7

These are just a few things you may go through during the break in period.

Just keep it running, apply the throttle on and o as smoothly as you can.

Sudden bursts or quick releases of the throttle can stall your engine. Soon

after break in your patience will pay o with a well running engine. The

performance level of the engine will be limited by the “rich’ fuel mixture which

you will use all during the break-in process. Once the engine is fully broken-in

the mixture can be “leaned out,” and speed and acceleration will increase.

Because of the rich fuel mixture and the wearing of the new parts, deposits will

form on the glow plug causing it to fail. Expect to replace the glow plug during

the break in period, and denitely when the engine is fully broken in and the

fuel mixture is leaned out.

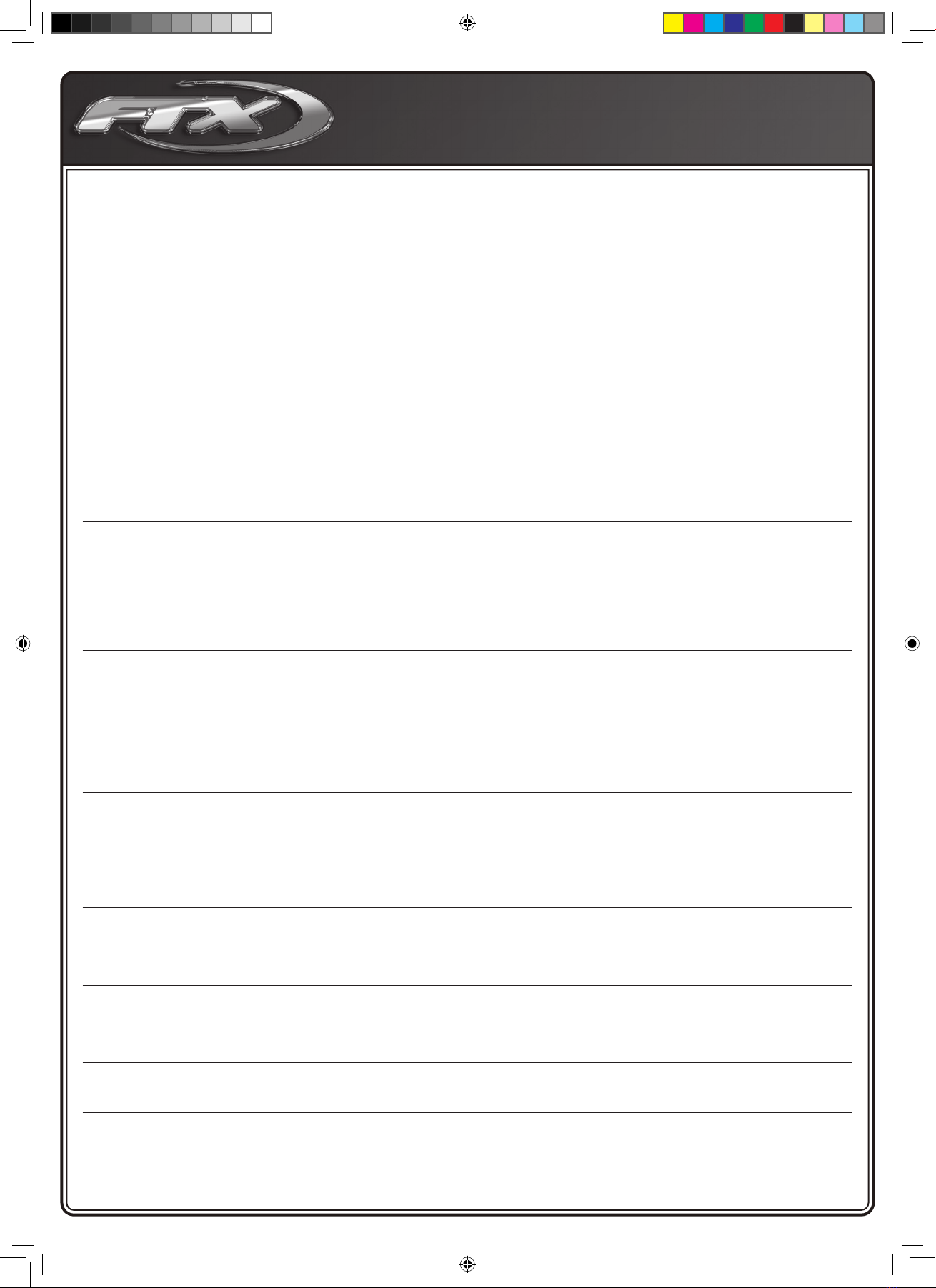

Setting Engine for Normal

Tuning High Speed

As you approach the rst 6-8 tanks running you can start to GRADUALLY

adjust you engine for normal performance. PLEASE NOTE any adjustments

need to be very small at 1/8th turn increments. You can then begin adjusting

the fuel mixture to maximize performance for your driving needs. To lean turn

the main fuel control needle in a clockwise direction. This will allow the car

to pull away faster and more cleanly, without hesitation and increase the top

speed. There should however still be a noticeable smoke trail.

If the main needle is screwed in too far thus allowing the engine to run too

lean, it will seem to run strong at rst, but will bog, hesitate, or stall when

running at high speed. The engine will also rapidly overheat when the setting

is too lean. This is because fuel includes lubrication, and that lubrication is

inadequate when the setting is too lean. CHECK THE ENGINE TEMPERATURE

