Arca Flow Weka VLI EconomyLine 6 User manual

Installation and

Operating Manual

Visual Level Indicator (VLI)

Date: 17.03.2020

Version: E 10.1

WEKA_IOM_VLI_EN / 17.03.2020 1 / 31

Notes

Order:

Date:

WEKA_IOM_VLI_EN / 17.03.2020 2 / 31

Content

1. Type overview ............................................................................................................................................................3

2. Symbols and marks used .........................................................................................................................................4

3. Safety information and warnings.............................................................................................................................4

4. Intended use...............................................................................................................................................................5

5. The visual level indicator at a glance ......................................................................................................................6

5.1 The four different types of bypass ......................................................................................................................7

5.2 Top-of-tank design ..............................................................................................................................................7

5.3 Options Indication rail .........................................................................................................................................8

6. Function description .................................................................................................................................................8

7. Scope of delivery for visual level indicator ............................................................................................................9

8. Preparation for assembly .........................................................................................................................................9

8.1 Unpacking ...........................................................................................................................................................9

8.2 Disposing of the packaging.................................................................................................................................9

8.3 Remove float protection ....................................................................................................................................10

9. Installation................................................................................................................................................................13

9.1 Mounting ...........................................................................................................................................................14

9.2 Inspecting..........................................................................................................................................................14

10. Commissioning ...................................................................................................................................................14

11. Maintenance ........................................................................................................................................................15

12. Cleaning visual level indicator ..........................................................................................................................16

12.1 Cleaning the outside .........................................................................................................................................16

12.2 Cleaning the float chamber and the float ..........................................................................................................16

12.3 Cleaning the float chamber and float for a top-of-tank assembly .....................................................................17

13. Operating, transport and storage conditions ..................................................................................................18

13.1 Operating conditions .........................................................................................................................................18

13.2 Transport and storage conditions .....................................................................................................................18

14. Technical data .....................................................................................................................................................18

15. Disassembly / disposal ......................................................................................................................................18

15.1 Disassembly......................................................................................................................................................18

15.2 Disposing of the visual level indicator...............................................................................................................19

16. Troubleshooting..................................................................................................................................................19

17. Label.....................................................................................................................................................................20

17.1 Type plate .........................................................................................................................................................20

17.2 Explosion-proof plate ........................................................................................................................................20

18. Customer service................................................................................................................................................20

19. EU Declaration of Conformity for non-explosion-proof devices ...................................................................21

20. EU Declaration of Conformity for explosion-proof devices ...........................................................................22

21. ATEX Certificate (Type Examination Certificate).............................................................................................23

22. IECEx Certificate of Conformity (CoC) .............................................................................................................26

WEKA_IOM_VLI_EN / 17.03.2020 3 / 31

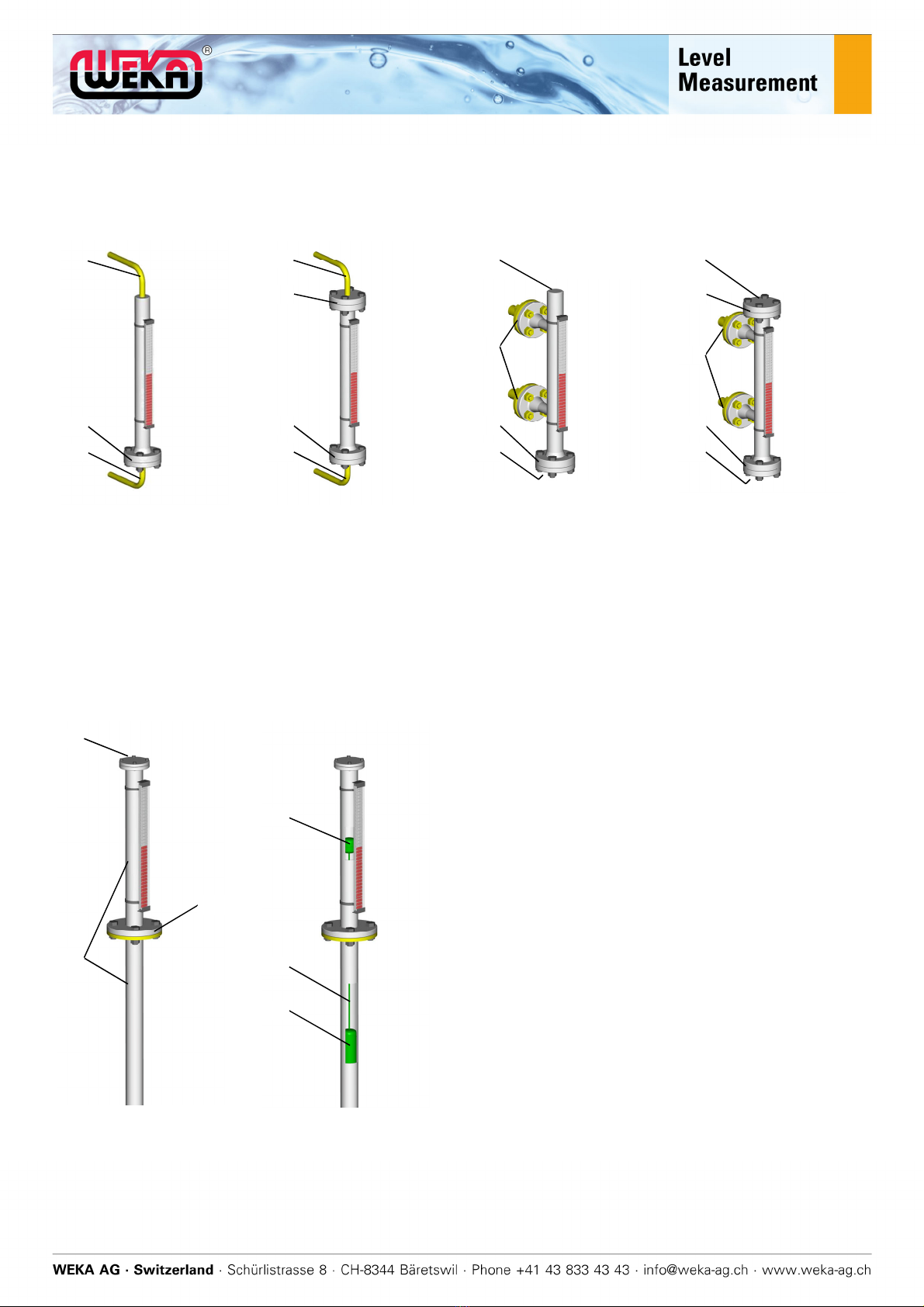

1. Type overview

23614E EconomyLine 6

34000E EconomyLine 6

23614 StandardLine 6

34300 StandardLine 28

32755 StandardLine 50

34000 SmartLine 50

34110 SmartLine 50

36800 HighPressure Power 80

26411 HighPressure Power 100

25683 HighPressure Power 160

32806 HighPressure Power 200

26421 HighPressure Power 250

26431 HighPressure Power 315

38400 HighPressure Power 400

38500 HighPressure Power 500

39020 PetroLine 20

39021 PetroLine 20-low density

39050 PetroLine 50

39051 PetroLine 50-low density

39068 PetroLine 68

39100 PetroLine 100

39150 PetroLine 150

39250 PetroLine 250

39420 PetroLine 420

39630 PetroLine 630

40350 LowDensityLine 50

Plastic VLI PVDF

,

PP

,

PVC

23013 Top of Tank Line 6

25270/6 Top of Tank Line 6

25270/28 Top of Tank Line 28

25270/50 Top of Tank Line 50

Plastic ToT PVDF, PP, PVC

WEKA_IOM_VLI_EN / 17.03.2020 4 / 31

2. Symbols and marks used

Warning

Indicates possible damage to the visual level indicator or injury to the operator or

user if the instructions are not followed.

Caution

Indicates possible damage to the visual level indicator if the instructions are not

followed.

Safety information

For equipment intended for use in potentially explosive atmospheres in accordance

with the European directive 2014/34/EU (ATEX) or IECEx.

