tecan MIO2 User manual

MIO2 Operating Manual, 394934, en, V3.0

Operating Manual

Monitored Incubator Option 2 (MIO™)

6 Positions

4 Positions

© 2017, Tecan Trading AG, Switzerland, all rights reserved.

Information contained in this document is subject to change without notice.

Document Status Sheet

Title: MIO2 Operating Manual Part number: 30032210.04

ID: 394934, en, Version 3.0 Translated from: -

Version Revision Issue Document History

1 0 2007-12-05 New edition

1 1 2009-11-09 Minor corrections

2 0 2010-03-12 Added the 4 slotted monitored incubator

2 1 2014-08-07 Added the installation of the instrument plate and the connection of the CAN

cable

3 0 2017-08-31 Corrected shutters’ description in chapter “Part Locations”

Added chapter “Customer Support”

MIO2 is available for Freedom EVO and Fluent

“Product Safety Signs” added

MIO2 Operating Manual, 394934, en, V3.0 i

Table of Contents

Table of Contents

1 About This Manual

1.1 Scope of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 Improper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.6 Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7 Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.1 Instrument Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.7.2 Software Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.7.3 Other Reference Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.8 Compliance with Laws and Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.9 Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.10 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2Safety

2.1 Safety Message Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Operating Company. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 User Qualification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.1 Operator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4.2 Key Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Product Safety Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6 Decontamination Declaration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

3 Technical Data

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Product Identification and Appendix Labels. . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.5 Electrical Module Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.6 Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.7 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.8 Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

