TECH ST-707 User manual

ST-707 Rotations Control

Declaration of Conformity No. 32/2010

Hereby, we declare under sole responsibility that the ST-707

230V 50Hz thermoregulator manufactured by TE H,

headquartered in Wieprz 1047A, 34-122 Wieprz, is compliant

with the Regulation by the Ministry of Economy. (Journal of Laws

Dz.U. 155 Item 1089) of July 21, 2007 implementing provisions

of the Low Voltage Directive (LVD) 2006/ 5/EC of January 16,

2007.

The ST-707 controller has been tested for electromagnetic

compatibility (EM ) with optimal loads applied.

For compliance assessment, harmonized standards were

used:

PN-EN 60730-2- :2006.

- 2 -

ST-707 Rotations Control

ATTENTION!

High voltage!

Make sure the regulator is disconnected from the

mains before working on the power supply (cable

connections, device installation, etc.)!

All connection works must only be carried out by

qualified electricians.

Before activating the controller, measure the motor

resetting efficiency and inspect wire insulation.

- 3 -

ST-707 Rotations Control

I. Description

Temperature regulator ST–707 is designed for H boilers equipped

with a wormwheel feeder. It controls the water circulation pump , the hot

usable water pump (HUW), the floor heating pump, the circulation pump,

the blow-in (fan) and the fuel feeder. This device may also cooperate

with two three-way or four-way valves, the room regulator ST-208, the

GSM module and the Ethernet module.

The advantage of this controller is its simplicity in operation. The

User makes all changes of parameters by means of the pulse

generator knob.

Another advantage is a large and transparent graphic display, where

the user can exactly see the current condition of the boiler's operation.

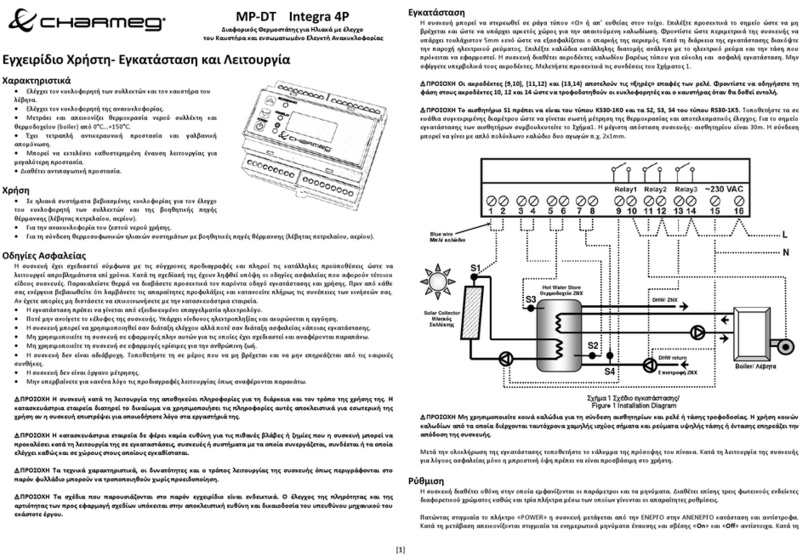

ontroller ST-

707

- 5 -

Pumps operation mode Time

Current CH temp.

Boiler operation phase

Boiler power

Temp. Of flue gas

Set CH temperature

Work of

CH pump

Work of

HCW pump

Work of

floor pump

Pump operation

of circulation pump

Wprk of

blow-in

Work of

the feeder

ST-707 Rotations Control

Rotations ontrol is a regulator with a continuous output signal, using

PID regulation algorithm. In this type of controller the blow-in power

is calculated on the basis of the measurement of the boiler temperature

and the temperature of flue gas measured on the boiler's outlet.

Operation of the fan proceeds on an ongoing basis and the blow-in power

depends directly on the measured boiler temperature, the temperature of

flue gas and the difference of these parameters from their preset values.

Stable maintenance of the set temperature without any unnecessary

adjustments and oscillations are the advantages of the zPID regulator.

Each controller should be set individually, for own needs, depending

on the type of fuel used for burning as well as the type of the boiler. The

TE H company will not be liable for any incorrect settings of the

controller.

When using this type of controller with a flue gas outlet sensor,

savings in fuel combustion may reach up to more than ten percent; The

outlet water temperature is very stable, which affects the longer life span

of the exchanger (boiler . Checking the temperature of flue gas at the

outlet from the boiler causes low emission of dusts and gases harmful for

the environment. Thermal energy from the flue gas is not wasted and

released to the chimney, but used for heating.