This information is applicable in addition to all other information.

3. Safety information and warnings

The manufacturer accepts no liability for damage caused as a result of failure to comply with the safety

information and warnings.

Risk of burning! Working on hot visual level indicators may result in physical injuries and burns.

The surfaces of the standpipes and the process connections may become hot. Allow the tank to

cool to the ambient temperature before working on the visual level indicator. Wear suitable

protective equipment (gloves, face guard, possibly breathing apparatus). Keep a sufficient

distance away while the machine is in operation.

Visual level indicators run at excessive pressure carry pressure-related risks. Depressurise the

tank before working on the visual level indicator and observe the information in the European

Pressure Equipment Directive 2014/68/EU.

When opening the visual level indicator, bear in mind that the fluids and gases it contains could

be hazardous to health. It is imperative that you comply with the safety data sheets for the

process liquids and gases used.

The visual level indicator may stop working due to the float gauge being blocked, and this may go

unnoticed. If you are unsure about the fluid level shown, the visual level indicator should be

tested using a different method (see “Troubleshooting”)

If you suspect that there is a malfunction or determine that there is one, this must be rectified.

Only use the visual level indicator if you have read and understood this manual in full.

This manual must also be accessible for later users.

Keep magnetic and magnetisable parts (magnets, structural steel, iron wire or iron clips, etc.)

away from the visual level indicator. The same applies for strong electromagnetic fields

(transformers, welding equipment, etc.). Both can interfere with the magnetic force of the

magnets inside the visual level indicator and lead to the gauge and any attached accessories

(switch, transducer) malfunctioning and dropping out.

Replace damaged or faulty components with original replacement parts.

Solvents may dull or crack any plastic parts used. Clean the indication rail with soapy water or a

plastic cleaner.

The visual level indicator must not be installed under mechanical tension.

The visual level indicator must not be used to mechanically reinforce the tank or the system.

WEKA_IOM_VLI_EN / 17.03.2020 5 / 31

Falling parts (screws, floats, etc.) may create impact sparks and lead to an explosion in

potentially explosive atmospheres. Make sure that there isn’t a potentially explosive atmosphere

and that no parts are falling when working on the visual level indicator.

When working on the visual level indicator, only use equipment and tools permitted in

accordance with the European Directive for potentially explosive atmospheres.

Polycarbonate indication rails may become statically charged – e.g. during cleaning. Sparks

created when discharging in a potentially explosive atmosphere may cause an explosion. Only

clean these parts with antistatic cleaning agents and tools.

4. Intended use

The visual level indicator may only be used for fluids.

The visual level indicator may only be used for the purposes recorded on the type plate. The

information noted down on the type plate and data sheet must conform with ideal plant operating

parameters.

Uses not intended by the manufacturer, modifications and alterations to the visual level indicator

are at your own risk and may be dangerous (guarantee exclusion).

The visual level indicator may only be installed, commissioned and maintained by a trained

professional.

The manufacturer accepts no liability for damage caused by incorrect use or operation.

The visual level indicator may only be used for the purposes recorded on the type plate and the Ex

label.

The visual level indicator may only be installed, commissioned and maintained by a trained

professional with expertise in explosion prevention.

The visual level indicator may only be repaired and modified by the manufacturer (or, if

appropriate, in consultation with the notified body).

