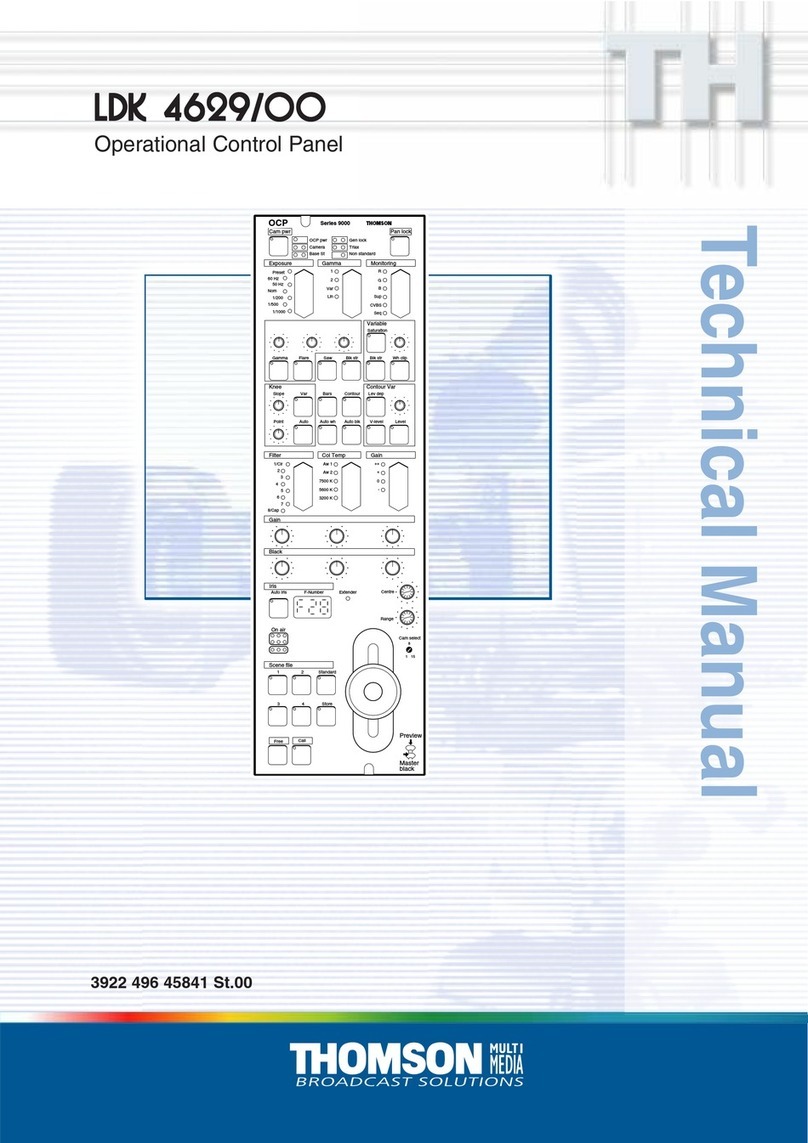

Technicolor - Thomson LDK 4628/01 User manual

LDK 4628/01LDK 4628/01

LDK 4628/01LDK 4628/01

LDK 4628/01

Operational Control Panel

Technical Manual

3922 496 48361 St.00

M black

Col Temp Gain

1/Clr

2

3

4

5

6

7

8/Cap

Aw 1

Aw 2

7500 K

5600 K

3200 K

++

+

0

-

Filter

Gain

Black

Scene file

1 2 3 Standard Store

On air

Auto iris F-Number Extender Cam select

4

115

8

Iris

Free

Call

Preview

Centre Range

Series 9000OCP

Cam pwr

Pan lock

OCP pwr

Camera

Base St

Gen lock

Triax

Non standard

Exposure Gamma Monitoring

1

2

Var

Lin

Variable

R

G

B

Sup

CVBS

Seq

Saturation

Wh clipBlk strBlk strSawGamma Flare

Contour Var

V-level Level

Lev depVar Bars Contour

Auto Auto wh Auto blkPoint

Slope

Knee

Preset

60 Hz

50 Hz

Nom

1/200

1/500

1/1000

Für diese Unterlage behalten wir uns

alle Rechte vor (Gemäß DIN 34).

Technische Änderungen im Zuge der

Weiterentwicklung vorbehalten.

