Team Digital BlocD8 User manual

TEAM DIGITAL

1

BlocD8

High Density Block Detector

Improving the world of DCC

>8 block detectors

> Electrical isolation from the track

> No track voltage drop

> LED indicator for each block

> 8 outputs for external LEDs or relays

> Featuring “Smart” Programming

> LocoNet® compatible

>Eight configurable routes

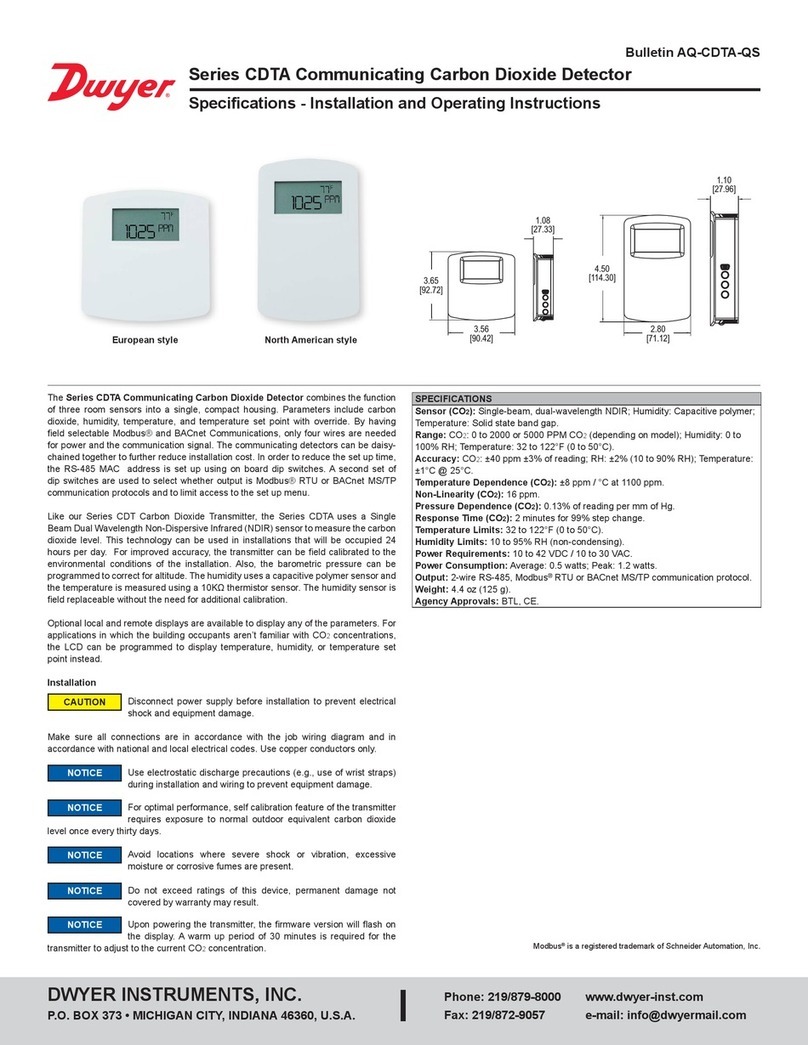

Description

The BlocD8 is an eight block occupancy

detector for DCC. It is particularly useful

where high density or centrally located

detection is desired. Yards and automatic

train control are some examples. It provides

complete isolation from the track by using

transformer type sensors. This also means

there is no drop in track voltage as there is

with sensing diodes. The BlocD8 is designed

to work well with the family of SIC24 Signal

and Indicator Controllers and the CSC

Central Signal Controller. The BlocD8 can be

in a stand-alone mode with using the output

connector or in a network with other devices

using the serial bus.