WEKA_IOM_VLI_EN / 17.03.2020 6 / 31

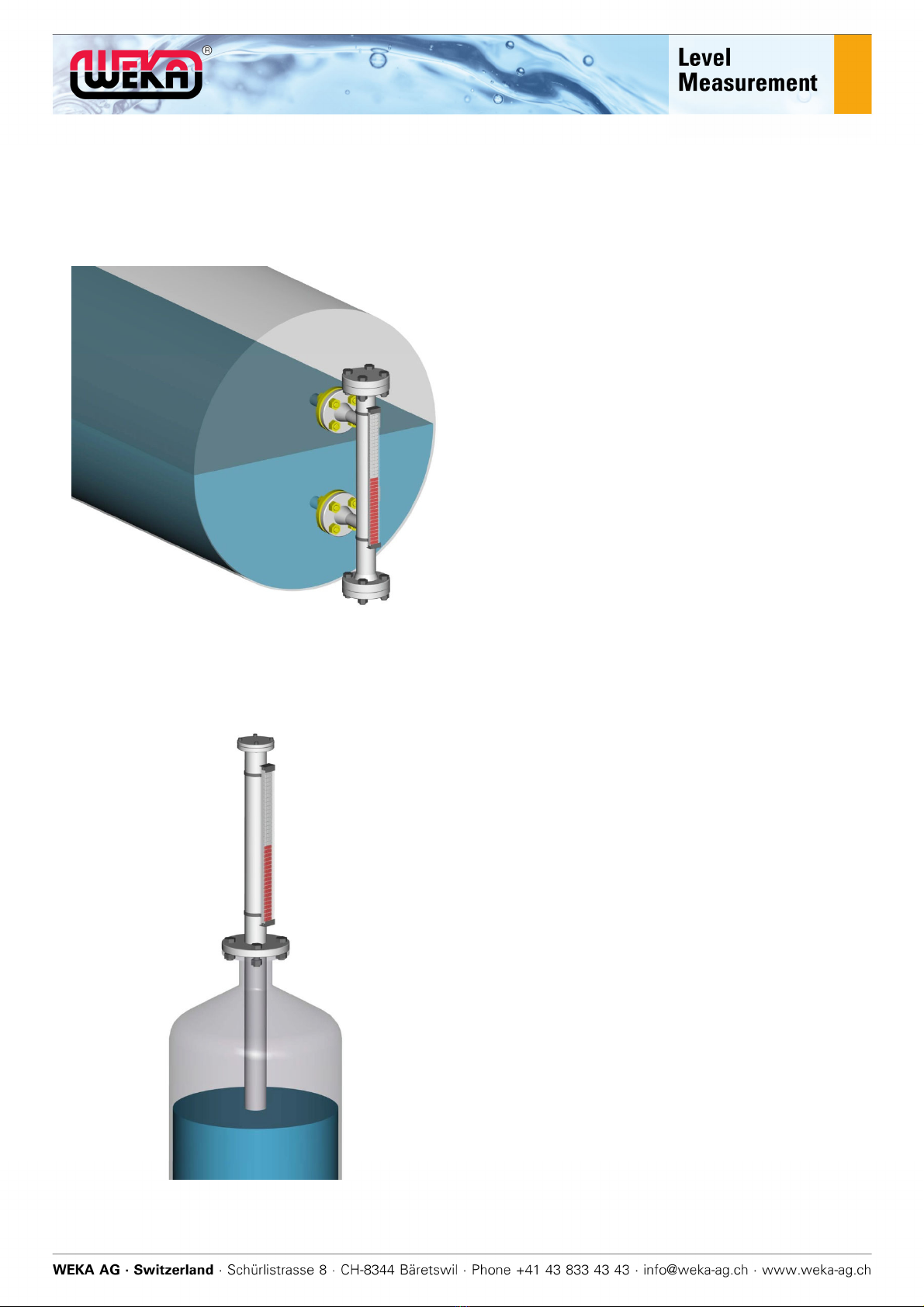

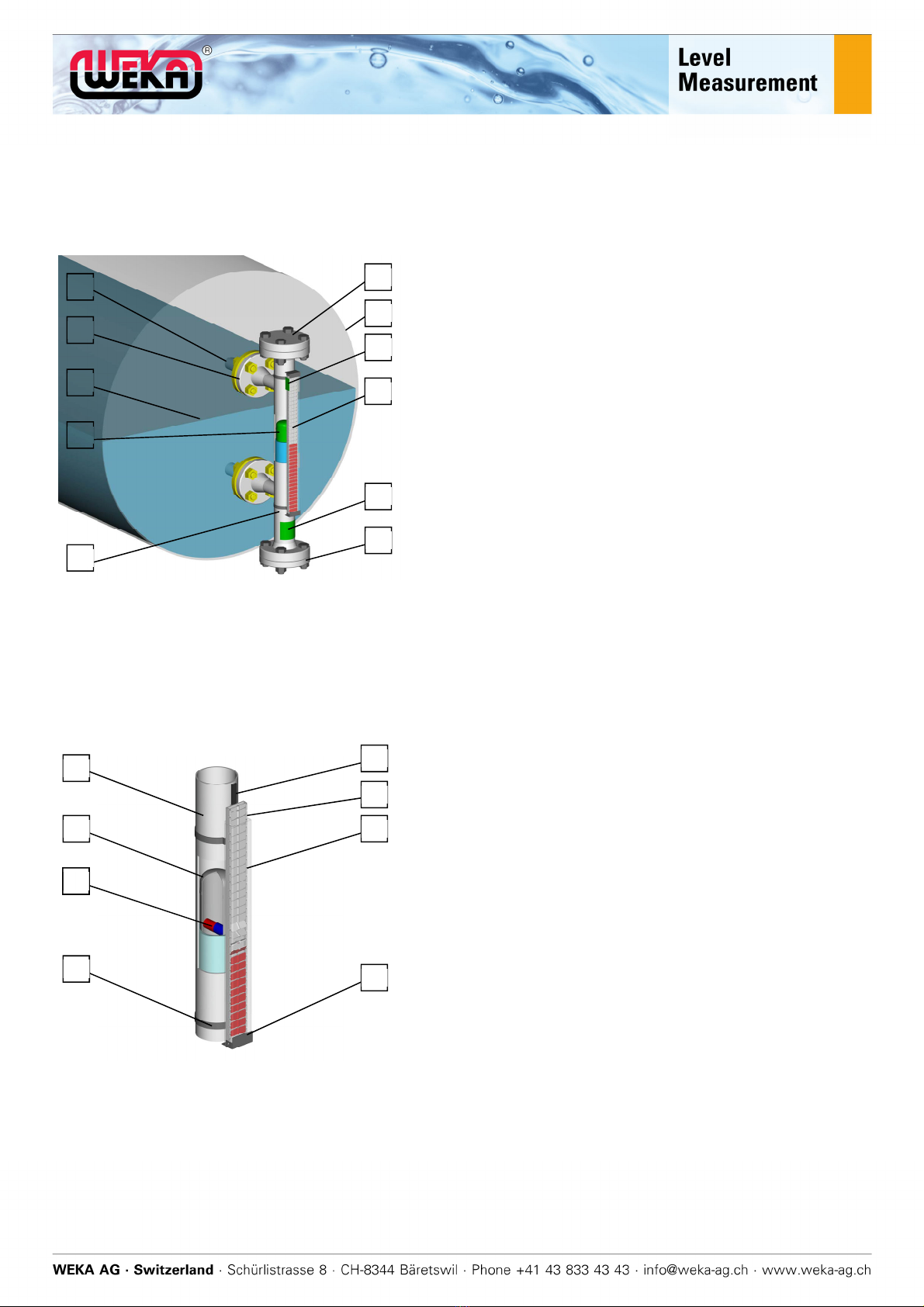

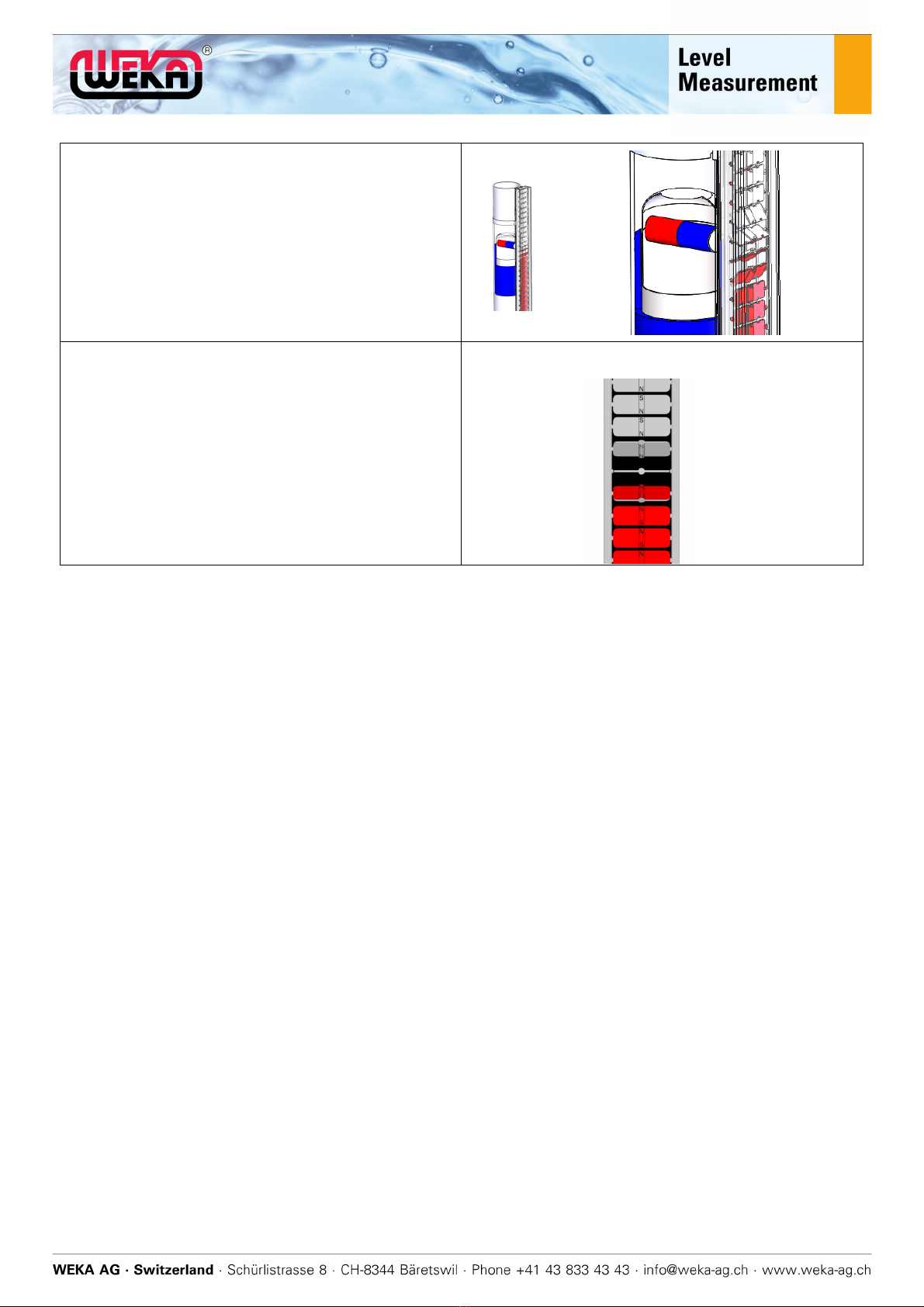

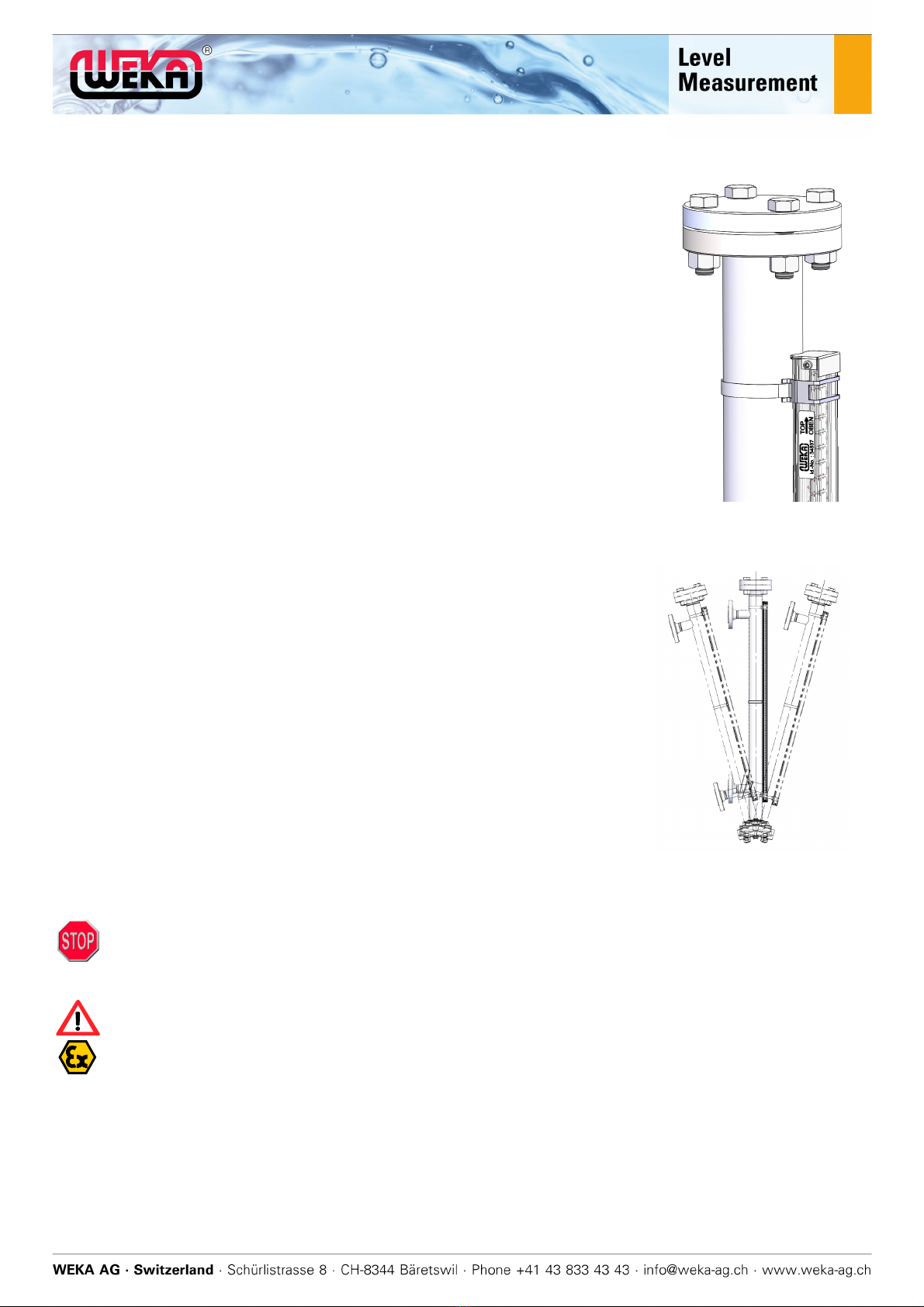

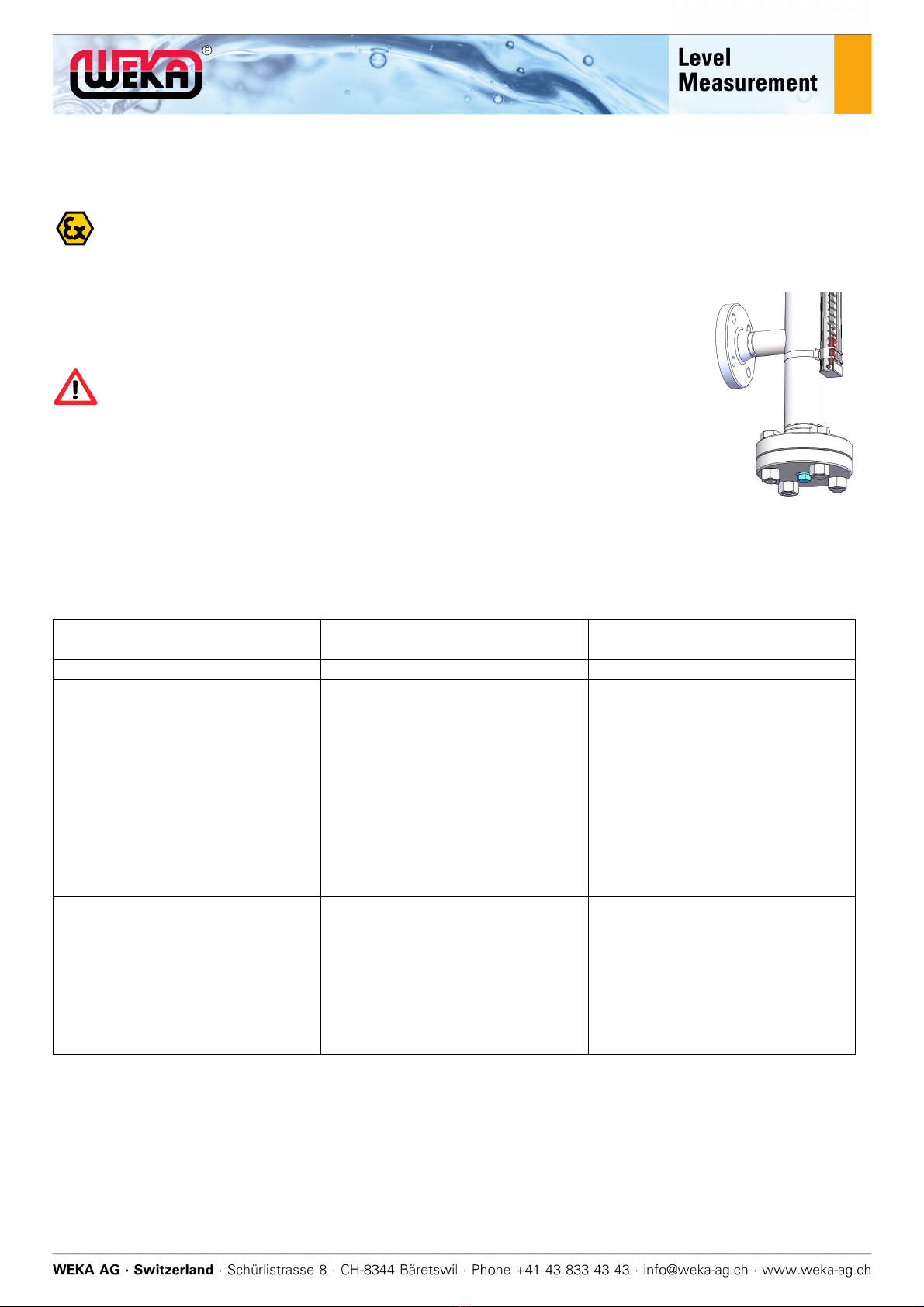

5. The visual level indicator at a glance

Visual level indicators are used to continuously record the fluid level of the contents of a tank. They are

connected as a bypass on the side of the tank, or as a top-of-tank gauge on the tank.

Figure 4A

Visual level indicators may be built in a way that differs

from the way depicted in this manual, and individual

parts may not be present.

