TECHCON SYSTEMS Micro-Meter Mix TS8200D Series User manual

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

______________________________________________________________________

______________________________________________________________________

1. INSTALLATION

Required tools: 8 mm (5/16”) wrench; 3.0 mm hex wrench; 2.5 mm hex wrench;

2.0 mm hex wrench

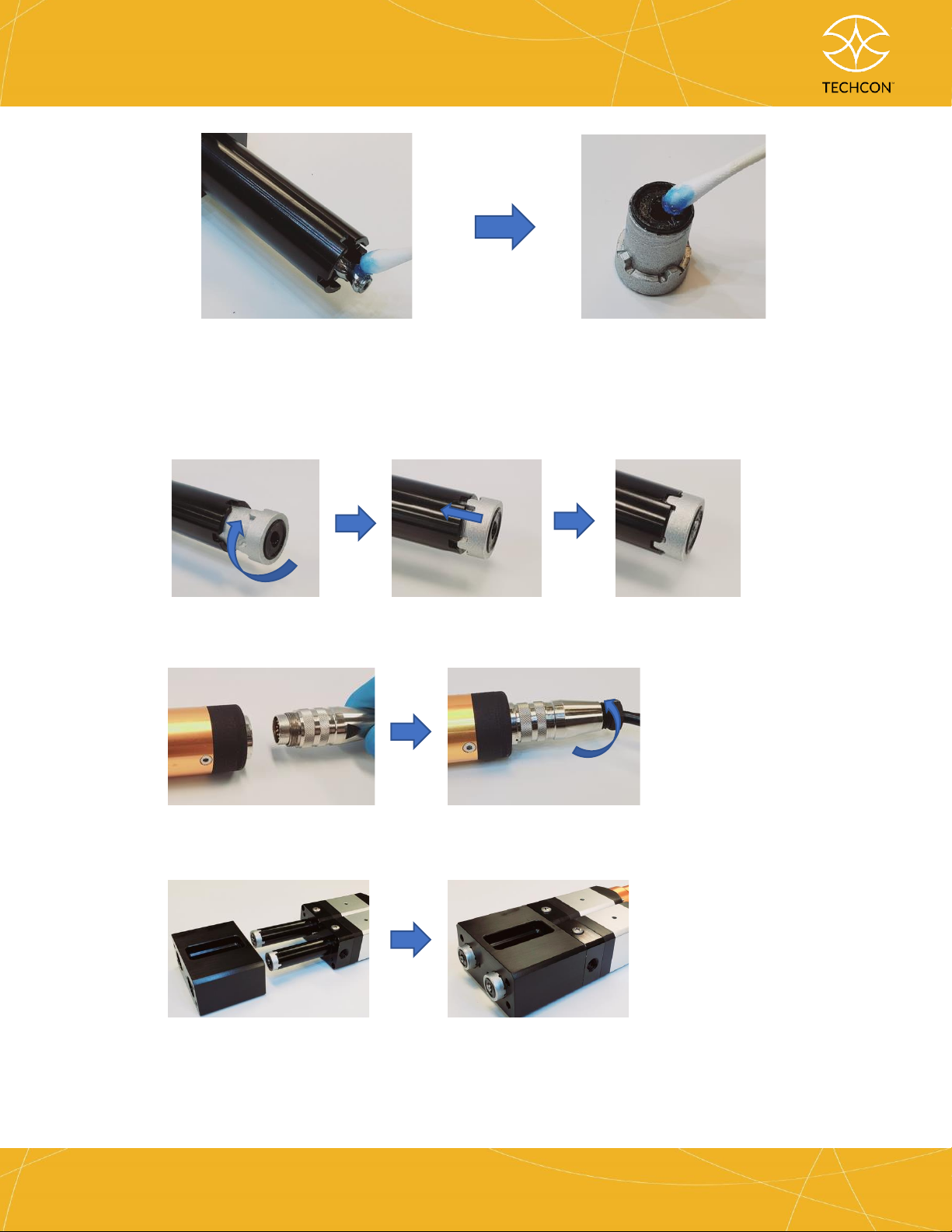

Warning! Do not dry-assemble the rotor and stator. Excessive friction between dry

components may damage stators and effect pump performance.

a. Apply the dispensing fluid or any appropriate lubricant compatible with the

dispensing fluid to the surface of the rotor.