TEAM DIGITAL, LLC

3111 Timber Valley Dr

Kokomo IN 46902

www.teamdigital1.com

08.30.17

BlocD8

1

1

8

Status LEDs Sensitivity

Smart

button

Output connector Serial bus

Track

or

DC power

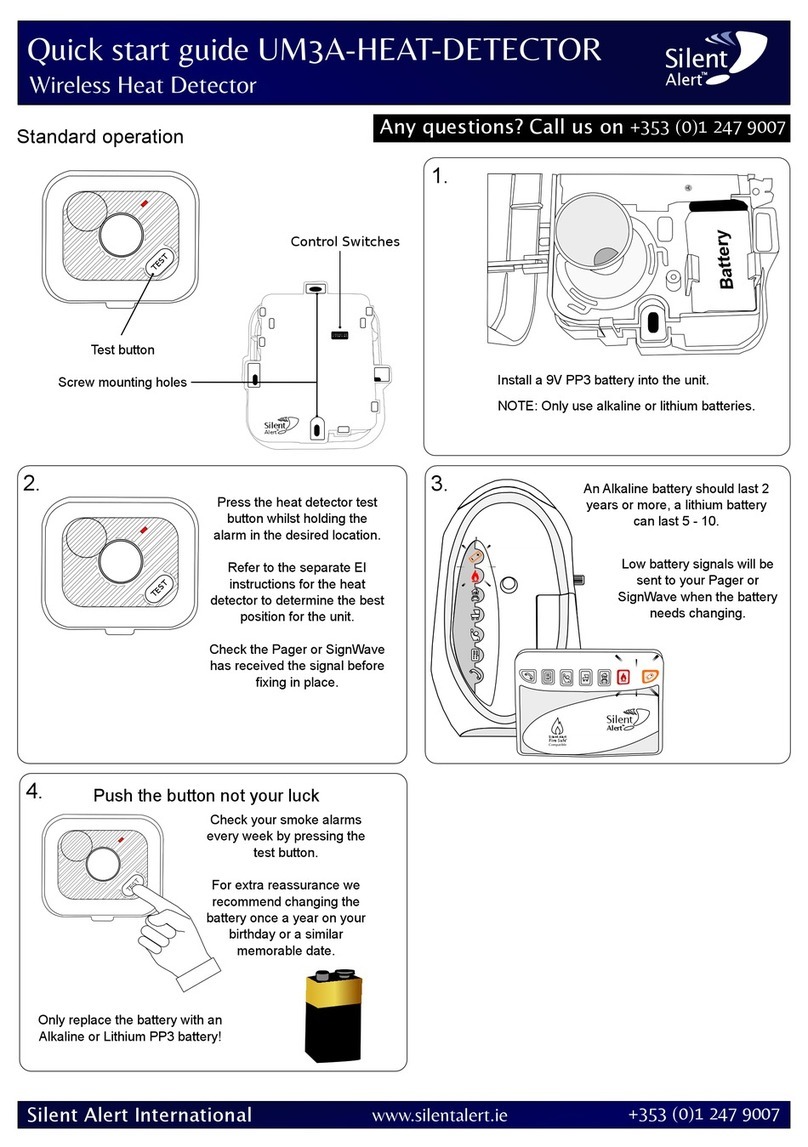

1 Operation!3

2 Getting Started!3

1.1 LED Indicators!4

3 “Smart” Programming!4

4 Configuration Variables (CVs)!4

4.02 Reset the BlocD8 to factory defaults!5

4.1 Output Address!5

4.2 Output Control!5

4.3 Unoccupied Delay !5

4.4 Decoder Configuration!5

4.5 Status Report!5

4.6 Input Control!6

4.7 Route Execute Address!6

4.8 Route Cell Address!6

4.9 Send Address Delay !6

4.10 Operations Mode Loco Address!6

5 Connections!7

5.1 Power!7

5.2 Track Block Sensors!7

5.3 Output Drive!7

5.4 10 PIN Output!7

5.5 Serial Bus!7

6 Applications!7

6.1 Relay drive!7

6.2 Routes!7

7 Summary of Configuration Variables!8

2

1 Operation

The BlocD8 is capable of sensing current in eight isolated sections of track called blocks. This provides for detecting the

presence of locomotives or other rolling stock that draw current from the track. The status LEDs on the BlocD8 indicate

when a block is occupied. For eternal block

status indication the 10 pin connector and/or

the serial bus can be used.

The track feed wire for one rail of the block

is passed through one of the BlocD8 sensors

before connecting the feeder to the track. All

current flowing to a block must pass through

a detector for proper operation. Do not

power any type of accessory from the track

feeder or there will be false block detection.

Locomotives, lighted cars and rolling stock with resistive wheels sets draw different amounts of current from the track. The

BlocD8 has two potentiometers to adjust sensitivity. Turning the pot CCW will increase the sensitivity. If the pot is turned

fully CCW there may be false block detection. Passing the feed wire through each sensor two times will increase the

sensitivity and can improve reliable detection. See “TIP” in section 2.

Duty track can cause intermittent current flow. A built in filter keeps the BlocD8 from rapidly turning the status indicator off

and on if the current flow is interrupted. This filter also keeps the status indicator on after a train leaves the block for a short

period of time.

The BlocD8 includes a serial bus. If the bus is used the BlocD8 will send a message indicating the status of the related block.

This message is available to any other device on the bus. The default address is 1 to 8 for the eight sensors respectively.

2 Getting Started

The BlocD8 does NOT require the

serial bus to operate. If the serial bus

is NOT used, no programming is

required. Even if the serial bus is used

programming may not be necessary if

only one BlocD8 is used.

The following diagram shows the

BlocD8 detecting three blocks in a

single power district. Since each

detector is completely isolated from

the track and each other, no special

provision is required for the BlocD8 to

be used across several power districts.

The wire that passes through the sensor

should be stranded with a recommend

maximum size of AWG 18. The stiffer

the wire the more likely a sensor could be

damaged. The wire sheathing should not be

removed. In an actual application a terminal

strip can be used to connect the wire that

loops though the sensors to the other wires.

The current sensors used in the BlocD8 are

sensitive to radiated noise that can occur

when high current is flowing through a wire.

For this reason the track power wires to and

from the BlocD8 must be carefully routed.

The diagram shows correct and incorrect ways to route wires. Incorrect routing of wires will cause false block

detection.Wires with DCC current should be routed away from the sensors in a perpendicular manner.