4 Description of Function

4.1 Principles of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

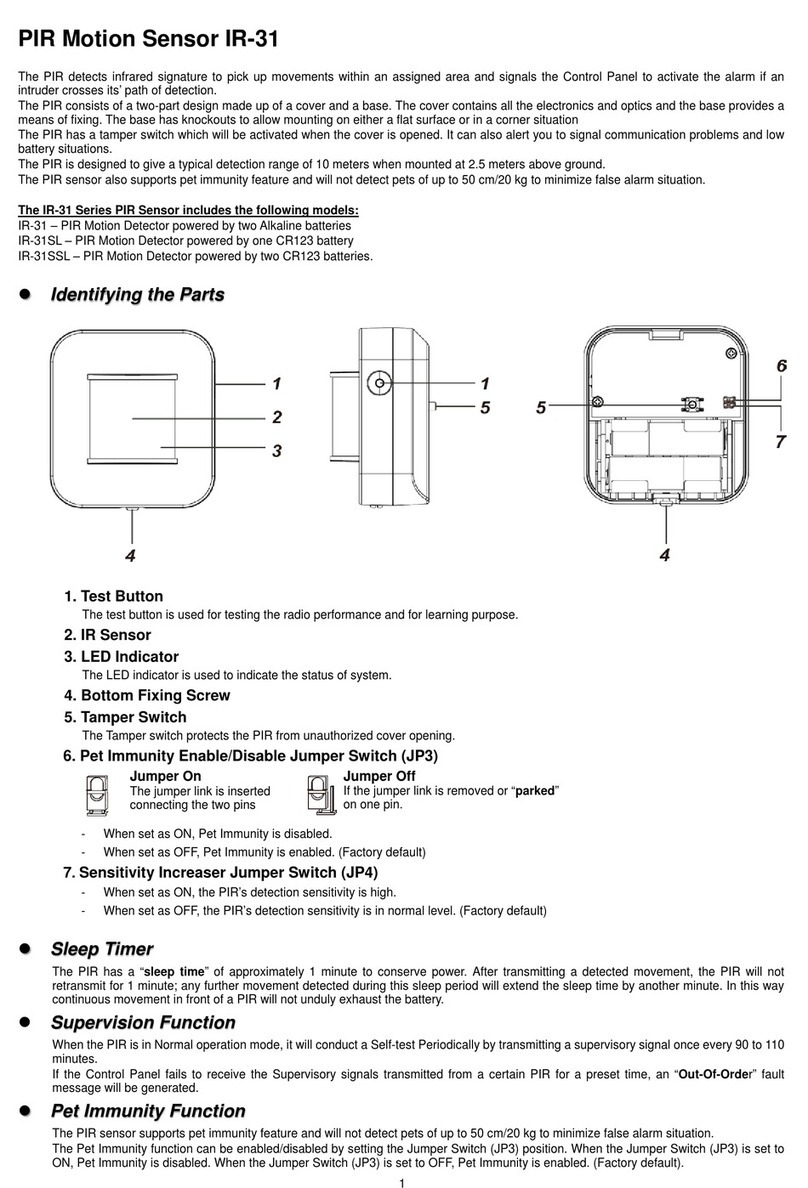

4.1.1 Part Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

ii MIO2 Operating Manual, 394934, en, V3.0

Table of Contents

5 Installation

5.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Labels on the Packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Incubator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.1 Connecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.2 Multiple Incubators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.2.3 Leveling Incubator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

6 Operation

6.1 Operating Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Display and Operating Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 Operating the MIO2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3.1 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3.2 Process Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3.3 Switching the Incubator On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.4 Switching Incubator Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.5 After an Aborted Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3.6 Incubating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

7 Maintenance

7.1 Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Cleaning Agents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.3 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.4 Special Maintenance Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.4.1 Incubator Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.4.2 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

8 Troubleshooting

8.1 Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

9 Disposal

10 Customer Support

10.1 Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

11 Index

1 - About This Manual

Scope of This Manual

MIO2 Operating Manual, 394934, en, V3.0 1 - 1

1 About This Manual

This Operating Manual describes the MIO2 and provides all the information

required for operating it safely and for maintaining it in good working order. This

manual must be read carefully before performing any work on the MIO2 and

before using it.

This chapter outlines the purpose of this manual and specifies the product

referred to. Furthermore, it explains the use of symbols and conventions as well

as further general information.

This Operating Manual contains no software description. For more information on

the software please consult the corresponding software manual. Refer to section

1.7 “Reference Documents”, 1-2.

1.1 Scope of This Manual

This manual is applicable for MIO2 (6 positions and 4 positions) valid from the

serial number 706005497 designated for operation on instruments (e.g., Freedom

EVO and Fluent).

Note: The MIO2 with 4 position is not compatible with the Freedom EVO 75.

1.2 Manufacturer

1.3 Intended Use

The MIO2 is used on Tecan instruments to incubate and / or shake substances in

microplates.

The MIO2 is an instrument component. The intended use is defined for the

instrument where it is used on. Refer to the corresponding Operating Manual of

the instrument. Refer to section “1.7 “Reference Documents”, 1-2.

Tecan Schweiz AG

Seestrasse 103

CH-8708 Männedorf

Switzerland

1 - 2 MIO2 Operating Manual, 394934, en, V3.0

1 - About This Manual

Improper Use

1.4 Improper Use

Improper use may prejudice the MIO2 safety concept.

The MIO2 must not be used with options or components that are not approved

by Tecan.

The MIO2 is not explosion-proof and should not be installed in locations

where there is a hazard of explosion.

The MIO2 should not be used in the absence of functional safety devices.

The MIO2 is not suitable to defrost frozen microplates.

Only liquids suitable for the MIO2, with respect to the chemical resistance of the

liquid system and explosion/fire hazard, may be used. Special applications

requiring the use of hazardous substances are run at the user’s own risk.

1.5 Warranty

The MIO2 must not be used with components that are not approved by Tecan.

The use of unapproved components may impair the safety concept of the MIO2.

This would invalidate any warranty of safety and compliance to national and

international standards, as required for UL/CSA certification, by EC directives, etc.

1.6 Trademarks

The product names, whether registered or unregistered trademarks, mentioned in

this manual are reproduced solely for identification purposes and remain the

exclusive property of their respective owners. For simplicity reasons, the

trademark symbols such as ®and ™ are not repeated in the manual.