TS8200D Series Micro-Meter Mix

True volumetric measuring, mixing, and dispensing

of 2-component materials

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

b. Screw the stator onto the rotor in a clockwise direction, align the four tabs of the

stator with the four notches of the stator housing, and push in the stator to lock it

into place with the stator housing.

c. Plug and thread in the motor cables.

d. Insert pump assemblies into the pump housing.

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

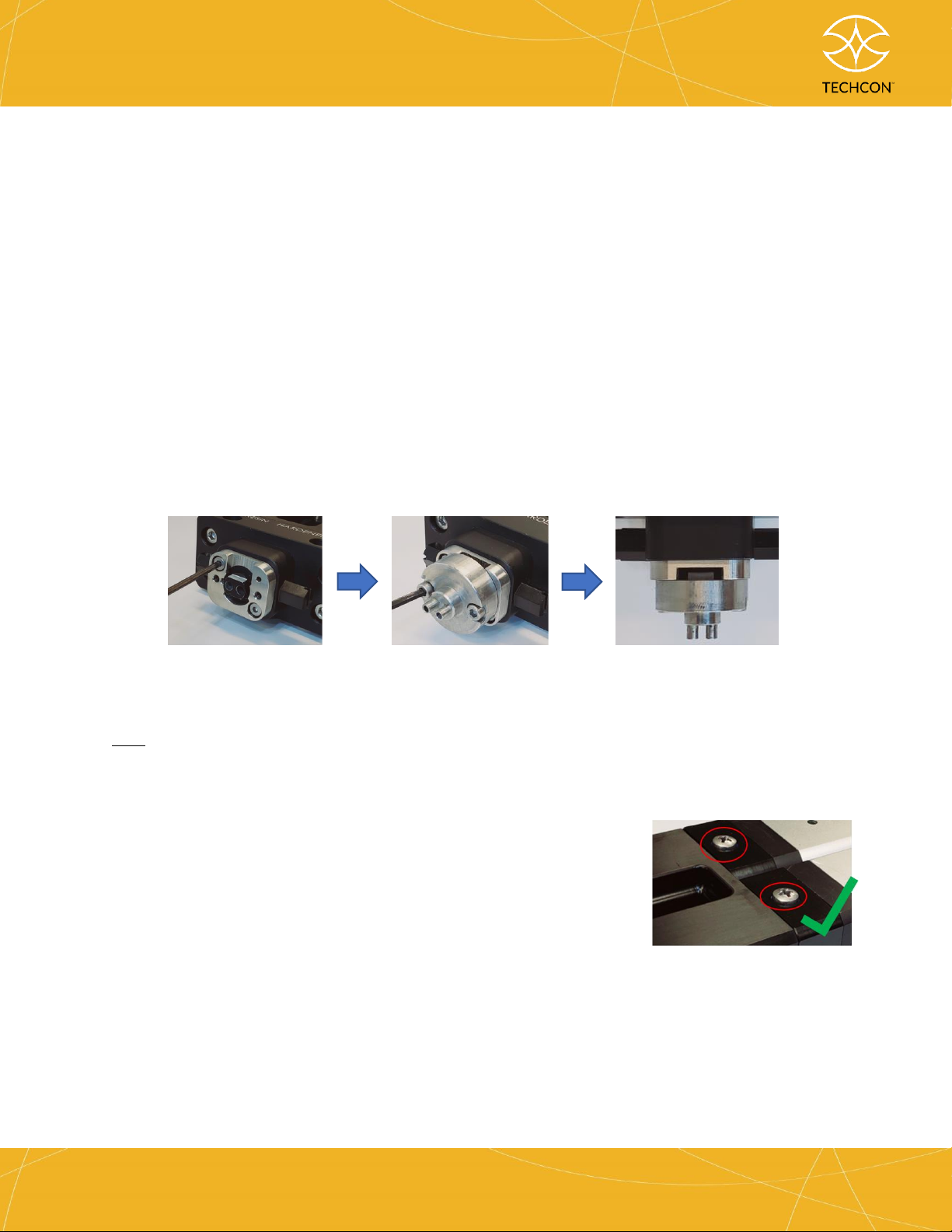

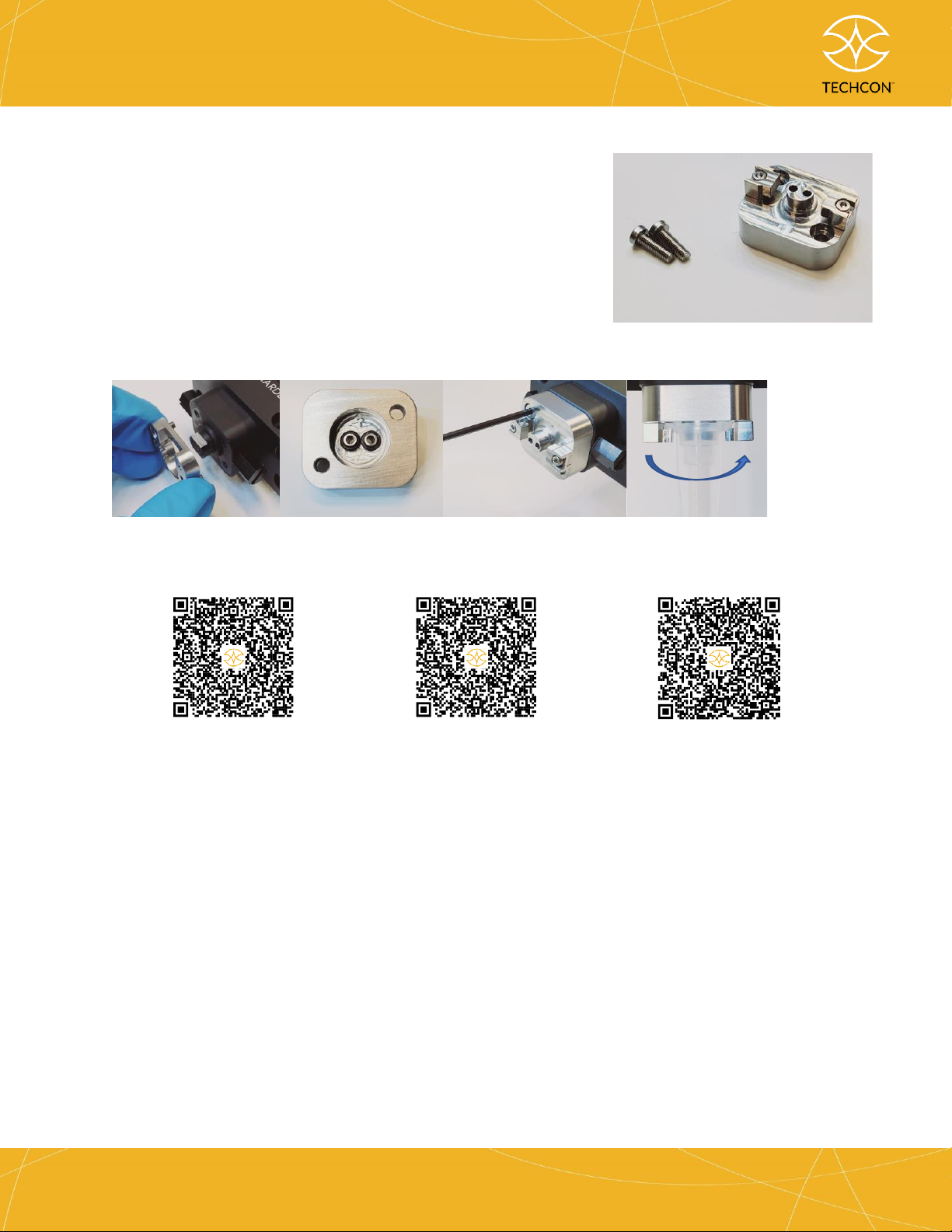

e. Make sure that the high-pressure seals sit and fit properly along the groove

located inside the manifold.

f. Align the manifold with the now-assembled pump and pump housing. The

engraved labels “RESIN” and “HARDENER” should be facing you. Insert and

fasten four 3.0 mm hex screws with lock washers in the order shown in the image

below. Make sure the two now-assembled pumps are vertically symmetrical and

not flaring outwards. Make sure there are no gaps or any visible

light between pump housing and mating parts. If there are issues,

relieve tension on the screws and tighten evenly.

g. Install fluid inlet fittings. There are several different fluid inlet fittings available.

The fluid inlet fitting required will depend on the fluid reservoir option you select.

In the picture below, we use 1/8”NPT x luer lock elbow. Reference the

“Accessories” section for information on fluid inlet fittings. It is recommended that

Teflon tape be applied to the thread of the fluid inlet fitting prior to installation.