One track block

Track feeder wire

All current to track

Track power

Sensor for one section of BlocD8

Booster

Track

or DC

power

Serial bus

Open collector

outputs

BlocD8

1

1

8

Status LEDs Sensitivity

Smart

button

Sensitivity adjustment

for sensors 1 - 4

Sensitivity adjustment

for sensors 5 - 8

Example of connections

for three blocks

NOTE: turning pot all

the way CCW may give

poor results

Recommended minimum

distance for any parallel

wire ~ 3”

To terminal strip

Correct wire routing

Incorrect wire routing

3

The BlocD8 can be powered from the track or 12 volt DC filtered power supply. See section 5.1 for

more details.

If external LED status indicators are used a separate DC power supply is required as shown.

If more than one BlocD8 is used in a serial bus network then the addresses will have to changes so

there is no duplicates. See section 3, “Smart” Programming. For very custom programming see section

4, Configuration Variables for various options.

1.1 LED Indicators

The status LEDs will all light at power on. Subsequently they will light indicating which block is occupied. The green LED

flashes about ever four seconds indicating normal operation.

3 “Smart” Programming

“Smart” programming is a term used to describe an easy way to program the BlocD8 addresses. The throttle is used to issue

switch or accessory commands just like controlling switches (turnouts).

Programming is only require if the

serial bus (called LocoNet® in a

Digitrax system) is used and the

addresses need to be changed from the

factory settings.

To program in “Smart” mode, connect

the BlocD8 power terminals to track

power. Turn on power. Wait about 5 or

6 seconds.

Press the “Smart” program button and

hold it down for approximately one

second until status LED1 starts to flash.

Then release it. The BlocD8 is now

ready to have the addresses changed.

Using the throttle select the switch

address or accessory number you want

for the start of eight sequential

addresses and issue a throw (reverse)

command. The BlocD8 will reset and

be ready to use with the new addresses.

To program other items start with Section 2 or 3 as show in the Smart

Programming Summary table.

In steps 1 and 2 of section 3 a CV value is programmed instead of an

address. Check the appropriate section in the manual to determine the CV

value and use a switch address for that value.

4 Configuration Variables (CVs)

The BlocD8 supports Paged Mode Programming in Service Mode and Operations (Ops) Mode programming. To program in

paged mode, connect the Track Power terminals to the programming track. See diagram on the front page. When power is

applied, status LED 1 will come on and the green LED will flash when programming is successful. Some systems only apply

power during actual programming, so LED1 will only be on during that time. The BlocD8 does not have built in feedback

like a mobile decoder. Therefore, some systems may show a “no decoder on track” error or “can not read CV”. However it

still is programmed. To enter normal operation, disconnect from the program track and connect as defined is section 5.

12

109

5

DC

Power +-

4

Smart Programming Summary

Smart Programming Summary

Smart Programming Summary

Smart Programming Summary

#Flashes

Description

t

c

Section 1: To start - Press the “Smart” button until LED1 starts to flash

Section 1: To start - Press the “Smart” button until LED1 starts to flash

Section 1: To start - Press the “Smart” button until LED1 starts to flash

Section 1: To start - Press the “Smart” button until LED1 starts to flash

1

Beginning address for 8 sequential addresses

accept

accept

Section 2: To start here - Press the “Smart” button until the green LED lights - Non-sequential addresses

Section 2: To start here - Press the “Smart” button until the green LED lights - Non-sequential addresses

Section 2: To start here - Press the “Smart” button until the green LED lights - Non-sequential addresses

Section 2: To start here - Press the “Smart” button until the green LED lights - Non-sequential addresses

1

Input 1 address

accept

accept

2

Input 2 address

accept

accept

3

Input 3 address

accept

accept

4

Input 4 address

accept

accept

5

Input 5 address

accept

accept

6

Input 6 address

accept

accept

7

Input 7 address

accept

accept

8

Input 8 address

accept

accept

Section 3: To start here - Press the “Smart” button until the green LED lights and then turns off

Section 3: To start here - Press the “Smart” button until the green LED lights and then turns off

Section 3: To start here - Press the “Smart” button until the green LED lights and then turns off

Section 3: To start here - Press the “Smart” button until the green LED lights and then turns off

1

Value of CV9 - Decoder configuration

set

clear

2

Value of CV10 - Status report

set

clear

Switch (Turnout) Terminology

Switch (Turnout) Terminology

Switch (Turnout) Terminology

This manual

throw or t

close or c

Digitrax

throw or t

close or c

NCE

reverse or OFF or 2

normal or ON or 1

Lenz

-

+

MRC

OFF

ON

To program in ops mode hold down the Smart button just before power is turned on. When the green LED turns on release

the button then wait until LED1 turns off. The BlocD8 is now in ops mode until power is turned off. The default ops address

is one (1). This is a loco address, so be careful when using this feature. The BlocD8 can be programmed so it is always in

ops mode by setting option 3 in CV9. When using ops mode to change CV values, the BlocD8 does not recognize some

new values until power is turned off and then back on. Programming CV7 with a value of 1 will restart the BlocD8 so

power need not be cycled when programming in ops mode. This is the same as turning power off and then back on.

4.02 Reset the BlocD8 to factory defaults

To “reset” all CVs to factory defaults, turn power on and wait until all the red LEDs turns off. Then press the “Smart” button

and continue to hold the button down (at least 16 seconds) until a red LED and the green LED are alternately flashing. Also

programming CV7 with a value of 170 in ops mode will “reset” all CV’s to the factory default value.

