TECHCON SYSTEMS TS6500CIM User manual

Techcon Systems

TS6500CIM

Automatic Techkit Mixer

User Guide

English, German, French

2

CONTENTS

Page Number

1. Safety……………………………………………………….………..………..

2. Unpacking and Inspection…………………………………….……..……….

3. Description …………………………………………………….…………….

4. Symbol Definitions……………………………………………..….……………

5. Emergency Stop………………………………………………………………

6. Specifications……………………………………………………..…………

7. Features and Function……………………………………………………………

7.1 Features………………………………………………..……………

7.2 Operation Function …………………………………….…..…….…..

8. Setup and Operation……………………………………………………….

8.1 Voltage Selection and Fuse Replacement ………………………..

8.2 Plastic Tray Installation……….………………………….…….……

8.3 Spindle and Extension Installation…………………………………………

8.4 Turn on the Unit…………….…………………………….…………….

8.5 Cartridge Kit Preparation….………………………………….…….……..

8.6 Loading the Cartridge Kit……………………………………….…..

8.7 Mix Cycle Program Setup……..…………………………………...

8.8 Start the Unit………...……………………………………..…………

8.9 Unloading the Cartridge Kit…….……………………………………..

8.10 Manual Mode………………………………………………………

9. Speed Control…………………………………………………………………

9.1 For Main Cylinder…………………………..………………………

9.2 For Injection Rod………………………………………………..……

10. Troubleshooting………………………………………………………………

11. Program Selection………………………………………………………………

12. Cycle Counter Reset………..…………………………………………….….

13. Cartridge Holder Installation………………………..…………….…………..

14. Maintenance…………………………………………………………………

15. Warranty…….…………………………………………………………………..

16. Appendix 16.1 Spare Parts List……………..……….……….……………..

16.2 Techkit Part Number Chart……………..……….……….

3

3

4

4

4

5

6-10

6-8

9-10

11-17

11

12

12-13

13-14

14

15

16

16

16

16-17

17

17

17

18

19

19

19-20

21

21

22-24

25

3

1. SAFETY

Intended Use:

WARNING: Use of this equipment in ways other than those described in this

User Guide may result in injury to persons or damage to property. Use this

equipment only as described in this User Guide.

OK International cannot be responsible for injuries or damages resulting from

unintended applications of its equipment. Unintended uses may result form taking

the following actions:

•Making changes to equipment that has not been recommended in the User

Guide

•Using incompatible or damaged replacement parts. Using unapproved

accessories or auxiliary equipment

Safety Precautions:

•Do not operate this unit in excess of maximum ratings/settings

•Always wear appropriate personal protective clothing or apparel

•Care must be taken to prevent the ingress of corrosive or flammable fluid back

into the Refer to Material Safety Data Sheet for proper handling and safety

precautions

•Do not smoke or use open flame when flammable materials are being dispensed

•This equipment is for indoor use only.

2. UNPACKING AND INSPECTION:

Carefully open the crate and examine all items contained inside.

The following items should be included:

1. TS6500CIM Main Assembly –in the main compartment

2. Accessory parts –packaged in a box and stored in an accessory

compartment, which include:

Description (Quantity)

Description (Quantity)

Cartridge Holder Assembly (1)

Air Filter (1)

Plunger Assembly (1)

Wrench holder (1)

Tool Holder (1)

User Guide (1)

Plunger Holder (1)

Air Hose (1)

Spare O-ring (5)

Fuse (1)

Spindle Assembly (1)

Power Cord (1)

Spindle Extension (1)

Screws (8)

4

3. DESCRIPTION

The TS6500CIM Series Automatic Techkit Mixer provides complete automatic

mixing of two-component materials packaged in cartridge.ts.niversal power

supply.

Equipped with a universal power supply, the TS6500 mixer is immediately usable

anywhere in the world. The automatic fluid sensing device makes it very simple

for the operator to install and setup all cartridge kit sizes. The user friendly

firmware provides up to 10 programmable mixing sequences with storage for 10

profiles.

The TS6500CIM Series is available in five versions:

•TS6500CIM-6 for 2.5oz. (60ml), 6.0oz. (160ml) and 8.0oz. (220ml) Kit

•TS6500CIM-20 for 20oz. (550ml) Kit

•TS6500CIM-RS-6 for 6.0oz. (160ml) Kit with reduced motor speed (116 RPM)

•TS6500CIM-SMR-6 for 6.0oz. (160ml) Kit with steel mix rod

•TS6500CIM-SMR-20 for 20oz. (550ml) Kit with steel mix rod

The following conversion kits are also available for your conveniences:

•CK6500-6 Conversion kit for 2.5 (60ml), 6.0 (160ml) and 8.0 oz. (220ml) Kit

•CK6500-10 Conversion kit for 1/10 gal.(310ml) Kit

•CK6500-20 Conversion kit for 20 oz.(550ml) Kit

4. SYMBOL DEFINITIONS

5. EMERGENCY STOP

In case of an emergency, the mixing operation can be stopped at any time by

pressing the EMERGENCY STOP BUTTON, (Fig 2, 10). After the problems have

been fixed, the machine can be restarted by pulling and turning the emergency

button counter clockwise. The mix cycle will start from the beginning.

