Example of jig for TC-XR(T)20KN-G6 and TC-XR(T)50KN-G6

TC-XR

m6

∅56

∅56

30 30

P.C.D.44

4 × Ø5.5 through,

Ø9.5 counterbore,

15depth

Curved load-receiving

surface

Surface for contacting load

cell ground to a maximum

parallelism tolerance of 0.01

Load distributed evenly

across entire load cell surface

4 × Ø5.5 through,

Ø9.5 counterbore, 15 depth

Jig boss depth of 8

Tolerance through product

center hole is H7 JIS

Dimensions in millimeters (mm)

TEDS overview

TEDS (Transducer Electronic Data Sheet) is a memory chip

that can electronically read and write sensor-specific data.

The TEDS built into this unit has serial number, load cell rated

output and manufacturer name data recorded on it. By

connecting an indicator that supports TEDS, the TEDS data

of the connected load cell will be automatically read and

equivalent input calibration will be completed. (For details,

read the operation manual of the connected indicator.)

Refer to the connection diagrams in “Electrical connection

of load cell with built-in TEDS” as well as the operation

manual for the indicator being connected for procedures

to make connections.

TEAC indicators and signal conditioners that support TEDS

include the TD-01 Portable, TD-700T, TD-260T, TD-9000T

and TD-SC1. For details, inquire at the retailer where you

purchased the unit.

If not using the TEDS function, do not connect the orange

and green load cell cores.

Moreover, take measures to prevent the orange and green

cores from touching other terminals.

Data recorded in TEDS are tested values from calibration

conducted at room temperature during inspection before

shipping from our company.

Load cell output will be affected by the environmental

temperature where used, even when within the compen-

sated temperature range established in the specifications.

Although load cell output is calculated from the calibration

value saved in TEDS, when the environmental temperature

differs greatly from room temperature, the temperature

impacts increase on the zero point and the output. For

this reason, consideration of the effect on output voltage

is necessary. Output voltage changes will be within the

specification range as long as the unit is used at tempera-

tures within the specification range.