4.1 Output Address

These CVs determine the address of the outputs and how the output responds. Normally the output indicates the status of it’s

respective block and has the same address.

However, for special applications, each output

can be controlled independent of the input by

assigning a unique address.

Each output has two CVs, an address and a type

which includes the address adder, that makes up

the address. See section 7 for CV numbers. The

type CV also contains the message type the

output responds to. That is, the output will turn

on when a command is received when this

criteria is met. The following table shows the

CV value to set the criteria.

To calculate the type CV value add up the

selected values.

The address is constructed with two CVs, an

address and an address adder. If an address

greater than 255 is needed then the address

adder value will be greater than zero.

Otherwise the address is set by the address

value only.

The address adder value represents a number that is added to the address value to give the required address. The address

adder table shows the CV value to use for the adder. When using “Smart” Programming to change the input (block address),

these get changed also.

4.2 Output Control

See section 4.1 for special control of the outputs. This applies to both the status LEDs and open collector outputs as they are

linked together.

4.3 Unoccupied Delay

CV56 to 63 - Unoccupied delay. Value x 256 ms = delay. Default is 12 (~3 seconds).

These CVs determines how long the BlocD8 waits to show unoccupied after the block actually becomes unoccupied.

4.4 Decoder Configuration

CV9 - Configuration.

This CV determines the configuration which consist of only one option.

Ops Mode Programming. Allows Operations mode (On the Main) programming using a Loco address to be enabled all the

time. Programming this CV to a value of one (1) will set this option. See section 4.10.

4.5 Status Report

CV10 - Status report. Default is one (1).

This CV provides options for sending the state of all

inputs on the serial bus.

Option 1 - Input state messages are sent on the serial bus

at power on.

Option 2 - N/A

Option 3 - Input state messages are sent on the serial bus when a Digitrax interrogation command is received.

5

Output

Output

Output

Address CV

Value

Select

Address

1 - 255

Program this value into the appropriate address CV

Type CV

Value

Select

Close

64

Select

Throw

0

one

Message type, sensor

32

Select

Message type, feedback (actual switch position)

16

Message type, switch (commanded switch position)

0

one

Address adder (see the address adder table for amount to add)

0 - 9

Program this value into the appropriate type CV

Status Report CV

Value

Select

No options

0

Option 1 - Send input state at power on enabled (default)

1

Option 2 - Not used

-

Option 3 - Interrogate input state enabled

4

Program this value into the status report CV

Address Adder

Address Adder

Address Adder

Address Adder

Address Adder

Address Adder

Address Adder

Address Adder

Address Adder

Address Adder

Address Adder

CV Value

0

1

2

3

4

5

6

7

8

9

ADD

0

256

512

768

1024

1280

1536

1792

2048

2304

4.6 Input Control

These CVs determine what action the inputs

will have when a block state changes. Normally

the action causes block status (sensor) messages

to sent. However, for special applications, other

actions can be programmed.

Unless you understand these special features, it

is recommended that they not be changed. Use

“Smart” programming to change addresses.

For each input there is a primary and secondary

address and type. One or two messages can be

sent on the serial bus when a block state

changes. If an address greater than 255 is

needed then use the address adder. The address

adder value represents a number that is added to

the address value to give the ‘actual’ address.

See section 7 for CV numbers.

4.7 Route Execute Address

These CVs determine the top or execute address

of a route. Each top address is completely

independent of an input address. A route is

executed when a message from any source on

the serial bus including those from the BlocD8

or computers matches the top address, message

type and state for that route. When a route is

executed, turnout commands are sent for each

cell containing an address.

4.8 Route Cell Address

These CVs determine the address in a route cell.

When a route is executed all cell addresses are

sent one at a time. For all addresses in a route to

be sent there must be no empty cells between

cells with addresses.

4.9 Send Address Delay

CV11 - Send address time delay, value 0 to 255.

This CV determines the time delay the BlocD8

waits before sending the next address in a route.

Some switch machine drivers require a time delay between switch activation.

The delay is the CV11 value x 0.25 seconds.

4.10 Operations Mode Loco Address

CV1 - Ops mode address, a value of 1 to 127. Default is one (1).

This CV sets the operations mode program address. This address is used ONLY for programming and has NOTHING to do

with normal operation. This allows programming the BlocD8 just like you would a loco in ops mode. This is a loco 2 digit

address and therefore must be unique among locomotive addresses. Ops mode must be enabled to use this address for

programming on the main. The programming track is not required once this address and ops mode is enabled.

TIP: If the “Smart” program button is pressed when power is turned on, ops mode is enable until power is removed. Useful if

you do not want to have ops mode enabled all the time.