1.7 Reference Documents

This section provides a list of the documents that are needed or may be useful

when using the MIO2.

The Doc IDs listed below are root numbers. Therefore, they do not contain

information about the language, document version, or the medium (data storage

medium, hard copy, downloadable file, etc.) of the document.

Note: On the basis of your order configuration, the Operating Manuals for optional

equipment apply as well.

Check the scope of the corresponding document to ensure that you are in

possession of the correct version.

The Doc ID does not refer to ordering information. When placing orders, please

refer to the number on the binder, CD casing, etc.

1 - About This Manual

Compliance with Laws and Standards

MIO2 Operating Manual, 394934, en, V3.0 1 - 3

1.7.1 Instrument Manuals

Freedom EVO®Operating Manual (Doc. ID 392886)

Fluent®Operating Manual (Doc. ID 396327)

Fluent®Operating Manual (Doc. ID 399706)

Fluent®Reference Manual (Doc. ID 398090)

Fluent®Reference Manual (Doc. ID 399937)

1.7.2 Software Manuals

Freedom EVOware®Software Manual (Doc. ID 393172)

Freedom EVOlution™ Application Software Manual (Doc. ID 394802)

FluentControl™ Application Software Manual (Doc. ID 396329)

Instrument Software Manual (Doc. ID 392888)

Fluent®Instrument Software Manual (Doc. ID 396330)

1.7.3 Other Reference Documents

Certificate of Decontamination Form (Doc. ID 40205TMt01)

1.8 Compliance with Laws and Standards

Covered by instrument conformity and certification.

Refer to the corresponding Operating Manual of the instrument. Refer to section

1.7 “Reference Documents”, 1-2.

1.9 Document Conventions

Cross-references appear as follows—e.g.:

“Refer to section 1.1.1, 1-1”

– 1.1.1 refers to the corresponding section number

– The symbol denotes “page number”

– 1-1 refers to the page number, whereas the first number stands for the

chapter number (chapter 1 - page 1)

Note: For safety conventions and symbols refer to chapter 2 “Safety”,

2-1.

1 - 4 MIO2 Operating Manual, 394934, en, V3.0

1 - About This Manual

Abbreviations

1.10 Abbreviations

FSE Field service engineer

MIO Monitored Incubator Option

2 - Safety

Safety Message Conventions

MIO2 Operating Manual, 394934, en, V3.0 2 - 1

2 Safety

This chapter describes the safety concept of MIO2, provides general rules of

correct behavior, and warnings concerning hazards associated with the use of the

MIO2.

2.1 Safety Message Conventions

2.1.1 Signal Words

WARNING indicates the possibility of personal injury or even loss of life if the

instructions are not followed.

ATTENTION indicates the possibility of equipment damage, malfunctions or

incorrect process results, if instructions are not followed.

2.1.2 Safety Symbols

General Warning

Warning for hot surface

Read this

2 - 2 MIO2 Operating Manual, 394934, en, V3.0

2 - Safety

General Safety Information

2.2 General Safety Information

WARNING

MIO2 is designed and built in accordance with the present state-of-the-art

technology and the recognized technical safety regulations. Nevertheless, risks to

users, property and the environment can arise if the MIO2 is used without due

care and attention.

The safety of all users and personnel depends on the strict observation of these

safety instructions and awareness of the safety-related warnings provided in this

manual.

Please pay great attention to the following general safety information.

This manual must always be available to all persons performing the tasks

described herein.

Legal regulations, such as local, state and federal laws concerning the use or

application, as well as the handling, of dangerous materials in connection with

the MIO2 must be strictly followed.

The operating company is responsible for defining instructions in accordance

with company procedures and local legal requirements. The instructions

provided by the operating company must be strictly observed.

Observe the correct environmental conditions for storage and operation.

Structural changes to the safety devices are forbidden.

