TDS VG2 Series Operating manual

VG2 Series Maintenance Guide

Important Notes on Handling and Use

Printer

This machine is a precision device.

-Never subject the machine to impacts or excessive force

-Never needlessly put your fingers inside the cover, the ink-pouch ports, or internal

areas of the machine.

-There is a small area for small article storage on the front of the machine. Do not place

in this area any items to which cleaning liquid or ink is affixed. Doing so may damage

the area for small article storage.

Install in a suitable location.

-Install the machine in a location having the specified temperature and humidity.

-Install the machine in a quiet, stable location offering good operating conditions.

The print heads are delicate.

-Never needlessly touch or allow media to scrape them.

-The print heads may be damaged if allowed to dry out. The machine prevents

desiccation automatically, but improper operation may render this feature

inoperative. Operate the machine properly, as specified in this manual.

-Never leave the machine with an ink pouch removed. Remaining ink in the printer

may harden and clog the print heads.

-Depending on the situation, the print heads require various types of cleaning. Read

this manual thoroughly and perform the appropriate maintenance at the appropriate

times.

-The print heads are components that wear out. Periodic replacement is required, with

the frequency of replacement depending on use.

This machine becomes hot.

-Never cover the ventilation holes with cloth, tape, or anything else.

VG2 Series Maintenance Guide

Ink Pouches

Ink pouches come in various types.

-Us e a type that is compatible with the printer.

Never subject to impact or attempt to disassemble.

-Never drop the ink pouches or shake them forcefully. The impact may rupture the

internal pouch and cause ink to leak.

-Never attempt to disassemble the ink pouches.

-Never attempt to refill the ink.

-If ink gets on your hands or clothing, wash it off as soon as possible. Removal may

become difficult if you leave such adhered ink unattended.

Storage

-Store the ink pouches unopened in a well ventilated location at a temperature of -5

to 40 degrees Celsius. However do not store the ink pouches for a prolonged period

of time in low- or high-temperature environments.

Basic Maintenance Knowledge

Types and Timing of Maintenance

To use this machine under its optimal conditions, it is important to perform the appropriate

maintenance at the appropriate times.

Regular maintenance

These are the maintenance items that are required on a daily basis.

VG2 Series Maintenance Guide

Advanced maintenance

These maintenance methods consume a large amount of ink. Thoroughly read the explanation in

the User’s manual, and then perform the operation at the appropriate point in time.

Replacing consumable parts

These items are for replacement of consumable parts. Thoroughly read the explanation in the

User’s Manual, and then perform the operation at the appropriate point in time.

VG2 Series Maintenance Guide

Measures When the Printer Is Not in Use for Prolonged Period

Be sure to follow the instructions shown below when the printer is not in use for a prolonged

period.

Empty the drain bottle.

If you know that you will not use the machine for a prolonged period, empty the drain bottle.

When the main power is on, the machine periodically performs automatic maintenance in

which fluid is discharged.

The drain bottle is filled when the following periods elapse. Leaving the drain bottle as-is will lead to the discharged fluid

overflowing.

Do not allow machine to run out of ink or cleaning liquid.

The machine discharges ink and cleaning liquid during the automatic maintenance that is

performed periodically. Set in the machine ink and cleaning liquid pouches having sufficient

remaining ink and cleaning liquid. The machine cannot perform automatic maintenance if it

has run out of ink or cleaning liquid.

Switch on the sub power once a month.

Switch on the sub power once a month. When you turn on the power, the machine

automatically performs operations such as those to keep the print heads from drying out.

Leaving the machine unused for a prolonged period may damage the print heads, so be sure

to switch on the power to perform these automatic operations.

Keep the machine at a constant temperature and relative humidity.

Even when the machine is not in use, keep it at a temperature of 5 to 40 degrees Celsius and

a relative humidity of 20 to 80% (with no condensation). Temperatures that are too high may

degrade the ink and cause malfunctions. Temperatures that are too low may cause the ink to

freeze and damage the print heads.

VG2 Series Maintenance Guide

Cleaning the Machine

Cleaning the Media Path

Wipe away any ink or grime on the media path and other areas as part of the daily cleaning

procedure. It is easy for ink or grime to affix to the media path, and, if left unattended, this

will contaminate the new media and have a negative effect on the transport of media when

it is output. Pinch rollers, grit rollers, and the platen are particularly prone to the buildup of

grime.

Note: Never use solvent such as gasoline, alcohol, or thinner to perform cleaning.

Doing so may cause fire.

Note: Before attempting cleaning, switch off the sub power and wait until the heater and

dryer cool (approximately 30 minutes).

