Team Digital SRC16 User manual

Cont. Summary of Configuration Variables

>DCC compatible accessory decoder

> Control switches (turnouts)

> Drive switch status LEDs

> Drive low current switch machines

> Eight configurable routes

> 16 Individually configurable inputs & outputs

> Featuring “Smart” Programming

>DCC gateway to serial bus

> LocoNet® compatible

TEAM DIGITAL

WARNING: This product contains a chemical known to thestate of

California to cause cancer, birth defects or other reproductive harm.

16

03.28.11 V16

LocoNet is a registered

trademark of Digitrax Inc

TEAM DIGITAL, LLC

3111 Timber Valley Dr

Kokomo IN 46902

www.teamdigital1.com

CV#

Function/Default Value

CV#

Function/Default Value

173

Route 3 Cell 7 Address Adder

0

215

Route 6 Cell 4 Address Adder

0

174

Route 3 Cell 8 Address

0

216

Route 6 Cell 5 Address

0

175

Route 3 Cell 8 Address Adder

0

217

Route 6 Cell 5 Address Adder

0

176

Route 4 Cell 1 Address

0

218

Route 6 Cell 6 Address

0

177

Route 4 Cell 1 Address Adder

0

219

Route 6 Cell 6 Address Adder

0

178

Route 4 Cell 2 Address

0

220

Route 6 Cell 7 Address

0

179

Route 4 Cell 2 Address Adder

0

221

Route 6 Cell 7 Address Adder

0

180

Route 4 Cell 3 Address

0

222

Route 6 Cell 8 Address

0

181

Route 4 Cell 3 Address Adder

0

223

Route 6 Cell 8 Address Adder

0

182

Route 4 Cell 4 Address

0

224

Route 7 Cell 1 Address

0

183

Route 4 Cell 4 Address Adder

0

225

Route 7 Cell 1 Address Adder

0

184

Route 4 Cell 5 Address

0

226

Route 7 Cell 2 Address

0

185

Route 4 Cell 5 Address Adder

0

227

Route 7 Cell 2 Address Adder

0

186

Route 4 Cell 6 Address

0

228

Route 7 Cell 3 Address

0

187

Route 4 Cell 6 Address Adder

0

229

Route 7 Cell 3 Address Adder

0

188

Route 4 Cell 7 Address

0

230

Route 7 Cell 4 Address

0

189

Route 4 Cell 7 Address Adder

0

231

Route 7 Cell 4 Address Adder

0

190

Route 4 Cell 8 Address

0

232

Route 7 Cell 5 Address

0

191

Route 4 Cell 8 Address Adder

0

233

Route 7 Cell 5 Address Adder

0

192

Route 5 Cell 1 Address

0

234

Route 7 Cell 6 Address

0

193

Route 5 Cell 1 Address Adder

0

235

Route 7 Cell 6 Address Adder

0

194

Route 5 Cell 2 Address

0

236

Route 7 Cell 7 Address

0

195

Route 5 Cell 2 Address Adder

0

237

Route 7 Cell 7 Address Adder

0

196

Route 5 Cell 3 Address

0

238

Route 7 Cell 8 Address

0

197

Route 5 Cell 3 Address Adder

0

239

Route 7 Cell 8 Address Adder

0

198

Route 5 Cell 4 Address

0

240

Route 8 Cell 1 Address

0

199

Route 5 Cell 4 Address Adder

0

241

Route 8 Cell 1 Address Adder

0

200

Route 5 Cell 5 Address

0

242

Route 8 Cell 2 Address

0

201

Route 5 Cell 5 Address Adder

0

243

Route 8 Cell 2 Address Adder

0

202

Route 5 Cell 6 Address

0

244

Route 8 Cell 3 Address

0

203

Route 5 Cell 6 Address Adder

0

245

Route 8 Cell 3 Address Adder

0

204

Route 5 Cell 7 Address

0

246

Route 8 Cell 4 Address

0

205

Route 5 Cell 7 Address Adder

0

247

Route 8 Cell 4 Address Adder

0

206

Route 5 Cell 8 Address

0

248

Route 8 Cell 5 Address

0

207

Route 5 Cell 8 Address Adder

0

249

Route 8 Cell 5 Address Adder

0

208

Route 6 Cell 1 Address

0

250

Route 8 Cell 6 Address

0

209

Route 6 Cell 1 Address Adder

0

251

Route 8 Cell 6 Address Adder

0

210

Route 6 Cell 2 Address

0

252

Route 8 Cell 7 Address

0

211

Route 6 Cell 2 Address Adder

0

253

Route 8 Cell 7 Address Adder

0

212

Route 6 Cell 3 Address

0

254

Route 8 Cell 8 Address

0

213

Route 6 Cell 3 Address Adder

0

255

Route 8 Cell 8 Address Adder

0

214

Route 6 Cell 4 Address

0

SRC16

Switch & Route Controller

Improving the

world of DCC

or 9 -12 V DC

use only with an

accessory bus

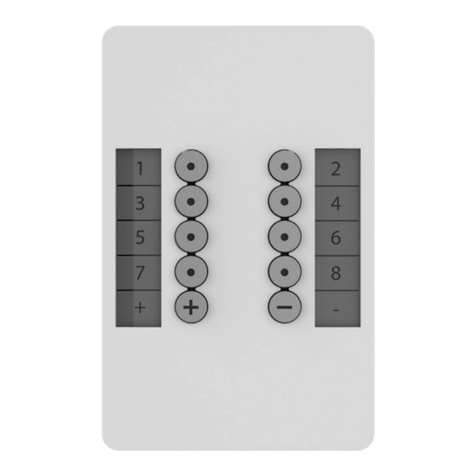

1 Operation

The SRC16 has 16 inputs and outputs which can each have a unique address. By assigning