OFTEN AS YOU LEAN THE MIXTURE. DO NOT LET THE ENGINE OVERHEAT.

You should always see smoke coming from

the exhaust.

At the optimum setting, the engine will clean

out; have a strong-sounding, high-pitched

whine at full speed; and there will be a

thin trail of whitish smoke coming from the

exhaust. It is always better to set the engine

a little rich rather than too lean.

If the engine stalls on acceleration, begins

to bog or slow down at full throttle, or if

there is a reduction in exhaust smoke, then

the engine is running too lean. Immediately

turn the high speed mixture screw

counterclockwise 1/4 of a turn and operate

the car at medium speeds for 1 to 2 minutes

to allow the engine to cool.

Tuning Low Speed

The low-speed mixture aects how the

engine will perform in the low to mid

range rpms. Turning the low-speed needle

clockwise will lean the mixture. As with the

high-speed mixture, leaning the low-speed

mixture increases performance. Again, if the

mixture here is set too lean, the engine may

be starved for lubrication in the lowand mid-

rpm ranges, thus causing overheating and

excessive engine wear.

Perform the following test to determine if

the low speed mixture is set correctly. With

the engine warm and running, allow it to idle

for approximately 15 seconds. Now quickly

apply throttle and note the performance. If the engine bogs, accelerates

erratically, and a large pu of blue smokes emitted, then the low speed mixture

is too rich. Turn the low-speed screw clockwise 1/8 of a turn. If the engine

speeds up for a moment then bogs, hesitates, or stalls, then the low speed

mixture is too lean. Turn the screw counterclockwise 1/8 of a turn. Adjust the

mixture screws in 1/8 of a turn increments, wait 15 seconds, and retest after

each change. Adjust for the best acceleration without the car stalling.

