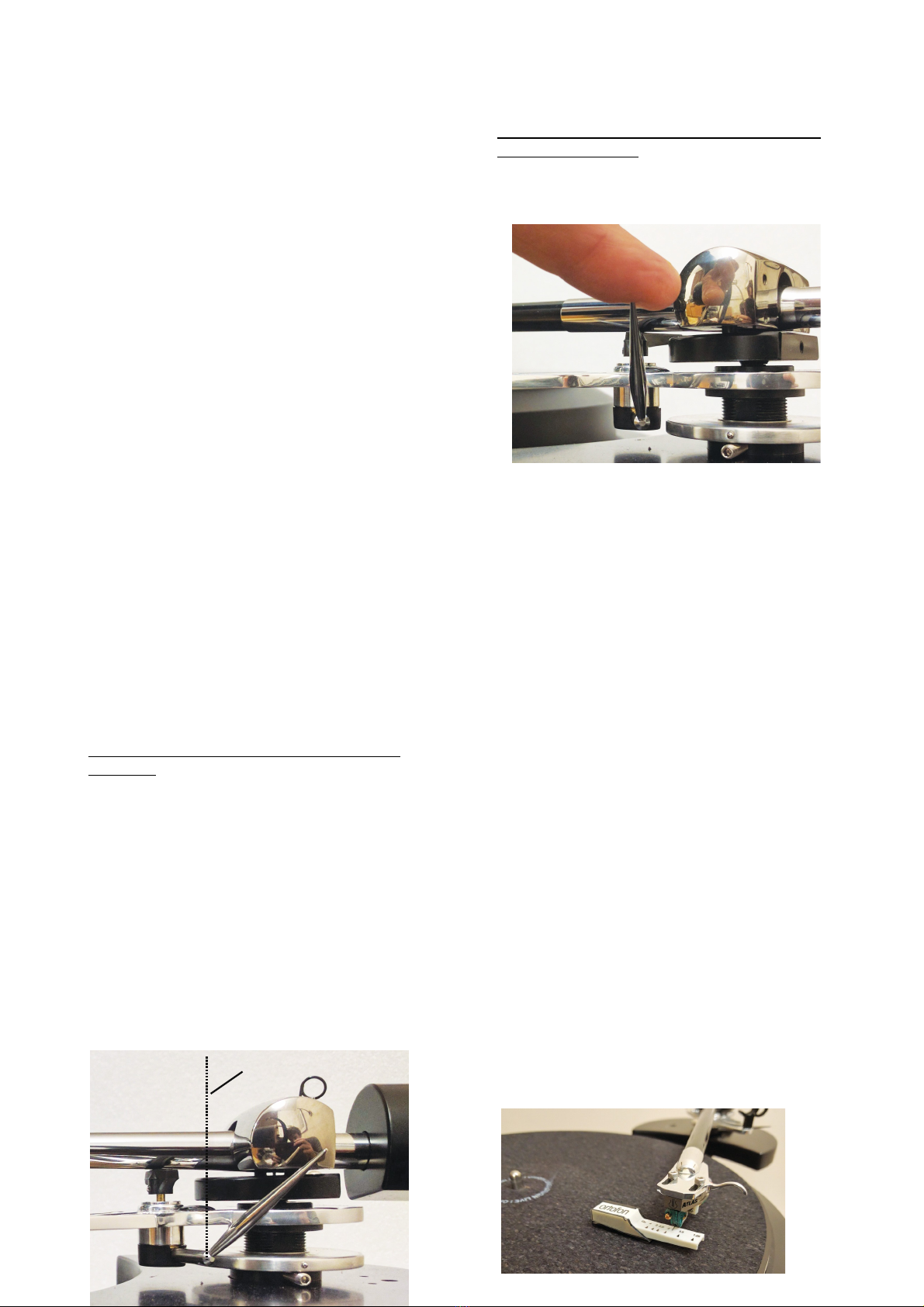

VTA on the most commonly used thickness of record.

Cartridge alignment tools

Tools required are an alignment gauge, a ruler, a tracking

force gauge, a FLAT record, a screwdriver or Allen keys

of the right size (usually 2mm , a good light may also be

helpful. Small needle-nose pliers and a magnifying glass

all help. A good “test record” such as the Hi Fi News test

record is useful.

Bear in mind that the most severe “tracking ability” tests

are hopelessly unrealistic and nothing tracks properly on

them.

Treat the arm with care as some parts are fragile. To this

end ensure that tightening of any bolts is carried out

gently and without causing undue strain.