Sudden movement of the machine may cause injury, or hot components may cause burns.

Clean by wiping with a cloth moistened by neutral detergent diluted with water then wrung

dry.

VG2 Series Maintenance Guide

Cleaning the Knife Carriage Roller

Paper dust affixes to the separating knife carriage roller during media separation. Periodically

wipe that area clean.

Note: Never use a solvent such as gasoline, alcohol, or thinner to perform cleaning.

Doing so may cause fire.

Note: Before attempting cleaning, switch off the sub power and wait until the heater and

dryer cool (approximately 30 minutes).

Sudden movement of the machine may cause injury, or hot components may cause burns.

Clean by wiping with a cloth moistened by neutral detergent diluted with water then wrung

dry.

VG2 Series Maintenance Guide

Disposing of Discharged Fluid

Precautions for Disposing of Discharged Fluid

Note: Never place discharged fluid or ink near an open flame.

Doing so may cause fire.

Note: To store discharged fluid properly, in accordance with the laws in effect in your locale.

Discharge fluid is flammable and contains toxic ingredients. Never attempt to incinerate

discharged fluid or discard it with ordinary trash. Also, do not dispose of it in sewer systems,

rivers, or streams.

Doing so may have an adverse impact on the environment.

If the Discharge Fluid Disposal Message appears

The message shown below appears when a certain amount of discharged fluid has collected

in the bottle. If this message appears dispose of the discharged fluid.

Note: Before you detach the drain bottle, be sure to wait for the screen to display “EMPTY

DRAIN BOTTLE.” After discarding the discharged fluid, promptly attach the drain bottle to the

machine.

VG2 Series Maintenance Guide

Failing to follow this procedure may cause discharged fluid to flow out of the tube and spill, soiling your hands or the floor.

Note: If you did not discard the discharged fluid and selected [NO]. The display also returns

to the original screen if you did not discard the discharged fluid and selected [NO] In this case

the [EMPTY DRAIN BOTTLE] message disappears temporarily. The message appears

temporarily. The message appears again once a certain amount of discharged fluid has

collected.

Note: When the [NOW EMPTY?] message appears on the screen, discharged fluid as early as

possible.

Repeatedly selecting [NO] without discarding the discharged fluid may cause it to spill out of the drain bottle, soiling your

hands or the floor.

If the Drain Bottle Exceeds Its Capacity Limit

The drain bottle collects discharged fluid. You can dispose of discharged fluid even if the

message “EMPTY DRAIN BOTTLE” is not displayed on the screen. Discard the discharged fluid

before the drain bottle exceeds its capacity limit.

VG2 Series Maintenance Guide

Note: Before you detach the drain bottle, be sure to wait for the screen to display “EMPTY

DRAIN BOTTLE.” After discarding the discharged fluid, promptly attach the drain bottle to the

machine.

Failing to follow this procedure may cause discharged fluid to flow out of the tube and spill, soiling your hands or the floor.

VG2 Series Maintenance Guide

Daily Print Head Checks

Printing Tests and Normal Cleaning

The print heads are important components that discharge ink. They require periodic and

appropriate maintenance. Before daily operations, perform a printing test to ensure that no

dot drop-out or dot displacement occurs. If dot drop-out or dot displacement occurs, perform

cleaning of the print heads (normal cleaning).

Note: This operation is unnecessary if you are only performing cutting. When performing

printing tests successively, you can select “SCAN” (vertical printing) or “FEED” (horizontal

printing) as the print position for the 2nd and later tests in comparison to the 1st test.

