COOLING AND DISPENSING SYSTEMS 2

Introduction:

Thank you for purchasing a Lindr product.

This instruction manual is for models:

AS - 40, AS - 80, AS - 110 GL, AS-110 INOX

TROPICAL, AS-110 INOX TROPICAL GL, AS- 160

INOX TROPICAL, AS - 160GL, AS - 200GL, CWP

100 GL, CWP 200, CWP 200GL, CWP 300GL,

CWP 200GL mobile, CWP 300GL mobile.

General instructions and precautions Safety

instructions:

Respect the basic safety instructions

given by the manufacturer. This cooling

equipment is designed for ow type cooling

of beverages dispensed from kegs. Any other

use is considered inaccessible, and therefore

dangerous. The supplier shall not be liable for

damages caused by improper use.

DO NOT USE THE EQUIPMENT FOR ANY OTHER PURPOSES THAN

WHAT IT IS INTENDED FOR BY MANUFACTURER!

General safety rules Follow these safety

instructions.

The supplier shall not be liable for damages

caused by activities performed on this device

without following the instructions below!

This appliance can be used by children aged

15 years and older people with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

should under supervision, or have been

instructed about using the appliance safely

and understand any potential hazards.

Children should not play with the appliance.

Cleaning and maintenance of the appliance

cannot be performed by unattended children.

CAUTION: Before connecting the main power

supply check if the voltage and frequency

match the data shownon the device.

CAUTION: Always make sure the power socket

to connect the cooler is eqipped with sucient

circuit breaker (16A depending on the type)

according to ČSN 33 1500.

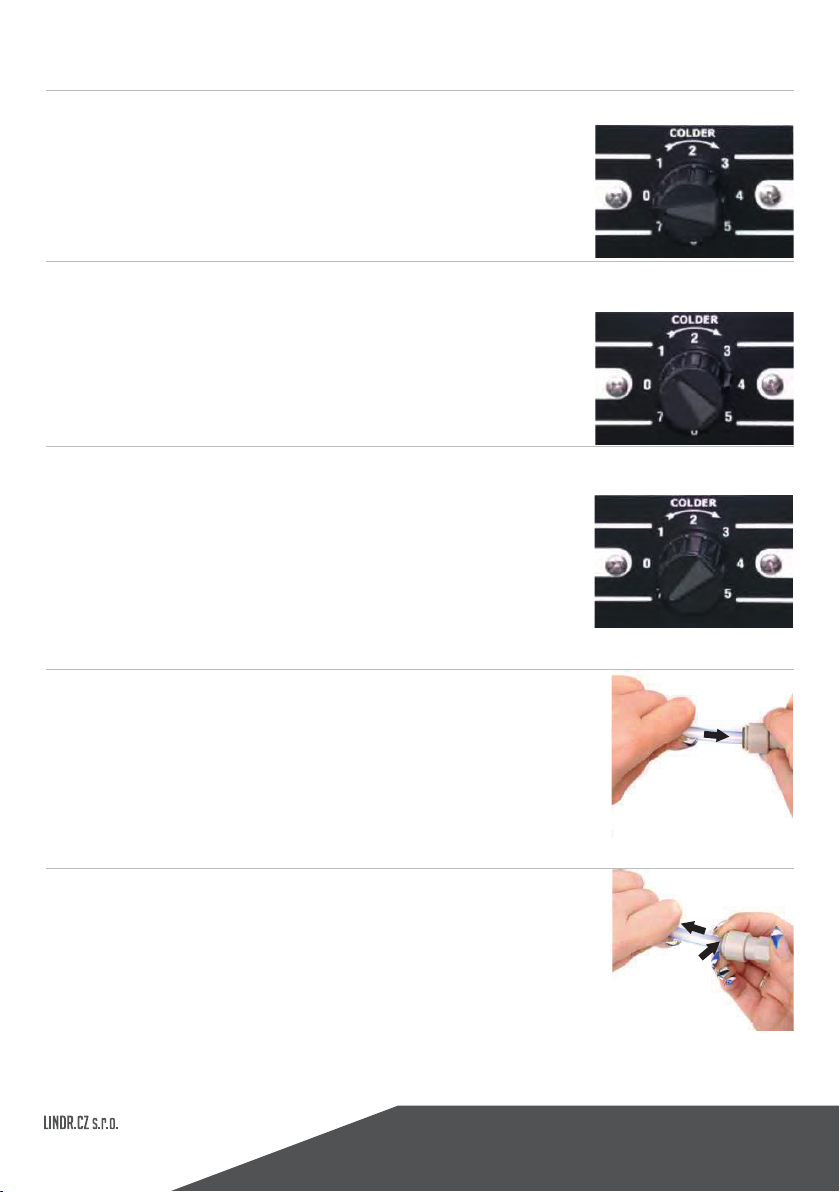

CAUTION: Before any intervention on the

device, eg cleaning and machine maintenance,

ALWAYS disconnect the appliance from the

electrical supply: set the thermostat to the„O“

position and pull out the plug.

CAUTION: Never put tools or other objects into

the propeller fan.

CAUTION: Never touch the electrical parts

with wet or damp hands.

CAUTION: To ensure the performance of the

cooling unit, never block the air inlet.

CAUTION: With the CWP 100GL, CWP 200,

CWP 200GL, CWP 200GL mobile, CWP

300GL a CWP 300GL mobile models, they

should NEVER BE used if the door is opened.

Otherwise, there would be a distruption of air

circulation and the subsequent failure of the

machine.

WARNING:

When sanitizing, the water temperature must

not be higher than 25 ° C!

CAUTION: Always make sure the power socket

is in a freely accessible place in case of the

need to pull the plug immediately.

CAUTION: When pulling the plug out of the

socket, grasp the plug and pull out. Do not pull

the supply cord under any circumstances or

you may cause a damage.

CAUTION: To disconnect the device

completely, pull the plug out of the electricity

socket.

CAUTION: In case of damage to the electrical

circuit, you have to call trained service

technician. In no case should you repair it

yourself.