ADCP-92-159 • Issue 1 • 2/2015

Page 10

© 2015, Tyco Electronics Corportation

3PANEL-SPECIFIC INSTALLATION PROCEDURES

For purposes of installation, the FPX fiber panel is divided into four types:

• Empty panel (includes rear management hardware to accept adapter packs, pigtails, and

splice trays);

• Termination panel loaded with adapters only (includes rear management hardware to

accept multi-fiber cable assemblies);

• Termination/splice panel: loaded with adapters, pigtails, and splice trays;

• Stubbed panel: completely equipped with a preterminated cable stub.

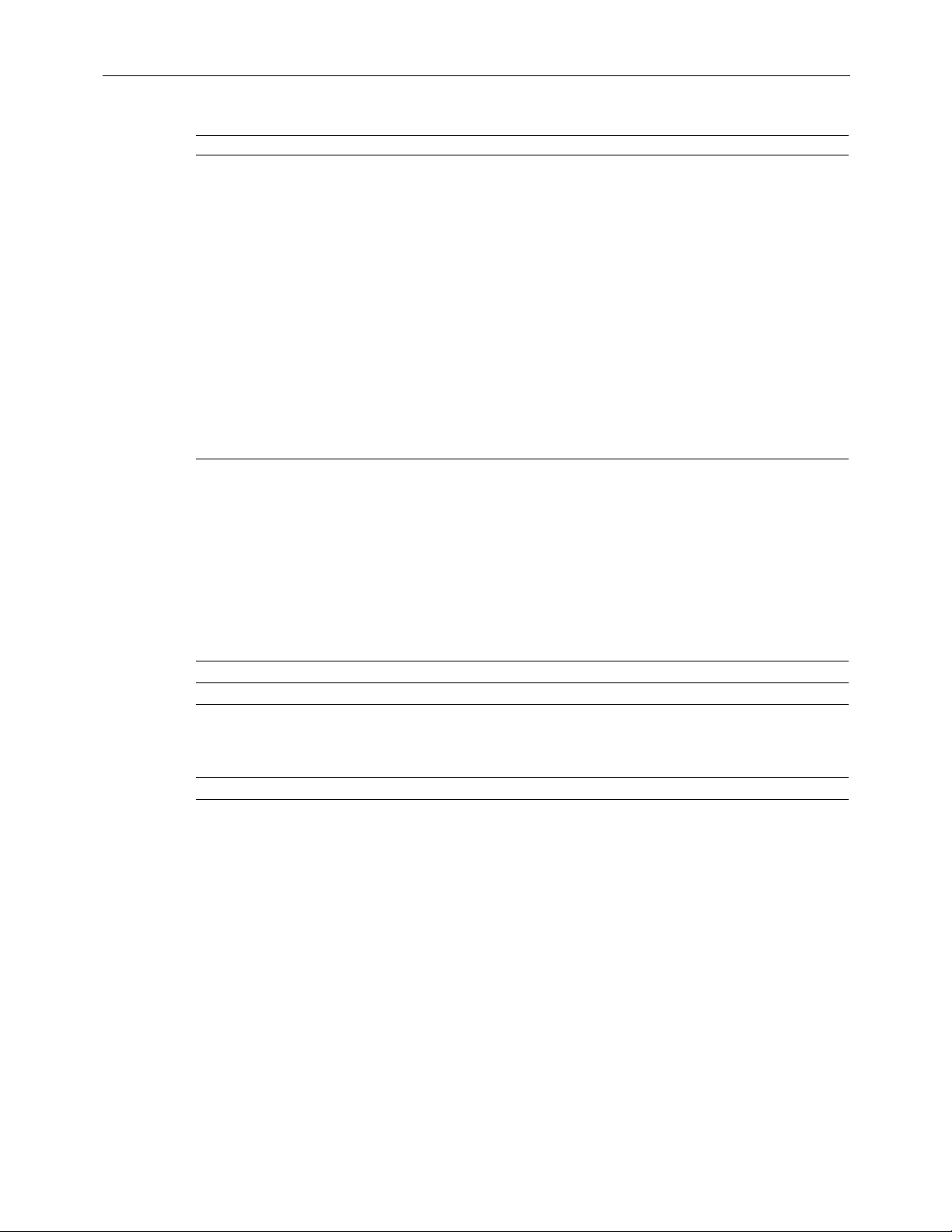

3.1 Panel Types and Procedures Done for Each Type

Table 1

lists the main panel types shipped to the customer and the installation procedures that may

be done for each type.

3.2 Installing Adapter Packs (LC, SC, or MPO)

This section describes how to install adapter packs (LC, SC, or MPO) in an empty FPX panel.

The 1RU panel accommodates two adapter packs. The 2RU accommodates four adapter packs.

Adapter packs are installed in the same manner for both 1RU and 2RU panels. Adapter packs

installed on left side of panel are angled left while adapter packs installed on right side are

angled right.

Install the adapter packs as shown in Figure 11 (2RU shown).

Table 1. Panel Types and Procedures Required

PANEL TYPE PROCEDURE REFER TO SECTION

Empty Panel Basic installation 2 on Page 5

Install adapter packs (LC, SC, or MPO) 3.2 on Page 10

Install MPO cassettes 3.3 on Page 11

Install an MPO cable 3.5 on Page 14

Install a cable clamp 3.6 on Page 16

Prepare and connect a pre-connectorized cable 3.6 on Page 16

Install pigtail adapter pack assemblies and splice trays 3.7 on Page 19

Install an IFC/OSP cable and prepare for splicing 3.8 on Page 22

Termination Only Panel Basic installation 2 on Page 5

Prepare and connect a pre-connectorized cable 3.6 on Page 16

Termination/Splice Panel Basic installation 2 on Page 5

Install pigtail adapter pack assemblies and splice trays 3.7 on Page 19

Install an IFC/OSP cable and prepare for splicing 3.8 on Page 22

Stub cable Basic installation 2 on Page 5