Damaged safety devices must be replaced immediately as described in this

manual.

The MIO2 must not be modified in any way without prior consultation and

written approval of Tecan. Authorized modifications to the system may only be

performed by an FSE certified for the repair and upgrading of the MIO2.

Tecan will reject any claim resulting from unauthorized modifications.

Fire hazard caused by the improper use of the MIO2. The MIO2 should not be

installed in locations where there is a hazard of explosion.

Chemical, biological, and radioactive hazards can be associated with the

substances used or the samples and reagents processed with the MIO2 (e.g.,

during loading and unloading). The same applies to waste disposal.

– Always be aware of possible hazards associated with these substances.

– Use appropriate protective clothing, safety goggles and gloves.

– The handling of substances and the disposal of waste may be subject to

local, state, or federal law, or to regulations with regard to health,

environment, or safety. Strictly observe the corresponding provisions.

Any contamination must be dealt with immediately as described in this

manual.

The user is responsible for ensuring that the MIO2 is always operated under

proper conditions, and that maintenance, service, and repair tasks are

performed with care, on schedule, and only by authorized personnel.

Risk of incorrect measuring results. After system care or maintenance has

been performed, operation must only be resumed after the correct system

operating conditions have been verified.

Always use recommended consumables and original spare parts for

maintenance and repair to assure good system performance and reliability.

Observe all safety instructions of the instrument the MIO2 is used on.

Maximum microplate fill levels are microplate specific and need to be

validated.

2 - Safety

Operating Company

MIO2 Operating Manual, 394934, en, V3.0 2 - 3

Risk of spillage. Microplate filled over the specified fill level will lead to spillage

during operation resulting in contamination.

– Make sure the microplate is not filled more than the specified fill level.

The MIO2 has to be operated with heat-resistant microplates.

Risk of deformation of microplates. Non heat-resistant microplates will get

deformed if heated up.

– Make sure only heat-resistant microplates are used for incubation.

Caustic substances can cause burns and eye injury.

– Avoid exposure to caustic substances.

Avoid the formation and accumulation of flammable vapors.

Avoid the spillage of flammable material.

Prior to using hazardous materials perform a risk assessment.

Consider specific workplace conditions, such as temperature, air ventilation,

electrostatic discharge.

Make sure that the risk is acceptable prior to use of the instrument.

The MIO2 is a heated device. The outer surface may develop temperatures

up to a maximum of 45°C.

– Let the MIO2 cool down hand-hot before removal.

2.3 Operating Company

The operating company must ensure that the MIO2 and in particular the safety

features, function properly and that all the personnel in contact with the instrument

are adequately trained.

Responsibilities Method and process validation.

Defining the processes in compliance with the Standard Operating

Procedures.

Ensuring that installation and operational qualifications (IQ OQs) have been

completed.

Ensuring that all personnel in contact with the MIO2 are adequately trained.

Ensuring the availability of appropriate protective clothing and equipment.

Ensuring the maintenance and safe operation of the MIO2.

Requiring adherence to laboratory safety regulations and directives.

2.4 User Qualification

The laboratory personnel must be fully qualified and trained to operate the MIO2.

The work described in this Operating Manual must only be performed by

authorized personnel with the qualifications prescribed below.

Laboratory personnel must:

have suitable technical training,

be familiar with the laboratory safety regulations and directives,

be familiar with the instructions for the safety elements of the instrument,

use protective clothing and equipment,

be familiar with and adhere to good laboratory practices,

2 - 4 MIO2 Operating Manual, 394934, en, V3.0

2 - Safety

User Qualification

and have read and understood the instructions in the Operating Manual.

Tecan recommends that the operator attends an operator training course. Please

ask the Tecan Customer Service about available courses. Refer to section

10 “Customer Support”, 10-1.

2.4.1 Operator

The operator (lab technician) works for the operating company.