1

2

3

4

2

3

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

h. Install calibration adaptor. The calibration adaptor is required whenever

calibration is performed, when a new fluid is introduced, when the valve is

disassembled & reassembled, or when the stators or rotors are changed.

Connecting calibration adaptor can protect the TS8200D from having direct

contact with the material as it exits the pump.

i. Mount the 1:1/2:1 K-type Nozzle Locking Plate and use a 2.0 mm hex wrench to

fasten screws into place.

i. Mount the calibration adaptor and use a 2.5 mm hex wrench to fasten screws

into place.

ii. Make sure that the calibration adaptor rest evenly against the nozzle locking

plate.

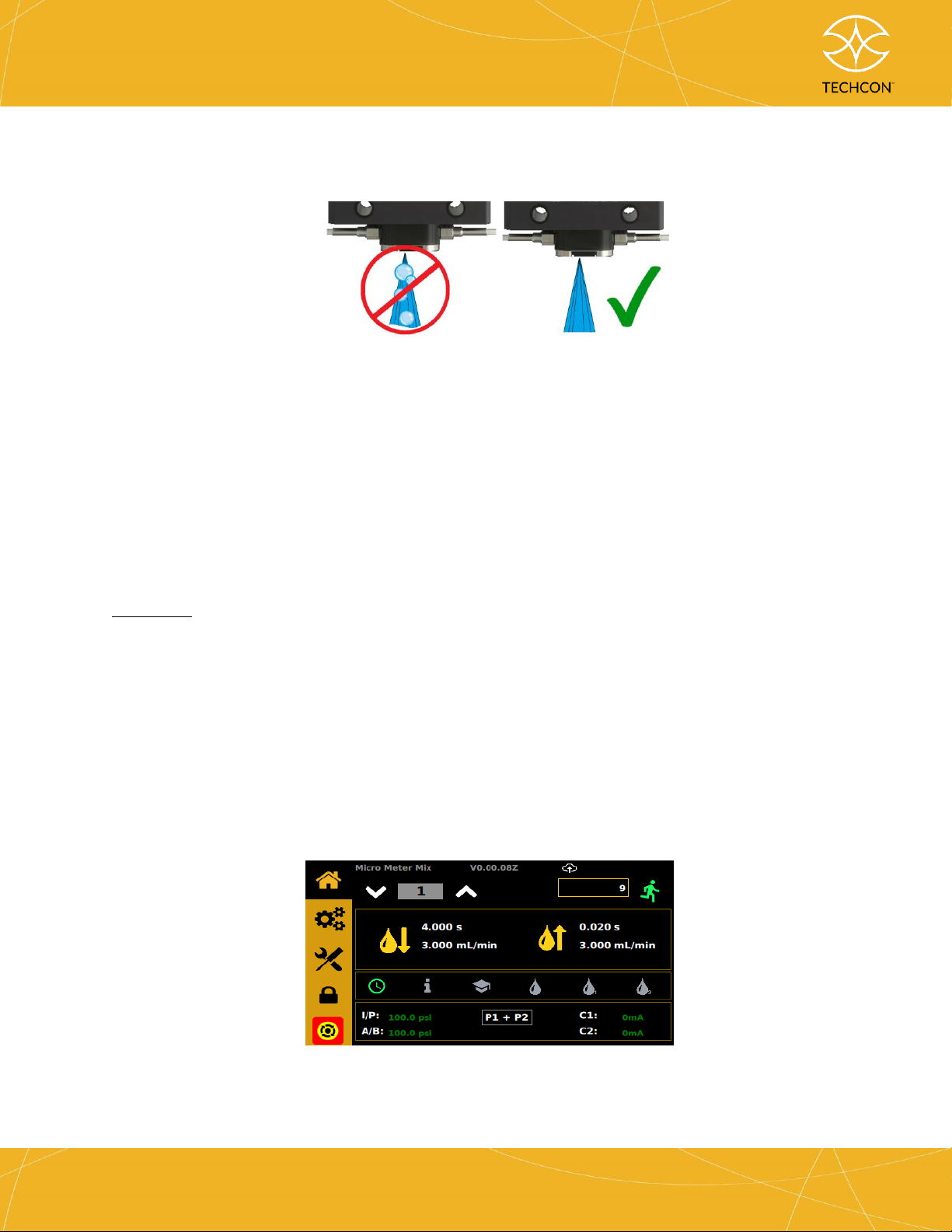

2. DISPENSING

Tip: Avoid over-tightening vent screws. Over-tightening may lead to tears to the

vent seal O-ring.

a. Connect the fluid supply to the fluid inlet of the pump. If

using a fluid reservoir, reference the “Accessories”

Section for information on compatible fluid lines. Make

sure the resin is connected to the pump with the “RESIN”

label and the hardener is connected to the pump with the

“HARDENER” label.

b. Connect the pump to the controller.