6

Input Control

Input Control

Input Control

Address CV

Value

Select

Address

1 - 255

Program this value into the appropriate address CV

Type CV

Value

Select

Invert the normal state

128

Select

Normal state

0

one

Message type, sensor

32

Select

Message type, feedback (actual switch position)

16

Message type, switch (commanded switch position)

0

one

Address adder (see the address adder table for amount to add)

0 - 9

Program this value into the appropriate type CV

Transition CV (Default = 3, use for secondary message)

Value

Select

Send message on change transition

15

Select

Send message on hi to low transition

11

Send message on low to hi transition

7

Disable secondary message

3

One

Program this value into the appropriate transition CV

Route Top (Execute) Address

Route Top (Execute) Address

Route Top (Execute) Address

Address CV

Value

Select

Address

1 - 255

Program this value into the appropriate address CV

Type CV

Value

Select

Close

64

Select

Throw

0

one

Execution type, sensor

32

Select

Execution type, switch (turnout command)

0

one

Address adder (see the address adder table for amount to add)

0 - 9

Program this value into the appropriate type CV

Route Cell Address

Route Cell Address

Route Cell Address

Address CV

Value

Select

Address

1 - 255

Program this value into the appropriate address CV

Type CV

Value

Select

Close

64

Select

Throw

0

one

Address adder (see the address adder table for amount to add)

0 - 9

Program this value into the appropriate type CV

Delay between sending route addresses

Delay between sending route addresses

Delay between sending route addresses

Delay between sending route addresses

Delay between sending route addresses

Delay between sending route addresses

Delay between sending route addresses

Delay between sending route addresses

Delay between sending route addresses

CV11 Value

0

1

2

4

8

12

16

20

Delay (sec)

0

0.25

0.5

1

2

3

4

5

5 Connections

5.1 Power

The BlocD8 can be powered from the track (16 volts max) or a filtered DC voltage (12 VDC, 35mA) power supply. Most

analog 'Power Packs' will not work because they do not provide smooth (filtered) DC power. The BlocD8 power connector is

non polarized and either terminal can be connected to plus or minus of the DC power supply. The power supply should be

isolated from the system ground. That is, not connected to ground (booster ground, house wiring ground, etc). When multiple

BlocD8 s are used they can be all connected to one power supply. The power supply must be able to supply the current for all

the BlocD8s. The plus and minus of the power supply must be connected to the same power power terminal on each BlocD8.

5.2 Track Block Sensors

There is no electrical connection to the sensors. They are completely isolated. They have a hole in them to pass a wire that

carries the track current. See diagram in section 1. Maximum of one pass if the sensor is labeled PE-51687. Maximum

continuous current 3 amps.

5.3 Output Drive

The outputs are open collector and can drive LEDs and other low current devices such as low current relays. Maximum

current is 50 mA.

5.4 10 PIN Output

Connections can be made using our terminal strip adapter (TSA) or our Connector Cable Kit. You can build

your own by using flat ribbon cable Insulation Displacement (IDC) and connectors from Jameco. The mating

connector is #138376. 10 ft of multicolor flat ribbon cable is #639672. Pins 1-4 are outputs for detectors 1-4.

Pins 7-10 are outputs for detectors 5-8. See the diagram on the front page for connector location.

5.5 Serial Bus

The BlocD8 has two RJ12 connectors for ease in

making connections between devices. In a Digitrax

system the data pins are LocoNet® and the RS pins are

Rail Sync. RS is not used by the BlocD8. In a systems

when more than 10 Team Digital devices with a serial

bus are used the bus terminating resistor lead should be

cut on any additional devices.

Warning: This bus IS NOT compatible with other systems 6 pin connectors i.e. NCE, MRC etc.

6 Applications

6.1 Relay drive

The BlocD8 outputs can drive a relay with a low current coil. The relay shown has a coil

current of 30 mA and a contact rating of 10 amps (Digikey PB380-ND). A clamping diode

(1N4148) is required when driving a relay to suppress the voltage spike. Example shows

relay connected to output 2, pin 2.

6.2 Routes

The BlocD8 supports eight routes which

requires the use of the serial bus. Each

route has eight cells. There is one top or

route execution address for each route.

A route can be executed by a block

sensor or switch type message. When

using a block sensor message several

turnouts can automatically be alined

went a block becomes occupied.

Multiple routes can be executed be

having more than one top address the

same address. Also a route can execute

from other routes (nested). This occurs

when a route cell has an address that

matches the top address of another route.

Warning: Do not create recursive loops.

That is, do not have a route executing

itself or two routes executing each other.

Otherwise various unexplained problems will occur. The diagram shows an example of five routes using four switches. The

route CV values were determined using the information in sections 4.6 and 4.7.

1

210

9

Terminating

Resistor

Data

GrounGround

Data

RS RS

12

109

5

- minus + 12V

SW 33

SW 34

SW 35

SW 36

Route 1 (SW 33 -t, SW 36 - c)

Route 2 (SW 33 -t, SW 36 - t)

Route 3 (SW 33 - c, SW 34 - c)

Route 4 (SW 33 - c, SW 34 - t, SW 35 -t)

Route 5 (SW 33 - c, SW 34 - t, SW 35 - c)