Required Skills No specific application or system knowledge

Command of local languages

Command of English is preferable

The operator has application software access rights allowing him to run methods

and perform system care.

2.4.2 Key Operator

The key operator (application specialist) supports the operating company or works

for the same company.

Required Skills Extensive application knowledge

Limited system knowledge

Command of local languages

Command of English

In-depth knowledge of the corresponding software manual

Responsibilities Instructing the operator

Writing, running and validating methods

Helping the operator to solve problems with the instrument

2 - Safety

Product Safety Signs

MIO2 Operating Manual, 394934, en, V3.0 2 - 5

2.5 Product Safety Signs

Safety signs are affixed for safety purposes. Damaged, lost or illegible safety

signs must be replaced immediately as illustrated. For the meaning of safety

symbols refer to section 2.1.2 “Safety Symbols”, 2-1.

2.6 Decontamination Declaration

In addition to regular system care, and in accordance with standard laboratory

regulations, the MIO2 and its parts and accessories must be thoroughly

decontaminated in the following circumstances:

Before any maintenance or service work is performed on the MIO2 and, in

particular, before an FSE intervention on the MIO2

In the event of accidents (e.g., crash, spillage, etc.)

Before returning the MIO2 or its parts or accessories, to Tecan (e.g., for

repair)

Prior to storage

Prior to disposal

In general, before moving the MIO2 or its parts from its location

The owner of the instrument has full responsibility for the effective

decontamination of all the equipment.

Before any intervention on the MIO2 by an FSE, and before returning the MIO2 or

its parts or accessories to Tecan, the owner of the instrument must complete and

sign the Decontamination Declaration form, confirming that the decontamination

has been performed in accordance with good laboratory practice guidelines.

Contact your local service organization to obtain this form and refer to section

7.1 “Decontamination”, 27-1.

Note: Tecan reserves the right to refuse to deal with any MIO2 or its parts or

accessories that is not accompanied by the Decontamination Declaration form.

Fig. 2-1 Safety signs

2 - 6 MIO2 Operating Manual, 394934, en, V3.0

2 - Safety

Decontamination Declaration

3 - Technical Data

Overview

MIO2 Operating Manual, 394934, en, V3.0 3 - 1

3 Technical Data

3.1 Overview

Overview The MIO2 is a precision instrument designed for automating incubating tasks on a

heated air incubation concept.

Configurations The MIO2 is provided in a 4 and a 6 slot configuration with the following features:

Standard

The standard configuration does not contain the shaking option.

Shaking Incubator

Both incubators can be equipped with a shaking option.

The 6 positions incubator can optionally be equipped with a cooling fan to

provide room temperature incubation in conjunction with shaking.