Copyright

FCC Class A Statement

Declaration of Conformity

Copying of this document and giving

it to others, and the use or com-

munication of the contents thereof,

are forbidden without express au-

thority. Offenders are liable to the

payment of damages. All rights are

reserved in the event of the grant of

a patent or the registration of a utility

model or design. Liable to technical

alterations in the course of further

development.

Toute communication ou reproduc-

tion de ce document, toute ex-

ploitation ou communication de son

contenu sont interdites, sauf au-

torisation expresse. Tout man-

quement à cette règle est illicite et

expose son auteur au versement de

dommages et intérêts. Tous nos

droits sont réservés pour le cas de la

délivrance d'un modèle d'utilité. Sous

réserve de modification au cours de

l'évolution technique.

© Thomson Multimedia Broadcast Solutions 2002

We, Thomson Broadcast Solutions Nederland B.V., Kapittelweg 10, 4827 HG Breda, The Netherlands declare under

our sole responsibility that this product is in compliance with the following standards:

EN60065

EN55103-1

EN55103-2

following the provisions of:

a. the Safety Directives 73/23//EEC and 93/68/EEC

b. the EMC Directives 89/336/EEC and 93/68/EEC

: Safety

: EMC (Emission)

: EMC (Immunity)

This product generates, uses, and can radiate radio frequency energy and if not installed and used in accordance with

the instructions, may cause interference to radio communications.

It has been tested and found to comply with the limits for a class A computing device pursuant to Subpart J of part 15

of FCC rules, which are designed to provide reasonable protection against such interference when operated in a com-

mercial environment.

Operation of this product in a residential area is likely to cause interference in which case the user at his own expense

will be required to take whatever measures may be required to correct the interference.

02.33.2 Technical Manual LDK 4628 - Operational Control Panel 1

LDK 4628/01

Operational Control Panel

Technical Manual

Contents

Safety Summary ........................................................... 2

Cautions and Warnings ................................................ 2

Earthing ........................................................................ 3

Packing/Unpacking ...................................................... 4

Opening the Operational Control Panel ...................... 5

Mounting in a Desk ....................................................... 6

Mounting in a 19 inch Rack .......................................... 8

Internally Selectable Functions .................................. 10

Replacing the fuses .................................................... 11

Interconnections ......................................................... 12

Two-wire Data Control Bus ........................................ 14

Connectors and Cables ............................................. 15

Dimensions................................................................. 17

2Technical Manual LDK 4628 - Operational Control Panel 02.33.2

Safety Summary

This informaton is intended as a guide for trained and

qualified personnel who are aware of the dangers involved

in handling potentially hazardous electrical/electronic

equipment. It is not intended to contain a complete list of

all safety precautions which should be observed by

personnel in using this or other electronic equipment.

Theinstallation, maintenance andserviceofthis equipment

involves risks both to personnel and equipment and must

be performed only by qualified personnel exercising due

care.

Personnel engaged in the installation, operation,

maintenance or servicing of this equipment are urged to

become familiar with First Aid theory and practises.

During installation and operation of this equipment, local

building safety and fire protection standards must be

observed.

Before connecting the equipment to the power supply of

the installation, the proper functioning of the protective

earth lead of the installation needs to be verified.

Whenever it is likely that safe operation is impaired, the

apparatus must be made inoperative and secured against

any unintended operation. The appropriate servicing

authority must then be informed. For example, safety is

likely to be impaired if the apparatus fails to perform the

intended function or shows visible damage.

This product has been designed and tested according to

EN60065.

Cautions and Warnings

When performing service, be sure to read and comply with

the warning and caution notices appearing in the manuals.

Warnings indicate danger that requires correct procedures

orpracticesto prevent deathorinjurytopersonnel.Cautions

indicate procedures or practices that should be followed

to prevent damage or destruction to equipment or property.

WARNING

THE CURRENT AND VOLTAGES PRESENT IN THIS

EQUIPMENT ARE DANGEROUS. ALL PERSONNEL

MUST AT ALL TIMES FOLLOW THE SAFETY

REGULATIONS.

ALWAYS DISCONNECT POWER BEFORE REMOVING

COVERS OR PANELS.

ALWAYS DISCHARGE HIGH VOLTAGE POINTS

BEFORE SERVICING.

NEVER MAKE INTERNAL ADJUSTMENTS, PERFORM

MAINTENANCE OR SERVICE WHEN ALONE OR WHEN

FATIGUED.