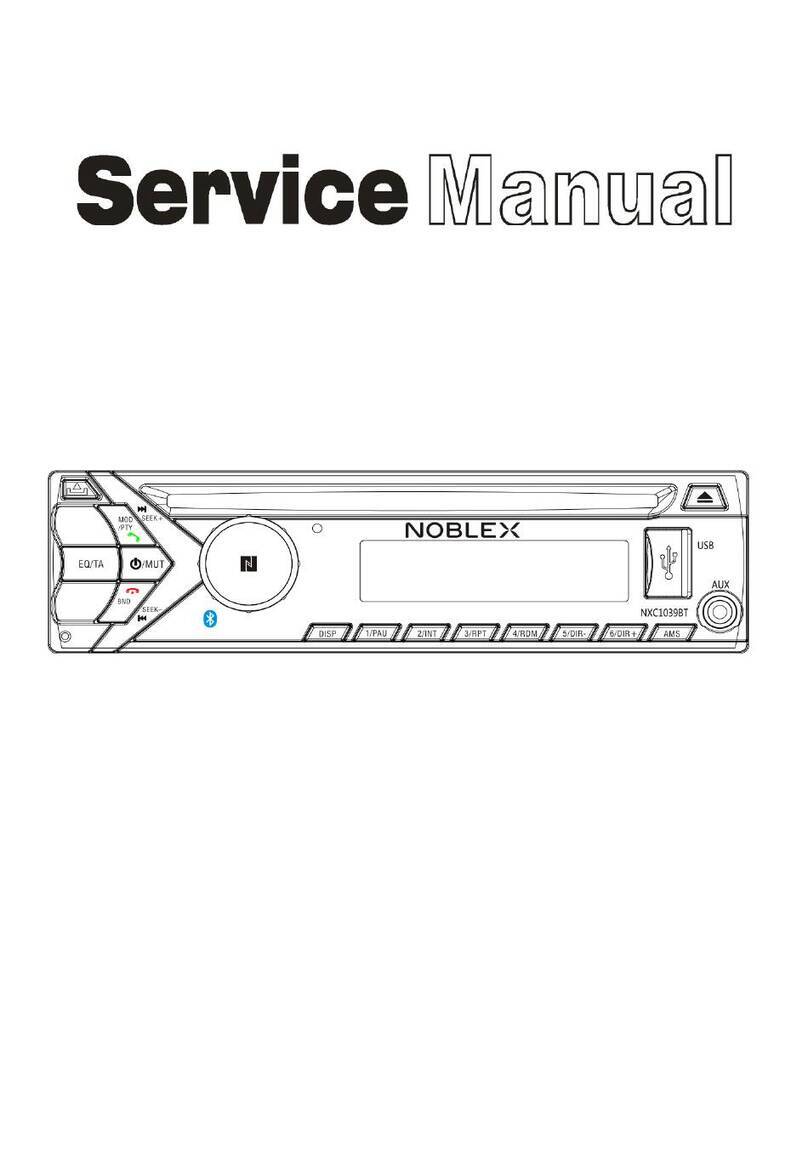

Tonearm wiring

Tonearm wiring uses a standard colour code for channel

and polarity identification: White = L Hot, Blue = L

Ground, Red = R Hot, and Green = R Ground. If the

cartridge pins aren’t colour-coded the same way, they

will have letter identifications next to them.