Below we present the results of tests conducted with the use of the Tech

controller with PID control:

and the same controller without PID control:

- 6 -

ST-707 Rotations Control

Any comments concerning the program should be reported to the

boiler's manufacturer.

Each controller should be set individually for personal needs,

depending on the type of fuel used for burning as well as the type of the

boiler. The TE H company shall not be liable for any incorrect settings of

the controller.

II. Functions of the regulator

This chapter describes the functions of the regulator, the method of

changing the settings as well as navigation in the menu which is made

using the pulse generator (knob). The boiler's operational parameters

are displayed on the main screen of the controller. The user selects the

operation mode and a number of settings of the boiler according to their

own needs.

After activation of the controller the name of the manufacturer of

the boiler as well as the version of the program are displayed on the

graphic display. A message with language selection appears after a few

seconds. In this function, the user may change the language version.

II.1. Basic definitions

Ignition – this cycle begins at the moment of activation in the menu of

the ignition function controller and when the choice is approved (the

following message will appear on the display: "PID: IGNITION" ) and

lasts until the time when the flue gas temperature reaches the value of at

least 60 o (preset ignition threshold), provided that this temperature

does not fall below this value for 30 seconds (preset ignition time).

Operation – after completion of ignition the regulator switches to the

operation cycle and the following message is shown on the display:

"PID: OPERATION". This is the basic functioning condition of the

- 7 -

ST-707 Rotations Control

regulator, in which the blow-in and fuel feeding proceeds automatically

according to the PID algorithm, oscillating around the temperature set by

the user. If the temperature unexpectedly rises by more than 5o above

the set value, the so-called supervision mode will be activated.

Supervision mode – this mode will activate automatically, if the

temperature in the operation cycle rises by more than 5o above the set

value. In such a case, in order to reduce the temperature of circulating

water, the controller will change the PID regulation to manual settings

(according to the parameters in the installer's menu) and the following

message will be shown on the display: "PID: SUPERVISION".

Extinguishment – if the flue gas temperature drops below 37o (preset

extinguishment threshold) and does not rise above this value for 30

seconds (preset extinguishment time), the regulator switches to the

extinguishment condition. In this state the blow-in and the feeder stop

working and the following message is shown on the display: "PID:

EXTINGUISHED".

II.2. Homepage

During normal operation of the regulator, the main page is visible on

the graphic display. Depending on the operation mode, one of the

following screens is displayed:

Pressing the knob of the pulse generator brings the user to the first

level menu. The first three menu options are shown on the display. Turn

the knob to move to subsequent options. Press the knob to select a given

function. Similar actions are made when changing parameters. To

introduce changes it is necessary to approve them by pressing the pulse

generator when the APPROVE message is shown. If the user does not

want to make any changes in a given function, they should press the

pulse generator when the CANCEL message is shown. To exit the menu

select the exit option.

II.3. Screen view

In this function, the user may choose one of the three main

- 8 -

ST-707 Rotations Control

thermoregulator operation screens. They are:

➢H screen (the current boiler operation mode is displayed),

➢valve 1 (displays the operational parameters of the first valve),

➢valve 2 (displays the operational parameters of the second valve).

➢manufacturer's screen - this view is unavailable to the user. This is

a special screen view only for the device's manufacturer.

NOTE

To make the views with valve parameters active, these valves must be

earlier accordingly installed and configured by the installer.

II.4. Ignition

The boiler can be easily kindled using this function. After initial

lighting up of a fire source, the user activates the automatic ignition

cycle. Thanks to selection of optimum parameters, the boiler will

smoothly switch to the operation mode using the PID function.

II.5. Set CH

This option is used to adjust the set boiler temperature. The user may

change the temperature range in the boiler from 45O to 80O . The set

H can also be changed directly from the main controller screen by

turning the pulse generator knob.

II.6. Set HUW

This option is used to adjust the set value of the hot utility water

temperature. The user may change this temperature in the range from

40O to 75O .

- 9 -

ST-707 Rotations Control

II.7. Manual mode

For the user's convenience, the regulator has been equipped with a

Manual operation module. In this function, each executive device (the

feeder, the blow-in, the H pump, the HUW pump, the circulation pump

and the floor pump) is activated and deactivated independently of the

others.

Pressing the pulse generator activates the engine of the chosen

device. This device remains activated until the pulse generator is

pressed again.