5

6. SPECIFICATIONS

Size

16.5'' (420mm) X 16.8'' (426mm) X 38.2'' (970mm)

Weight

80lbs (36kg)

Input Voltage

120/230 VAC, 50/60 Hz

Rated Fuse

2A @ 120 VAC / 230 VAC

Motor Speed

139 RPM

Motor Torque

42 in-lb (4.7 Nm)

Indoor Use

Altitude up to 6,562ft (2,000m)

Operating Temperature

32˚F to 122˚F (0˚C to 50˚C)

Storage Temperature

-10˚C to 60˚C (14˚F to 140˚F)

Max. Relative Humidity

80% for temperature up to 87.8˚F ( 31˚C)

Decreasing linearly to 50% relative humility at

104˚F (40˚C)

Air Input

50 to 100 psi (3.5 –6.9 bar)

Display

LCD 20 X 4 display segments

Figure 1.0 Outside Dimensions

6

7. FEATURES AND FUNCTIONS

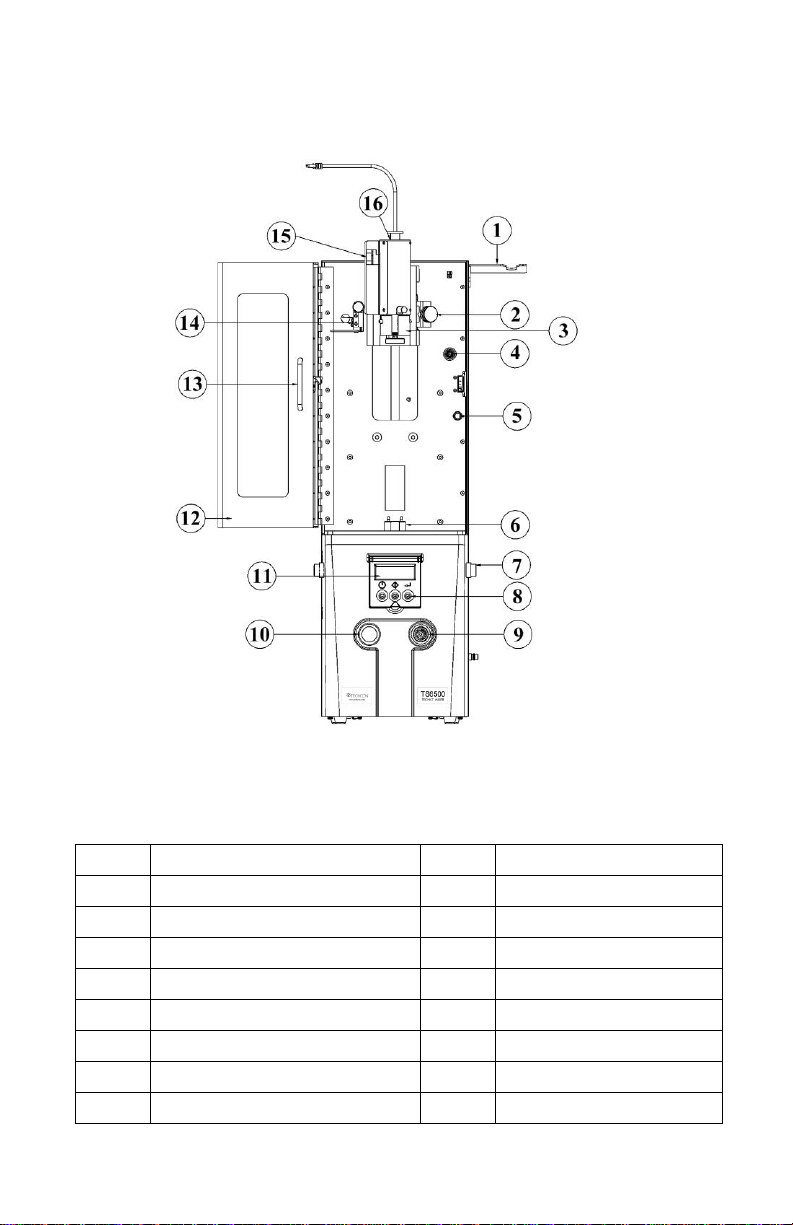

7.1 Features

ITEM

DESCRIPTION

ITEM

DESCRIPTION

1

Plunger Bracket

9

Air Regulator

2

Cartridge Holder

10

E-Stop Button