1 Tank (container), supplied by customer

2 Process connections*, supplied by

customer

3 Surface of the liquid

Visual level indicator

4 Process connections*, top and bottom

5 Float chamber

(also called standpipe)

6 Float

7 Indication rail

(see below for details)

8 Type plate

with customer-specific parameters

9 “Top” sticker

10 Service connections*, top and bottom

* Process and service connections may be:

Flanges

Couplers

Weld sockets

Internal and external threads

Figure 4B

A1 Float chamber

A2 Flat with integrated bar magnet

A3 Horizontal bar magnet

A4 Crossed, two-part hose clip*

(also called bride)

* also possible in single-piece design with a

bracket for reinforced mounting

B1 Outer profile**

B2 Inner profile*** with two-tone gauge flaps

inserted

B3 Rotating magnetic band

B4 End caps with seal, screwed

** Aluminium outer profile used with plastic or

glass strips or polycarbonate profile, sealed

*** Aluminium or polycarbonate inner profile,

consistent with outer profile

2

1

3

4

5

6

7

8

9

10

10

A1

B2

A2

A3

A4 B4

B1

B3

WEKA_IOM_VLI_EN / 17.03.2020 7 / 31

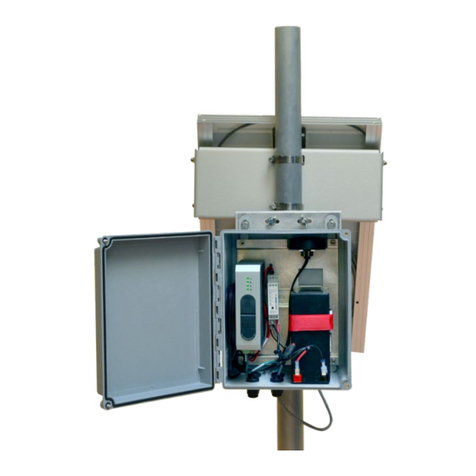

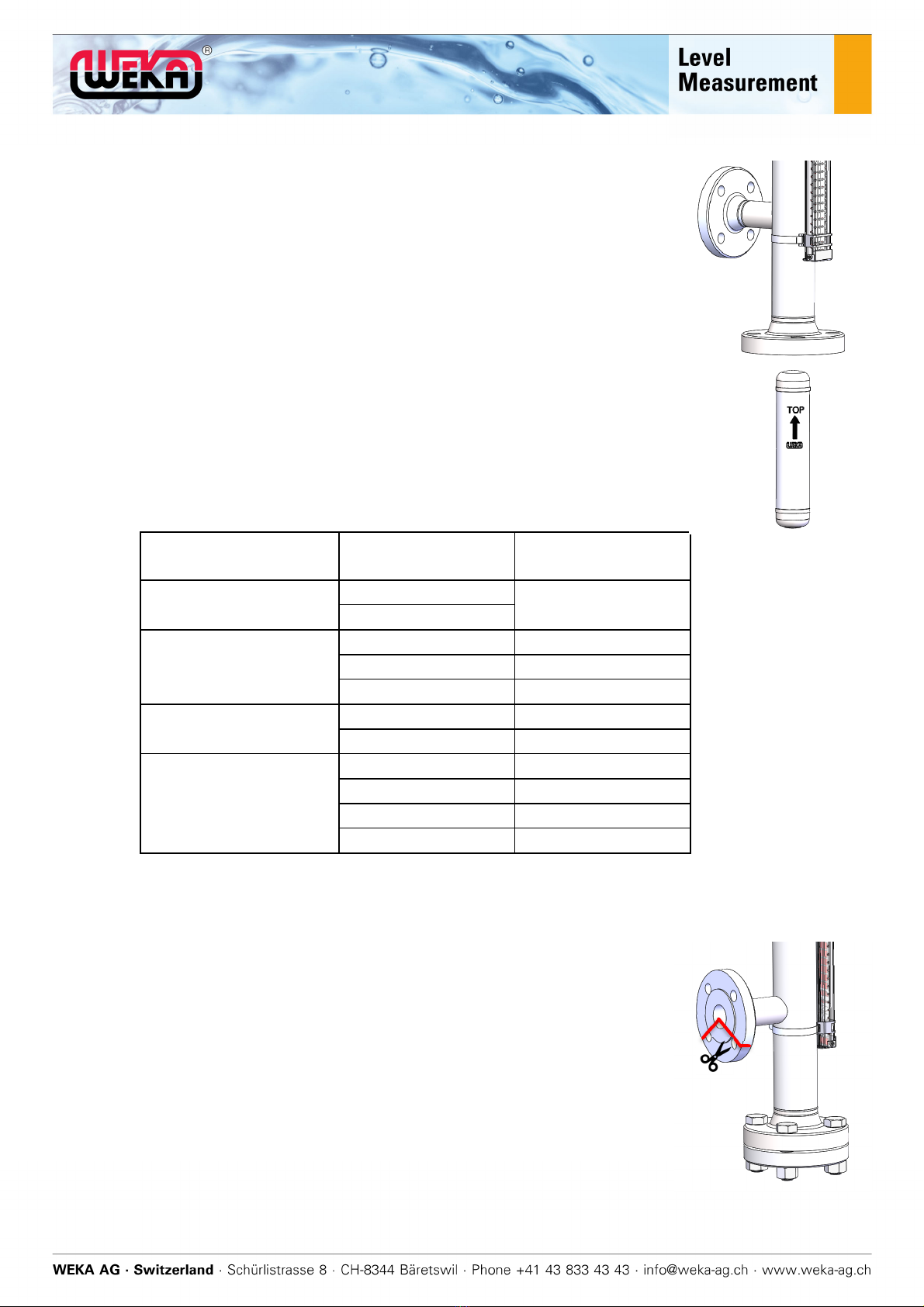

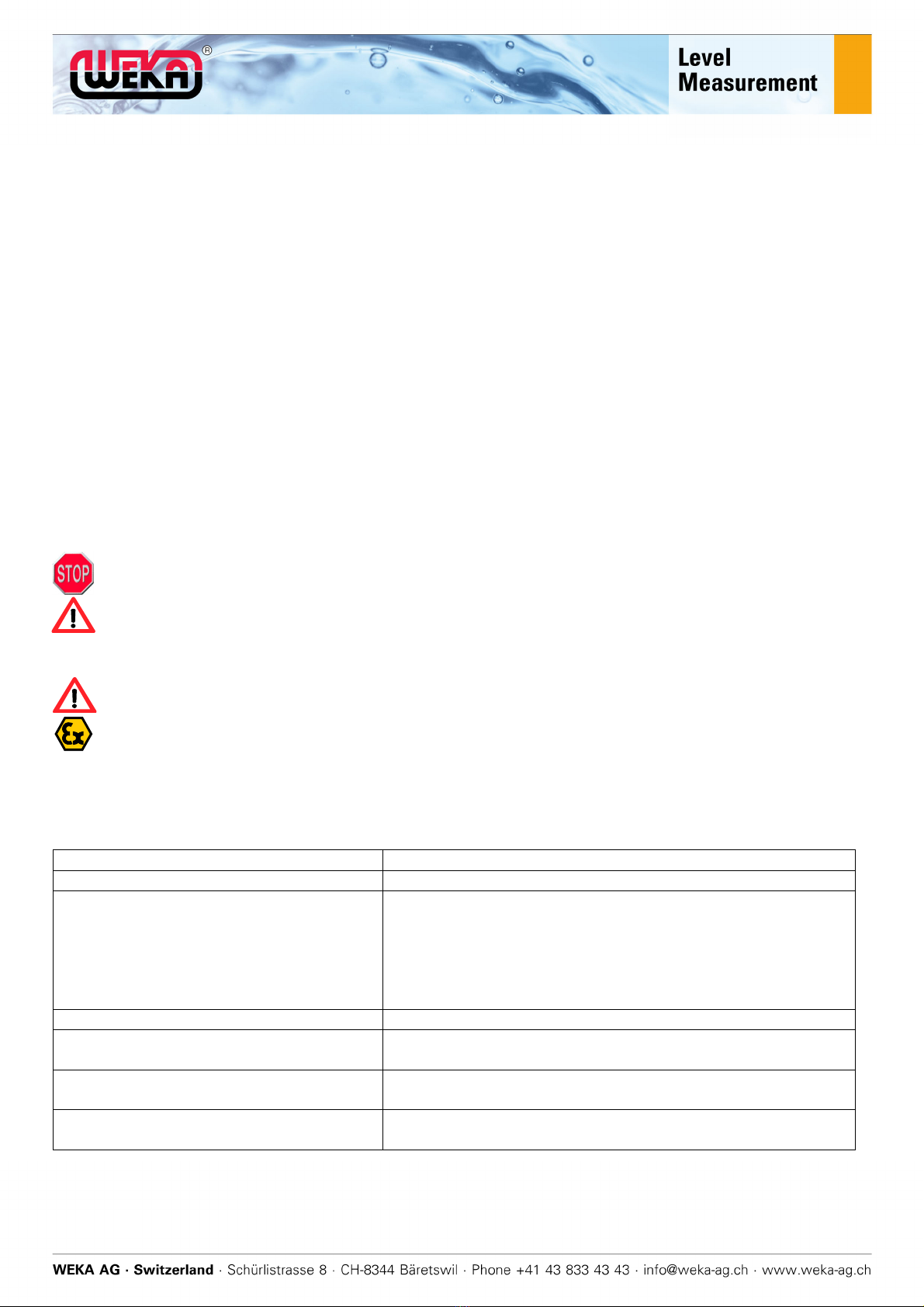

5.1 The four different types of bypass

Type A

Type B Type K Type O

20 Top process connection

21 Top service flange/plug

22 Bottom service flange/plug

23 Bottom process connection

(Drain and vent omitted)