The blow-in power, where the user has the possibility to set any

rotational speed of the fan in manual operation, is additionally available.

II.8. Operation mode

In this function, the user selects one of four options of the boiler's

operation.

II.8.a) House heating

By choosing this option, the regulator switches to heating the house

only. The H pump starts to work above the pump activation threshold

(preset to 40O ). Below this temperature the pump stops working.

- 10 -

ST-707 Rotations Control

II.8.b) Reboiler priority

In this mode, the reboiler pump (HUW) is turned on first, until the set

temperature is reached. After reaching the set reboiler temperature, the

HUW pump shuts down and causes activation of the H pump. The H

pump operates constantly, until the moment when the temperature at

the reboiler drops below the set value. At that time, the H pump shuts

down and the HUW pump is activated

In this mode, operation of the fan and the feeder is limited to 62 degrees

in the boiler, since this prevents the boiler from overheating.

Note: The boiler should be equipped with return valves on the circuits

of the CH pump and the HUW pump. The valve mounted on the HUW

pump prevents hot water from being sucked out of the reboiler.

II.8.c) Parallel pumps

In this mode, both pumps work simultaneously above the pump

activation threshold temperature (preset to 40O ).

The H pump operates continuously and the HUW pump shuts down after

reaching the temperature set at the reboiler. The HUW pump will be re-

activated when the reboiler temperature drops below the set value (see

HUW hysteresis in the installer's menu).

NOTE: In this mode, one should install a three-way valve or another

mixing valve causing maintenance of a different temperature in the

reboiler and of a different in the house.

II.8.d)Summer mode

After activation of this function, only the HUW pump, whose task is

additional heating of the reboiler, operates. This pump is activated above

- 11 -

ST-707 Rotations Control

the set activation threshold (see the pump activation temperature

function) and operates until the set temperature is reached. The pump

will be activated again when the temperature drops below the set value

and the set hysteresis. In the summer mode, one sets only the set

temperature in the boiler which additionally heats the water in the

reboiler (the set boiler temperature is at the same time the set reboiler

temperature).

II. . Weekly control

The function is used to programme daily changes in the boiler

temperature. The preset temperature deviations are within the range of +/-

100.

Step 1:

The user needs to set current time and date first (Installer menu > Clock .

Step 2:

The user sets temperature values for individual days of the week (Set mode 1):

Monday– Sunday

Select specific hours and required deviations from the preset temperature (how

many degrees the temperature should rise or drop) for each day of the week.

Additionally, the preset values can be copied to facilitate the operation.

Example

Monday

preset: 3 00 , temp. -100 (temperature change– 100)

preset: 4 00 , temp. -100 (temperature change – 100)

preset: 5 00 , temp. -100 (temperature change – 100)

In such a case, if the temperature preset on the boiler is 60º , it will drop

10º to 50º between 3 a.m. and 6 a.m. on Monday.

As an alternative to the temperatures being preset separately for

individual days, the temperatures can also be set collectively, in the second

mode, for the working days (from Monday to Friday) and the weekend

(Saturday and Sunday) separately - Set mode 2.

Monday - Friday; Saturday - Sunday

Similarly to the previous mode it is necessary to select specific times and

required deviations from the temperature preset for the working days (Monday -

Friday) and the weekend (Saturday, Sunday).

- 12 -

ST-707 Rotations Control

Example

Monday - Friday

preset: 3 00 , temp. -100 (temperature change – 100)

preset: 4 00 , temp. -100 (temperature change – 100)

preset: 5 00 , temp. -100 (temperature change – 100)

Saturday - Sunday

preset: 16 00 , temp. 50 (temperature change +50)

preset: 17 00 , temp. 50 (temperature change +50)

preset: 18 00 , temp. 50 (temperature change +50)

In this case, if the preset boiler temperature is 60º , the temperature will drop

10º to 50º between 3 a.m. and 6 a.m. on each day from Monday to Friday.

However, the temperature will rise 5º to 65º during weekend (Saturday,

Sunday) between 4 p.m. and 7 p.m.

Step 3:

The user enables one of two preset modes (Mode1, Mode2) or disables the

weekly control option.

Once the mode is enabled the value of the deviation currently set is displayed

on the main page of the controller next to the preset central heating system

temperature. This, additionally, indicates that the weekly control is active.

Data deletion function is a simple method to remove all previously

saved weekly programme settings to enter new settings.

II.10. Fuel granulation

This option allows to choose the main fuel granulation, with which the

boiler is fired .