the same address to a pair of inputs and outputs, called a group, the SRC16 can control eight

turnouts (switches) or display the state (closed or thrown) of eight turnouts. If the serial bus

(LocoNet® compatible) is enabled, activating an input (close or throw) sends a turnout

command (message) that correspond to it’s address over the serial bus. Any device con-

nected to the bus can receive the command. The SRC16 monitors the bus for commands

from other sources. When a turnout command is received with an address that matches a

group’s address, that output (closed or thrown) is activated. LEDs or stall motors can be

connected to the outputs. The SRC16 does not require a serial bus connection to operate. It

receives it’s own messages.

The SRC16 supports eight routes. Each route has eight cells. There is one top or route exe-

cution address for each route. Each top address is completely independent of an input or

output address.

Any input can be used for turnout position reporting which tells the system the actual state

(closed or thrown) of the turnout. Any input can be used for sensor state reporting such as

track block occupancy.

Since the SRC16 is a accessory decoder, it can be controlled via DCC commands. It can

also be controlled via the serial bus (LocoNet® compatible). For non-Digitrax systems a

DCC gateway feature allows DCC switch commands to be passed directly to the serial bus.

This allows DCC switch commands to control devices connected to this serial bus.

LED 1 flashes indicates “Smart” programming steps. LED 2 flash indicates accepted pro-

gram value. LED 3 slow flash indicates heartbeat (fast flash indicates serial bus short).

2 Getting Started

The SRC16 comes from the factory ready to use with inputs and outputs configured in

groups of two with group addresses of 1 to 8. Once you connect LEDs and/or stall motors to

the outputs and perhaps a push button or other device to the inputs, you are ready to connect

to track power and use the SRC16. If you want to change some of the output or input ad-

dresses or configuration values see the “Smart” Programming section. For very custom

programming see section 4, Configuration Variables for various options. If you will be us-

ing Team Digital MotoDs with the SRC16 see section 5.4.

2.1 Control via LocoNet®- Digitrax Users

The SRC16 comes from the factory ready to use by control from DCC commands when the

SRC16 is connected to track power. To control the SRC16 via LocoNet®, it must be en-

abled. Connect the SRC16 track power terminals to the programming track and program

CV9 with a value of 48. The SRC16 can now be powered from a 12 volt supply and con-

trolled via LocoNet®.

3 “Smart” Programming

“Smart” programming is a term used to describe an easy way to program Configuration

Variables (CVs). The throttle is used to issue switch or accessory commands just like con-

trolling switches (turnouts). “Smart” programming only works when connected to track

power.

To program in “Smart” mode, connect the SRC16 power terminals to track power. Connec-

tion to the serial bus (LocoNet® in Digitrax system) is not used. Turn on power.