Care and Maintenance

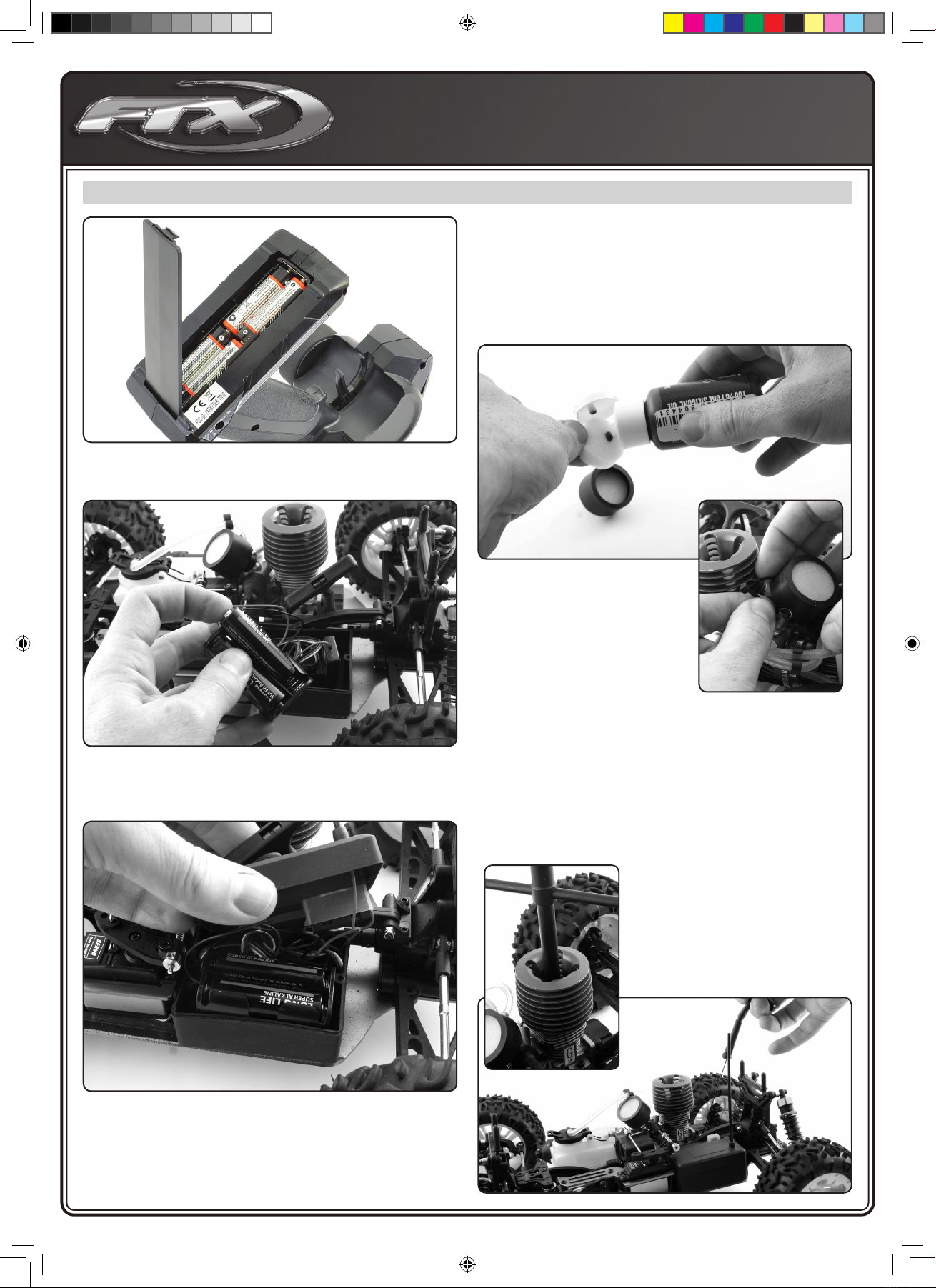

When you are nished racing for the day, drain the fuel tank. Afterwards,

energize the glow plug with your glow plug starter and try to restart the engine

in order to burn o any fuel that may remain inside the

engine. Repeat this procedure until the engine fails to re.

Try to eject residue while the engine is still warm. Finally,

inject some corrosion inhibiting oil, and rotate the

engine to distribute the oil to all the working parts.

Do not, however, inject the oil into the carburetor, for

it may cause the O-rings inside to deteriorate. When

cleaning the exterior of the engine, use WD-40. Do

not use gasoline or any solvents that might damage

the silicone fuel tubing.