4

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

1. Air Filter, 2. Pump, 3. Pressure Tank, 4. Pressure Tank

2.1 Venting and Purging the Pumps

Venting and purging the pumps is recommended before placing them into

operation. Failure to vent and purge during the initial setup may lead to dispensing

issues.

Set the fluid pressure to around 0.3 bar (5 psi). The fluid pressure will depend on the

viscosity of the material. Increase fluid pressure if needed.

A. Purging and Venting “RESIN” – Pump 1

To purge the resin though the manifold:

1. Navigate to the Home page.

2. Unlock the unit by clicking lock icon. Default password = 0000.

3. Select the Purge Pump 1 icon.

4. Press the foot switch.

Using Fluid Reservoir

Using Syringes

5

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

5. Allow the fluid to flow from the manifold until a steady stream of air-free

material is observed.

6. Release the foot switch.

7. We are now done purging Pump 1.

To vent the resin:

8. Using a Phillips head screwdriver, loosen the front vent screw by turning it in

the counterclockwise direction. Loosen screw in one-revolution increments.

At around the 6th –7th revolution, you should begin to see material seep out.

Allow material to escape until no more air bubbles are observed.

Warning: Do not loosen to more than eight (8) complete revolutions. Doing so will

unfasten the screw allowing pressurized material to spray out.

9. Fasten the venting screw. Avoid over tightening the screw. Over tightening

may lead to tearing of the vent seal O-ring.

B. Purging and Venting “HARDENER” – Pump 2

To purge the hardener though the manifold:

1. Navigate to the Home page.

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

2. Unlock the unit by clicking lock icon. Default password = 0000

3. Select the Purge Pump 2 icon.

4. Press the foot switch.

5. Allow the fluid to flow from the manifold until a steady stream of air-free

material is observed.

6. Release the foot switch.

7. We are now done purging Pump 2.

To vent the hardener:

8. Have a cleaning towel or container under the pump ready to

catch material.

9. Using a Phillips head screwdriver loosen front vent screw by turning in the

counterclockwise direction. Loosen screw in 1 revolution increments. At

around the 6th –7th revolution you should begin to see material seep out. Allow

material to escape until no more air bubbles

are observed.

Warning: Do not turn more than eight (8) complete revolutions. Doing so will

unfasten the screw allowing pressurized material to spray out.

10. Fasten the venting screw. Avoid over tightening the screw. Over tightening

may lead to tearing of the vent seal O-ring.

6

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

2.2 Calibrating the Pumps

The TS8200D Micro-Meter Mix needs to be calibrated before operation. Go to the

TS580D Controller User Guide for calibration instructions. Return here once

calibration has been completed.

3. DETERMINING CONTROLLER SETTINGS AND FINAL SET-UP

To determine and enter the correct settings and ratio for Resin (Pump 1) and

Hardener (Pump 2), please refer to TS580D Controller User Guide for

instructions on setting up the forward run settings, reverse run settings, ratio

settings, and dispense mode settings.