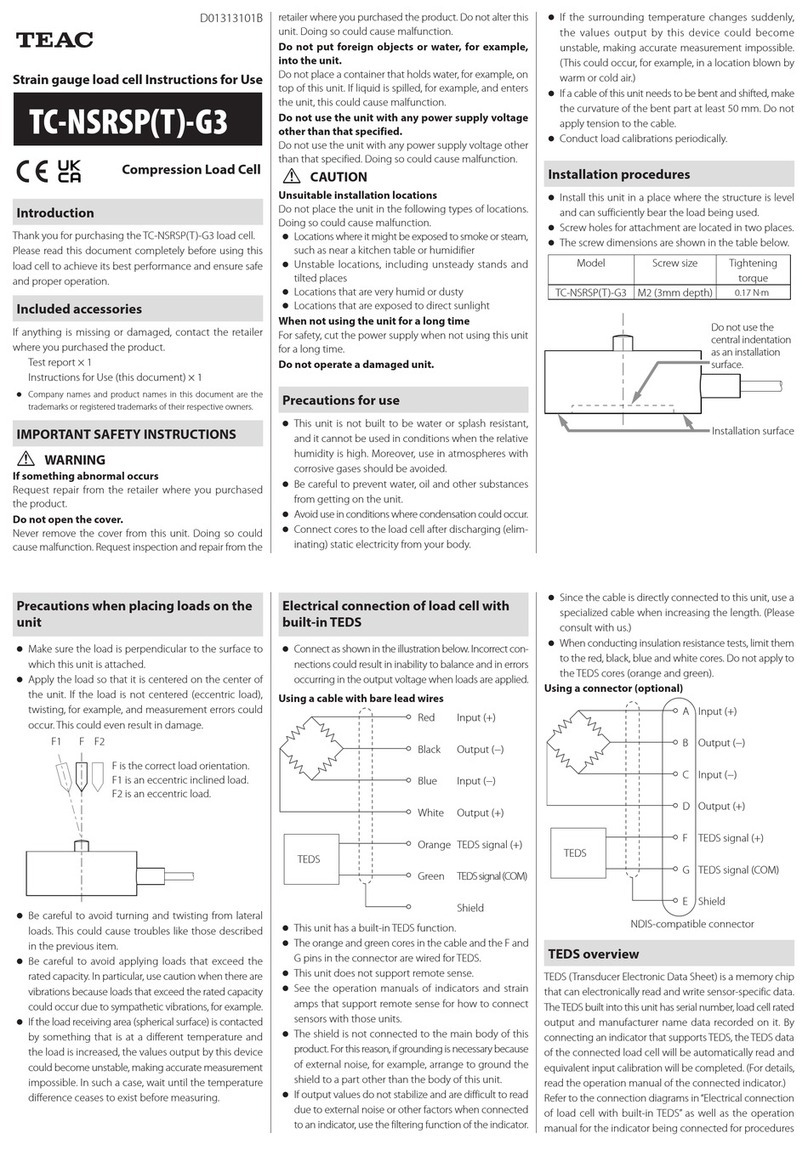

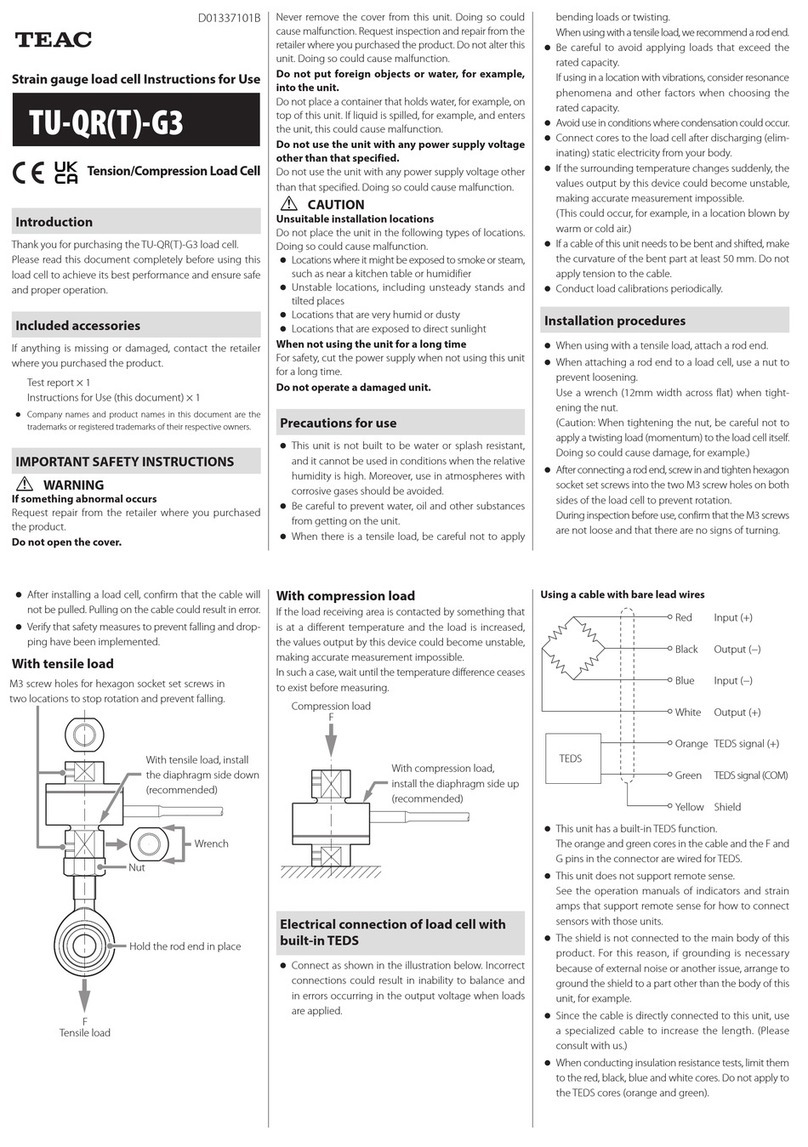

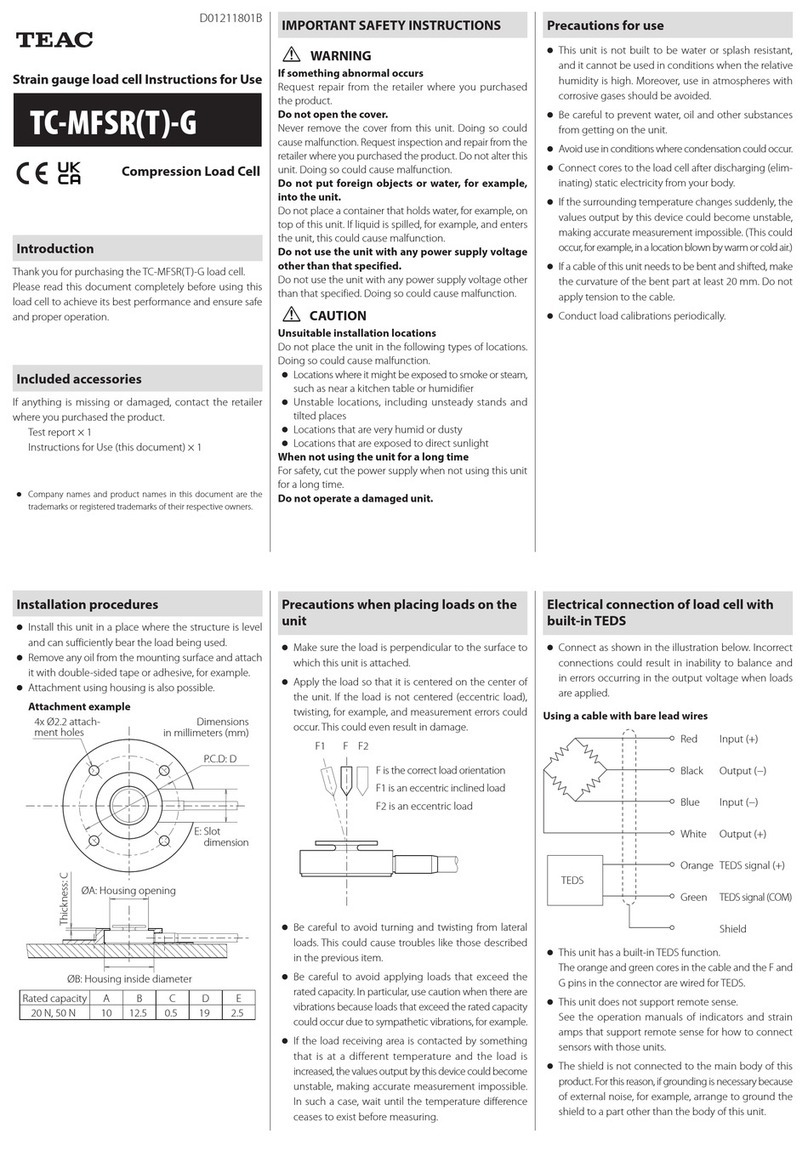

When using the TEDS function

This product’s cores for TEDS (orange and green) are

protected by a plastic cover as shown in the illustration.

This is to prevent miswiring and contact with other connec-

tors during use, for example, which could cause shorting.

To use the TEDS function, remove the tip of the plastic cover,

following the perforations, from the end of the cables. Then,

connect the TEDS cores (orange and green) to the indicator.

Refer to“Electrical connection of load cell with built-in TEDS”

for how to connect each wire.

Cores

for sensor

Load cell cable Protective plastic Perforations

Cores for TEDS (orange and green)

When not using the TEDS function

If not using the TEDS function, remove the entire protective

plastic cover and cut off the TEDS cores (orange and green)

around where the plastic cover was attached to the cable.

If you use it without removing these cores, do not remove

the protective plastic or make other arrangements to prevent

the cores from touching other places.

Refer to“Electrical connection of load cell with built-in TEDS”

for how to connect each wire.

NOTE

Explanations related to TEDS are available on our website.

https://loadcell.jp/en/info/teds.html

ATTENTION

Since the protective plastic and tag are not suitable for

the entire temperature range of this unit’s specifications,

do not expose them to high temperatures.

Handling after use

oWhen moving this unit while it is installed, take protective

measures to prevent it from being shaken or subjected

to excessive external forces.

oWhen storing it, keep it in a dry place where it will not

be exposed to water or oil, for example.