II.11. Installer's menu

The functions in the installer's menu should be set by the person

installing the boiler or by the manufacturer's service.

II.12.a) Fan coefficient

This function is used to control the fan power. The control is based on shifting

the fan performance curve up or down. If the blowing rate in the whole control

range is too low/high, the coefficient should be increased/decreased accordingly

to ensure proper efficiency of the fan operation.

Malfunctioning of the blowing system is most frequently caused by relatively

large differences between voltages supplied to individual units, which has a

- 13 -

ST-707 Rotations Control

significant impact on the fan operation.

II.12.b) Power coefficient

Fuel feeding coefficient is intended to optimize the feeder operation so as to

ensure that fuel is fed to the furnace in proper quantities. This function allows

setting the percentage increase or decrease of fuel being supplied.

Once the proper fuel size is selected in the main menu it is possible, by using

the coefficient, to adapt precisely the fuel quantity to be fed by the feeder to

the furnace.

II.12.c) Room regulator

ontroller ST-707 Rotations ontrol can be connected to room

regulator ST-208 (additional option). This regulator is an extended

device, allowing to control several parameters at the same time. The user

has the opportunity to change the set temperature of the boiler and the

mixing valves. An additional advantage of the device is the weekly

heating program and the parental lock protecting against unwanted

changes in the settings.

After activation of the TECH Regulator options on the main screen

of the controller at the top part of the display, the letter "P" will appear.

Flashing letter "P" means the room is underheated; when the set

temperature is reached in the flat, "P" will glow permanently.

NOTE: No external voltage may be connected to the output of the room

regulator.

II.12.d) Valve 1 and 2

NOTE ontrolling the valve is possible only after purchasing an

additional ST-61 control module and connecting it to the controller, which

is not included to the room regulator as a standard feature. Two ST-61

modules should be connected to control two valves.

This option is used to set the operation of the mixing valve. To make

sure that the valve works properly in accordance with the user's

- 14 -

ST-707 Rotations Control

expectation, is should be registered by entering the module number

(this is number of the valve in accordance with the documentation) and

then several parameters should be set.

1. Switch on

This feature allows you to temporarily make the valve inactive.

2. Temperature control

In this function, the opening time of the valve is set - in other

words, how long it takes the valve to open to the value of 100%. This

time should be selected in accordance with the owned valve servomotor

(stated on the rating plate).

3. Opening time

In this function, the time of full valve opening is set, in other words,

how long it takes the valve to open to the value of 100%. This time

should be selected according to the owned valve servomotor (stated on

the rating plate).

4. Unit step

In this function, the unit percentage valve opening stroke, that is the

minimum percent of opening or closing the valve is expected to execute,

is set.

- 15 -

ST-707 Rotations Control

5. Minimum opening

In this function, the minimum value of the valve opening is set.

Below this value, the mixing valve will not close any further.

6. Valve type

With the use of this option, the user selects the type of the valve:

H or floor.

7. Weather-based control

To activate the weather function, external sensor should be placed in

the place which is not isolated and not exposed to atmospheric impacts.

After installation and connection, a sensor should have the function of

Weather sensor activated in a controller menu.

To make sure that the valve works correctly, the set temperature is

set (behind the valve) for three intermediate external temperatures:

Set temperature threshold 1 -20 o

Set temperature threshold 2 0o

Set temperature threshold 3 + 20o

Below, an example for the valve set as Type> floor:

Heating curve – this is a curve, according to which the preset controller

temperature is determined, on the basis of external temperature. In our

controller, this curve is constructed on the basis of three points of set

temperatures for the respective external temperatures. Set temperatures

- 16 -

ST-707 Rotations Control

must be determined for external temperatures of - 20º , 0º and 20º .

The more points constructing the curve, the greater its accuracy,

which allows its flexible shaping. In our case three points, seem a very

good compromise between the accuracy and the ease in setting the

course of this curve.

Where, in our controller:

XA=20˚

XB =0º ,

X=20º ,

YA, YB , Y – set for external temperatures XA, XB , X ,

O1 – operation of increasing the set

[Temperatura zewnętrzna – External temperature; Temperatura zadana –

Set temperature]

Increasing/reduction the set temperature consists in increasing /

reducing the current set temperature visible on the main screen. Such a

change causes automatic shift of the heating curve by the changed value.

This shift consists in adding to parameters YA, YB , Y temperature change

O1.

