Technische Alternative ATON User manual

ta.co.at

ATON

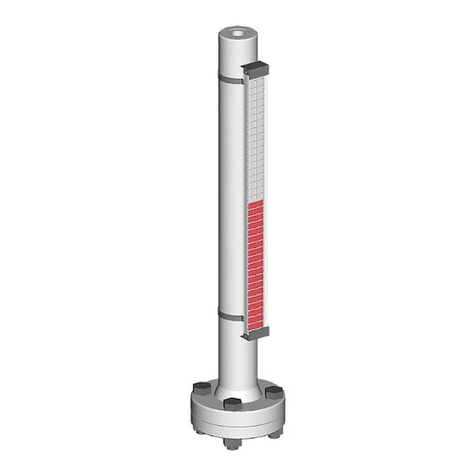

ELECTRIC IMMERSION HEATER EHS-R

CAN ENERGY METER CAN-EZ3A

End user guide

English

Manual Version 1.25 (CAN-EZ3)

Manual Version 1.16 (EHS-R)

2

Table of contents

Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General information on programming parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Work settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Function overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Statistics – export to grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Statistics – import from grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Statistics – own consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Heater 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Forced operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Principles

3

Principles

These instructions are aimed at the final user of the energy meter. For details about the device, pro-

gramming, etc., detailed operating instructions are available on our website www.ta.co.at or on the

official Technische Alternative wiki.

The CAN-EZ3A is a freely programmable energy meter, which communicates wirelessly with a vari-

able EHS-R immersion heater. The purpose of this device is to identify surplus output, e.g. from PV

systems, and convert this surplus into domestic hot water, instead of exporting it to the mains, which

can be less profitable.

The energy meter is operated via a display, a rotary dial and a button.

Device overview

The display (1) is used to navigate within the energy meter, to program functions, read in values, ac-

cess other devices, etc.

The dial (2) to the right of the display is used for navigation. A clockwise rotation moves you down

the menu; anti-clockwise moves you up.

Pressing the dial (2) opens the selected menu/allows you to change the selected value/parameter.

(= Enter button)

Pressing the button (3) below the dial will exit a menu. (= Back button)

Pressing "Enter" or "Back" relates to the value/menu item framed on the display.

The "Status" LED (4) above right of the rotary dial provides information on the status of the device.

Green flashing means the energy meter is starting up. A continuous green light shows normal oper-

ation. Orange means there is a "message", for example concerning a collector overtemperature shut-

down. Red means there is a "fault", such as a DL sensor failure.

Briefly pressing the reset button (5) restarts the device. For a total reset, press and hold the button

until the status LED (4) stops quickly flashing orange and starts slowly flashing red.

Principles

4

General information on programming parameters

for inputs, outputs, fixed values, functions, general settings, and CAN and DL inputs and outputs.

If you want to discard your entries, select .

Example:

Entering numeric values

The following window is displayed for entering numerical values:

Name of the numeric value, entry range

Current numeric value

The current value is shown (example: 20.0 °C).

The top line shows the name of the value, then the entry range (example: 0.0 – 100.0 °C).

The value is entered by turning the rotary dial. As there are no symbols for confirming or rejecting a

value, the entry is confirmed by pressing the dial or rejected by using the back button.

If displayed, entries must be confirmed with a .

User manual

5

Work settings

The essential function of programming is converting surplus output (e.g. from PV systems) into

DHW instead of less profitable export to the mains. An optional function is also available for heating

DHW with an immersion heater within a user defined time window (disabled at the factory). “Cylinder

temperature” in this case relates to the first sensor input on the immersion heater itself.

An energy meter also runs together with a date-specific memory for viewing meter readings and

yields.

The energy meter is programmed at the factory, including a function overview. If this has not been

changed, here are the instructions for various parameter settings.

These instructions relate to the factory programming and function overview.

As the energy meter is freely programmable, the displays on your device may differ in some cases

drastically from the figures in these instructions.

If the system malfunctions, it is generally advisable to contact the system installer. These instruc-

tions are not intended to be used for troubleshooting; instead, they should be used for customis-

ing the energy meter with factory programming to suit the requirements of the end user.

User manual

6

Function overview

The function overview referred to in these instructions can be ac-

cessed via the top item in the main menu called "Function overview".

Overview

Date and time

Temperature of the cylinder sensor, connected to the immersion heat-

er. If 9999.9 °C is displayed here, there is a sensor lead break. The sen-

sor may not have been fitted. This sensor is required for the basic

function of the immersion heater.

Power exported to/drawn from the grid. A positive value means that

this power is drawn from the grid. A negative value means that this

power is exported to the grid. Important: by default, 200 W is exported

to the grid before the immersion heater switches on.

Surplus power that is utilised by all consumers that the CAN-EZ3(A)

energy meter controls.

These entries are to links of other pages of the function overview. They

are described on the following pages of the instructions.