IN CASE OF AN EMERGENCY ENSURE THAT THE

POWER IS DISCONNECTED.

ANY INTERRUPTION OF THE PROTECTION

CONDUCTOR INSIDE OR OUTSIDE THE APPARATUS,

OR DISCONNECTION OF THE PROTECTIVE EARTH

TERMINAL, IS LIKELY TO MAKE THE APPARATUS

DANGEROUS. INTENTIONAL INTERRUPTION IS

PROHIBITED.

FOR SAFETY REASONS THE CPU MUST BE MOUNTED

IN A 19-inch RACK WHICH HAS SAFETY COVERS

ACCORDING TO IEC65.

WHEN TWO CPUs ARE MOUNTED ABOVE EACH

OTHER THE MINIMUM DISTANCE BETWEEN THEM

MUST BE 50MM OR THE RACK MUST BE FORCE-AIR

COOLED.

USE ONLY FUSES OF THE TYPE AND RATING

SPECIFIED.

CAUTION

To prevent risk of overheating, ventilate the product

correctly.

Connect the product only to a power source with the

specified voltage rating.

Only connect a Triax cable from the LDK 6 camera

family to an LDK 6 CPU. Never connect it to any other

base station.

Never connect the Triax cable from a camera to a

CPU of a different family; never connect the LDK

family to the TTV family.

Do not allow system ground currents to exceed 1.5A

in the outer shield of the triax cable or 0.2A in other

cable shields.

It is strickly prohibited to short circuit the inner and

outer shields of a triax cable used to connect a

camera to a base station.

02.33.2 Technical Manual LDK 4628 - Operational Control Panel 3

Symbol Colour Explanation

Red High voltage terminal at which a

voltage, with respect to an other

terminal, exists or may be

adjusted to 1000V or more.

Yellow/Black Live part.

Yellow/Black This marking indicates that the

operator must refer to an

explanation in the Instruction

Manual, or that a specific

component must be replaced by

the component specified in the

documentation for safety

reasons.

White/Black Protective earth (ground)

terminal.

Cathode ray tubes

Components marked on the circuit diagram are critical

for safety and include those specified to comply with X-ray

emission standards for units using cathode ray tubes and

those specified for compliance with various regulations

regarding spurious radiation emission.

When servicing units that use cathode ray tubes (CRTs),

the cathode ray tubes themselves, the high voltage circuits

and related circuits are specifically chosen so that they

complywith recognized codespertainingtoX-ray emission.

Consequently, when servicing, replace the cathode ray

tubes and other parts with specified parts only. Do not

attempt to modify these circuits as any unauthorized

modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

Handlethecathoderay tube only whenwearingshatterproof

goggles and after discharging the high voltage completely.

Earthing

The rear of a CPU has two separate screw terminals for

protective earth (PE) and video earth (VE).

These are normally connected by a metal strap. The

protective earth terminal is internally connected to the

protective earth conductor of the power cable. If required,

the central earth connection wire of the studio can be

connected to terminal PE.

In normal circumstances the connection between the

protective earth and the video earth should not be broken.

The metal strap may be removed only if the studio (or OB

van) is equipped with separate protective and video earth

systems. Under these circumstances the video earth

terminal must be connected to the central functional earth

potential (video earth) of the studio. This earth potential

should have functional protective and noiseless earth

(FPE) qualities as stated in the VDE regulation 0800/part2.

A low impedance interconnection of both earth conductors

must be provided at the central studio earthing point.

WARNING

THE UNIT MUST ALWAYS BE CONNECTED TO

PROTECTIVE EARTH.

VE

PE

Metal

strap

Mains Lead Wiring for UK Users

The wires in the mains lead are coloured in accordance

with the following code:

GREEN AND YELLOW - EARTH

BLUE - NEUTRAL

BROWN - LIVE

As the colours of the wires in the mains lead of this

apparatus may not correspond with the coloured markings

identifying the terminals in your plug proceed as follows:

• The wire coloured GREEN AND YELLOW must be

connected to the terminal on the plug marked with the

letter E or by the safety earth symbol or coloured

GREEN or GREEN AND YELLOW.

• The wire coloured BROWN must be connected to the

terminal marked with the letter L or coloured RED.

• The wire coloured BLUE must be connected to the

terminal marked with the letter N or coloured BLACK.

Ensure that your equipment is connected correctly - if you

are in any doubt consult a qualified electrician.