Below there are formulas for calculating the current set temperature:

where:

X – current temperature outside,

Y – calculated set temperature

- 17 -

ST-707 Rotations Control

8. Return protection

This function permits setting the boiler protection against too cool

water returning from the main circulation, which could cause low-

temperature boiler corrosion. The return protection operates in the way

that when the temperature is too low, the valve is closed, until the short

circulation of the boiler reaches the appropriate temperature. This

function also protects the boiler against dangerously high temperature of

return in order to prevent boiling of water.

. Additional sensors

When two mixing valves are used and you select this function you will be

able to select the sensors from which temperature data are to be retrieved for a

valve (for return and outside temperature sensors). Temperatures can be

retrieved from the sensors of the valve being set (Own) or as per the controller

sensors (Main controller).

10.Pump activation temperature

This option is used to set H and HUW pump activation temperature (this is the

temperature measured on the boiler). Both pumps do not operate below the set

temperature and above this temperature they are activated, but operate

depending on the operation mode (see: pump operation mode).

11. Changing the set valve

This setting is used to set the circuit temperature to be maintained by the

mixing valve. This is the main temperature based on which the room

thermostat reduction function is to be run (see Section III.a.10). The room

thermostat reduction function is set separately for the H system (setting in the

user menu) and separately for each of the valves.

12. Room temperature difference

This function is active only when the unit is operated with a (standard or TE H)

room thermostat. When the room thermostat reaches the desired temperature

in the house/flat (reports heated up condition), the valve will close to such an

extent so that the temperature downstream of the valve drops by the <room

thermostat reduction> temperature.

- 18 -

ST-707 Rotations Control

NOTE: If the installation includes a TECH room thermostat with RS

communication (four-wire cable , you may choose an option providing dynamic

control for the mixing valve

13. Factory settings

This parameter allows you to restore the mixing valve settings saved by the

manufacturer. By restoring the factory settings you will not change the valve

type setting (central heating or floor type).

14. Valve removal

This function is used for a complete removal of the valve from the

controller memory. Valve removal is used e.g. at disassembling the valve

or module replacement (re-registration of a new module is necessary).

II.12.e) GSM module

NOTE Controlling of this type is possible after purchasing and connecting,

to the controller, the additional control module ST-65 which is not attached to

the regulator as a standard feature.

The GSM module is an optional device cooperating with the boiler

controller, enabling remote control of the boiler operation with the use of a

mobile phone. The User is notified with a text message on each alert of the

boiler controller, and by sending an appropriate text message at any time, he

or she receives a return message with the information on the current

temperature of all sensors. After entering an authentication code it is also

possible to remotely change the set temperatures.

The GSM module can also operate independently from the boiler

controller. It has two inputs with temperature sensors, single contact input for

use in any configuration (detecting short circuit/opening of contacts) and one

controlled output (e.g. possibility to connect additional contactor to control any

electrical circuit).

When any temperature sensor reaches the preset deactivation

temperature, maximum or minimum, the module will automatically send a text

message with such information. It is similar in the case of a short-circuit or

- 19 -

ST-707 Rotations Control

opening of contact input, which may be used e.g. for simple protection of

property.

If ST-707 controller is equipped with an additional GSM module, in order to

activate this device, it is required to start the activated option (MENU> Installer

menu> GSM module> Activated).

II.12.f) Internet module

NOTE: Controlling of this type is possible after purchasing and connecting, to

the controller, the additional control module ST -500 which is not attached to

the regulator as a standard feature.

The Internet module is a device enabling remote control of the boiler over

the Internet or local network . On the home computer screen the user controls

the condition of all boiler system devices and the operation of each device is

presented in the animated form.

Apart from the possibility to view the temperature of every sensor, the

user has the possibility of introducing changes of the set temperatures for both

the pumps and the mixing valves.

After activating the Internet module and selecting the DH P option, the

controller will automatically download such parameters from the local network

as: IP address, IP Mask, Gateway address and DNS Address. In the case of any

problems with downloading network parameters of the existing network, there

is a possibility of setting these parameters manually. The method of obtaining

local network parameters has been described in the instructions for the Internet

module.

The function Reset module password may be used when the User, on the

login page, has changed the factory user's password to his or her password.

When a new password is lost, it is possible to return to the factory password

after resetting the module password.

II.12.g)Pumps switch on temperature

Use this option to set the activation temperature of the pumps. The pumps

will start to run above the pre-set temperature. The pumps will be switched off

when the boiler temperature drops below the activation temperature (minus a

hysteresis of 2° ).