2 15

CV#

Function/Default Value

CV#

Function/Default Value

87

Output 8 Control

0

130

Route 1 Cell 2 Address

0

88

Output 9 Address

5

131

Route 1 Cell 2 Address Adder

0

89

Output 9 Type & Address Adder

0

132

Route 1 Cell 3 Address

0

90

Output 9 Control

0

133

Route 1 Cell 3 Address Adder

0

91

Output 10 Address

5

134

Route 1 Cell 4 Address

0

92

Output 10 Type & Address Adder

64

135

Route 1 Cell 4 Address Adder

0

93

Output 10 Control

0

136

Route 1 Cell 5 Address

0

94

Output 11 Address

6

137

Route 1 Cell 5 Address Adder

0

95

Output 11 Type & Address Adder

0

138

Route 1 Cell 6 Address

0

96

Output 11 Control

0

139

Route 1 Cell 6 Address Adder

0

97

Output 12 Address

6

140

Route 1 Cell 7 Address

0

98

Output 12 Type & Address Adder

64

141

Route 1 Cell 7 Address Adder

0

99

Output 12 Control

0

142

Route 1 Cell 8 Address

0

100

Output 13 Address

7

143

Route 1 Cell 8 Address Adder

0

101

Output 13 Type & Address Adder

0

144

Route 2 Cell 1 Address

0

102

Output 13 Control

0

145

Route 2 Cell 1 Address Adder

0

103

Output 14 Address

7

146

Route 2 Cell 2 Address

0

104

Output 14 Type & Address Adder

64

147

Route 2 Cell 2 Address Adder

0

105

Output 14 Control

0

148

Route 2 Cell 3 Address

0

106

Output 15 Address

8

149

Route 2 Cell 3 Address Adder

0

107

Output 15 Type & Address Adder

0

150

Route 2 Cell 4 Address

0

108

Output 15 Control

0

151

Route 2 Cell 4 Address Adder

0

109

Output 16 Address

8

152

Route 2 Cell 5 Address

0

110

Output 16 Type & Address Adder

64

153

Route 2 Cell 5 Address Adder

0

111

Output 16 Control

0

154

Route 2 Cell 6 Address

0

112

Route 1 Top Address

0

155

Route 2 Cell 6 Address Adder

0

113

Route 1 Top Address Adder

0

156

Route 2 Cell 7 Address

0

114

Route 2 Top Address

0

157

Route 2 Cell 7 Address Adder

0

115

Route 2 Top Address Adder

0

158

Route 2 Cell 8 Address

0

116

Route 3 Top Address

0

159

Route 2 Cell 8 Address Adder

0

117

Route 3 Top Address Adder

0

160

Route 3 Cell 1 Address

0

118

Route 4 Top Address

0

161

Route 3 Cell 1 Address Adder

0

119

Route 4 Top Address Adder

0

162

Route 3 Cell 2 Address

0

120

Route 5 Top Address

0

163

Route 3 Cell 2 Address Adder

0

121

Route 5 Top Address Adder

0

164

Route 3 Cell 3 Address

0

122

Route 6 Top Address

0

165

Route 3 Cell 3 Address Adder

0

123

Route 6 Top Address Adder

0

166

Route 3 Cell 4 Address

0

124

Route 7 Top Address

0

167

Route 3 Cell 4 Address Adder

0

125

Route 7 Top Address Adder

0

168

Route 3 Cell 5 Address

0

126

Route 8 Top Address

0

169

Route 3 Cell 5 Address Adder

0

127

Route 8 Top Address Adder

0

170

Route 3 Cell 6 Address

0

128

Route 1 Cell 1 Address

0

171

Route 3 Cell 6 Address Adder

0

129

Route 1 Cell 1 Address Adder

0

172

Route 3 Cell 7 Address

0

Cont. Summary of Configuration Variables

7 Summary of Configuration Variables

14 3

CV#

Function/Default Value

CV#

Function/Default Value

1

Ops Mode Loco Address

1

44

Input 10 Type & Address Adder

128

2

reserved

-

45

Input 10 Transition & Route

2

3

reserved

-

46

Input 11 Address

6

4

reserved

-

47

Input 11 Type & Address Adder

0

5

reserved

-

48

Input 11 Transition & Route

2

6

reserved

-

49

Input 12 Address

6

7

Manufacturer Version No.

-

50

Input 12 Type & Address Adder

128

8

Manufacturer ID

25

51

Input 12 Transition & Route

2

9

Decoder Configuration

0

52

Input 13 Address

7

10

Status Report

0

53

Input 13 Type & Address Adder

0

11

Route send delay

0

54

Input 13 Transition & Route

2

12

Pwr on state - Outputs 1 - 8

170

55

Input 14 Address

7

13

Pwr on state - Outputs 9 - 16

170

56

Input 14 Type & Address Adder

128

14

Input Lockout Address

0

57

Input 14 Transition & Route

2

15

Input Lockout Address Adder

0

58

Input 15 Address

8

16

Input 1 Address

1

59

Input 15 Type & Address Adder

0

17

Input 1 Type & Address Adder

0

60

Input 15 Transition & Route

2

18

Input 1 Transition & Route

2

61

Input 16 Address

8

19

Input 2 Address

1

62

Input 16 Type & Address Adder

128

20

Input 2 Type & Address Adder

128

63

Input 16 Transition & Route

2

21

Input 2 Transition & Route

2

64

Output 1 Address

1

22

Input 3 Address

2

65

Output 1 Type & Address Adder

0

23

Input 3 Type & Address Adder

0

66

Output 1 Control

0

24

Input 3 Transition & Route

2

67

Output 2 Address

1

25

Input 4 Address

2

68

Output 2 Type & Address Adder

64

26

Input 4 Type & Address Adder

128

69

Output 2 Control

0

27

Input 4 Transition & Route

2

70

Output 3 Address

2

28

Input 5 Address

3

71

Output 3 Type & Address Adder

0

29

Input 5 Type & Address Adder

0

72

Output 3 Control

0

30

Input 5 Transition & Route

2

73

Output 4 Address

2

31

Input 6 Address

3

74

Output 4 Type & Address Adder

64

32

Input 6 Type & Address Adder

128

75

Output 4 Control

0

33

Input 6 Transition & Route

2

76

Output 5 Address

3

34

Input 7 Address

4

77

Output 5 Type & Address Adder

0

35

Input 7 Type & Address Adder

0

78

Output 5 Control

0

36

Input 7 Transition & Route

2

79

Output 6 Address

3

37

Input 8 Address

4

80

Output 6 Type & Address Adder

64

38

Input 8 Type & Address Adder

128

81

Output 6 Control

0

39

Input 8 Transition & Route

2

82

Output 7 Address

4

40

Input 9 Address

5

83

Output 7 Type & Address Adder

0

41

Input 9 Type & Address Adder

0

84

Output 7 Control

0

42

Input 9 Transition & Route

2

85

Output 8 Address

4

43

Input 10 Address

5

86

Output 8 Type & Address Adder

64

Wait 6 or 7 seconds then press the “Smart” program button and hold it down for approxi-

mately one second until LED1 (red) starts to flash. Then release it. The SRC16 is now

ready to have the input and output group addresses changed.

