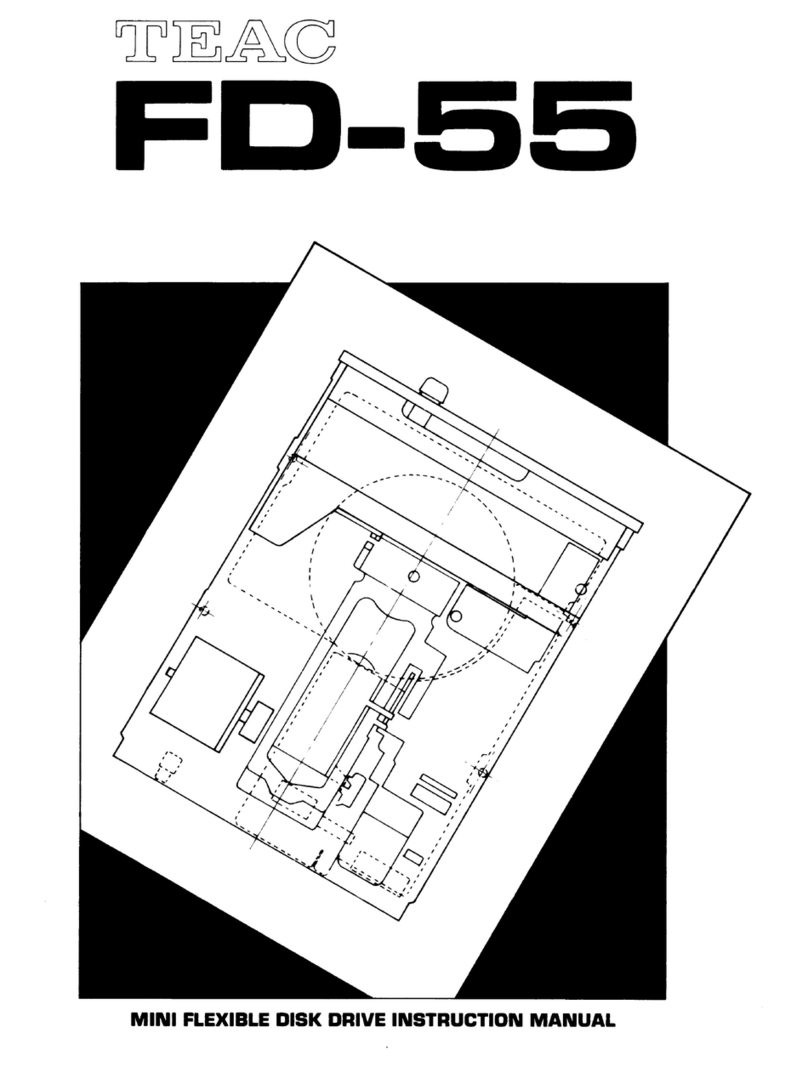

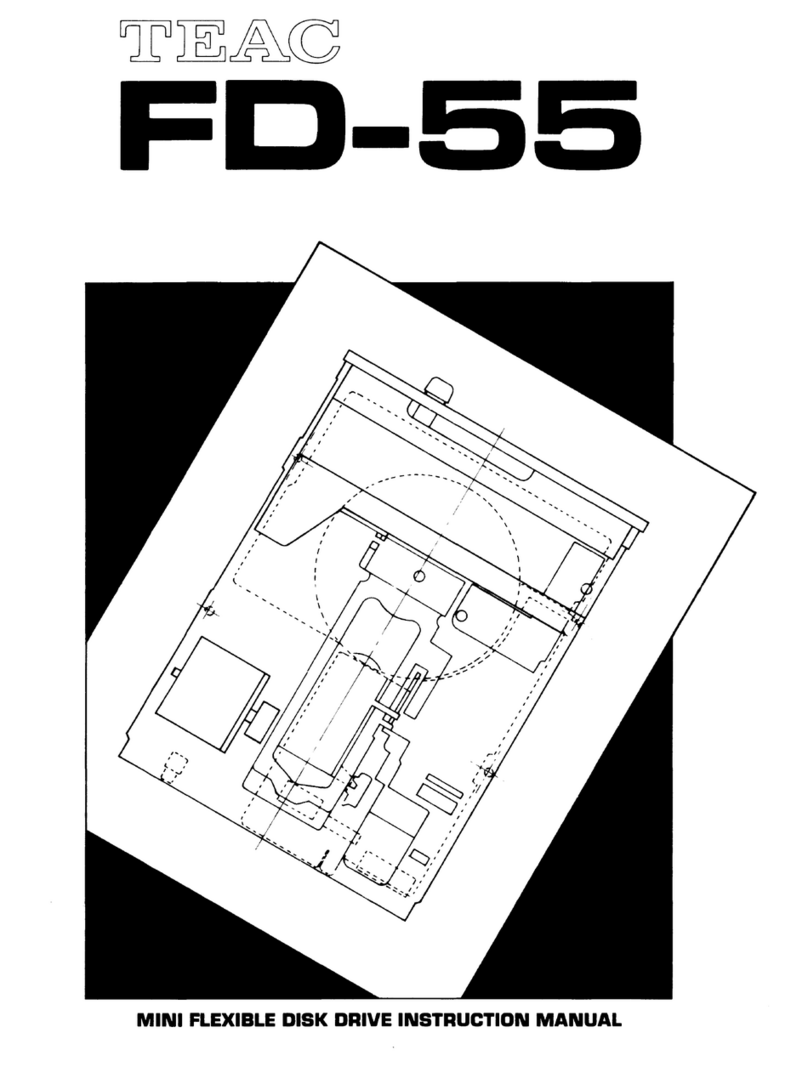

3-1-2. Mechanical Section

Since the disk is a flexible recording media made of mylar film base

and data interchangeability between disks and FDDs is required, the

mechanical section of the FDD uses precision parts and it is also

assembled with high precision. For this reason, only trained technicians

can handle the internal mechanism. Never apply excessive impact nor

drop the FDD down on the desk.

The mechanical section is constructed’ with frame, door mechanism, disk

clamp mechanism# disk rotation mechanism, magnetic head and carriage,

head load' mechanism (or CSS mechanism) , head seek mechanism, various

detection mechanisms, etc.

(1) Frame «

The main structure for mounting the various mechanisms and printed

circuit boards. The frame is made of aluminum die cast to maintain

the stability of the FDD in strength, precision, durability, and

expansion coefficient.

(2) Door mechanism and disk clamp mechanism

The door mechanism .is constructed with the main parts of set arm which

forms the structure for installing the disk on the spindle other parts

of front*lever, clamp arm, etc. The set arm is sttacKed to the rear

of the frame with leaf springs and on the tip of the set arm a collet,

which forms the disk clamp mechanism, is attached.

When a disk is inserted and the door is closed, the tip of the collet

is inserted in the central window of the disk and the window area is

depressed to the spindle so that the center of the disk is clamped in

the correct position along the outer circumference of the collet.

(3) Disk rotation mechanism

302