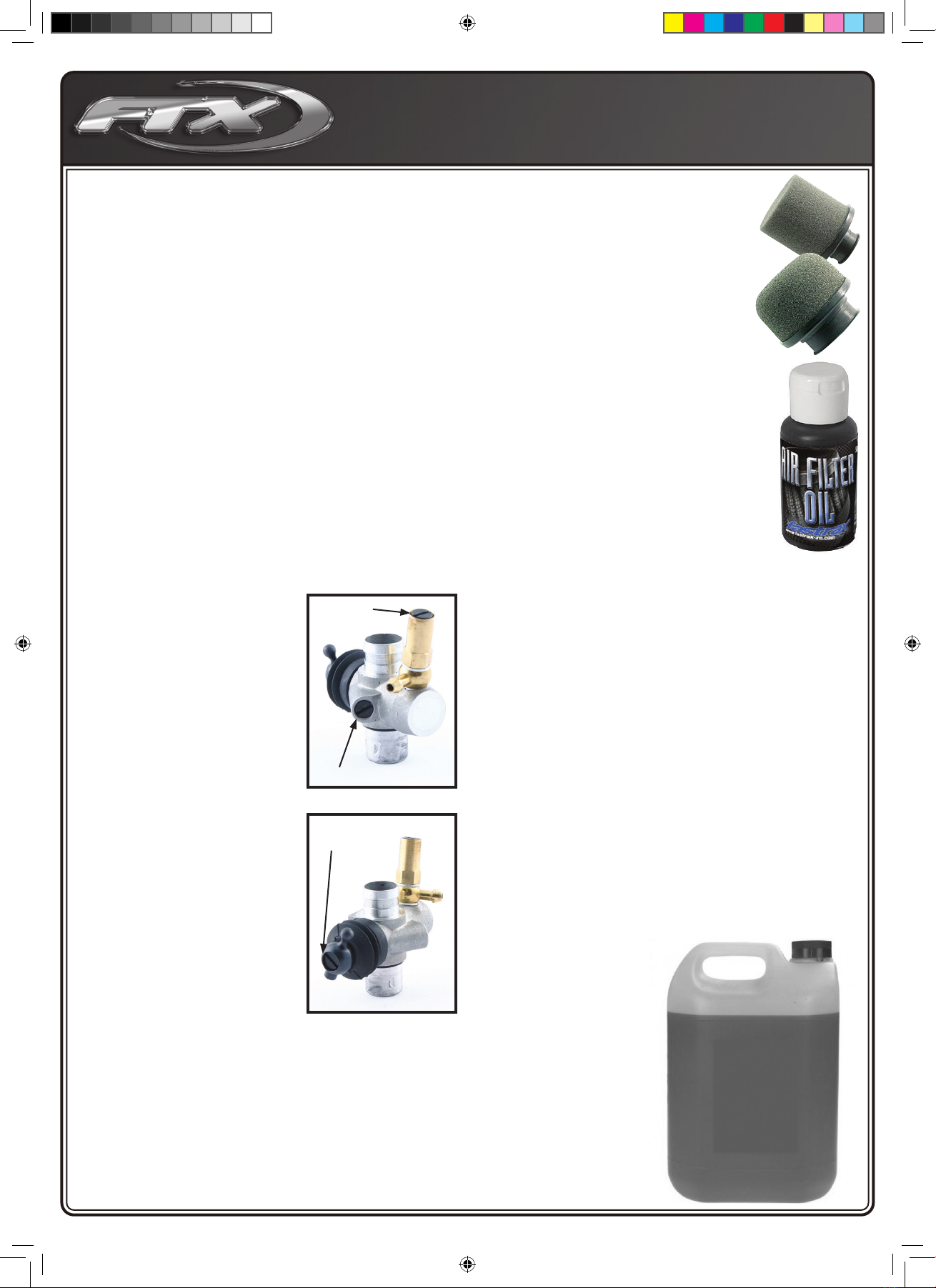

Cleaning the air lter. When the air lter starts to get

dirty, do the following steps:

Step 1. Clean the foam with fuel. Do this by

pouring a little fuel in a small can and

kneading the lter in the fuel. When it

looks cleaner, then dispose of the fuel.

Step 2. Dry the lter. Squeeze out the fuel with a paper

towel until it’s dry.

Step 3. Fastrax Fast63 Filer Oil to help keep the dirt out.

Dab the treatment all around the lter, put the lter

in a plastic sandwich bag, and knead it until the

lter is saturated, but not soaked.

Troubleshooting

Glow Plug Problems

The glow plug in your engine is an inexpensive consumable

item which must be replaced periodically to maintain peak performance and

starting ease. Most often, any starting problems or erratic performance can

be traced back to the glow plug. The glow plug should also be checked if the

engine’s acceleration and top speed performance suddenly becomes at. The

only sure way to test for a faulty glow plug is simply install a new one to see if

the problem goes away. Remove the plug from the cylinder head with a 8mm

nut driver. Make sure there is no dirt or debris on top of the head which could

fall into the engine. Do not loose the copper gasket which seals the glow plug.