Using the throttle select the switch address or accessory number you want for group 1 and

issue a throw (reverse) command. LED2 (green) will flash briefly.

LED1 now flashes twice with a pause and then repeats indicating that the group 2 address

is ready to be programmed.

As you progress through the “Smart” programming steps, LED1 flashes the number of

times indicating which step in the section is ready to be programmed. When either sections

one or two have been completed LED2 lights indicating the start of the next section.

There are three sections to “Smart” programming. You can start from any section. At any

time you can exit “Smart” mode by pressing the button for approximately one second until

LED1 stops flashing.

Example to set the SRC16 for addresses from 9 to 16. See section 1 in the table below.

Power on the SRC16 with track power, after 6 or 7 seconds hold down the Smart button

until LED1 (red) is flashing. Using the throttle in switch mode issue the desired address (9)

for group 1 with a close or throw. LED 2 (green) will flash briefly. The LED 1 (red) now

flashes a two (two quick flashes with a pause then repeat) indicating group 2 address is

ready to be programmed with a 10. Continue this for the rest of the groups. When LED 2

(green) lights continually the 8 groups addresses have been programmed. Exit Smart pro-

gramming by holding down the button until the red led stops flashing. The green led will

also turn off.

Smart Programming Summary

#Flashes

Description

t

c

Section 1: To start - Press the “Smart” button until LED1 starts to flash

1

Input/Output group 1 address

accept

accept

2

Input/Output group 2 address

accept

accept

3

Input/Output group 3 address

accept

accept

4

Input/Output group 4 address

accept

accept

5

Input/Output group 5 address

accept

accept

6

Input/Output group 6 address

accept

accept

7

Input/Output group 7 address

accept

accept

8

Input/Output group 8 address

accept

accept

Section 2: To start here - Press the “Smart” button until LED2 lights - Output addresses are not changed

1

Input group 1 address

accept

accept

2

Input group 2 address

accept

accept

3

Input group 3 address

accept

accept

4

Input group 4 address

accept

accept

5

Input group 5 address

accept

accept

6

Input group 6 address

accept

accept

7

Input group 7 address

accept

accept

8

Input group 8 address

accept

accept

Section 3: To start here - Press the “Smart” button until LED2 lights and continue until it turns off

1

Value of CV9 - Decoder configuration

set

clear

2

Value of CV10 - Status report

set

clear

3

Beginning address of 16 sequential input/output addresses - Useful

for block sensors or high density switch control with MotoDs

Sensor

type

Switch

type

Section 3 is a little different then the other sections because in steps 1 and 2 a CV value is

programmed instead of an address. Check the appropriate section in the manual to deter-

mine the CV value and use a switch address for that value.

In step 3 of section 3 the input and corresponding output are programmed with 16 sequen-

tial addresses. Input 1 and output 1 are

programmed with the issued switch

address. The rest of the input/outputs are

automatically programed with sequential

addresses. Switch type or sensor type

messages can be chosen.

4 Configuration Variables (CVs)

The SRC16 supports Paged Mode Programming in Service Mode and Operations (Ops)

Mode programming. To program in paged mode, connect the Track Power terminals to the

programming track. See diagram on the front page. When power is applied, LED 1 will

come on and LED 2 will flash when programming is successful. Some systems only apply

power during actual programming, so LED1 will only be on during that time. The SRC16

does not have built in feedback like a mobile decoder. Therefore, some systems may show a

“no decoder on track” error or “can not read CV”. However it still is programmed. To enter

normal operation, disconnect from the program track and connect as defined is section 5.

Ops mode or “programming on the main” is very convenient because you can try out the

CV changes almost immediately. In order to use this type of programming the ops mode

loco address must be set in CV1 (default is 1) and option 3 must be set in CV9. This is a

loco address, so be careful when using this feature. You can immediately start program-

ming in “Power On” ops mode without programming CV9 by holding down the Smart but-

ton just before power is turned on. When LED2 turns on release the button then wait until

LED1 turns off. This temporarily sets option 3 until power is turned off. When using ops

mode to change CV values, the SRC16 does not recognize the new values of CV 1 - 13

until power is turned off and then back on.

Programming CV7 with a value of 1 will restart the SRC16 so power need not be cycled

when programming in “Power On” ops mode. This is the same as turning power off and

then back on. For programming with DecoderPro and other programming tips see Team

Digital’s web site.

Reset the SRC16 to factory defaults.

To “reset” the SRC16 to factory defaults, turn power on and wait until LED 1 turns off.

