended When the Following Symptoms Occur

It is recommended to perform manual cleaning when any of the symptoms given below

occur and cannot be solved by automatic cleaning functions such as normal cleaning.

Replacing the wipers or felt wipers is also an effective means of improving symptoms.

EJ-640 Maintenance Guide

Manual Cleaning

Note: Be sure to perform operations as specified by the instructions, and never touch any

area not specified in the instructions. Sudden movement of the machine may cause injury.

1. Enter manual cleaning mode.

EJ-640 Maintenance Guide

2. Clean the wipers using a cleaning stick.

Note: Clean the two wipers one at a time.

EJ-640 Maintenance Guide

EJ-640 Maintenance Guide

3. Clean the area around the print heads with the cleaning stick.

EJ-640 Maintenance Guide

EJ-640 Maintenance Guide

4. Reattach the left and right covers, and then end the manual cleaning mode.

5. Perform a printing test to verify the results of the procedure.

Perform a printing test to check the results. Perform cleaning using the machines cleaning feature

several times when necessary.

EJ-640 Maintenance Guide

Maintenance That Should Be Performed Once every Six Months or

More.

Refreshing Subtanks (REFRESH SUBTANKS)

Refresh the subtanks once every six months to resolve issues with ink components precipitating

in the subtanks. If this procedure is not performed once every six months, print quality may be

adversely effected, e.g. printed colors may be uneven. This operation is effective when

performing light choke cleaning does not resolve uneven color issues.

Procedure

Note: When [EMPTY DRAIN BOTTLE] is displayed, you must discharge fluid.

If you do not discharge it at this stage, discharged fluid will overflow from the drain bottle during the procedure that

follows.

Note: Before you detach the drain bottle, be sure to wait for the screen to display “EMPTY

DRAIN BOTTLE.”

EJ-640 Maintenance Guide

Failing to follow this procedure may cause discharged fluid to flow out of the machine and spill, soiling your hands or the

floor.

When Problems such as Dot Drop-out are Not Fixed

When Problems such as Dot Drop-out are Not Fixed

Perform the procedure below if ink discharge issues such as dot drop-out are not corrected

after performing cleaning using the cleaning function (normal, medium, powerful) or

manual cleaning.

Table of contents

Other TDS Printer manuals