4Technical Manual LDK 4628 - Operational Control Panel 02.33.2

Packing/Unpacking

Inspectthe shippingcontainerforevidenceof damage

immediately after receipt. If the shipping container or

cushioningmaterial isdamaged, itshould bekept until

the contents of the shipment have been checked for

completeness and the camera has been checked

mechanically and electrically.

The shipping container should be placed upright and

openedfrom thetop. Removethe cushioningmaterial

and lift out the contents.

The contents of the shipment should be checked

againstthe packinglist. Ifthe contentsareincomplete,

if there is mechanical damage or defect, or if the

camera does not perform correctly when unpacked,

notifyyourThomson Multimedia BroadcastSolutions

sales or service centre within eight days. If the

shipping container shows signs of damage or stress,

notify the carrier as well.

Transport

If the unit is being returned to Thomson Multimedia

Broadcast Solutions for servicing, try to use the

containers and materials of the original packaging.

Attach a tag indicating the type of service required,

returnaddress,model number,full serial numberand

the return number which will be supplied by your

Thomson Multimedia Broadcast Solutions service

centre.

If the original packing can no longer be used, the

following general instructions should be used for

repacking with commercially available materials:

a. Wrap unit in heavy paper or plastic.

b. Use strong shipping container.

c. Use alayer ofshock-absorbing materialaround all

sidesof theunit toprovide firmcushioning andpre-

vent movement inside container.

d. Seal shipping container securely.

e. Markshipping containerFRAGILEtoensurecare-

fulhandling.

Storage

The unit may be stored (non-operating condition) in

environments within the following limits:

Temperature: -20 to +50 degrees C

Humidity: up to 90%

Altitude: 50,000 feet

When stored, the unit should be protected from

temperatureextremeswhichmaycausecondensation,

and should also be protected from high levels of dust.

02.33.2 Technical Manual LDK 4628 - Operational Control Panel 5

Opening the Operational Control Panel

6Technical Manual LDK 4628 - Operational Control Panel 02.33.2

Mounting in a Desk

5.510

100

61

40

23 7

Series 9000 THOMSONOCP

OCP pwr

Camera

Base St

Gen lock

Triax

Non standard

Cam pwr

Pan lock

1

2

Var

Lin

R

G

B

Sup

CVBS

Seq

Preset

60 Hz

50 Hz

Nom

1/200

1/500

1/1000

Exposure Gamma Monitoring

Variable

Saturation

Wh clipBlk strBlk strSawGamma Flare

Contour Var

V-level Level

Lev depVar Bars Contour

Auto Auto wh Auto blk

Point

Slope

Knee

1/Clr

2

3

4

5

6

7

8/Cap

Aw 1

Aw 2

7500 K

5600 K

3200 K

++

+

0

-

Gain

Black

Scene file

1 2 3 Standard Store

On air

Auto iris F-Number Extender Cam select

4

115

M black Iris

8

Free

Call

Preview Centre Range

Col Temp GainFilter

Hole in desk required: 350.7 mm x 106.3 mm.

1. Remove upper panel by loosening screws and

disconnecting the flat cable.

2. Remove mounting plates by loosening the two

screws securing each plate.

Mounting Plate

Mounting

Plate

Mounting Plate

02.33.2 Technical Manual LDK 4628 - Operational Control Panel 7

Series 9000 THOMSONOCP

OCP pwr

Camera

Base St

Gen lock

Triax

Non standard

Cam pwr

Pan lock

1

2

Var

Lin

R

G

B

Sup

CVBS

Seq

Preset

60 Hz

50 Hz

Nom

1/200

1/500

1/1000

Exposure Gamma Monitoring

Variable

Saturation

Wh clipBlk strBlk strSawGamma Flare

Contour Var

V-level Level

Lev depVar Bars Contour

Auto Auto wh Auto blk

Point

Slope

Knee

1/Clr

2

3

4

5

6

7

8/Cap

Aw 1

Aw 2

7500 K

5600 K

3200 K

++

+

0

-

Gain

Black

Scene file

1 2 3 Standard Store

On air

Auto iris F-Number Extender Cam select

4

115

M black Iris

8

Free

Call

Preview Centre Range

Col Temp GainFilter

350.7

5

Mounting Plates

3. Usetwo screwsto attachthe mountingplatestothe

sides of the hole.