Then press the “Smart” button and continue to hold the button down (at least 16 seconds)

until both LED 1 & 2 are alternately flashing. Alternately, programming CV7 with 170 will

“reset” all CV’s to the factory default value. In page mode this may not work with some

systems as they do not keep power applied to the programming track long enough for all the

CVs to be programmed.

4.1 Output Address

These CVs determine the address of the outputs and how the output responds. Each output

has two CVs, an address and a type which includes the address adder, that makes up the

address. See section 7 for CV numbers. The type CV also contains the message type the

output responds to. That is, the output will turn on when a command is received when this

criteria is met. The following table shows the CV value to set the criteria.

To calculate the type CV value add up the selected values.

4

6.2 Routes

The SRC16 is well suited to handle routes in a yard. The following shows an example of

five routes using four switches. The route CV values were determined using the information

in sections 4.6 and 4.7. One very nice tool that makes custom programming much easier is

JMRI DecoderPro.

A route can be executed with an actual turnout (switch) address or a pseudo address of a

switch (not a physical switch). Program the top address of the route with the address you

want to execute the route.

13

2 4 6 8 10

13579

Pin Out

Outputs

Inputs

1

23

4

6

5

7

8

2 4 6 8 10

1 3 5 7 9

Pin Out

Pin # connec tion1234 78910 1234 78910 Serial Bus

Connectors

Pin # c onnection 1 2 3 4 5 7 8 9 10 1 2 3 4 5 7 8 9 10

G1

G2 G3

G4 G5

G6 G7

G8

2 4 6 8 10

13579

Pin Out

2 4 6 8 10

1 3 5 7 9

Pin Out

SW 33

SW 34

SW 35

SW 36

Route 1 (SW 33 -t, SW 36 - c)

Route 2 (SW 33 -t, SW 36 - t)

Route 3 (SW 33 - c, SW 34 - c)

Route 4 (SW 33 - c, SW 34 - t, SW 35 -t)

Route 5 (SW 33 - c, SW 34 - t, SW 35 - c)

Yard diagram

Route Example

Route

1

2

3

4

5

6

7

8

Execute address

101 t

101 c

102 t

102 c

103 t

Address 1

33 t

33 t

33 c

33 c

33 c

Address 2

36 c

36 t

34 c

34 t

34 t

Address 3

35 t

35 c

Address 4

Address 5

Address 6

Address 7

Address 8

Switch (Turnout) Terminology

This manual

throw or t

close or c

Digitrax

throw or t

close or c

NCE

reverse or OFF or 2

normal or ON or 1

Lenz

-

+

MRC

OFF

ON

4.2 Output Control

This CV determines how the output will respond when it is turned on. The following table

shows how each output control is defined. See section 7 for CV numbers.

The normal state for the outputs is to drive common anode LEDs . If you want to use a

common cathode connected LED select the invert normal state. If you want to change all

the outputs set Option 8 of the Decoder Configuration CV.

The delay effect causes the output to delay turn on once it has been commanded.

Reciprocal is used only with the flash effect to cause two outputs to flash alternately. Both

outputs have to be selected to flash with the same dura-

tion. One of the outputs is selected for reciprocal. This

can be used for grade crossing flashers.

The duration of time works only when one of the ef-

fects is selected. It determines the flash rate and delay

time. See the table to get the value for selection based

on the time.

12 5

Output Control CV

Value

Select

Invert the normal state (for common cathode)

128

Select

Normal state

0

One

Effect, flash

16

Select

Effect, delay

8

No effect

0

One

Reciprocal or alternate (use with flash effect only)

4

Duration time, use with effect (see duration table)

0 - 3

Program this value into the appropriate output control CV

6 Applications

6.1 Switch Machine drive

The SRC16 is capable of driving low current stall type switch machines. It has been tested

with the Tortoise TM switch machine and can drive up to eight of them. Programming is the

same whether using a switch machine or LEDs. A group of two outputs for throw and close

needs to be used. “Smart” programming will automatically do this when addresses are

assigned.

Each switch machine is connected to one of the SRC16 group outputs. When the SRC16

receives a switch command for that group, lets say a close command, that output is

grounded. The thrown output is at 5 volts, so 5 volts is applied to the motor. It then moves

in the close direction. Likewise, when a throw command is received for that group, that

output is grounded. The closed output is now at 5 volts, so 5 volts is applied to the motor in

the opposite direction. Consequently, it moves in the throw direction.

Since the SRC16 uses 5 volts for motor drive, the switch machine moves slower than if 12

volts were applied. If a higher voltage is desired use the Team Digital MotoD. A MotoD is

a satellite motor driver that is controlled by the SRC16. Up to four MotoDs can be con-

trolled by the SRC16.

See section 5.4 for more information.

If an address greater than 255 is needed then use the address adder. The address adder value

represents a number that is added to the address value to give the ‘actual’ address. The fol-

lowing table shows the CV value to use for the adder. To set addresses for output groups see

“Smart” Programming for easier programming.