30 Lateral process connections, top and bottom

31 Top service flange/plug

32 Possible ventilation hole with plug

33 Bottom service flange/plug

34 Possible drain hole with plug

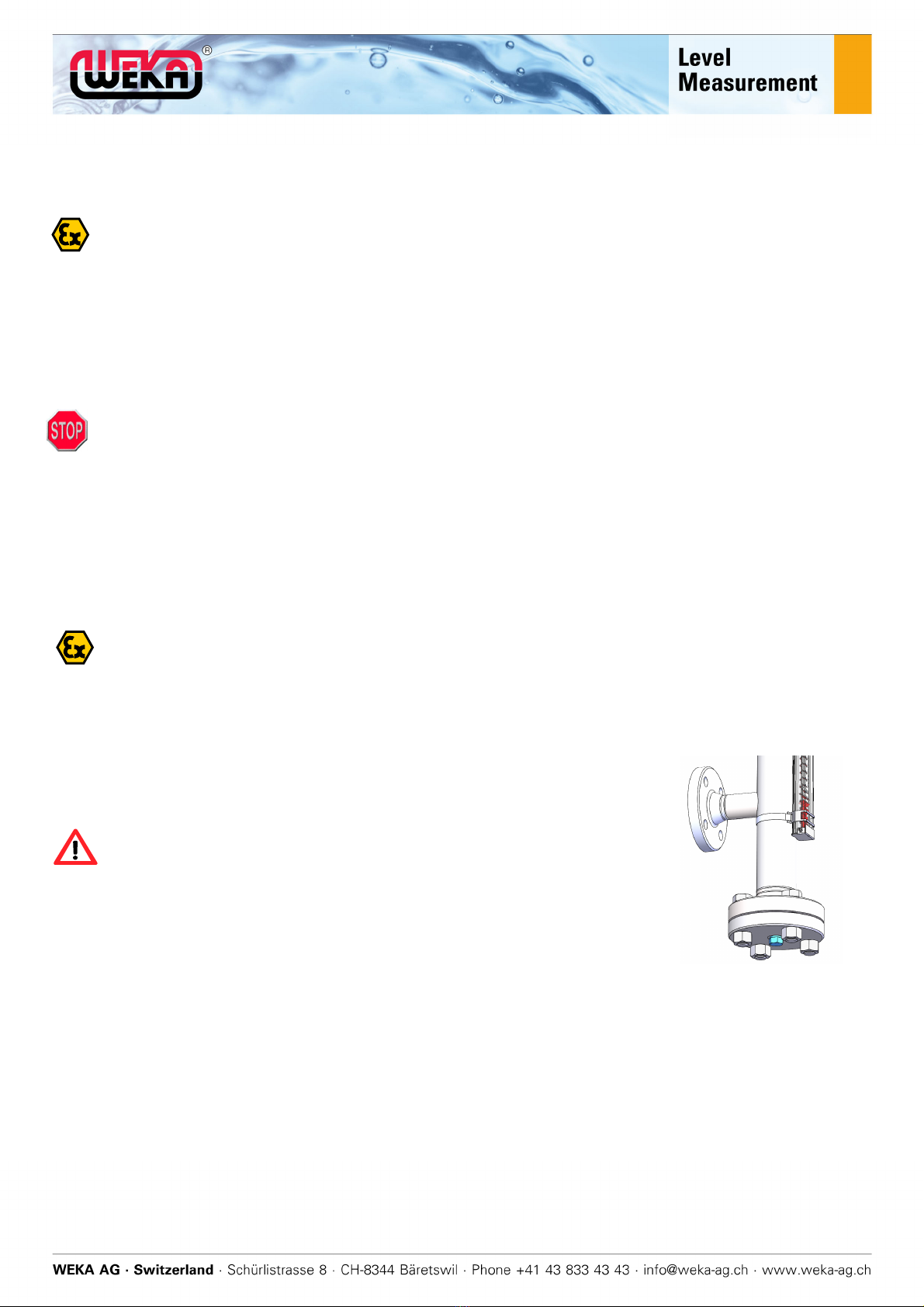

5.2 Top-of-tank design

Figure 4.2

40 Float chamber

41 Process connection

42 Service flange, possibly with

ventilation hole and plug

43 Float

44 Rod

45 Magnet holder, possibly rotatable,

with integrated, horizontal bar magnet

20

22

23

20

22

21

23

32

33

34

30

32

33

31

34

30

42

41

40

45

44

43

WEKA_IOM_VLI_EN / 17.03.2020 8 / 31

5.3 Options Indication rail

See data sheets for more options.

Measuring scale Reinforced

indication rail

mounting

Indication rail with

protective hose

Coloured gauge

flaps

6. Function description

The fluid level in the float chamber corresponds to

the fluid level in the tank (communicating vessels).

The bar magnet has been integrated into the float

in a way that means the centre of the bar magnet

is level with the surface of the liquid.

Each float has been designed for a specific liquid

density.

The magnetic band in the indication rail aligns the

bar magnet with the indication rail – like a

compass needle.

WEKA_IOM_VLI_EN / 17.03.2020 9 / 31

The magnetic field of the bar magnet penetrates

the non-magnetic standpipe and rotates the gauge

flaps by 180° when it goes past.

Information on options: Magnetic switches and

transducers can also be controlled using the bar

magnet in the float.

Magnets built into the gauge flaps keep the gauge

flaps in position (magnetic coupling).

7. Scope of delivery for visual level indicator

Visual level indicator, as ordered

Visual level indicator manual

Works test certificate EN 10204 – 2.2 (function and pressure testing)

Optional: acceptance test certificate EN 10204 – 3.1 (material certificate)

Optional: other certificates like NACE

8. Preparation for assembly

8.1 Unpacking

1. Lay the visual level indicator and the packaging flat on the floor.

2. Remove the packing tape.

3. Remove the staples in the overlapping cardboard at both ends of the packaging with a big

screwdriver or an appropriate tool.

4. Open the packaging and remove the visual level indicator together with the packing trays at both

ends.

5. Carefully remove the packing trays. Make sure that the visual level indicator is on a clean, smooth

surface so that the process connections or supplied parts are not damaged.

6. Make sure that no other parts are in the packaging.

7. Visually inspect the visual level indicator and all the supplied parts for possible damage caused

during transport. Don’t use any damaged or dubious parts.

8.2 Disposing of the packaging

Protect the environment and take the packaging material to be disposed of / recycled properly.

WEKA_IOM_VLI_EN / 17.03.2020 10 / 31

8.3 Remove float protection

If the float is not suitable for the intended use (density, max. operating pressure, max. operating

temperature, connection dimensions, material, etc.), the visual level indicator may display an

incorrect level, and it may be damaged and pose a risk. Make sure that the float is suitable for

the intended application.

Incorrect or incorrectly inserted seals result in leaks. It is imperative that you ensure the correct

seals (material, design) are used for your specific application, and that the seals are positioned

correctly.

Damaged floats adversely affect the functioning of the visual level indicator. Handle the float

carefully and don’t drop it!

Foreign substances in the float chamber adversely affect the functioning of the visual level

indicator. Remove them completely!

An incorrectly installed float will lead to the incorrect fill level being displayed! Slide the float into

the float chamber as shown.