1. Performing a printing test

VG2 Series Maintenance Guide

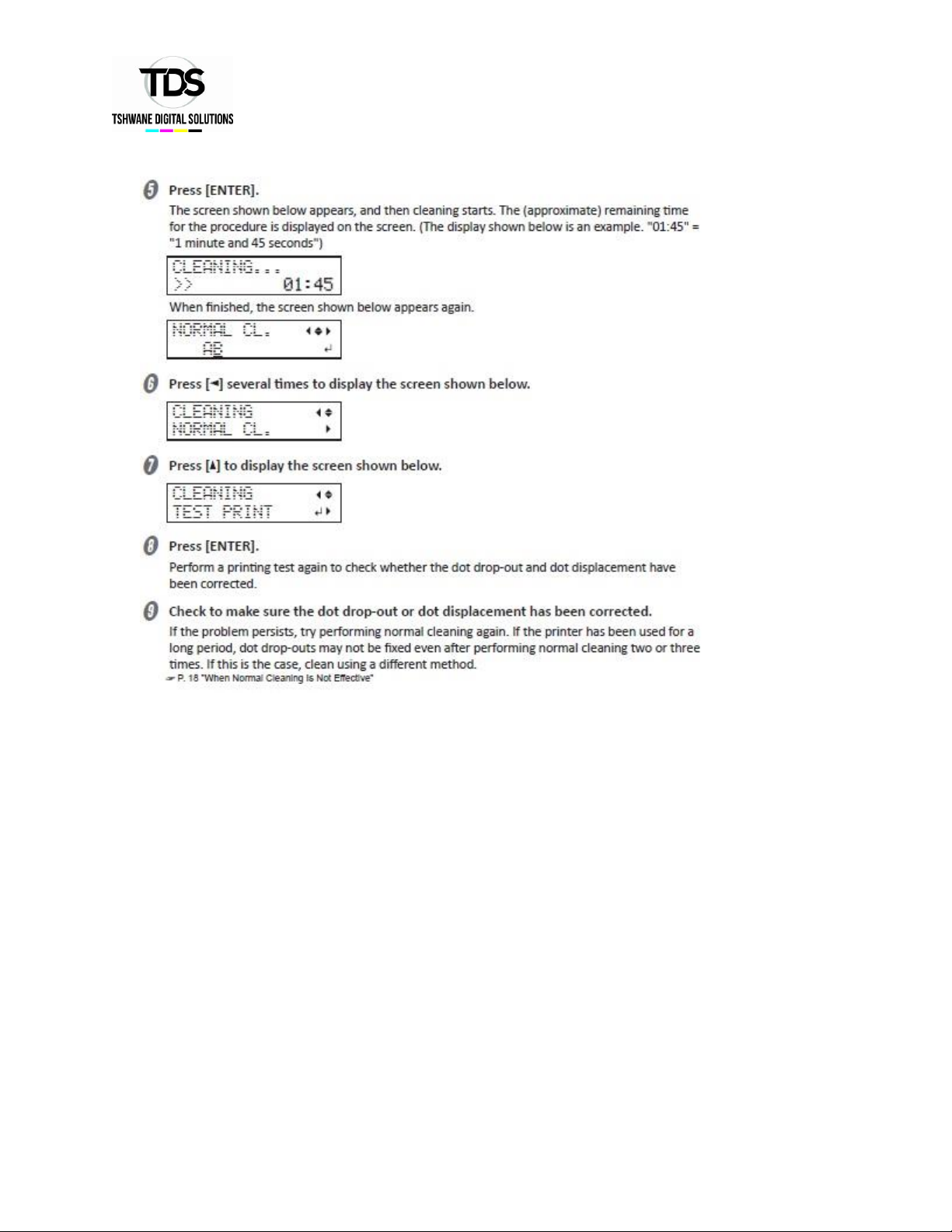

2. Performing Normal Cleaning

Note: If the printing-test results are difficult to interpret, check the results in a bright location,

changing your line of vision. It is visible using the reflection of the light.