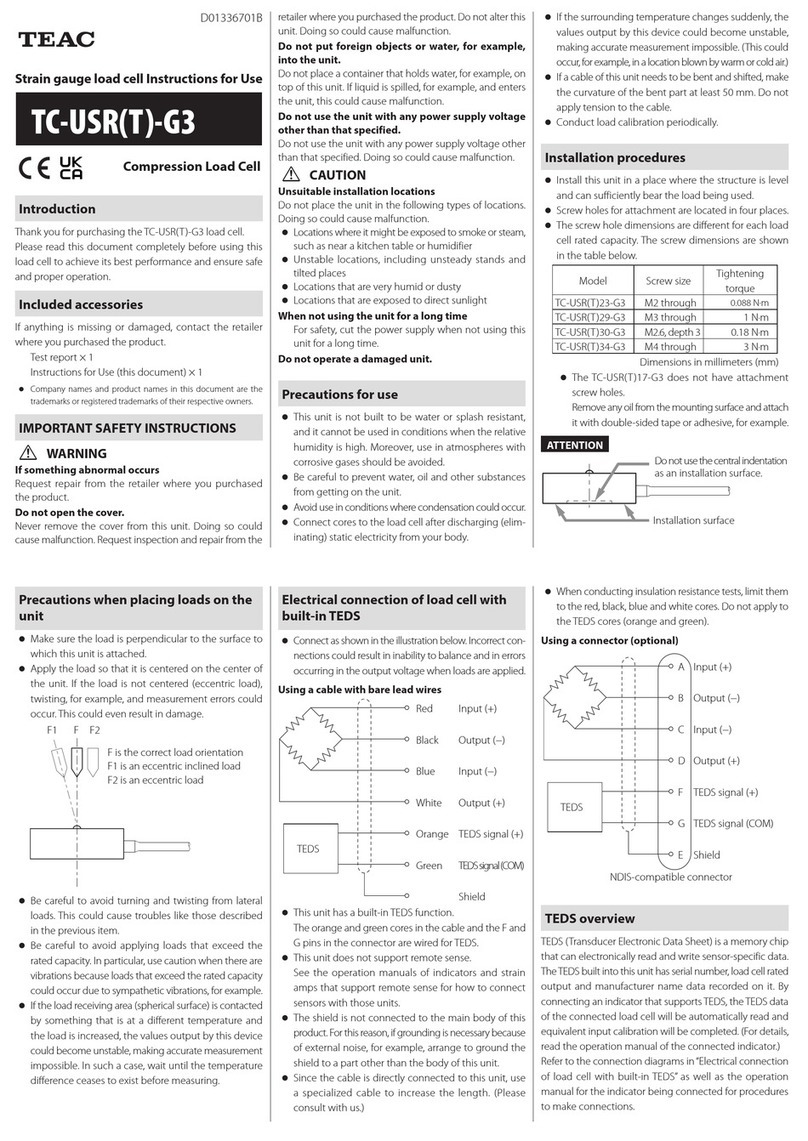

Specifications

TC-XR(T)-G6

Model Capacity

kN A B C D E F G H J K Wt.

kg

20KN-G6 20 62 56 35 1 44 18 2x4-M5

Depth 7

17.5 20 40 0.8

50KN-G6 50 62 56 35 1 44 18 17.5 20 40 0.8

100KN-G6 100 62 56 40 1 44 18 20 20 40 0.9

200KN-G6 200 86 78 50 2 60 20 2x4-M8

Depth 10 25 26 52 2.0

300KN-G6 300 100 90 70 2 70 20 2x4-M8

Depth 12 35 26 59 4.0

Safe overload rating: 120% R.C.

Rated output: 1mV/V ±1%

Linearity: 0.5% R.O.

Hysteresis: 0.5% R.O.

Repeatability: 0.1% R.O.