Yard diagram

7

Cables are wired pin 1to pin 1

Route Example

Route Example

Route Example

Route Example

Route Example

Route Example

Route Example

Route Example

Route Example

Route

1

2

3

4

5

6

7

8

Execute address

101 t

101 c

102 t

102 c

103 t

Address 1

33 t

33 t

33 c

33 c

33 c

Address 2

36 c

36 t

34 c

34 t

34 t

Address 3

35 t

35 c

Address 4

Address 5

Address 6

Address 7

Address 8

7 Summary of Configuration Variables

CV#

Function/Default Value

CV#

Function/Default Value

CV#

Function/Default Value

1

Ops Mode Loco Address

1

60

Input 5 delay x 256 ms

12

119

Route 4 Top Address Adder

0

2

reserved

-

61

Input 6 delay x 256 ms

12

120

Route 5 Top Address

0

3

reserved

-

62

Input 7 delay x 256 ms

12

121

Route 5 Top Address Adder

0

4

reserved

-

63

Input 8 delay x 256 ms

12

122

Route 6 Top Address

0

5

reserved

-

64

Output 1 Address

1

123

Route 6 Top Address Adder

0

6

reserved

-

65

Output 1 Type & Address Adder

32

124

Route 7 Top Address

0

7

Manufacturer Version No.