If desk height is less than 20 mm use two angled

profiles to mount plates

4. Secure operational control box to mounting plates

and return upper panel to its original position.

350.7

5

Angled

Profile

Angled

Profile

8Technical Manual LDK 4628 - Operational Control Panel 02.33.2

5.510

100

61

40

23 7

Series 9000 THOMSONOCP

OCP pwr

Camera

Base St

Gen lock

Triax

Non standard

Cam pwr

Pan lock

1

2

Var

Lin

R

G

B

Sup

CVBS

Seq

Preset

60 Hz

50 Hz

Nom

1/200

1/500

1/1000

Exposure Gamma Monitoring

Variable

Saturation

Wh clipBlk strBlk strSawGamma Flare

Contour Var

V-level Level

Lev depVar Bars Contour

Auto Auto wh Auto blk

Point

Slope

Knee

1/Clr

2

3

4

5

6

7

8/Cap

Aw 1

Aw 2

7500 K

5600 K

3200 K

++

+

0

-

Gain

Black

Scene file

1 2 3 Standard Store

On air

Auto iris F-Number Extender Cam select

4

115

M black Iris

8

Free

Call

Preview Centre Range

Col Temp GainFilter

Mounting Plate

Mounting Plate

Mounting in a 19 inch Rack

1. Remove upper panel by loosening screws and

disconnecting the flat cable.

2. Remove mounting plates by loosening the two

screws securing each plate. The mounting plates

are not needed for rack mounting.

02.33.2 Technical Manual LDK 4628 - Operational Control Panel 9

Series 9000 THOMSONOCP

OCP pwr

Camera

Base St

Gen lock

Triax

Non standard

Cam pwr

Pan lock

1

2

Var

Lin

R

G

B

Sup

CVBS

Seq

Preset

60 Hz

50 Hz

Nom

1/200

1/500

1/1000

Exposure Gamma Monitoring

Variable

Saturation

Wh clipBlk strBlk strSawGamma Flare

Contour Var

V-level Level

Lev depVar Bars Contour

Auto Auto wh Auto blk

Point

Slope

Knee

1/Clr

2

3

4

5

6

7

8/Cap

Aw 1

Aw 2

7500 K

5600 K

3200 K

++

+

0

-

Gain

Black

Scene file

1 2 3 Standard Store

On air

Auto iris F-Number Extender Cam select

4

115

M black Iris

8

Free

Call

Preview Centre Range

Col Temp GainFilter

19" module rail

with mounting

strip

19" module rail

with mounting

strip

3. Use four screws to mount operational control into

the rack using a 19" module rail with mounting

strip.

4. Secure operational control box to 19" rack and

return upper panel to its original position.

10 Technical Manual LDK 4628 - Operational Control Panel 02.33.2

Internally Selectable Functions

Call Buzzer

The call buzzer can be disabled by repositioning a

jumperwhich islocated onthe sideofthecontrolpanel

printed circuit board.

This jumper, S100, has two positions:

AB: Buzzer Off

AC: Buzzer On

The operational control panel is normally delivered

with the jumper S100 in position AC - buzzer on.

LED Intensity

Thereare threeLEDintensitypotmeterson thecontrol

panel:

- R25 for LED intensity general,

- R101 for LED intensity On Air Yellow,

- R100 for LED intensity On Air Red.

Button Click

The button click can be regulated by repositioning

jumper S2. This jumper, S2, has two positions:

AB: Button click On

AC: Button click Off

The jumper, S2, is located on the left side of the board

lookingat itfromthe switchpanelside.Theoperational

control panel is normally delivered with the jumper in

position AB.

Watchdog

Thefunction WatchdogOn/Offcan beselected bythe

jumper S1 on the Data Subboard.

This jumper, S1, has two positions:

AB: WatchdogOn

AC: Watchdog Off

The Data Subboard is normally delivered with the

jumper S1 in position AB (=Watchdog On).

User Jumpers

With Jumper S4 you can choose between Complete

Panel Lock or beneath Gain Field no Panel Lock.

This Jumper, S4, has two positions:

AB: Complete Panel Lock

AC: Beneath Gain Field no Panel Lock

The Data Board is normally delivered with the jumper

S4 in position AB (=Complete Panel Lock).

Jumpers S5 through S7 have no function assigned.

Theyshould bealways inposition AB.ThejumpersS8

through S11 form the OCP internal address number

when the OCP is used in multiple control mode. For

correct settings of these jumpers see the Series 9000

ApplicationGuide.