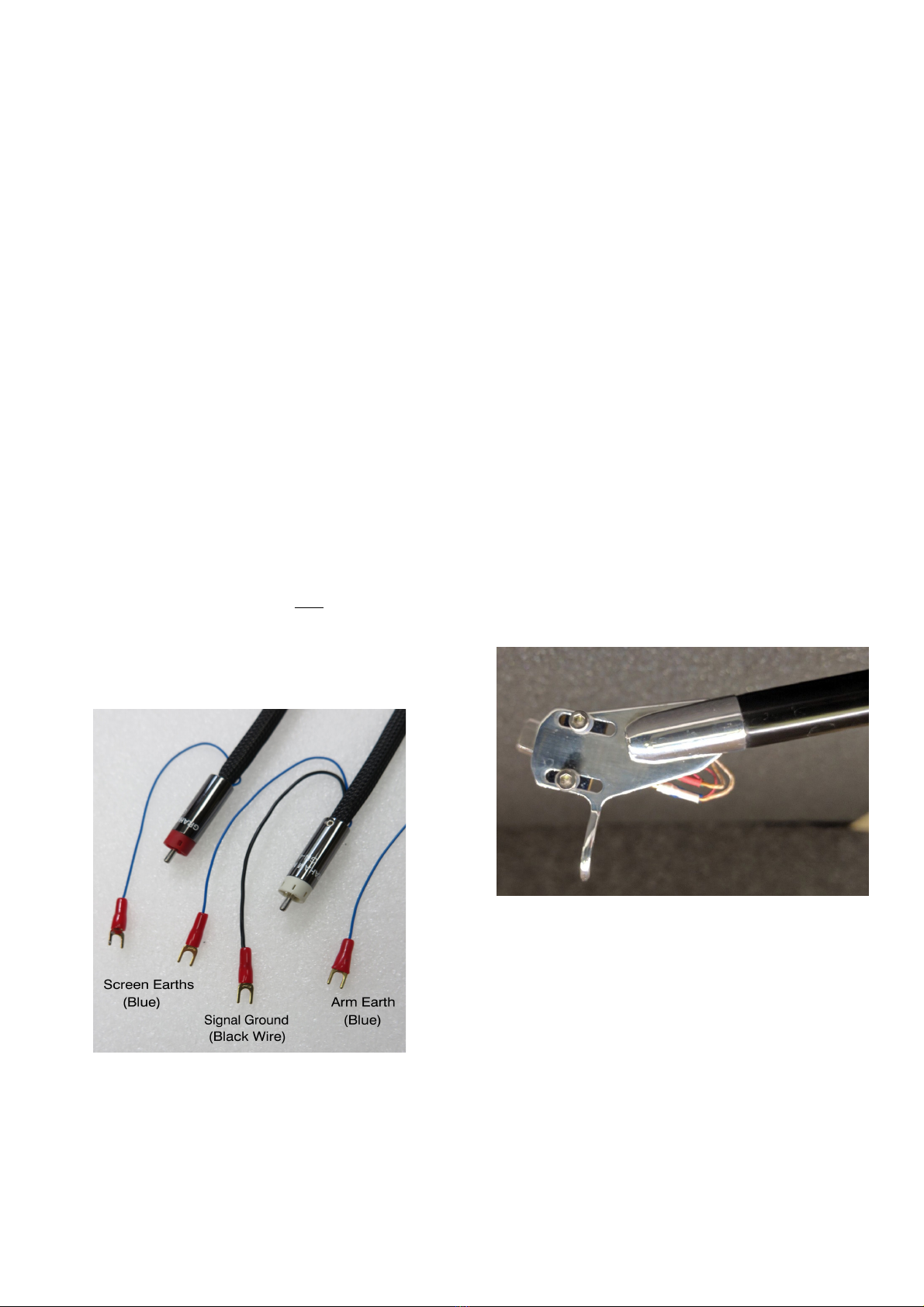

Cartridge tag conduction & fit

Low level signals are unbelievably sensitive, so good

conduction is essential and joints can be critical.

Make sure that the arm’s wires, wire clips, and solder

joints are in very good condition. At minimum, clean the

contact between cartridge pins and wire clips by

removing and replacing each clip. Holding the clips with

needle-nose pliers can make this easier, but be careful

that you don’t strain the wires where they join the clip.

Check the clips for a proper fit on the cartridge pins, and

adjust them if necessary. “Proper” means snug but not

tight. To check clip size, hold the cartridge tail-up close

to the head wires, grasp a clip firmly right behind its

tubular part with the tweezers, line it up with the

cartridge pin, and press. If it does not slide on with

moderate force, the clip needs opening-up. If it slides on

easily but flops around when attached, it needs

tightening. Re-sizing is the operation most likely to

detach a clip.

The trick is to avoid bending the wire at its attachment

point or putting too much tension on it. To avoid either,

always hold the clip with its wire slightly slack-looped

behind it while adjusting. For opening a clip, hold it

firmly with the tweezers or needle-noses, right behind its

tubular section, and press the tip of the jeweler’s

screwdriver into the open end of its longitudinal slot

until you see this widen very slightly. (Here’s where

you’ll probably need the magnifier or reading glasses. .

You’re dealing with thousandths of an inch here, so a

barely visible spreading may be all that’s needed.

Try it for fit, and repeat until it does. For tightening a

clip, press a toothpick inside it as far as it will go, then

use the needle-nose pliers to gently squeeze

together the sides of the clip near its free end, while

watching the slot for any change. (Attempting to

squeeze a clip without the toothpick inside it will

flatten its sides. Try it for size, and re-squeeze if

necessary until the fit is correct. When it is, close

up the middle section of the tube to match the end.

Static on Arm

Under certain conditions it's possible for severe

static charge to build up on the arm, which then

causes a noise when the finger lift is touched.

Dry climates or air conditioned environments are

the worst for this so remedies include:

•Place a pot plant in the room to get

moisture into the air.

•Wipe the arm with antistatic fluid such as

L'art du Son which leaves no residue ( do

not use furniture spray .

•Avoid Synthetic carpets and clothing.

RECORD & STYLUS CARE

Record and stylus care are big subjects well beyond

the brief scope of these instructions. To help on this

we've produced Youtube videos which can be found

on the Origin Live Youtube channel (use google to

find this .

CARE OF CARTRID ES

Suspension Aging

Replace your cartridge when due. Most hi-fi

cartridges have a lifespan for their cantilever

suspensions, which age even when not in use. This

will vary from manufacturer and type of cartridge

but 6 years is common.

Stylus Wear

Styli wear down due to record friction. Cleaning

records and stylus properly will dramatically

improve the life of both. It also increases

performance significantly.

Cleaning Strategies

There are a number of strategies for cleaning styli,

each with it's own merits. We recommend a

combination of the below. The items concerned are

available on the Origin Live website.

Small cartridge cleaning brush

These brushes are usually supplied with your

cartridge. If there is a build-up of dust and dirt

Page 10