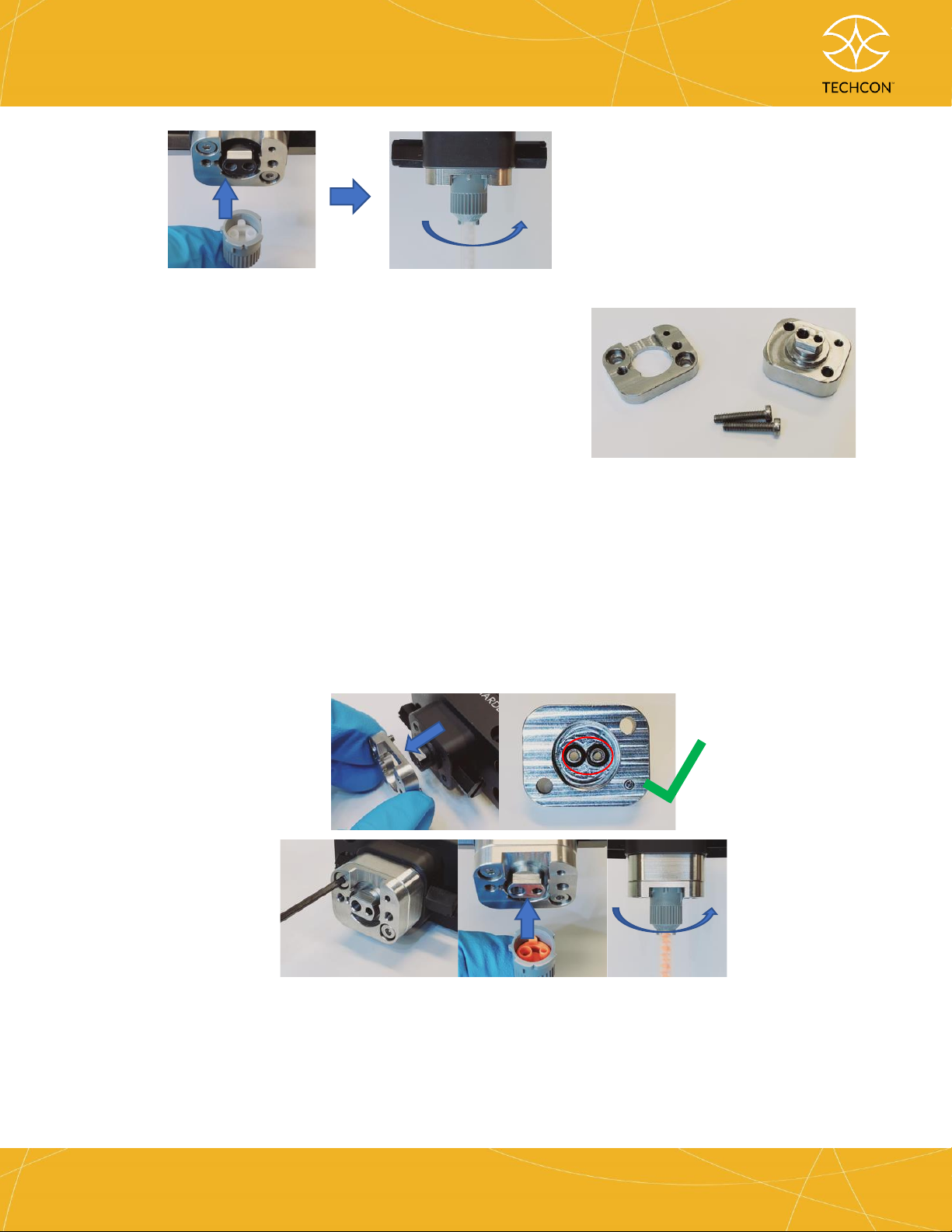

a. Remove calibration adapter.

b. Install dispense adaptor required for

corresponding static mixing nozzle.

For using 1:1/2:1 bayonet socket type

The static mixing nozzle can be mounted directly onto the pump using the

already installed 1:1/2:1 K-type nozzle locking plate.

c. Align the holes and rotating cap of the mixing nozzle with the holes of the

fluid manifold and “keyed” entry of the base plate adaptor.

d. Insert the nozzle and make sure it rests evenly with the base of the fluid

manifold. Lock into place by rotating the mixing nozzle’s rotating cap

counterclockwise.

e. Pull on the nozzle to confirm it is securely locked into place.

7

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

If using a 4:1/10:1 bayonet socket type

a. Remove bayonet socket base plate adapter.

b. Confirm 4:1/10:1 base plate adapter has x2 O-

ring seals.

c. Mount 4:1/10:1 base plate adapter followed by

the bayonet socket base plate adapter.

d. Align the holes and rotating cap of the mixing nozzle with the holes of the

fluid manifold and “keyed” entry of the base plate adaptor.

e. Insert the nozzle and make sure it rests evenly with the base of the fluid

manifold. Lock into place by rotating the mixing nozzle’s rotating cap

counterclockwise.

f. Pull on the nozzle to confirm it is securely locked into place.