Dip Switches

The Dip Switches S2 and S3 have factory settings.

Never change these settings.For correct settings of

these dip switches see the Series 9000 Application

Guide.

TICKER

ON OFF

ON

OFF

LED intensity ONAIR RED

LED intensity ONAIR YELLOW

LED intensity general

BUTTON CLICK

bit0

bit1

bit2

bit3

bit4

bit5

bit6

bit7

bit6

bit7

bit4

bit5

mp4

mp2 mp1

OFF ON

S11

S10

S9

S8

S7

S6.

S5.

S4

S1

S2

S3

Reset

button

Data Subboard

C

BA

S1

02.33.2 Technical Manual LDK 4628 - Operational Control Panel 11

Replacing the fuses

12 Technical Manual LDK 4628 - Operational Control Panel 02.33.2

Clear

ND1/4

ND1/16

ND1/64

Clear

Star4P

Star6P

SoftFocus

1

2

3

4

A

B

C

D

VTR

Save

Ext.

Iris

Std.

File

Smart

card

Power

on

Pwel

Tracker

Aux

Prod

Prog

Cam+Floor

Eng

Camera Base Station

LDK 6000HD

Triax Cable

Maximum

Length

1,000 m (3,300 ft)

with 14 mm cable

Base Station

LDK 4502

Data Cable

(2-wire)

Triax Cable

Maximum

Length

1,000 m (3,300 ft)

with 14 mm cable

Base Station

LDK 4502

Prod

Prog

Cam+Floor

Eng

Camera Base Station

THOMSON

POWER

21

DIGI

LDK 6000HD with LDK 4482 SuperXPander

LDK 20

Triax Cable

Maximum

Length

2,400 m (7,875 ft)

with 14 mm cable

Base Station

LDK 4501

LDK 200

Triax Cable

Maximum

Length

2,400 m (7,875 ft)

with 14 mm cable

LDK 23HS mkII (with LDK 4482 SuperXPander)

CABLETEST

AC

DC

CAMON

ONAIR

0

mains

Camera Processing Unit HS mkII

Triax Cable

Maximum

Length

800 m (2,625 ft)

with 14 mm cable

1000 m (3281 ft) with minor

performance degradation

Base Station

LDK 4501

CPU

LDK 4058 mkII

Clear

ND1/4

ND1/16

ND1/64

Clear

Star4P

Star6P

SoftFocus

1

2

3

4

A

B

C

D

VTR

Save

Ext.

Iris

Std.

File

Smart

card

Power

on

Pwel

Tracker

Aux

Prod

Prog

Cam+Floor

Eng

Camera Base Station

Prod

Prog

Cam+Floor

Eng

Camera Base Station

AWB

AWB

Bars

Bars

STDfile

STDfile

Gain

Gain

Filter

Filter

Data Cable

(2-wire)

Data Cable

(2-wire)

Data Cable

(2-wire)

THOMSON

THOMSON

THOMSON

THOMSON

HDTV

HDTV

Interconnections

02.33.2 Technical Manual LDK 4628 - Operational Control Panel 13

RS 232

PCI

PC

1 - 4

Remote Control Interface

RCI

Color Control

Panels 1 to 4

Mono Knob

Control Panels

1 to 4

Multicore Cable 25 p

Maximum Length

350 m (1,150 ft)

14

Multicore Cable 25 p

Maximum Length

350 m (1,150 ft)

Data Cable (2-wire)

Maximum total

Length

310 m (1,118 ft)

Operational Control Panels

MCP II

LDK4609

MCP

LDK 4607

AWB Bars STDfile

Gain Filter

Data Cable (2-wire) Data Cable (2-wire)

Data Cable (2-wire)

Data Cable (2-wire)

Note: A maximum of 15 looped-through standard

camera systems in one chain can be handeld,

however,in amultiplesystem theload ofa LDK

23 HS (mkII) is twice the load of a standard

camera.

This configuration is the multiple camera Triax mode.

The camera is connected to a CPU as in the single

camera Triax mode. The data bus is looped-through

from CPU to CPU's, Base Stations, OCP's and MCP.

The OCP's (Operational Control Panels) are used to

controlthecamerasandaMCP (masterControlPanel)

can also be connected to extend the control facilities.