3

Guide Block

11

LCD Display

4

Plunger Air Inlet

12

Safety Cover

5

Pressure Relief Valve

13

Handle

6

Drive Spindle with Injection Rod

14

Fluid Level Sensor

7

Start Buttons

15

Fluid Level Sensor Magnet

8

Control Buttons

16

Plunger

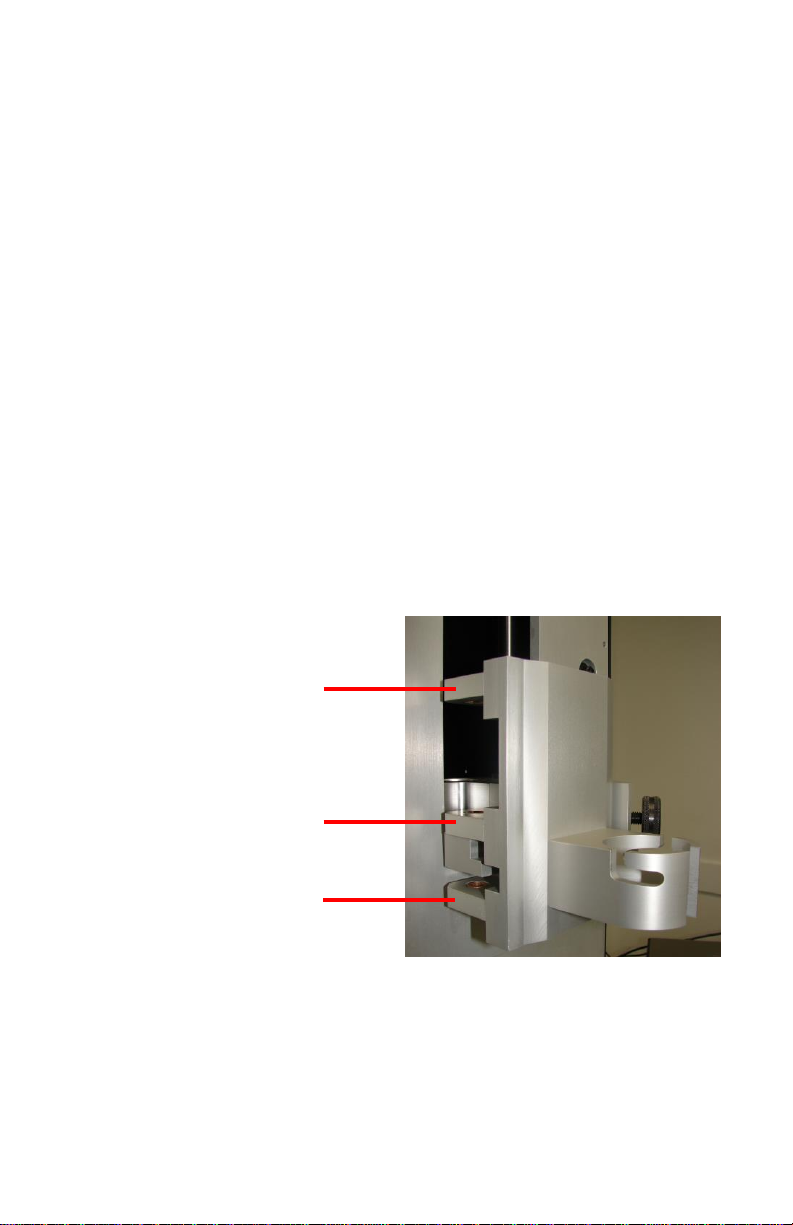

Figure 2.0 Front View

7

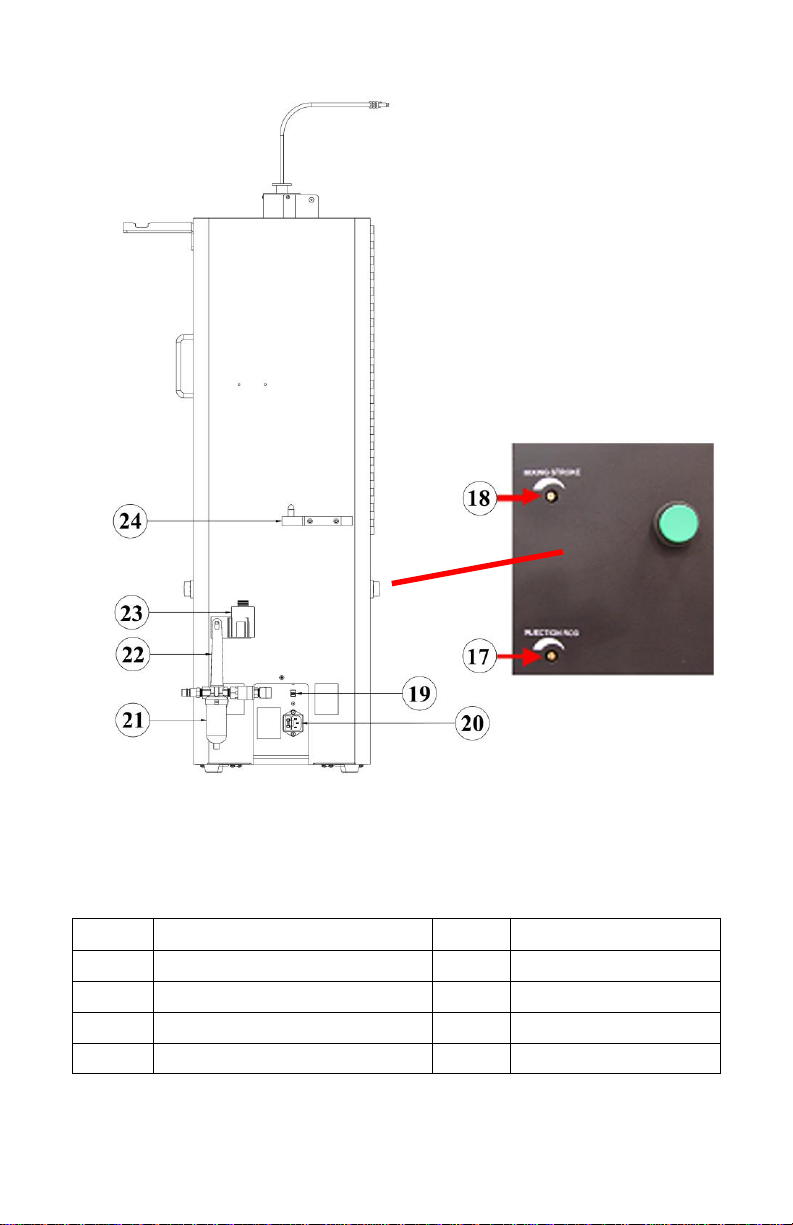

ITEM

DESCRIPTION

ITEM

DESCRIPTION

17

Flow Control, Injection Rod

21

Air Filter

18

Flow Control, Main Cylinder

22

Wrench

19

Voltage Select Switch

23

Accessories Bracket

20

Power Input Socket with Fuse box

24

Cartridge Holder Bracket

Figure 3.0 Back View

8

Figure 4.0 Buttons and Screen Identification

SAFE TO

RUN

TOTAL

MIX

TIME

CYCLE

COUNTER

MIX

CYCLE

SET

PROGRAM

MODE

PRESSURE

POWER/(-)

CYCLE

BUTTON

MODE/(+)