-

66

reserved

-

125

Route 7 Top Address Adder

0

8

Manufacturer ID

25

67

Output 2 Address

2

126

Route 8 Top Address

0

9

Decoder Configuration

0

68

Output 2 Type & Address Adder

32

127

Route 8 Top Address Adder

0

10

Status Report

1

69

reserved

-

128

Route 1 Cell 1 Address

0

11

Route send delay

0

70

Output 3 Address

3

129

Route 1 Cell 1 Address Adder

0

12

reserved

-

71

Output 3 Type & Address Adder

32

130

Route 1 Cell 2 Address

0

13

reserved

-

72

reserved

-

131

Route 1 Cell 2 Address Adder

0

14

reserved

-

73

Output 4 Address

4

132

Route 1 Cell 3 Address

0

15

reserved

-

74

Output 4 Type & Address Adder

32

133

Route 1 Cell 3 Address Adder

0

16

Input 1 Address

1

75

reserved

-

134

Route 1 Cell 4 Address

0

17

Input 1 Type & Address Adder

160

76

Output 5 Address

5

135

Route 1 Cell 4 Address Adder

0

18

Input 1 Transition

3

77

Output 5 Type & Address Adder

32

136

Route 1 Cell 5 Address

0

19

Input 1 Secondary Address

0

78

reserved

-

137

Route 1 Cell 5 Address Adder

0

20

Input 1 Sec Type & Address Adder

0

79

Output 6 Address

6

138

Route 1 Cell 6 Address

0

21

Input 2 Address

2

80

Output 6 Type & Address Adder

32

139

Route 1 Cell 6 Address Adder

0

22

Input 2 Type & Address Adder

160

81

reserved

-

140

Route 1 Cell 7 Address

0

23

Input 2 Transition

3

82

Output 7 Address

7

141

Route 1 Cell 7 Address Adder

0

24

Input 2 Secondary Address

0

83

Output 7 Type & Address Adder

32

142

Route 1 Cell 8 Address

0

25

Input 2 Sec Type & Address Adder

0

84

reserved

-

143

Route 1 Cell 8 Address Adder

0

26

Input 3 Address

3

85

Output 8 Address

8

144

Route 2 Cell 1 Address

0

27

Input 3 Type & Address Adder

160

86

Output 8 Type & Address Adder

32

145

Route 2 Cell 1 Address Adder

0

28

Input 3 Transition

3

87

reserved

-

146

Route 2 Cell 2 Address

0

29

Input 3 Secondary Address

0

88

reserved

-

147

Route 2 Cell 2 Address Adder

0

30

Input 3 Sec Type & Address Adder

0

89

reserved

-

148

Route 2 Cell 3 Address

0

31

Input 4 Address

4

90

reserved

-

149

Route 2 Cell 3 Address Adder

0

32

Input 4 Type & Address Adder

160

91

reserved

-

150

Route 2 Cell 4 Address

0

33

Input 4 Transition

3

92

reserved

-

151

Route 2 Cell 4 Address Adder

0

34

Input 4 Secondary Address

0

93

reserved

-

152

Route 2 Cell 5 Address

0

35

Input 4 Sec Type & Address Adder

0

94

reserved

-

153

Route 2 Cell 5 Address Adder

0

36

Input 5 Address

5

95

reserved

-

154

Route 2 Cell 6 Address

0

37

Input 5 Type & Address Adder

160

96

reserved

-

155

Route 2 Cell 6 Address Adder

0

38

Input 5 Transition

3

97

reserved

-

156

Route 2 Cell 7 Address

0

39

Input 5 Secondary Address

0

98

reserved

-

157

Route 2 Cell 7 Address Adder

0

40

Input 5 Sec Type & Address Adder

0

99

reserved

-

158

Route 2 Cell 8 Address

0

41

Input 6 Address

6

100

reserved

-

159

Route 2 Cell 8 Address Adder

0

42

Input 6 Type & Address Adder

160

101

reserved

-

160

Route 3 Cell 1 Address

0

43

Input 6 Transition

3

102

reserved

-

161

Route 3 Cell 1 Address Adder

0

44

Input 6 Secondary Address

0

103

reserved

-

162

Route 3 Cell 2 Address

0

45

Input 6 Sec Type & Address Adder

0

104

reserved

-

163

Route 3 Cell 2 Address Adder

0

46

Input 7 Address

7

105

reserved

-

164

Route 3 Cell 3 Address

0

47

Input 7 Type & Address Adder

160

106

reserved

-

165

Route 3 Cell 3 Address Adder

0

48

Input 7 Transition

3

107

reserved

-

166

Route 3 Cell 4 Address

0

49

Input 7 Secondary Address

0

108

reserved

-

167

Route 3 Cell 4 Address Adder

0

50

Input 7 Sec Type & Address Adder

0

109

reserved

-

168

Route 3 Cell 5 Address

0

51

Input 8 Address

8

110

reserved

-

169

Route 3 Cell 5 Address Adder

0

52

Input 8 Type & Address Adder

160

111

reserved

-

170

Route 3 Cell 6 Address

0

53

Input 8 Transition

3

112

Route 1 Top Address

0

171

Route 3 Cell 6 Address Adder

0

54

Input 8 Secondary Address

0

113

Route 1 Top Address Adder

0

172

Route 3 Cell 7 Address

0

55

Input 8 Sec Type & Address Adder

0

114

Route 2 Top Address

0

173

Route 3 Cell 7 Address Adder

0

56

Input 1 delay x 256 ms

12

115

Route 2 Top Address Adder

0

174

Route 3 Cell 8 Address

0

57

Input 2 delay x 256 ms

12

116

Route 3 Top Address

0

175

Route 3 Cell 8 Address Adder

0

58

Input 3 delay x 256 ms

12

117

Route 3 Top Address Adder

0

176

Route 4 Cell 1 Address

0

59

Input 4 delay x 256 ms

12

118

Route 4 Top Address

0

177

Route 4 Cell 1 Address Adder

0

8

CV#

Function/Default Value

CV#

Function/Default Value

178

Route 4 Cell 2 Address

0

220

Route 6 Cell 7 Address

0

179

Route 4 Cell 2 Address Adder

0

221

Route 6 Cell 7 Address Adder

0

180

Route 4 Cell 3 Address

0

222

Route 6 Cell 8 Address

0

181

Route 4 Cell 3 Address Adder

0

223

Route 6 Cell 8 Address Adder

0

182

Route 4 Cell 4 Address

0

224

Route 7 Cell 1 Address

0

183

Route 4 Cell 4 Address Adder

0

225

Route 7 Cell 1 Address Adder

0

184

Route 4 Cell 5 Address

0

226

Route 7 Cell 2 Address

0

185

Route 4 Cell 5 Address Adder

0

227

Route 7 Cell 2 Address Adder

0

186

Route 4 Cell 6 Address

0

228

Route 7 Cell 3 Address

0

187

Route 4 Cell 6 Address Adder

0

229

Route 7 Cell 3 Address Adder

0

188

Route 4 Cell 7 Address

0

230

Route 7 Cell 4 Address

0

189

Route 4 Cell 7 Address Adder

0

231

Route 7 Cell 4 Address Adder

0

190

Route 4 Cell 8 Address

0

232

Route 7 Cell 5 Address

0

191

Route 4 Cell 8 Address Adder

0

233

Route 7 Cell 5 Address Adder

0

192

Route 5 Cell 1 Address

0

234

Route 7 Cell 6 Address

0

193

Route 5 Cell 1 Address Adder

0

235

Route 7 Cell 6 Address Adder

0

194

Route 5 Cell 2 Address

0

236

Route 7 Cell 7 Address

0

195

Route 5 Cell 2 Address Adder

0

237

Route 7 Cell 7 Address Adder

0

196

Route 5 Cell 3 Address

0

238

Route 7 Cell 8 Address

0

197

Route 5 Cell 3 Address Adder

0

239

Route 7 Cell 8 Address Adder

0

198

Route 5 Cell 4 Address

0

240

Route 8 Cell 1 Address

0

199

Route 5 Cell 4 Address Adder

0

241

Route 8 Cell 1 Address Adder

0

200

Route 5 Cell 5 Address

0

242

Route 8 Cell 2 Address

0

201

Route 5 Cell 5 Address Adder

0

243

Route 8 Cell 2 Address Adder

0

202

Route 5 Cell 6 Address

0

244

Route 8 Cell 3 Address

0

203

Route 5 Cell 6 Address Adder

0

245

Route 8 Cell 3 Address Adder

0

204

Route 5 Cell 7 Address

0

246

Route 8 Cell 4 Address

0

205

Route 5 Cell 7 Address Adder

0

247

Route 8 Cell 4 Address Adder

0

206

Route 5 Cell 8 Address

0

248

Route 8 Cell 5 Address

0

207

Route 5 Cell 8 Address Adder

0

249

Route 8 Cell 5 Address Adder

0

208

Route 6 Cell 1 Address

0

250

Route 8 Cell 6 Address

0

209

Route 6 Cell 1 Address Adder

0

251

Route 8 Cell 6 Address Adder

0

210

Route 6 Cell 2 Address

0

252

Route 8 Cell 7 Address

0

211

Route 6 Cell 2 Address Adder

0

253

Route 8 Cell 7 Address Adder

0

212

Route 6 Cell 3 Address

0

254

Route 8 Cell 8 Address

0

213

Route 6 Cell 3 Address Adder

0

255

Route 8 Cell 8 Address Adder

0

214

Route 6 Cell 4 Address

0

215

Route 6 Cell 4 Address Adder

0

216

Route 6 Cell 5 Address

0

217

Route 6 Cell 5 Address Adder

0

218

Route 6 Cell 6 Address

0

219

Route 6 Cell 6 Address Adder

0

WARNING: This product contains a chemical known to thestate of

California to cause cancer, birth defects or other reproductive harm.