Falling parts (screws, floats, etc.) may create impact sparks and may lead to an explosion in

potentially explosive atmospheres. Make sure that there isn’t a potentially explosive atmosphere

and that no parts are falling when working on the visual level indicator. Only use approved tools.

To avoid damage in transit, the float for some designs is secured to the outside of the float chamber

separately in a cardboard tube. For all other devices, it is secured with a safety device inside the float

chamber to the lower process connection using a cord. This needs to be removed / detached before

assembly:

If the float is secured outside the float chamber, follow point A.

If the float is in the float chamber, follow point B.

If it is a top-of-tank gauge, follow point C.

WEKA_IOM_VLI_EN / 17.03.2020 11 / 31

A) Float attached

1. Detach the cardboard tube from the float chamber.

2. Open the cardboard tube and take out the float.

3. Remove the cardboard rings.

4. Remove the bottom service flanges/plugs.

5. Double check that the float is suitable for the chosen application using

the highlighted data.

6. Insert the float into the float chamber so that the arrow with the label

“TOP” is pointing upwards.

7. Bear in mind that the float can now move freely in the float chamber

and may be damaged. You should therefore now move the level gauge

with all due care.

8. Make sure that there are no foreign substances in the float chamber.

9. Make sure that seal has been inserted correctly.

10. Install the bottom service flange/plug. If you’re dealing with a flange,

tighten the screws diagonally. Bear any tightening torque information in

mind.

VLI line VLI type Torque [Nm]

SmartLine 34000 20

34110

StandarLline

23614 20

34300 60

32755 40

EconomyLine 34000E 20

23614E 20

HighPressureLine

36800 45

26411 25

25683 50

32806 50

Further torque values on datasheet, drawing or on request.

11. Remove the protective covers from the process connections.

B) Float secured in the float chamber

1. Sever the float safety device from the lower process connection.

2. Pull the float safety device completely out of the process connection

from one end. Make sure that there are no foreign substances in the

float chamber.

3. Bear in mind that the float can now move freely in the float chamber

and may be damaged. You should therefore now move the level

gauge with all due care.

4. Remove the protective covers from the process connections.

WEKA_IOM_VLI_EN / 17.03.2020 12 / 31

C) Float for top-of-tank designs

1. The float system for the top-of-tank design consists of a floatation body (called

a float here), the magnet holder and the rod that connects the two parts.

2. Type 23013:

The float moves along a guiding pipe and is fixed for transportation by a cable

tie against movement.

Type 25270:

The float is in the float chamber and is stopped from moving around thanks to

a screw at the bottom end of the chamber.

3. Type 23013:

Remove cable tie and dispose properly.

Type 25270:

Turn the screw until the float can move without too much resistance and move

the float further into the float chamber.

4. Bear in mind that the float can now move freely and may be damaged. You

should therefore now move the level gauge with all due care.

5. Type 25270:

Put the screw all the way back in and tighten it so that it can’t go missing. Now the float cannot

fall out.

WEKA_IOM_VLI_EN / 17.03.2020 13 / 31

9. Installation

Preparations for installing (point 8) the visual level indicator must be completed before installation.

If the data marked on the type plate (density, max. operating pressure, max. operating

temperature, connection dimensions, material, etc.), does not match the application, the visual

level indicator may display an incorrect level, and it may be damaged and pose a risk to people

and the environment. Make sure that the data marked on the type plate matches the application.

Unsuitable screws, nuts and seals may result in leaks and cause damage and may endanger

people and the environment. Only use components suited to the application.

For visual level indicators with weld sockets as process connections, only suitable (approved)

welding processes may be used. The same applies to the selection of filler materials.

Working on hot or pressurised visual level indicators may result in physical injuries, burns,

chemical burns or poisoning. Depressurise the tank and allow it to cool to the ambient

temperature before working on the visual level indicator. Wear suitable protective equipment

(gloves, face guard, possibly breathing apparatus).

The visual level indicator may only be used for the purposes recorded on the type plate and the

Ex label.

Falling parts (screws, floats, etc.) may create impact sparks and lead to an explosion in

potentially explosive atmospheres. Make sure that there isn’t a potentially explosive atmosphere

and that no parts are falling when working on the visual level indicator.

In the absence of equipotential bonding, static charges may build up, which may result in

sparking and lead to explosions. To equalise the potential, permanently connect the metallic

housing of the visual level indicator (float chamber) to the equipotential bonding conductor of the

system (tank).

Possible equipotential bonding connections:

-Weld the weld sockets (process connection) to the tank

-Connect the flanges (process connection) to the tank via at least two bolts.

-If none of these are possible, set up an equipotential bonding conductor of at least 4mm²

via a clamp connection.

-The connection points must be free of paint.

Also, the accessories, like magnet switches, transmitters, etc. must be connected to the potential

equalisation system.

WEKA_IOM_VLI_EN / 17.03.2020 14 / 31

9.1 Mounting

1. Lay out the tools, lifting aids, screws, nuts and seals that you need to

install the visual level indicator.

2. Position the visual level indicator on the tank. When doing so, make

sure that the TOP sticker on the indication rail is pointing upwards.

3. If needed, add seals to the connection threads or between the flange

connections.

-Flange connections

Tighten the flange connection screws diagonally. Check that the

screw connections are a tight fit.

-Weld sockets

Remember that heat will be built up when welding weld sockets.

Components at risk should be covered, cooled, or temporarily

removed.

-Screw-in threads

The visual level indicator and indication rail must not be used to

provide counter torque when installing the screw-in threads. Use a

suitable tool for counteraction without putting stress on or damaging

mounted parts.

9.2 Inspecting

For all types of installation, make sure that the process connections for the

visual level indicator are aligned with the tank’s process connections.

The visual level indicator must be installed in a vertical position. You can

check this with a spirit level on the float chamber. Deviations of up to 5° from

the vertical position are acceptable. Larger deviations may result in increased

friction on the float in the float chamber and may lead to blockages. It is

imperative that this is agreed with the supplier.

Twisting or bending of the float chamber, caused by incorrect socket

distances for example, may block the float and lead to the visual level

indicator breaking down!

10. Commissioning

Installation (point 8 to point 9) must be fully completed before commissioning.

If the data marked on the type plate (density, max. operating pressure, max. operating

temperature, connection dimensions, material, etc.), does not match the application, the visual

level indicator may display an incorrect level, and it may be damaged and pose a risk to people

and the environment. Make sure that the data marked on the type plate matches the application.

Check the visual level indicator for visible external damage before use. Do not put a damaged

visual level indicator into operation.

The visual level indicator may only be used for the purposes recorded on the type plate and the

Ex label.

WEKA_IOM_VLI_EN / 17.03.2020 15 / 31

The visual level indicator is filled with liquid from the tank. When filling the tank for the first time, bear in mind

that there will not yet be any liquid in the float outlet, and that the float will only float when this dead space

has been filled via the lower socket.

Once the float starts floating, some time will still be needed for it to align with the magnetic band of the

indication rail. From then on, the fill level should be shown when the gauge flaps are turned down.

If any of the gauge flaps are shifted into an incorrect position during transit, it is possible to move them back

to their intended locations using a weak hand-held magnet. This method can also be used to test the

mobility of the gauge flaps by hand. However, they should always then be put back in their original

positions.

It is advisable to completely drain the tank under supervision once, and to visually check the fill level so that

you can guarantee the level gauge is functioning properly.

Just to be on the safe side, check the entire device after it has been filled, including checking the seals for

leaks.

For steam applications, it is imperative that you ensure no pressure surges occur, as this may catapult the

float up into the float chamber and destroy it.

11. Maintenance

Only use the visual level indicator if it is working properly.

Do not use an unsealed visual level indicator.

Working on hot or pressurised visual level indicators may result in physical injuries, burns,

chemical burns or poisoning. Depressurise the tank and allow it to cool to the ambient

temperature before working on the visual level indicator. Wear suitable protective equipment

(gloves, face guard, possibly breathing apparatus).

If you suspect that there is a malfunction or determine that there is one, this must be rectified.

Damaged or faulty components must be replaced by original replacement parts.