CYCLE

BUTTON

SETUP/SAVE

BUTTON

Figure 5.0 Setup Screen Identification

9

7.2 Operation Function

DESCRIPTION

FUNCTION

1

Plunger Bracket

•Holds plunger assembly when not in use

2

Cartridge Holder

•Holds cartridge kit

•Operates with the plunger assembly and guide block

to drive the cartridge up and down for mixing

3

Guide Block

•Operates with the plunger assembly and cartridge

holder to drive the cartridge up and down for mixing

4

Air Plunger Inlet

•Provides air to plunger

5

Pressure Relief valve

•Relief plunger pressure when door is opened

6

Drive Spindle with

Injection Rod

•Rotates mix rods during mix cycle

•Injects the hardener into the resin

7

Start Buttons (Green)

•Starts the unit

•Press green buttons simultaneously to start

8

Control Buttons

•Input buttons (see Fig. 4.0 and Fig. 5.0)

9

Air Regulator

•Regulates the air pressure to the unit

10

Emergency Stop

button (Red)

•Stops the Unit in an Emergency

•Press to Engage

•“E-Stop!’‘ will be displayed,

•To reset, rotate the E-Stop knob a quarter turn

clockwise

11

LCD Display

•Displays unit status, operation and error messages.

12

Protective (Safety)

Cover

•Protects operators when machine is in use

13

Plunger Disk

•Part of Plunger Assembly

14

Fluid Level Sensor

•Senses the fluid level at the top of the cartridge

10

15

Fluid Level Magnet

•Works with fluid level sensor

16

Plunger Assembly

•Locks cartridge in place

•Applies steady pressure to prevent air entrapment

17

Flow Control; Main

Cylinder

•Controls the speed of the main cylinder

•Rotate the flow control screw clockwise to increase

the speed.

•Rotate the flow control screw counterclockwise to

decrease the speed

18

Flow Control;

Injection Rod

•Controls the speed of the injection rod

•Rotate the flow control screw clockwise to increase

the speed.

•Rotate the flow control screw counterclockwise to

decrease the speed

19

Voltage Select

Switch

•Select 115V or 230V

20

Power Input Socket

with Fuse Box

•Input power connection

21

Air Filter

•Provides air filtration

22

Wrench

•Used to install the air filter assembly and drive

spindle assembly

23

Accessories Bracket

•To hold wrench or other accessories

24

Cartridge Holder

Bracket

•To hold extra cartridge holder

11

8. SETUP AND OPERATION

WARNING: This unit is equipped with a voltage selector switch. Please check to

make sure the voltage selector is set to match the voltage input.