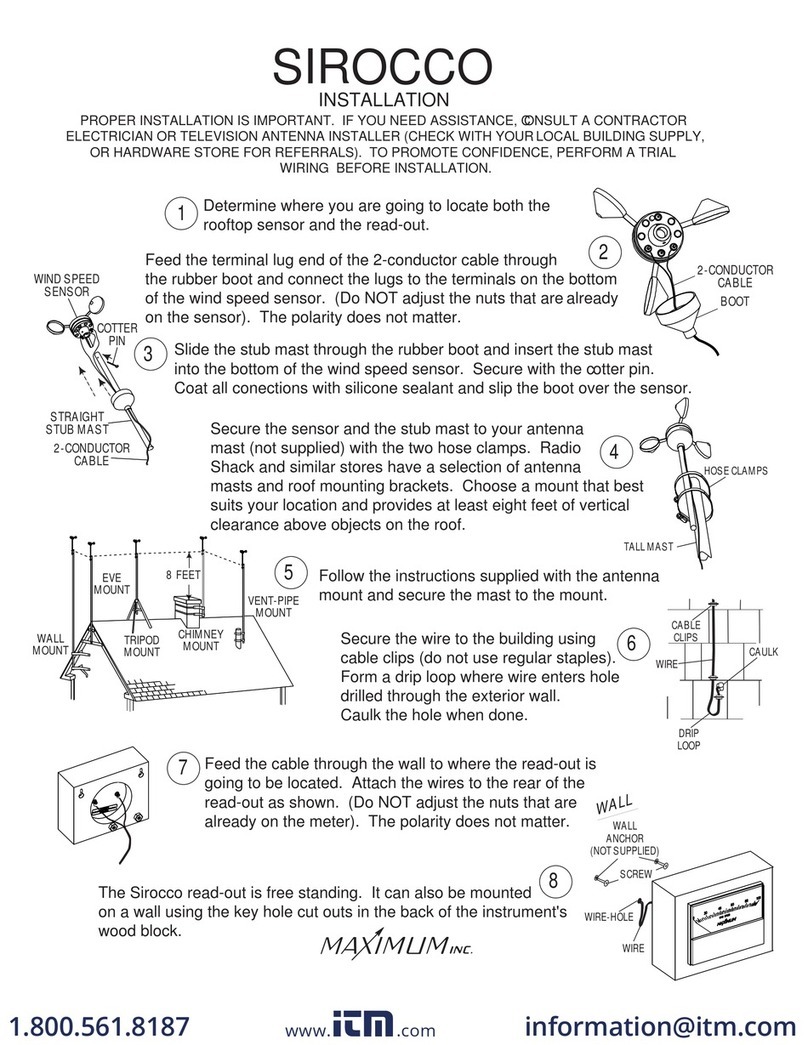

Fig. 3-1 MIO2

A

B

AIncubator with 6 positions (slots) BIncubator with 4 positions (slots)

3 - 2 MIO2 Operating Manual, 394934, en, V3.0

3 - Technical Data

Product Identification and Appendix Labels

Area of

Application The MIO2 is designated for all Fluent and Freedom EVO instruments—except for

Freedom EVO 75 that is incompatible with MIO2 with 4 positions.

Delivery It is recommended that theMIO2 is only delivered and installed by Tecan

authorized field service engineers.

3.2 Product Identification and Appendix Labels

6 Slot MIO

Fig. 3-2 MIO2, 6 positions, product identification and appendix labels

Calibrated at XY °C

INCUBATOR MIO2 XY°C

300YYYYY

24VDC

150W

T8AFuse

P

U,f

REF

Model

1001

SN 300YYYYY 1001

CB

A

D

E

AProduct identification label

BCalibration label

CConfiguration label

DMonitored Incubator Option

ECaution label

3 - Technical Data

Product Identification and Appendix Labels

MIO2 Operating Manual, 394934, en, V3.0 3 - 3

4 Slot MIO

Product

Identification

Label

The product identification label (A) provides the following instrument details Fig. 3-

2, 3-2:

Calibration

Label The calibration label (B) states the temperature the MIO2 was calibrated and

tested for Fig. 3-2, 3-2.

Configuration

Label The configuration label (C) Fig. 3-2, 3-2 specifies the resistance of the slots.

Fig. 3-3 MIO2, 4 positions, product identification and appendix labels

Calibrated at XY °C

INCUBATOR MIO2 4-Slot XY°C

300YYYYY

24VDC

150W

T8AFuse

P

U,f

REF

Model

1001

SN

300YYYYY 1001

CB

A

D

E

AProduct identification label

BCalibration label

CConfiguration label

DMonitored Incubator Option

ECaution label

Tab. 3-1 MIO2 product identification label

Note Definition

Identification data Model: Product name / model

REF: Reference number / Revision / Bar code

Manufacturing date

SN: Serial number

Technical data Voltage: supply voltage (Volts), 24 V DC

Power: power consumption (Watts) 150 W

Fuse: T8A 250V

Manufacturer’s name and address:

Tecan Schweiz AG, CH-8708 Männedorf

Barcode Barcode: Serial number and product type

3 - 4 MIO2 Operating Manual, 394934, en, V3.0

3 - Technical Data

Dimensions and Weights

3.3 Dimensions and Weights

6 Slot MIO

Dimensions

Weights

Fig. 3-4 Dimensions of the MIO2, 6 positions

W W

Lb

La

H H

A B

AMIO2 standard BMIO2 with shaker option

Tab. 3-2 Dimensions of the MIO2, 6 positions

Dimensions Value

La Length of standard configuration 213 mm (8.38 in.)