User manual

7

Statistics – export to grid

First, the power that is currently being exported to the grid is displayed,

followed by various meter readings.

At the bottom of the page is a button to reset the meter readings.

Statistics – import from grid

The next page is similar to the previous one, except that the meter readings are for power drawn from

the grid rather than exported to it.

Statistics – own consumption

This page is also similar to the two previous ones, except that it concerns the power that the immer-

sion heater expends. Surplus use and forced operation (DHW heating) are combined here.

User manual

8

Heater 1

This page provides an overview of the immersion heater itself.

Power that the immersion heater is currently consuming.

Temperature of the cylinder sensor, connected to the immersion heat-

er. If 9999.9 °C is displayed here, there is a sensor lead break. The sen-

sor may not have been fitted. This sensor is required for the basic

function of the immersion heater.

Second temperature sensor – not set at the factory.

Safety temperature limit: If the temperature at the immersion heater it-

self reaches 95 °C, the immersion heater switches off and must be re-

started manually.

Temperature at the PCB of the immersion heater.

If there is an error, a number above 0 is displayed here. This number

provides information about the errors that have been detected.

If Timeout is set to “Yes”, the energy meter has lost the connection to

the immersion heater.

User manual

9

Forced operation

Forced operation is used for DHW heating, as the immersion heater is factory-set to only switch on

if surplus power is available, not on the basis of any particular temperature.

Switching on forced operation (shown in the illustration as currently

switched off)

Time programs for DHW heating (see below)

Required DHW temperature

Power used to switch the immersion heater on when forced operation

becomes active.

If this button is pressed, heating to the set temperature is carried out

once, regardless of the time programs and surplus power.

Time programs

The days with a black background are the ones on which this time pro-

gram is to be active. In the illustration, this program is active from Mon-

day to Friday.

On the days selected above, forced operation is active at the times set

here.

A second time program can be set, e.g. to define different times at the

weekend.

User manual

10

Configuration

On the last page of the function overview, a few more settings can be made.

Set output

This value indicates the power that is exported to the grid as tolerance

before the energy manager activates the immersion heater. This pre-

vents inadvertent power drawn, which could otherwise occur due to the

system inertia.

A value of -0.20 kW means that the immersion heater is only activated

at a surplus of >200 W.

Soft startup

The soft start is used to slowly ramp up to the power that the immersion heater consumes. It is rec-

ommended to set this setting to “Yes” if there is a battery storage unit in the system.

Max. temp. cylinder

Maximum temperature at the top of the cylinder, measured at the sensor connected directly to the

immersion heater. If the temperature set here is reached there, the immersion heater switches off

until the temperature falls 5 °C below it again.

Forced operation

Link to the “Forced operation” page, described on page 9.

Warranty conditions

Note: The following guarantee conditions do not in any way limit the legal right to warranty, but rather

expand your rights as a consumer.

1. The company Technische Alternative RT GmbH provides a one-year warranty from the date of purchase

for all the devices and parts which it sells. Defects must be reported immediately upon detection and

within the guarantee period. Technical support knows the correct solution for nearly all problems. In this

respect, contacting us immediately will help to avoid unnecessary expense or effort in troubleshooting.

2. The warranty includes the free of charge repair (but not the cost of on site fault-finding, removal,

refitting and shipping) of operational and material defects which impair operation the event that a repair

is not, for reasons of cost, worthwhile according to the assessment of Technische Alternative, the

goods will be replaced.

3. Not included is damage resulting from the effects of over-voltage or abnormal ambient conditions.

Likewise, no warranty liability can be accepted if the device defect is due to: transport damage for which

we are not responsible, incorrect installation and assembly, incorrect use, non-observance of operating

and installation instructions or incorrect maintenance.

4. The warranty claim will expire, if repairs or actions are carried out by persons who are not authorised to

do so or have not been so authorised by us or if our devices are operated with spare, supplementary or

accessory parts which are not considered to be original parts.

5. The defective parts must be sent to our factory with an enclosed copy of the proof of purchase and a

precise description of the defect. Processing is accelerated if an RMA number is applied for via our

home page www.ta.co.at. A prior clarification of the defect with our technical support is necessary.

6. Services provided under warranty result neither in an extension of the warranty period nor in a resetting

of the warranty period. The warranty period for fitted parts ends with the warranty period of the whole

device.

7. Extended or other claims, especially those for compensation for damage other than to the device itself

are, insofar as a liability is not legally required, excluded.

Legal notice

These operating instructions are protected by copyright.

Use outside the copyright requires the consent of the company Technische Alternative RT GmbH.

This applies in particular to reproductions, translations and electronic media.

Technische Alternative RT GmbH

A-3872 Amaliendorf, Langestraße 124

Tel.: +43 (0)2862 53635 Fax +43 (0)2862 53635 7

E-Mail: [email protected] --- www.ta.co.at --- ©2023

This manual suits for next models

2

Table of contents

Other Technische Alternative Measuring Instrument manuals