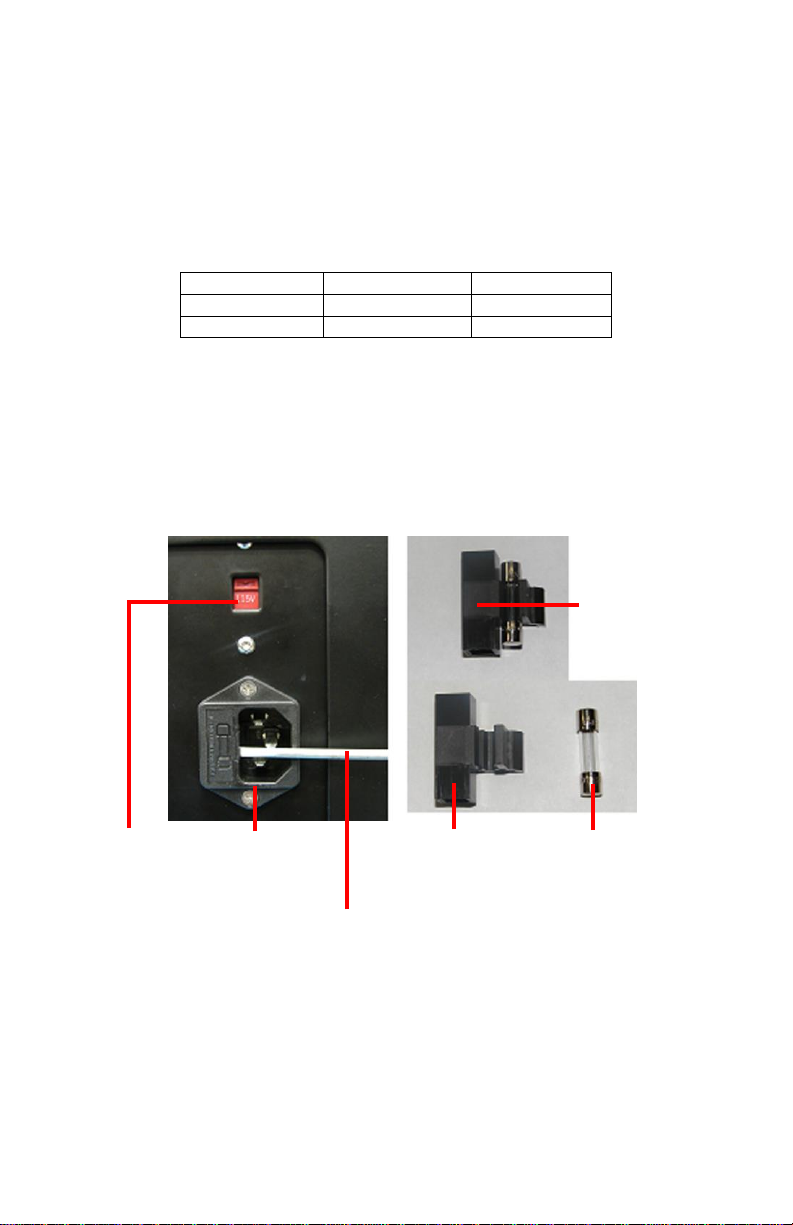

8.1 Voltage Selection and Fuse Replacement

1. Select the proper voltage by sliding the voltage switch up or down

Fuse Replacement: The unit is shipped with the fuse installed. If fuse

needs to be replaced please follow instructions below

2. Remove the fuse holder by using a flat head screw driver to pry it open.

3. Insert correct fuse into the fuse box, refer to table above

4. Re-install the fuse holder into the unit

Voltage Range

Voltage Setting

Fuse Rating

100V –120V

115V

2 Amp, Type F

220V –240V

230V

2 Amp, Type F

Figure 6.0 Fuse Installation

FUSE

HOLDER

VOLTAGE

SELECTOR

SWITCH

SCREW

DRIVER

FUSE

HOLDER

FUSE HOLDER

WITH FUSE

INSTALLED

FUSE

12

8.2 Plastic Tray Installation

The unit is shipped with a plastic tray to prevent any spilled material

migrating into the main control panel. Make sure to install the plastic tray

onto the base plate by aligning the four tabs into the base plate holes.

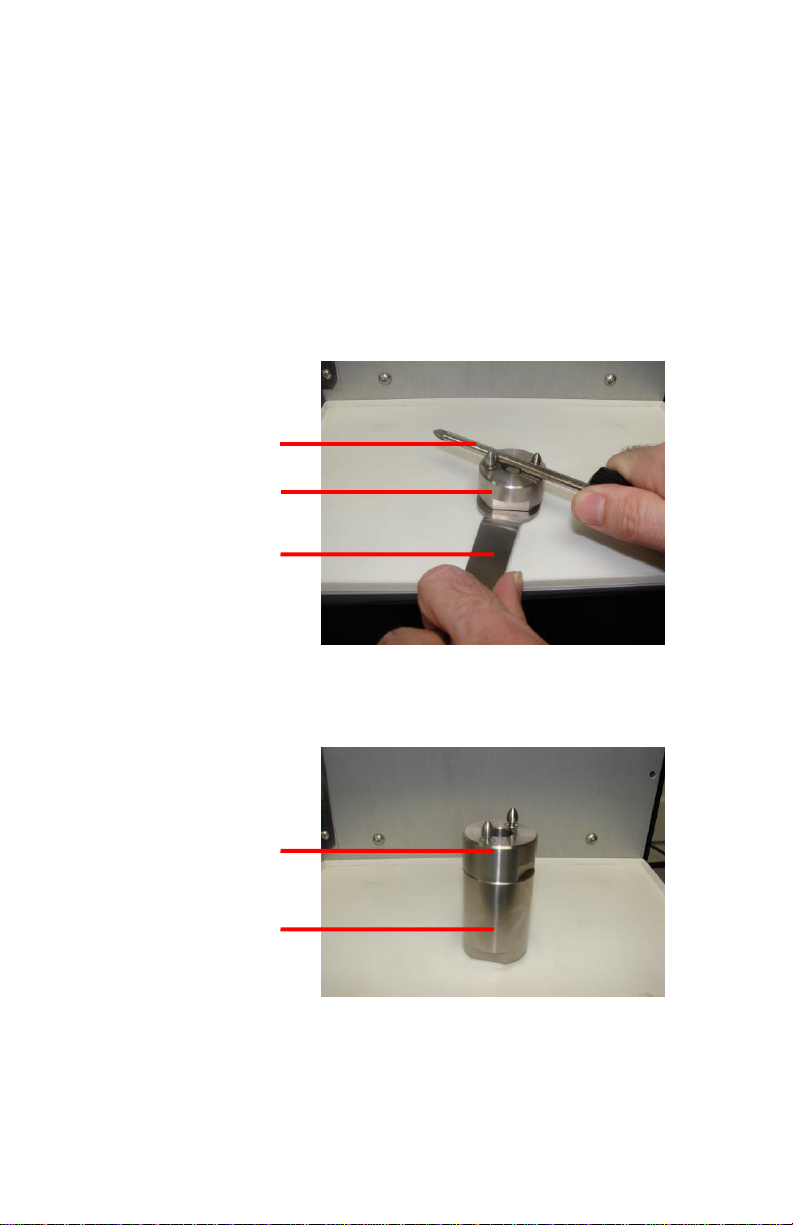

8.3 Spindle and Spindle Extension Installation

The unit is shipped with the spindle uninstalled. To install the spindle, align

it on the motor drive shaft then turn in clockwise direction.

Note: The spindle is designed to mix cartridge kits with 8'' (203mm) mix

rod. To mix cartridge kits with 6'' (152mm) mix rod, the spindle extension

needs to be installed. Follow the instructions below to install the spindle

extension:

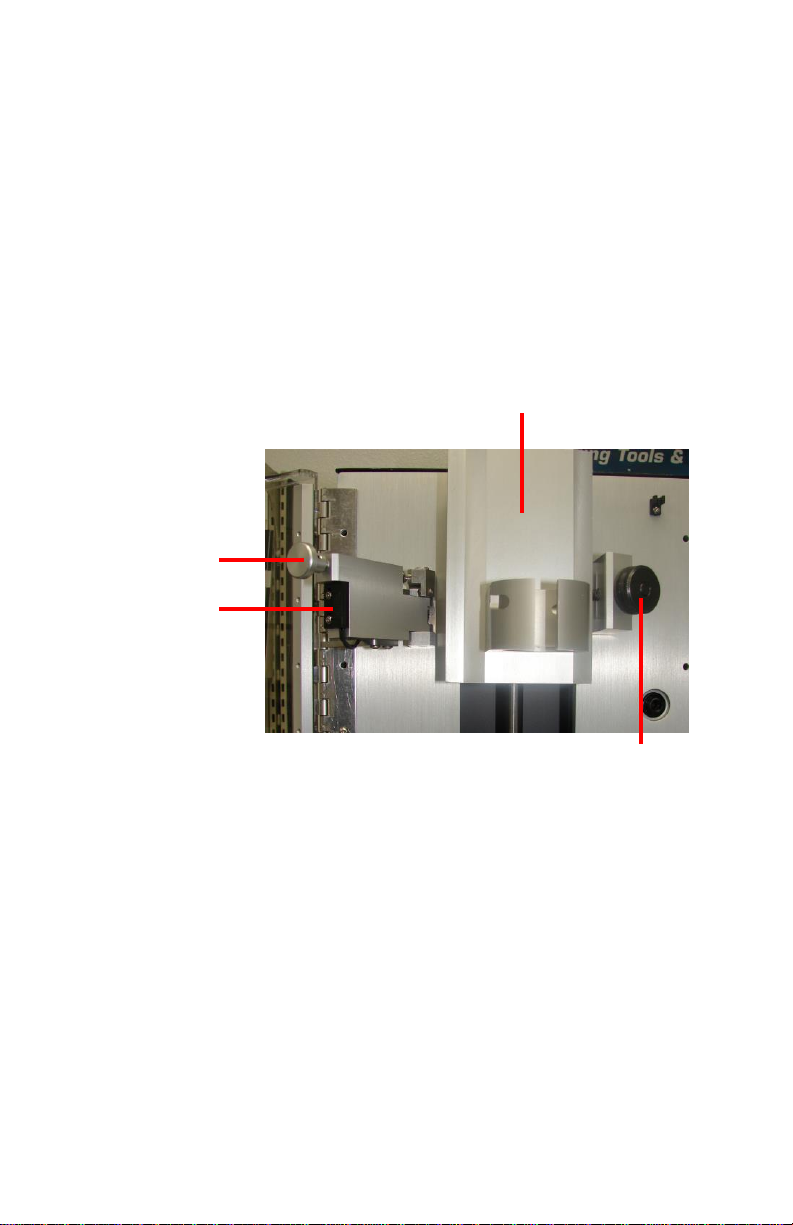

Figure 7.0. Remove Spindle Assembly

Figure 8.0. Spindle Assembly with Extension

SCREW

DRIVER

SPINDLE

ASSEMBLY

WRENCH

SPINDLE

ASSEMBLY

SPINDLE

EXTENSION

13

Figure 9.0 Air and Power Connection

1. Place the wrench on the motor shaft (beneath the spindle).

2. Place a screw driver between the two locking pins of the spindle.

3. Hold the wrench and turn the screw driver counter clockwise to unscrew the

spindle assembly.

4. Remove the spindle assembly from the motor shaft.

5. Install the spindle extension on the motor shaft by turning it clockwise.

6. Install the spindle assembly on the spindle extension by turning it

clockwise.

8.4 Turn On the Unit

Caution: Make sure the correct fuse has been installed and the correct

voltage has been set. Refer to section 8.1 for instructions.

1. Insert the power cord to the power socket (Fig. 3, 20).

2. Connect the air filter assembly to the air inlet (Fig. 3, 21).

3. Connect the air hose to the air filter assembly .

Caution: The air filter assembly (7091-9080), supplied with the unit, must be

installed to ensure proper air filtration.

4. Set the air Pressure to 80 psi (5.5 bar) minimum.

•Rotate the air pressure regulator knob (Fig. 2, 9) clockwise to increase the

air pressure.

•Rotate the air pressure regulator knob counterclockwise to decrease the air

pressure.

AIR FILTER

POWER CORD

14

5. The desired air pressure will be displayed on the screen.

6. Turn on the unit by pressing the power button (Fig. 4). The cartridge holder

should move up to home position. If it does not move up, please check

pressure connection.

8.5 Cartridge Kit Preparation

Injection Kit:

The TS6500 Mixer has an automatic injection device that will inject the hardener

into the catalyst before the mixing cycle starts. However, the valve in the mix rod

needs to be opened before placing the kit in the machine. Follow the below

instructions to open the valve.

1. Insert the ram rod into the mix rod.

2. Push the ram rod to force the valve open.

3. Follow the instructions in section 8.7 to mix the injection kit.

Barrier Kit

1. Remove barrier tape from the kit.

2. Pull the mix rod down to the fullest extend to remove the foil from the

dasher.

3. Follow instructions in section 8.7 to mix the barrier kit

Figure 10.0 Injection Kit

Figure 11.0 Barrier Kit

MIX ROD

VALVE

MIX ROD

BARRIER TAPE

FOIL

DASHER

15

8.6 Loading the Cartridge Kit

Note: The unit is setup to mix cartridge kit with 8'' (203mm) mix rod. To

mix cartridge kit with 6'' (152mm) mix rod, the spindle extension needs to

be installed. Refer to section 8.3 for instructions.

1. Open the safety cover (Fig. 2.0, 12).

2. Load the cartridge kit into the cartridge holder (Fig. 2.0, 2).

3. Pull the mix rod to the fullest extend then align the two through holes of the

rod to the drive spindle (Fig. 2.0, 6).

4. Turn the cartridge kit lightly in clockwise direction to lock it to the spindle.

5. Insert the plunger assembly (Fig. 2.0,16) into the cartridge holder with the

plunger correctly seated inside the cartridge.

6. Align the dowel pins of the plunger assembly with the bayonet slots in the

cartridge holder and turn counterclockwise until it locked in.

7. Connect the air hose into the plunger air inlet (Fig. 2.0, 4).

8. Close the safety cover.

Figure 12.0 Loading the Cartridge Kit

LOCKING DOWEL

PINS

MIX ROD

PLUNGER

ASSEMBLY

PLUNGER

AIR INLET

CARTRIDGE

HOLDER

DRIVE

SPINDLE

16

8.7 Mix Cycle Program Setup

Refer to Fig. 4.0.