8

TS8200D Series

Micro-Meter Mix Quick Start Guide

techcon.com/contact-us

If using a bayonet mixing nozzle:

a. Remove bayonet socket base plate adapter.

a. Confirm that the bayonet base plate contains x2

O-rings.

b. Install bayonet base plate adaptor.

c. Twist and lock.

d. Pull on the nozzle to confirm it is securely locked

into place.

The pump is now ready for use.

For complete information on the TS8200D Micro-Meter Mix System:

Micro-Meter Mix

User Guide

Micro-Meter Mix

Data Sheet

TS580D-MM Controller

User Guide

9

Other TECHCON SYSTEMS Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Halyard

Halyard FLUIDSHIELD 3 N95 Directions for use

Lifelines

Lifelines trackit T4 user manual

Benchmark Scientific

Benchmark Scientific MyGel E1201-E operating manual

ZOLL

ZOLL Propaq M Operator's guide

Terumo

Terumo Pinnacle Precision Access System Series Instructions for use

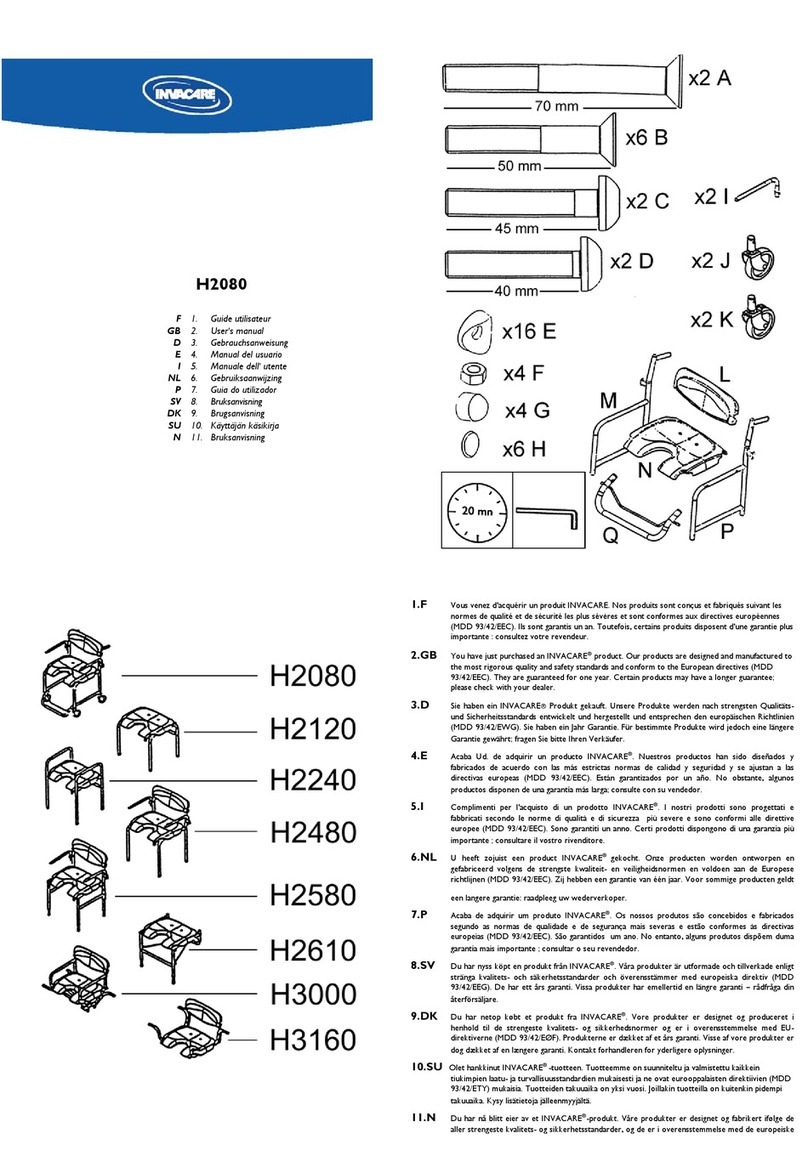

Invacare

Invacare H2080 quick guide

Olympus

Olympus OLYMPUS BF TYPE 160 Operation manual

Integra

Integra CUSA Clarity Cleaning Instruction Guide

Graham Field

Graham Field Hausted 6200 Series Assembly and operation instructions

Bestcare

Bestcare BestLift Luna Technical Service

ORTHOSERVICE RO+TEN

ORTHOSERVICE RO+TEN fixalker quick start guide

Dermlite

Dermlite DL4 instructions