Address Adder

CV Value

0

1

2

3

4

5

6

7

8

9

ADD

0

256

512

768

1024

1280

1536

1792

2048

2304

SRC16

Serial bus

To other serial

bus devices

Cut

Termination

resistor

SRC16

Serial bus

Data

RS

Ground

RS

Data

Ground

RJ12 Connector

5.5 Serial Bus

The SRC16 has two RJ12 connectors for ease in making connections as shown below. In a

Digitrax system the data pins are LocoNet and the RS pins are Rail Sync. In a Digitrax sys-

tem Rail Sync is a replica of the track power signal but has limited power. One of its uses is

to provide power to throttles connected to LocoNet. In the SRC16 the RS is only connected

to the two terminal RS connector. In a system where the SRC16 is NOT connected to Lo-

coNet the RS may be used to pass power from one SRC16 to another.

In a systems when more than 10 SRC16s are used the bus terminating resistor should be cut

on any additional devices.

Cables are wired pin 1to pin 1

Duration Time

Value

Flash

Delay

0

.5 sec

5 sec

1

1 sec

10 sec

2

2 sec

20 sec

3

4 sec

40 sec

Output

Address CV

Value

Select

Address

1 - 255

Program this value into the appropriate address CV

Type CV

Value

Select

Close

64

Select

Throw

0

one

Message type, sensor

32

Select

Message type, feedback (actual switch position)

16

Message type, switch (commanded switch position)

0

one

Address adder (see the address adder table for amount to add)

0 - 9

Program this value into the appropriate type CV

4.3 Power On Output State

CV12 - Power on state for output groups 1 to 4, a value from 1 to 170

CV13 - Power on state for output groups 5 to 8, a value from 1 to 170

These CVs determine the state of each output group at power on. Decoder configuration

option 1 or option 2 has to be enabled for this these CVs to function. You only need to pro-

gram these CVs if option 2 is enabled. If option 1 is enabled, the SRC16 automatically pro-

grams them. These tables only apply if the SRC16 outputs are configured in groups.

Output Groups 1 to 4

Value

Select

Output Groups 5 to 8

Value

Select

Output 1 throw

1

1

Output 5 throw

1

Output 1 close

2

Output 5 close

2

2

Output 2 throw

4

4

Output 6 throw

4

Output 2 close

8

Output 6 close

8

8

Output 3 throw

16

Output 7 throw

16

16

Output 3 close

32

32

Output 7 close

32

Output 4 throw

64

64

Output 8 throw

64

64

Output 4 close

128

Output 8 close

128

Program this value into CV12

101

Program this value into CV13

90

Example: CV12 = 1 + 4 + 32 + 64 = 101, throw output group 1, throw output group 2, close

output group 3 and throw output group 4

Example: CV13 = 2 + 8 + 16 + 64 = 90, close output group 5, close output group 6, throw

output group 6 and throw output group 6 (example shown above in table)

611

4.4 Decoder Configuration

CV9 - Configuration.

This CV determines the configuration which consists of several options.

Option 1 - Memory. The SRC8 will remember the output state at power off and at power on

the outputs will be set to the same state.

Option 2 - Default output state. At power on each output will be set to the state as deter-

mined by CV12 and CV13. You must program CV12 and CV13 to the desired state at

power on. Option 2 disables option 1. See section 4.3.

Option 3 - Ops Mode Programming. Allows Operations mode (On the Main) programming

using a Loco address to be enabled all the time. See section 4.10.

Option 4 - DCC to bus gateway. Allows DCC switch command packets to be put the serial

bus. Any device connected to the bus will have access to these DCC commands. Requires

option 5.

Option 5 - Serial Bus communication. Allows the SRC16 to communication with devices

connected to the serial bus.

Option 6 - DCC control. Allows the SRC16 to receive instructions from DCC (track). Note:

Selecting this option DISABLES this feature.

Option 7 - Output lockout. Allows an input, when grounded, to keep the respective output

from changing. Intended for use when inputs and outputs are configured as groups. This is

address independent.

Option 8 - Common cathode LEDs. Allows common cathode connection of LEDs to the

outputs.

using flat ribbon cable Insulation Displacement (IDC) and connectors from Jameco. The

mating connector is #138377. 10 ft of gray flat ribbon cable is #643794. 10 ft of multicolor

flat ribbon cable is #639672. See the diagram on the front page for connector location.

Warning: Do not connect the power supply ground (minus) to the ground (minus) pin of

the 10 pin IDC connector. Do not connect any outputs together or to other SRC16 outputs.

Conn --------- Outputs 1 to 8 ------------ --------- Outputs 9 to 16 -----------

Pin # 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

Output# 1 2 3 4 - + 5 6 7 8 9 10 11 12 - + 13 14 15 16

Conn --------- Inputs 1 to 8 -------------- ---------- Inputs 9 to 16 ------------

Pin # 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

Input# 1 2 3 4 - + 5 6 7 8 9 10 11 12 - + 13 14 15 16

Pin 1 Pin 1

246810

13579

Connector Pin Numbers

24+68

13- 57

1012 +1416

911 -1315

Inputs 1to 8

Pin 1

24+68

13- 57

Outputs 1to 8

Pin 1

1012 +1416

911 -1315

Outputs 9 to 16

Inputs 9to 16

12 volts

to pin 6

5 volts

to pin 6

Pin 6

Pin 6

Use shorting bar to select

voltage to supply pin 6.