1. Press the Mode button to select Auto mode.

2. Press and hold the Setup button for 3 seconds to enter setup screen.

3. Press the Setup button to move the cursor to the “CYCLE’‘ indicator.

4. Press the (+) and (-) button to set number of mix cycles required.

5. If a delay time is required, press the Setup button to move the cursor to the

“DELAY’‘ indicator then press the (+) and (-) button to adjust delay time,

for up stroke and down stroke. (Fig. 5.0 D: Down / U: Up)

6. Press and hold the Setup button for 3 seconds to save data. The unit is now

ready to run.

8.8 Start The Unit

1. Ensure the unit is in the Automatic Mode and the desired profile has been

selected.

2. Press and release the Start buttons (Green) (Fig 2.0, 7) simultaneously.

3. The unit will run the selected profile. The cycle count and elapsed time will

be displayed on the LED screen.

8.9 Unloading The Cartridge Kit

1. The machine will automatically stop once the mixing cycles are completed.

2. Open the protective cover (Fig. 2.0, 12).

3. Remove the retaining collar plunger assembly (Fig. 2.0, 16) by turning it

clockwise.

4. Place the retaining collar plunger assembly on the side bracket (Fig. 2.0, 1).

5. Turn the cartridge kit clockwise to remove it from the drive spindle.

6. Pull the cartridge kit out of the cartridge holder.

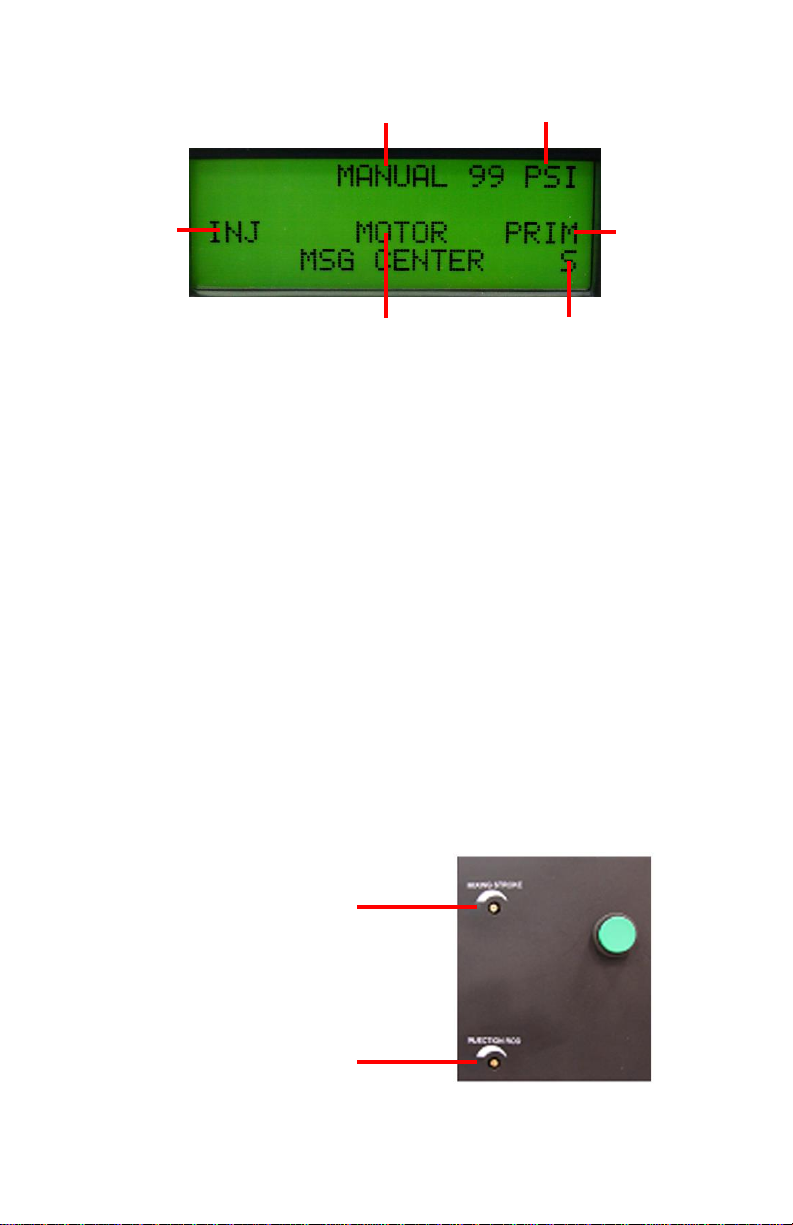

8.10 Manual Mode

While in the manual mode, the injection rod, main cylinder and drive spindle

motor may be controlled independently. Note: while in manual mode any errors

will not halt the operation of the motors. Refer to Fig. 13.0.

1. Press and hold the Mode button for 3 seconds to select Manual mode

2. Press the Power (-) button to activate the injection rod (the injection rod

will move up).

3. Press the Mode button (+) to activate the motor (the drive spindle will

rotate).

4. Press the Setup button () to activate the main cylinder (the cartridge

holder will move up and down).

17

9. SPEED CONTROL

9.1 For main cylinder

The main air cylinder drives cartridge kit up and down. The stroke speed of

the main air cylinder can be adjusted by rotating the flow control screw

(Fig. 14.0) counter clockwise to increase the speed and clockwise to

decrease the speed.

9.2 For injection rod

The injection rod air cylinder drives the injection rod up and down. The

injection speed can be adjusted by rotating the flow control screw (Fig.