The LDK 6000HD cameras are of course HDTV

cameras, however, SDTV cameras of the Thomson

Multimedia Broadcast Solutions family such as the

LDK 20, LDK 100, LDK200, and the LDK 23HS mkII

can also be included in this configuration.

14 Technical Manual LDK 4628 - Operational Control Panel 02.33.2

The two-wire data bus is used to connect all control

units in the Series 9000 control system. The data

cable loops-through from one unit to the other. The

orderof connectionis notimportant,however,thetotal

length of the cables must not exceed 310 meters

(1,118 ft).

Each unit connected directly to the data bus, either

Base station, camera head or OCP, is identified by a

number. In order to ensure, for example, that OCP 1

controls the camera connected to Base station 1, the

sameunique numbermustbeassignedto bothOCP 1

and Base station 1. The assignment number is set

internally on the units during installation.

Theassignment numberof acameraheadconnected

to a Base station is automatically set to the number of

the Base station to which it is connected. The number

on the Base station, which is connected to the data

bus,must besetto thenumber ofthe assignedcontrol

panel.

It is important to set a unique number for each Base

station/OCPgroup asunpredictable controlsituations

could arise otherwise.

The MCP is also connected to the data bus, however,

it is not necessary to set an internal assignment

number. The camera or cameras to be controlled are

selected on the MCP front panel itself when operating

the unit.

Note

A maximum of 15 looped-through standard camera

systems in one chain can be handeld, however, in a

multiple system the load of a LDK 23 HS (mkII) is

twice the load of a standard camera.

Two-wire Data Control Bus

02.33.2 Technical Manual LDK 4628 - Operational Control Panel 15

Connectors and Cables

MCP Rear Connector Panel

Mains Input Connector

Eurostyle 3-pin male

1. Neutral

2. Line

3. Earth

Mains input voltage: Between 230 Vac and 115 Vac + 15%

Mains frequency: 47 to 63 Hz

Fuses: 1 A slow, 250 Vac

X 1 - Mains Input Connector - Panel view

Rear view of OCP

X 891

X 890

X 897

X 878

not used

Mains input connector X 1

3

21

16 Technical Manual LDK 4628 - Operational Control Panel 02.33.2

Souriau 4-pin male, shielded cable

A. Data

B. Data not

C. Not Connected

D. Shield

Shield of cable to the pin marked shield

Note:

Data cable order nr.:

LDK 8113/01 = 1 meter

LDK 8113/10 = 10 meters

LDK 8113/99 = 100 meters

A

D

C

B

X 891/892 - Data Connector - Panel view

Data Connectors

9-pin male, shielded cable

1. Preview 1A

2. Preview 1B

3. Preview 1C

4. Not used

5. Not used

6. Not used

7. Not used

8. Not used

9. Shield

Shield of cable directly to the pin marked shield.

A 9-pin female cable connector is available under part

number 2422 022 06216.

The cable hood for this connector is available under

part number 2422 021 02467.

Preview switch not pressed: 1A connected to 1C

Preview switch pressed: 1A connected to 1B

6 9

1 5

X 897 - Preview Connector - Panel view

Preview Connector

02.33.2 Technical Manual LDK 4628 - Operational Control Panel 17

Dimensions

Series 9000 THOMSONOCP

OCP pwr

Camera

Base St

Gen lock

Triax

Non standard

Cam pwr

Pan lock

1

2

Var

Lin

R

G

B

Sup

CVBS

Seq

Preset

60 Hz

50 Hz

Nom

1/200

1/500

1/1000

Exposure Gamma Monitoring

Variable

Saturation

Wh clipBlk strBlk strSawGamma Flare

Contour Var

V-level Level

Lev depVar Bars Contour

Auto Auto wh Auto blk

Point

Slope

Knee

1/Clr

2

3

4

5

6

7

8/Cap

Aw 1

Aw 2

7500 K

5600 K

3200 K

++

+

0

-

Gain

Black

Scene file

1 2 3 Standard Store

On air

Auto iris F-Number Extender Cam select

4

115

M black Iris

8

Free

Call

Preview Centre Range

Col Temp GainFilter

100.00 mm

40.00 mm

58.94 mm

60.00 mm

105.93 mm

119.05 mm

351.01 mm

171.96 mm 157.04 mm

18 Technical Manual LDK 4628 - Operational Control Panel 02.33.2

Table of contents

Other Technicolor - Thomson Control Panel manuals