Touch the glow plug to the contacts of the glow plug starter. All of the coils

should glow white. Sometimes the rst few coils will not glow while the rest are

bright, most likely indicating a bad plug. If the glow is dim orange, then the glow

starter battery should be replaced or recharged.

At the high rpm that the engines operate only a top quality plug will cut the

mustard. Therefore we recommend the use of the Fastrax Platinum No.4

glowplug (FAST760-4).

Fuel Mixture

The fuel mixture is the largest variable you have to control while operating your

engine.

Fuel brand, ambient temperature, and humidity all eect how your mixture

should be set. If the engine runs great one day but runs rich or lean the next

day, it is probably the result of a change in the air quality and temperature. This

should be expected and adjusted for.

Although there are many fuels on the market, very few are designed to perform

and protect your engine at the likes of 35,000rpm that some of our engines can

attain.

Keep between 16-20%

nitromethene content for running

and rst use. The single most

popular reason for engine failure or

unreliability is poor or wrong fuel.

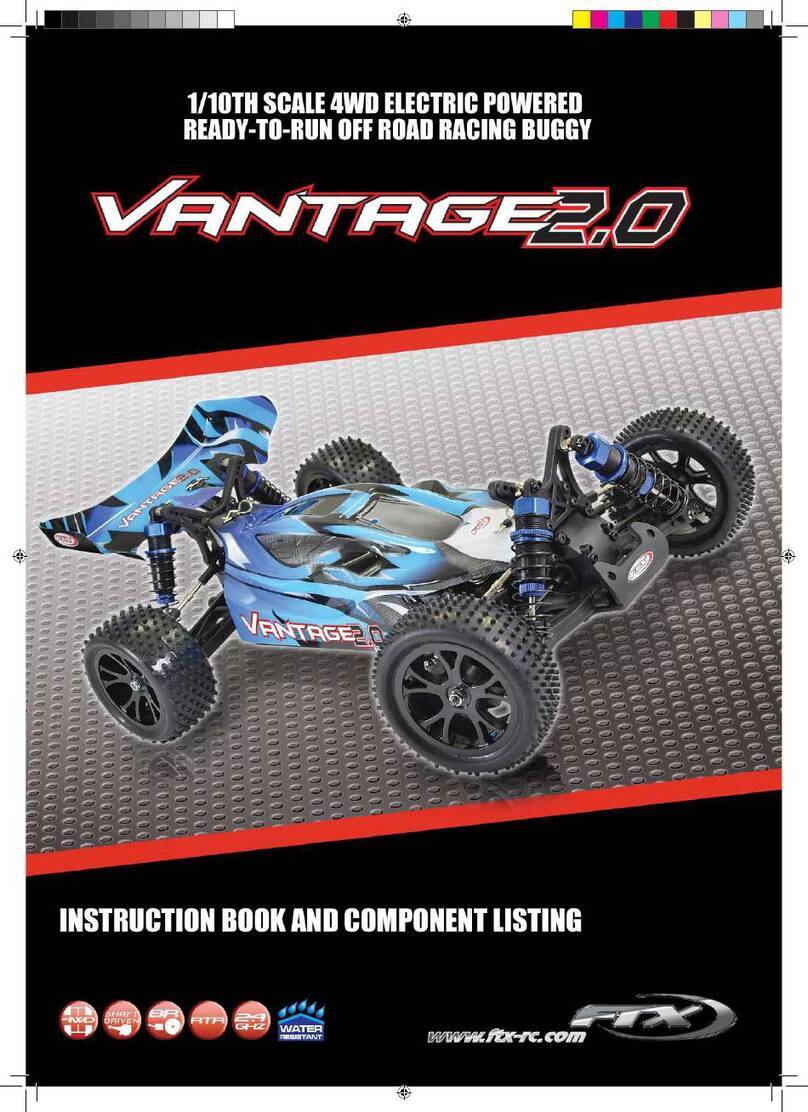

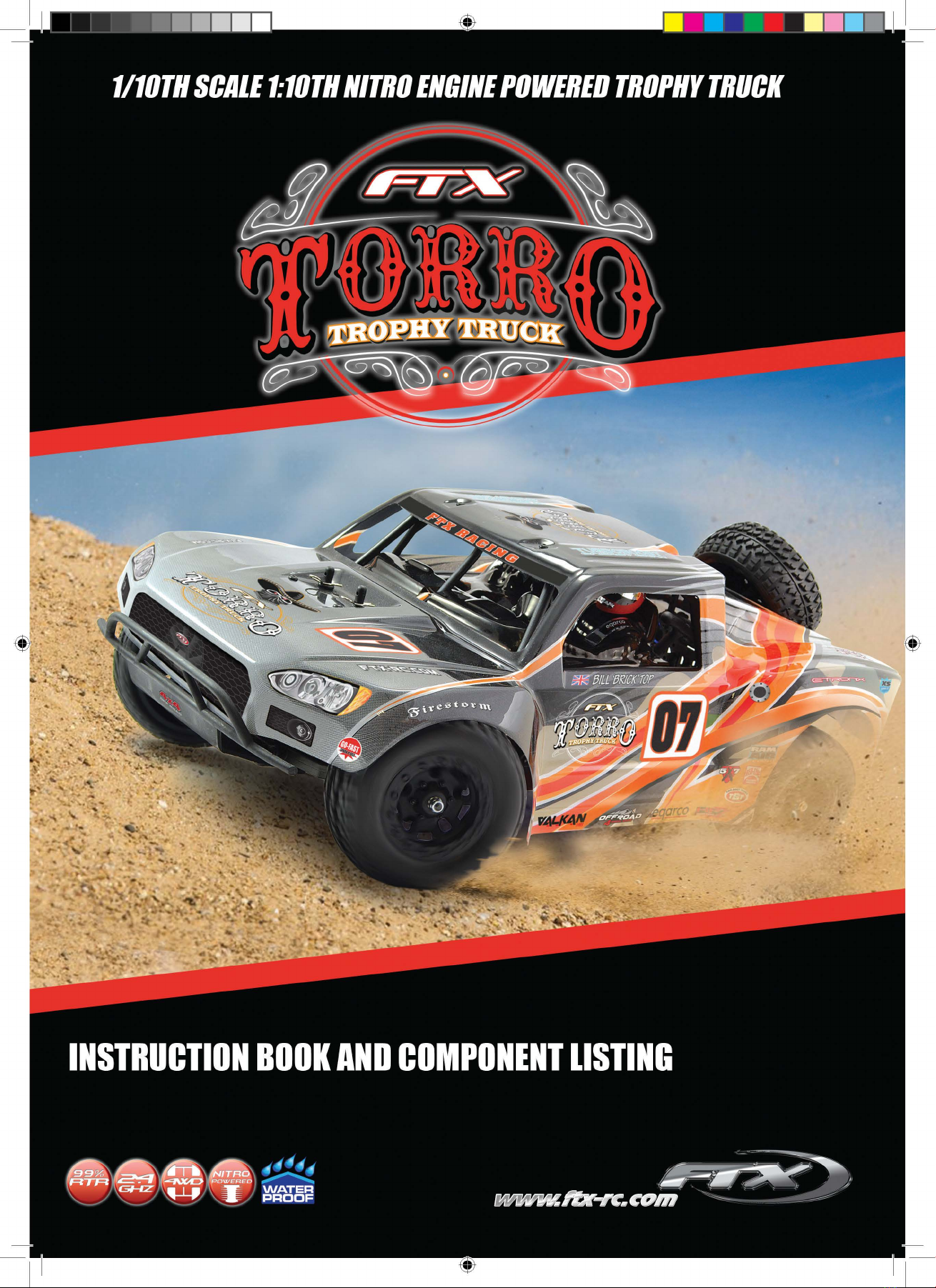

HIGH SPEED

ADJUSTMENT

IDLE ADJUSTMENT

LOW SPEED

ADJUSTMENT

FTXTorroIDManual.indd 7 12/07/2019 13:26