14.0) counterclockwise to increase the speed and clockwise to decrease the

speed.

Note: For TS6500CIM-SMR-6 and TS6500CIM-SMR-20 models, the

injection rod flow control is shut-off from the factory. To re-activate

the injection rod, slowly turn the flow control screw counter-clockwise

until the desired speed is achieved.

Figure 13.0 Manual Mode Screen

ACTIVATE

INJECTION

MODE

PRESSURE

ACTIVATE

MIX CYCLE

SAFE TO RUN

ACTIVATE

MOTOR

MAIN AIR CYLINDER

FLOW CONTROL

INJECTION ROD FLOW

CONTROL

Figure 14.0 Flow Control

18

10. TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

CORRECTION

Unit fails to start

•No power input

•Emergency button is

pressed

•Safety door is not

fully closed

•Check power

connections

•Release Emergency stop

button

•Close safety door

LCD does not light

•No power input

•Check power

connections

•Check Fuse

•Turn on power

Air Cylinder does not

move

•Insufficient air

pressure

•Air hoses not

plugged in

•Regulator defective

•Increase air pressure to

80 psi (5.5 bar)

•Check air connection

•Replace regulator

The hardener is not

completely injected

•Air cylinder is

damaged

•Replace air cylinder

The injection rod does

not retract

•Injection rod is dirty

•Injection rod is bent

•Clean rod

•Replace rod

Material is not

completely mixed

•Not enough mixing

cycle

•Insufficient air

pressure

•Increase number of

cycles

•Increase air pressure to

80 psi

Cartridge holder is not

in “Home’‘ position

•Insufficient air

pressure

•Air hoses not

plugged in

•Increase supply pressure

to 80 psi (5.5 bar)

•Check air connection

Mixing rod does not

reach spindle

•Extension spindle is

not installed for 6''

rod

•Mixing rod in not

fully extended

•Install extension spindle

for 6'' rod

•Extend mixing rod

No pressure on plunger

•Plunger air hose is

not connected

•Connect plunger air hose

Plunger disk does not

fit inside cartridge

•Wrong plunger disk

size

•Use correct plunger disk

size

Cartridge holder

remains in the down

position during mixing

cycle

•Sensor and magnet is

not aligned

•Turn off unit and adjust

sensor / magnet

alignment

Motor is not running

•No power to motor

•Motor burned out

•Check motor connection

•Replace motor

19

11. PROGRAM SELECTION

Up to 10 programs can be stored in the the TS6500 Mixer.

1. Press the Set button (Fig. 4.0) to highlight the program number selection.

2. Press the (+) or (-) buttons to select desired program.

3. Press the Set button to exit.

12. CYCLE COUNTER RESET

The cycle counter can record up to 99999 mix cycles. To reset the cycle counter

follow the below instructions:

1. Press and hold Setup button for 3 seconds to enter setup mode.

2. Once the setup mode is displayed, press and hold Setup button again until

the cycle counter resets to “00000”.

13. CARTRIDGE HOLDER INSTALLATION

Refer to Fig. 15.0 and 16.0

The TS6500CIM-6 is setup to mix the 6.0oz. (160ml) kit. To mix the 2.5oz (60ml)

or 8.0oz. (220ml) kit the cartridge holder needs to be re-installed at the correct

mounting locations as shown in Fig. 15.

Figure 15.0 Mounting Location

MOUNTING LOCATION

2.5oz (60ml) KIT

MOUNTING LOCATION

6.0oz (160ml) KIT

MOUNTING LOCATION

8.0oz (220ml) KIT

20

The cartridge holder can be installed in a few simple steps:

1. Pull the release knob and push the fluid level sensor assembly to the left.

2. Loosen the locking screw by turning it counter clockwise.

3. Rotate the cartridge holder outward and pull it up to remove from the

machine.

4. Install new cartridge holder in the reverse order.

5. Pull release knob to rotate fluid level sensor assembly back into position.

Figure 16.0 Cartridge Holder

RELEASE KNOB

FLUID LEVEL

SENSOR

CARTRIDGE HOLDER

LOCKING SCREW

Table of contents

Languages:

Other TECHCON SYSTEMS Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Basic American

Basic American Slide-W-I-D-E ZZ98674 Supplemental service manual

Medelco

Medelco OmniPlinth user manual

SPIRIVA

SPIRIVA Respimat re-usable Instructions for use

Instramed

Instramed EazyPro quick start guide

Enraf Nonius

Enraf Nonius TENSMED S82 Instructions for use

ConvaTec USA

ConvaTec USA Natura Ostomy System How to use

Blackrock Microsystems

Blackrock Microsystems Cerebus NeuroPort Instructions for use

React Health

React Health BMC Luna II CPAP user manual

BROWNMED

BROWNMED Intellinetix Vibrating Knee/Elbow Wrap manual

Invacare

Invacare Platinum IRC5LXAW user manual

Sirona

Sirona CEREC AC BLUECAM operating instructions

Satelec

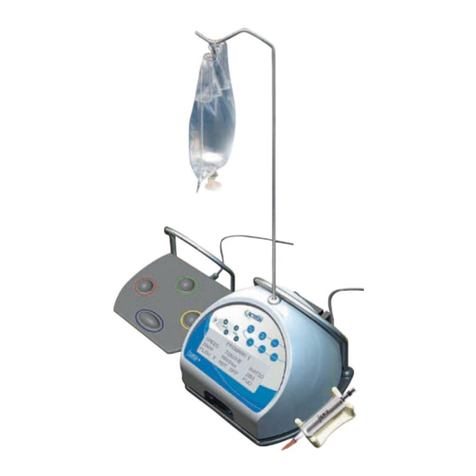

Satelec ACteon i-Surge+ user manual