9

Table of contents

Popular Security Sensor manuals by other brands

Dwyer Instruments

Dwyer Instruments CDTA-2E000 Installation and operating instructions

ActSafe

ActSafe ACC II Ascender user manual

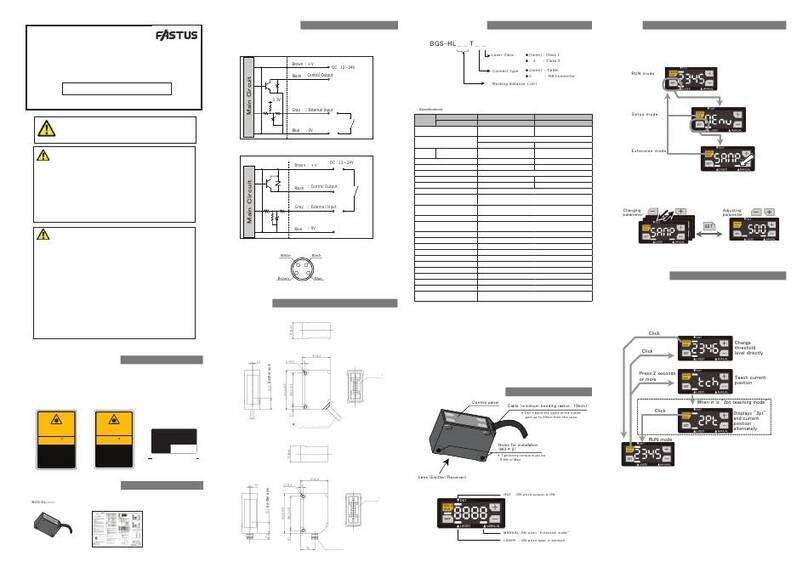

Fastus

Fastus BGS-HL Series instruction manual

Hokuyo

Hokuyo UGM-50LXP manual

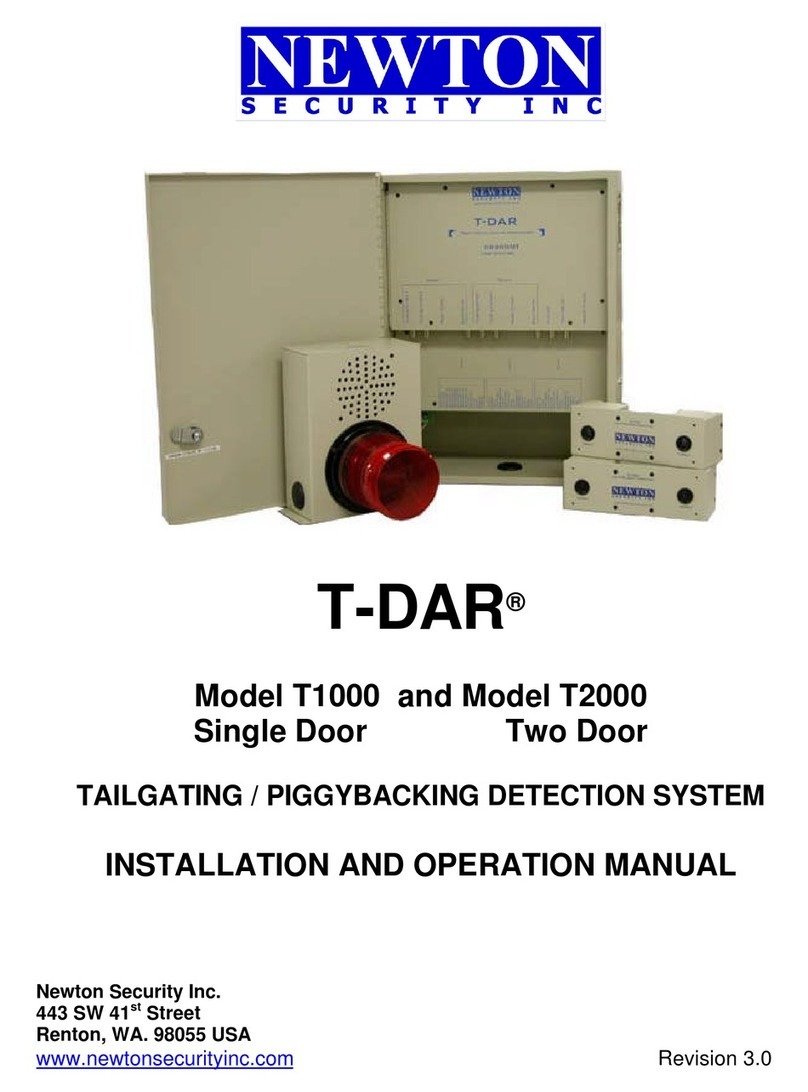

Newton Security

Newton Security T-DAR T1000 Installation and operation manual

Guardall

Guardall Vega DX installation instructions