SRC16

Inputs

1 to 8

Outputs

9 to 16

Outputs

1to 8

Inputs

9to 16

IDC

10

PIN

1

IDC

10

PIN

1

ID C

10

PIN

1

ID C

10

PIN

1

Voltage to

pin 6 based

on resisitor

Voltage applied to pin 6 of the two output connectors can be changed by the position of the

shorting bar. The standard position provides 5 volts when the SRC16 is driving LEDs or

other low current 5 volt devices. See section 5.3.

The other positions provide a higher voltage for use when Team Digital MotoDs are con-

nected to the outputs. A MotoD is a satellite motor driver that is controlled by the SRC16.

Up to four MotoDs can be controlled be the SRC16.

Caution: Do NOT move the shorting bar from the factory position unless MotoDs are

being used or the SRC16 may be damaged!

The programming track is not required once this address and option 3 have been set.

TIP: If the “Smart” program button is pressed when power is turned on, option 3 is enable

until power is removed. Useful if you do not want to have ops mode enabled all the time.

4.11 Input Lockout Address

CV14 - Address, value 0 to 255: CV15 - Address adder, value 0 to 9

These CVs set the input lockout address. When a switch (turnout) throw command is issued

that matches this address the SRC16 inputs are disabled. When a close command is issued

with this address the inputs are enabled. This feature is useful for dispatcher control when

the SRC16 inputs are used for local turnout control.

5 Connections

5.1 Power

The SRC16 is powered by using the two terminal connector labeled “Track Power or 9-12

VDC”. See diagram on front page. Power can be from the track (accessory decoder opera-

tion) or a filtered DC voltage (9 to 12 VDC) power supply. Most analog 'Power Packs' will

not work because they do not provide smooth (filtered) DC power. The SRC16 power con-

nector is non polarized and either terminal can be connected to plus or minus of the DC

power supply. The power supply should be isolated from the system ground. That is, not

connected to ground (booster ground, house wiring ground, etc). When multiple SRC16s

are used they can be all connected to one power supply. The power supply must be able to

supply the current for all the SRC16s.!The plus and minus of the power supply must be

connected to the same power input terminal on each SRC16. The rail sync terminals can be

used to connect power to other SRC16s when using an accessory bus. See section 5.5. Do

NOT use the rail sync terminals in a standard Digitrax system if the SRC16s are connected

to the main LocoNet bus. See Team Digital website for more information on using an acces-

sory bus.

5.2 Input Interface

Each input is at 5 volts when no device is connect. This is a hi or true state. When the input

is connected to ground by a push button switch or block sensor the state is low or false.

5.3 Output Drive

The output supplies about 5 volts to drive LEDs and other low current devices such as low

current stall type switch machines. The SRC16 has been tested with a TortoiseTM switch

machine which can be used for a switch machine drive.

If LEDs are used current limiting resistors are required and should not less the 470 ohms.

This is a general guide line for a typical LED. The current limit for any single output is 20

mA and the total of any connector group of eight outputs is 50 mA.

Warning: The output driver is rated for a maximum of 5 volts. Do not change the posi-

tion of the shoring bar from the factory setting unless MotoDs are being used. See sec-

tion 5.4.

5.4 10 PIN Input and Output

Input and output connectors have the same pin definitions. Connections can be made using

our terminal strip adapter (TSA) or our Connector Cable Kit. You can build your own by

710

4.5 Status Report

CV10 - Status report.

This CV determines which input and output states the SRC16 provides. This is typically

used when the serial bus is enabled. Options 3 and 4 will not work correctly if the outputs

are not configured as responding to switch commands and in groups of close/throw.

Option 1 - Input state messages are sent on the serial bus at power on. This options is typi-

cally used for inputs that are used for block detection. This does NOT apply to inputs that

are used for switch (turnout) control.

Option 2 - Output state messages are sent on the serial bus at power on. Eight messages are

sent based on output groups unless option 5 enabled. These are switch type messages.

Option 3 - Input state messages are sent on the serial bus when a Digitrax interrogation

command is received.

Option 4 - Output state messages are sent on the serial bus when a Digitrax interrogation

command is received. These are feedback type messages.

System

DCC

Control

Option 6

Gate-

Way*

Option 4

Serial

Bus

Option 5

CV

Value

Notes

All DCC Com-

patible Systems

Enabled

0

The SRC16 is controlled via the track

(DCC commands).

The bus is not used by the SRC16.

Digitrax System

Disabled

Enabled

48

The SRC16 is controlled via Loconet.

Digitrax System

Enabled

Enabled

Enabled

24

Provides a separate Loconet bus for

Loconet accessory devices.

Allows devices to receive turnout com-

mands from the track (DCC commands).

Reduces throttle bus traffic.

Easier trouble shooting.

NCE System and

others

Enabled

Enabled

Enabled

24

Provides separate bus for bus enabled

accessory devices.