- 20 -

Table of contents

Other TECH Thermostat manuals

TECH

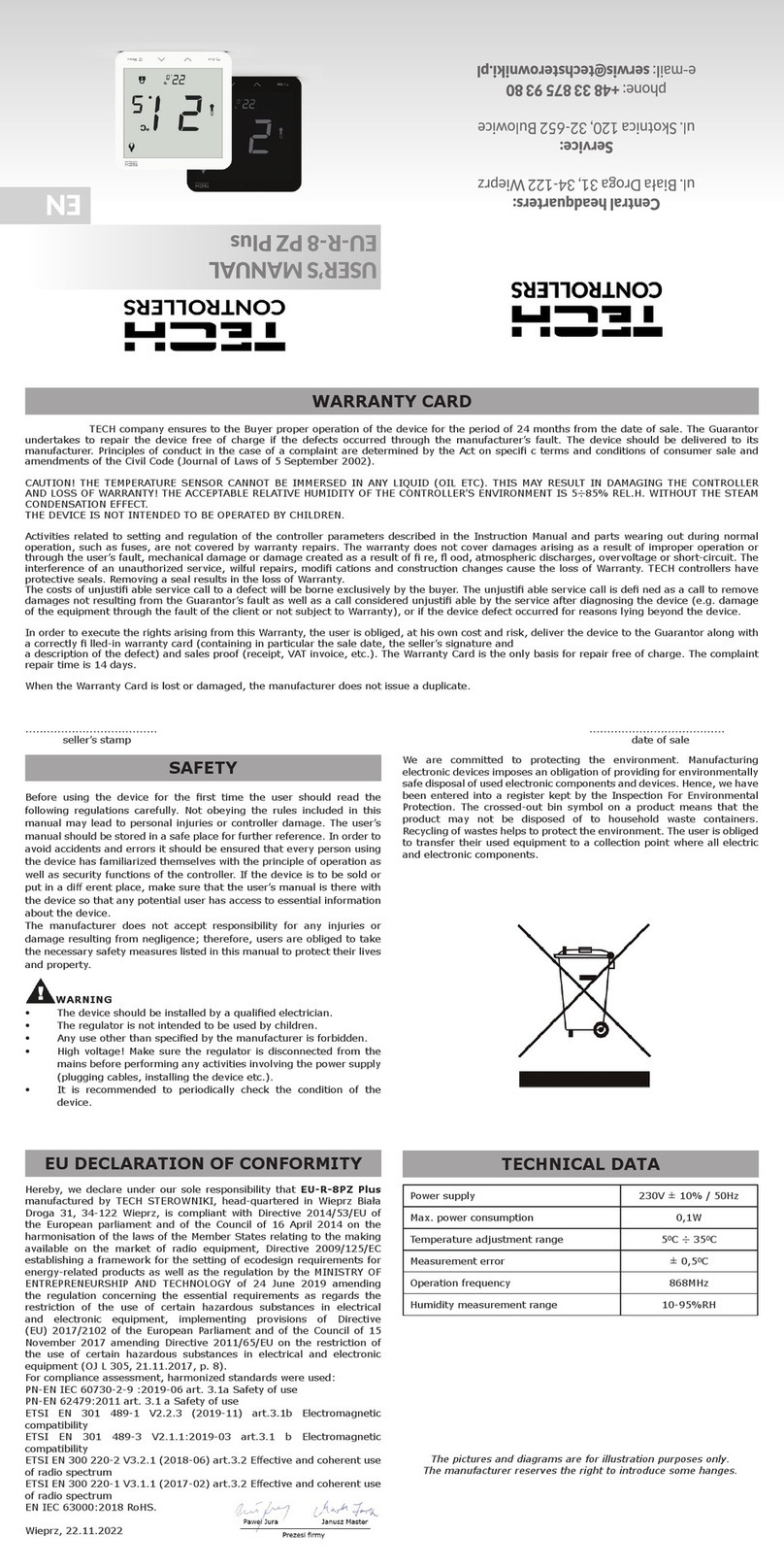

TECH EU-R-8b Plus User manual

TECH

TECH Sinum R-S3 User manual

TECH

TECH EU-R-8s Plus User manual

TECH

TECH EU-290 v1 User manual

TECH

TECH ST-280 User manual

TECH

TECH ST-29 v1 User manual

TECH

TECH ST-37 Assembly instructions

TECH

TECH Sinum R-S2 User manual

TECH

TECH EU-F-8z User manual

TECH

TECH EU-R-8PZ Plus User manual