Dimensions in millimeters (mm)

Safe excitation voltage: 15V

Input terminal resistance: 700Ω ±7Ω

Output terminal resistance: 700Ω ±7Ω

Insulation resistance: 2000MΩ or more (DC50V)

Compensated temperature range: 0 to 60°C

Permissible temperature range: −10 to 80°C

Temperature effect on zero balance: ±0.5% R.O./10°C

Temperature effect on output: ±0.5% R.C./10°C

Cable: Ø6mm 6-core shielded robot cable

3m direct connection with bare lead wires

Body material: nickel chromium molybdenum steel

Environmental compliance: RoHS (10 substances)

Other: built-in TEDS

Dimensional

drawings

K

(2)

17

21

J

H

D D

ØB

ØF

G

P.C.D.E

Cable

Rubber sleeve

TC-KR(T)-G6

Model Capacity

kN A B C D E F G H ØJ KWt.

kg

5KN-G6

5 40 35 50 1 24 10

2x4-M4

Depth 8 25 26 29 0.3

10KN-G6

10 62 55 70 2 44 18

2x4-M5

Depth 8

35 26 40 0.95

20KN-G6

20 62 55 70 2 44 18 35 26 40 1.0

30KN-G6

30 62 55 70 2 44 18 35 26 40 1.0

50KN-G6

50 62 55 70 2 44 18 35 26 40 1.0

100KN-G6

100 62 55 80 2 44 18 40 26 40 1.0

200KN-G6

200 88 80 100 2 60 20

2x4-M8

Depth 12 50 26 53 1.3

300KN-G6

300 100 90 120 2 70 20

2x4-M8

Depth 15 60 26 59 2.9

Safe overload rating: 120% R.C.

Rated output: 1mV/V ±1%

Linearity: 0.5% R.O.

Dimensions in millimeters (mm)

Hysteresis: 0.5% R.O.

Repeatability: 0.1% R.O.

Safe excitation voltage: 18V

Input terminal resistance: 700Ω ±7Ω (350Ω ±3.5Ω for 5KN)

Output terminal resistance: 700Ω ±7Ω (350Ω ±3.5Ω for 5KN)

Insulation resistance: 2000MΩ or more (DC50V)

Compensated temperature range: −10 to 70°C

Permissible temperature range: −20 to 100°C

Temperature effect on zero balance: ±0.1% R.O./10°C

Temperature effect on output: ±0.1% R.C./10°C

Cable: Ø6mm 6-core shielded robot cable

3m direct connection with bare lead wires

Body material: nickel chromium molybdenum steel

Environmental compliance: RoHS (10 substances)

Other: built-in TEDS

Dimensional

drawings

K

(2)

17

Ø20

J

(H)

G

E

D D

C

ØB

ØF

Cable

Warranty explanation

oThe warranty period for this device is one year from the

date of purchase.

oBe aware that repairs will require payment in the following

cases even during the warranty period.

1) Malfunction or damage due to misuse

2) Malfunction or damage caused by modifications or repairs

conducted by any party other than our company or a

service person designated by our company

3) Malfunction or damage caused by dropping, trans-

portation or similar handling after product delivery

4) Malfunction or damage caused by fire, earthquake,

water, lightning or other natural disaster

5) Malfunction or damage caused by external factors,

including power supplies and equipment environ-

mental conditions, that deviate from the operation

requirements of this product

6) Malfunction or damage if the product was not pur-

chased from our company or an agent designated

by our company

oWe offer paid service after the conclusion of the warranty

period. For details, please contact the retailer where you

purchased the unit.

oBe aware that our company will bear no responsibility for

any secondary damages resulting from the operation of

this device or related to data.

oInformation is given about products in this manual only for

the purpose of example and does not indicate any guarantees

against infringements of third-party intellectual property

rights and other rights related to them. TEAC Corporation

will bear no responsibility for infringements on third-party

intellectual property rights or their occurrence because of

the use of these products.

Contact information

TEAC CORPORATION (Manufacturer)

1-47 Ochiai, Tama-shi, Tokyo 206-8530 Japan

Phone: +81-042-356-9154

TEAC AMERICA, INC.

10410 Pioneer Blvd. Unit #1, Santa Fe Springs, California90670,

U.S.A.

Phone: +1-323-726-0303

TEAC EUROPE GmbH. (EU Importer)

Bahnstrasse 12, 65205 Wiesbaden-Erbenheim, Germany

Phone: +49-611-7158-349

TEAC UK Limited (UK Importer)

Luminous House, 300 South Row, Milton Keynes,

Buckinghamshire, MK9 2FR, UK

Phone: +44-1923-797205

0423 MA-3021B