Allows devices to receive turnout com-

mands from the track (DCC commands)

The following table will help you determine how to configuring the SRC16. If there are

more than one SRC16 or other Gateway capable devices, only one should have the gateway

enabled. In a Digitrax system DO NOT connect the SRC16 to the throttle Loconet if the

gateway, DCC control and serial bus are enabled. This could cause an endless sending of

switch commands from the track to Loconet and back to the track.

Decoder Configuration CV

Value

Select

No options

0

Option 1 - Memory enabled

1

Select

Option 2 - Default output state enabled

2

One

Option 3 - Ops mode programming enabled

4

Option 4 - DCC to bus gateway enabled

8

Option 5 - Serial Bus communication enabled

16

Option 6 - Control from DCC DISABLED

32

Option 7 - Output lockout enabled

64

Option 8 - Common cathode LEDs

128

Program this value into the configuration CV

To calculate the value of CV9, add up the selected values. Example: Option 1 and option 3 -

CV9 = 1 + 4 = 5

8 9

Input Control

Address CV

Value

Select

Address

1 - 255

Program this value into the appropriate address CV

Type CV

Value

Select

Invert the normal state

128

Select

Normal state

0

one

Toggle state (only if switch type)

64

Message type, sensor

32

Select

Message type, feedback (actual switch position)

16

Message type, switch (commanded switch position)

0

one

Address adder (see the address adder table for amount to add)

0 - 9

Program this value into the appropriate type CV

Transition CV

Value

Select

Execute route number x 16 (example to execute route 2, 2 x 16 = 32)

0 - 128

Send message on change transition

3

Select

Send message on hi to low transition

2

Send message on low to hi transition

1

One

Disable message

0

Program this value into the appropriate transition CV

4.6 Input Control

These CVs determine what action the inputs will have when activated. There are three CVs

for each input. An address, type and transition CV. See section 7 for CV numbers. If an

address greater than 255 is needed then use the address adder. The address adder value rep-

resents a number that is added to the address value to give the ‘actual’ address.

There are 16 physical input terminals. They can each be programmed to operate independ-

ently or to operate as a pair in a group (default). They are not linked or connected to the

outputs an any way except by a common address and type.

In order for an input to cause an action, a transition must be selected. Each input has a ‘pul-

lup’ resistor connected to 5 volts, so the input is normally at 5 volts. An input transition is

when the voltage on an input goes from high to low (falling edge) or from low to high (ris-

ing edge). For example, if a push button is connected to an input and ground, when it is

pressed the input is grounded. This causes a high to low transition. When the button is re-

leased this causes a low to high transition.

To set addresses for input groups see “Smart” Programming for easier programming.

Route execution feature requires version 16.

4.7 Route Execute Address

These CVs determine the top or execute address of a route. See section 7 for CV numbers.

Each top address is completely independent of an input or output address. A route is exe-

cuted when a turnout (switch) command from any source including those from the SRC16,

throttles or computers matches the top address and switch state for that route. When a route

is executed, turnout commands are sent for each cell containing an address. Optionally, a

route can be executed by a block sensor message. In this way several turnouts can auto-

matically be alined went a block becomes occupied.

4.8 Route Cell Address

These CVs determine the address in a route cell. See section 7 for CV numbers. When a

route is executed all cell addresses are sent one at a time. For all addresses in a route to be

sent there must be no empty cells between cells with addresses.

4.9 Send Address Delay

CV11 - Send address time delay, value 0 to 255.

This CV determines the time delay the SRC16 waits before sending the next address in a

route. Some switch machine drivers require a time delay between switch activation.

The delay is the CV11 value x 0.25 seconds.

4.10 Operations Mode Loco Address

CV1 - Ops mode address, a value of 1 to 127. Default is one (1).

This CV sets the operations mode program address. Program the SRC16 just like you

would a loco in ops mode. This is a loco 2 digit address and therefore must be unique

among locomotive addresses. Option 3 must be enabled to use this address for program-

ming on the main.

Route Top (Execute) Address

Address CV

Value

Select

Address

1 - 255

Program this value into the appropriate address CV

Type CV

Value

Select

Close

64

Select

Throw

0

one

Execution type, sensor

32

Select

Execution type, switch (turnout command)

0

one

Address adder (see the address adder table for amount to add)

0 - 9

Program this value into the appropriate type CV

Route Top (Execute) Address

Address CV

Value

Select

Address

1 - 255

Program this value into the appropriate address CV

Type CV

Value

Select

Close

64

Select

Throw

0

one

Address adder (see the address adder table for amount to add)

0 - 9

Program this value into the appropriate type CV

Delay between sending route addresses

CV11 Value

0

1

2

4

8

12

16

20

Delay (sec)

0

0.25

0.5

1

2

3

4

5

Status Report CV

Value

Select

No options

0

Option 1 - Send input state at power on enabled

1

Option 2 - Send output state at power on enabled

2

Option 3 - Interrogate input state enabled

4

Option 4 - Interrogate output state enabled

8

Option 5 - Send 16 output state messages at power enabled

16

Program this value into the status report CV

Option 5 - 16 output state messages sent if option 2 is enabled. Use section 3 of “Smart”

programming so the outputs are configured correctly for this option. Requires version 15.

Table of contents