Lb Length with shaking assembly / fan option

configuration 265 mm (10.43 in.)

W Overall width 130.5 mm (5.13 in.)

H Overall height 267.5 mm (10.53 in.)

Tab. 3-3 Weight of configurations, 6 positions

Type Value

Standard configuration weight 3.5 kg (7.7 lbs.)

Shaking assembly configuration 4.8 kg (10.6 lbs.)

Shaking assembly with fan option configuration 4.9 kg (10.8 lbs.)

3 - Technical Data

Dimensions and Weights

MIO2 Operating Manual, 394934, en, V3.0 3 - 5

4 Slot MIO

Dimensions

Weights

Fig. 3-5 Dimensions of the MIO2, 4 positions

W

La

H

A

W

Lb

H

B

AMIO2 standard configuration BMIO2 with shaker option

Tab. 3-4 Dimensions of the MIO2, 4 positions

Dimensions Value

La length of standard configuration 228 mm (8.98 in.)

Lb length with shaking assembly / fan option

configuration 278 mm (10.95 in.)

W Overall width 130.5 mm (5.13 in.)

H Overall height 267.5 mm (10.53 in.)

Tab. 3-5 Weight of configurations, 4 positions

Type Value

Standard configuration weight 3.6 kg (7.9 lbs.)

Shaking assembly configuration 4.6 kg (10.1 lbs.)

3 - 6 MIO2 Operating Manual, 394934, en, V3.0

3 - Technical Data

Operating Range

3.4 Operating Range

6 Slot MIO

4 Slot MIO

Tab. 3-6 Operating ranges, 6 positions

Number of Slots 6

Incubating tempera-

ture range from (actual room temperature + 5°C) to 60°C

from (actual room temperature + 9°F) to 140°F

Accuracy of chamber

temperature max. ±0.5°C at 37°C (max. ±0.9°F at 99°F)

max. ±0.5°C at 46°C (max. ±0.9°F at 115°F)

max. ±2.0°C at 60°C (max. ±3.6°F at 140°F)

Accuracy of tempera-

ture in microplate in

the chamber

max. ±1°C at 37°C (max. ±1.8°F at 99°F)

max. ±1°C at 46°C (max. ±1.8°F at 115°F)

max. ±2°C at 60°C (max. ±3.6°F at 140°F)

Warm-up time from

20°C to 37°C max. 20 min.

Warm-up time from

20°C to 45°C max. 20 min.

Warm-up time from

20°C to 60°C max. 30 min.

Shaking / rotation fre-

quency 1–8.5 Hz

Linear shaking max. 2 mm amplitude in Y-dimension

Tab. 3-7 Operating ranges, 4 positions

Number of Slots 4

Incubating tempera-

ture range from (actual room temperature + 5°C) to 60°C

from (actual room temperature + 9°F) to 140°F

Accuracy of chamber

temperature max. ±1°C at 37°C (max. ±1.8°F at 99°F)

max. ±1°C at 46°C (max. ±1.8°F at 115°F)

max. ±2°C at 60°C (max. ±3.6°F at 140°F)

Accuracy of tempera-

ture in microplate in

the chamber

max. ±1°C at 37°C (max. ±1.8°F at 99°F)

max. ±1°C at 46°C (max. ±1.8°F at 115°F)

max. ±2°C at 60°C (max. ±3.6°F at 140°F)

Warm-up time from

20°C to 37°C max. 30 min.

Table of contents

Other tecan Accessories manuals