VG2 Series Maintenance Guide

VG2 Series Maintenance Guide

When Normal Cleaning Is Not Effective

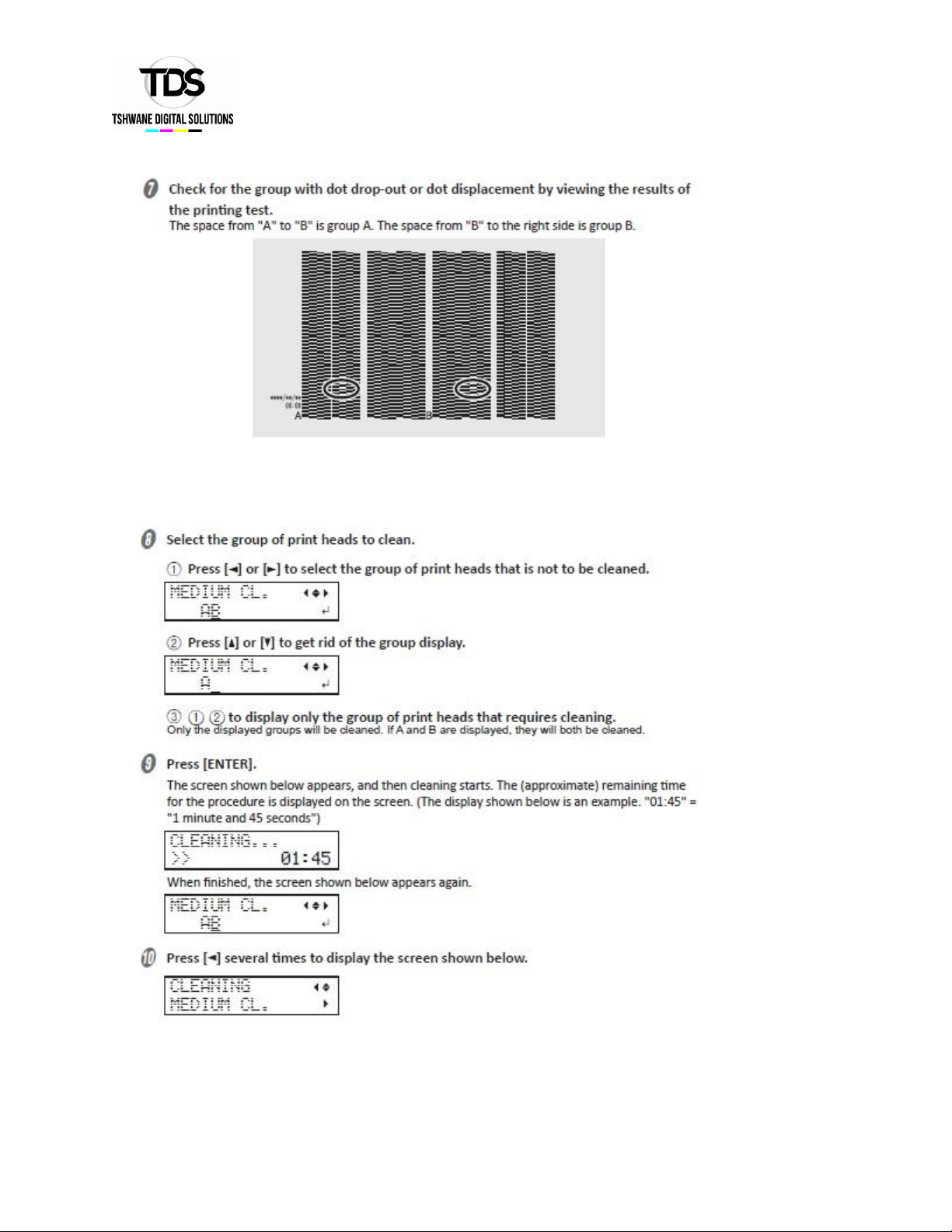

Medium Cleaning Method

The print heads are important components that discharge ink. They require periodic and

appropriate maintenance. When problems such as dot drop-out are not resolved by normal

cleaning, perform the more forceful “medium cleaning’ to remove clogging from the print

heads.

VG2 Series Maintenance Guide

Note: If the printing-test results are difficult to interpret, check the results in a bright location,

changing your line of vision. It is visible using the reflection of the light.

VG2 Series Maintenance Guide

Note: If the problem persists, try performing normal cleaning again. If problems such as dot

drop-out and dot displacement persist even after you have performed medium cleaning

several times, perform “powerful cleaning.” This cleaning can be effective when carried out

periodically, according to the frequency of use.

Powerful Cleaning Method

The print heads are important components that discharge ink. They require periodic and

appropriate maintenance. When problems such as dot drop-out are not resolved by medium

cleaning, perform the more forceful “powerful cleaning” to remove clogging from the print

heads.

VG2 Series Maintenance Guide

Note: If the printing-test results are as difficult to interpret, check the results in a bright

location, changing your line of vision. It is visible using the reflection of the light.

VG2 Series Maintenance Guide

Note: If the problem persists, try performing normal cleaning again. This cleaning can be

effective when carried out periodically, according to frequency of use. If problems such as

dot drop-out and dot displacement persist even after you have performed powerful cleaning

several times, perform “manual cleaning.”

Manual Cleaning

When manual cleaning is necessary

The print heads are important components that discharge ink. They require periodic and

appropriate maintenance. It is important to perform manual cleaning with the appropriate

timing.

When a Message Appears

Note: Wiper replacement may also be effective in improving these symptoms.

VG2 Series Maintenance Guide

Manual Cleaning Method

If the message “TIME FOR MAINTENANCE” is displayed or if dot drop-out or ink drip issues

that cannot be improved with a powerful cleaning occur, perform manual cleaning.

Note: Be sure to perform operations as specified by the instructions above, and never touch

any area not specified in the instructions.

Sudden movement of the machine may cause injury.

VG2 Series Maintenance Guide

1. Clean the print head caps

VG2 Series Maintenance Guide

Table of contents

Other TDS Printer manuals