The visual level indicator may only be repaired and modified by the manufacturer (or, if

appropriate, in consultation with the notified body).

The visual level indicator is generally maintenance-free.

The level gauge should only be cleaned on the outside – and on the inside if necessary – in the

event of a suspected malfunction, or in any of the circumstances listed below.

Time Scope

While in use

-In the event of a suspected

malfunction

-Periodically, depending on

usage and degree of

contamination

Check visual level indicator for leaks.

If required, clean inside and outside.

Check float for excessive wear marks.

Before each use Check for damage.

For highly-viscous and/or heavily

contaminated process liquids

Periodically clean the inside, depending on degree of

contamination.

After a long period of inactivity Check visual level indicator for leaks.

If required, clean inside and outside.

After cleaning

(see chapter 12)

Check visual level indicator for leaks.

WEKA_IOM_VLI_EN / 17.03.2020 16 / 31

12. Cleaning visual level indicator

12.1 Cleaning the outside

Polycarbonate indication rails may become statically charged – e.g. during cleaning. Sparks

created when discharging in a potentially explosive atmosphere may cause an explosion. Only

clean these parts with antistatic cleaning agents and tools.

Caution

Solvents and scouring agents may cause the indication rail window to become dull or cracked. Clean the

window with soapy water or a plastic cleaner.

12.2 Cleaning the float chamber and the float

Risk of burning! Working on hot visual level indicators may result in physical injuries and burns.

The surfaces of the standpipes and the process connections may become hot. Allow the tank to

cool to the ambient temperature before working on the visual level indicator. Wear suitable

protective equipment (gloves, face guard, possibly breathing apparatus). Keep a sufficient

distance away while the machine is in operation.

Visual level indicators run at excessive pressure carry pressure-related risks. Depressurise the

tank before working on the visual level indicator and observe the information of the local valid

pressure regulations, i.e. Pressure Equipment Directive 2014/68/EU.

When opening the visual level indicator, bear in mind that the fluids and gases it contains could

be hazardous to health. It is imperative that you comply with the safety data sheets for the

process liquids and gases used.

Falling parts (screws, floats, etc.) may create impact sparks and lead to an explosion in

potentially explosive atmospheres. Make sure that there isn’t a potentially explosive atmosphere

and that no parts are falling when working on the visual level indicator.

When using highly contaminated fluids or pipe systems, the float and the float chamber need to be cleaned

frequently.

In fluids with magnetic parts, they cluster on the float’s magnet. Remove them

frequently.

1. Empty the tank.

The float may fall out and get damaged when you remove the

connection flange.

Remove the float chamber via the lower service connection, see

Figure (Service plug/flange).

Remove the lower service plug/flange and the float.

2. Clean the float chamber and the float with a suitable cleaning agent.

WEKA_IOM_VLI_EN / 17.03.2020 17 / 31

3. Check the float.

Floats with heavy signs of wear need to be replaced occasionally. When

ordering replacements, make a note of the serial/order number and the

item number to make clear assignment possible.

If the density noted on the float doesn’t match with the density of the fluid,

the visual level indicator will show an incorrect fill level. Consult your

authorised WEKA dealer before using a float from a different visual level

indicator.

An incorrectly installed float will lead to the incorrect fill level being

displayed!

4. Slide the float into the float chamber as shown.

Unsuitable screws, nuts and seals may result in leaks and cause damage

and may endanger people and the environment. Only use components

suited to the application.

5. Reseal the service connection, as described in point 9.1.

Recommission the visual level indicator, as described in point 10.

12.3 Cleaning the float chamber and float for a top-of-tank assembly

Risk of burning! Working on hot visual level indicators may result in physical injuries and burns.

The surfaces of the standpipes and the process connections may become hot. Allow the tank to

cool to the ambient temperature before working on the visual level indicator. Wear suitable

protective equipment (gloves, face guard, possibly breathing apparatus). Keep a sufficient

distance away while the machine is in operation.

Visual level indicators run at excessive pressure carry pressure-related risks. Depressurise the

tank before working on the visual level indicator and observe the information of the local valid

pressure regulations, i.e. Pressure Equipment Directive 2014/68/EU.

When opening the visual level indicator, bear in mind that the fluids and gases it contains could

be hazardous to health. It is imperative that you comply with the safety data sheets for the

process liquids and gases used.

Falling parts (screws, floats, etc.) may create impact sparks and lead to an explosion in

potentially explosive atmospheres. Make sure that there isn’t a potentially explosive atmosphere

and that no parts are falling when working on the visual level indicator.

1. Remove the visual level indicator.

2. Loosen the lower float stopper (usually a screw in the guide pipe which stops

the float from falling out) until you can remove the float.

3. Clean the float chamber and the float system with a suitable cleaning agent.

Check the float system (floatation panel, connecting pipe and magnet holder)

for damage and replace them if needed.

Floats with heavy signs of wear need to be replaced occasionally. When

ordering replacements, make a note of the serial/order number and the item

number to make clear assignment possible.

WEKA_IOM_VLI_EN / 17.03.2020 18 / 31

4. Put the float system back in the float chamber and fit the float stopper, see chapter 8.3.

5. Reinstall the visual level indicator on the tank.

Unsuitable screws, nuts and seals may result in leaks and cause damage and may endanger

people and the environment. Only use components suited to the application.

6. Recommission the visual level indicator, as described in point 10.

13. Operating, transport and storage conditions

13.1 Operating conditions

According to the type plate and order confirmation / drawing

Environment (standard):

-Temperature: -20°C to +60°C

-Relative humidity: 10% to 95%

The operating and ambient conditions may be restricted for products for use in potentially

explosive atmospheres. Please comply with the information on the type plate and explosion-proof

plate.

13.2 Transport and storage conditions

-Protect the visual level indicator from severe jolts.

-Do not place heavy items on the visual level indicator or its packaging.

-To avoid damage in transit, secure the flat with a safety device.

-Store the visual level indicator in a dry environment.

-Avoid contact with water and moisture

-Temperature: -40°C to +80°C

-Relative humidity: 10% to 95%

14. Technical data

General information can be gathered from the data sheet for the model in question.

Order-specific data as per type plate and order confirmation / drawing.

15. Disassembly / disposal

15.1 Disassembly

Risk of burning! Working on hot visual level indicators may result in physical injuries and burns.

The surfaces of the standpipes and the process connections may become hot. Allow the tank to

cool to the ambient temperature before working on the visual level indicator. Wear suitable

protective equipment (gloves, face guard, possibly breathing apparatus). Keep a sufficient

distance away while the machine is in operation.

Visual level indicators run at excessive pressure carry pressure-related risks. Depressurise the

tank before working on the visual level indicator and observe the information of the local valid

pressure regulations, i.e. Pressure Equipment Directive 2014/68/EU.

WEKA_IOM_VLI_EN / 17.03.2020 19 / 31

When opening the visual level indicator, bear in mind that the fluids and gases it contains could

be hazardous to health. It is imperative that you comply with the safety data sheets for the

process liquids and gases used.

Falling parts (screws, floats, etc.) may create impact sparks and lead to an explosion in

potentially explosive atmospheres. Make sure that there isn’t a potentially explosive atmosphere

and that no parts are falling when working on the visual level indicator.

1. Empty the tank.

2. Remove the float chamber via the lower service connection (service

plug/flange).

3. Remove the lower service plug/flange and the float.

Caution: The float may fall out and get damaged when you remove the

connection flange.

4. To avoid damage in transit, the float should be furnished with a transport

safety device (original, if possible). If in doubt, pack the float in separate

packaging.

15.2 Disposing of the visual level indicator

Protect the environment and take the visual level indicator to be disposed of properly.

16. Troubleshooting

Problem Possible

causes

Possible solutions

No visual level shown even

though there is fluid in the tank

Float blocked by dirt in the float

chamber.

Float is damaged, has filled with

fluid and sunk.

Float is caught on iron parts

installed outside the float

chamber.

Clean the float and float chamber

(see “Maintenance” section).

Replace the float. Compare

system test pressure with

information on the type plate.

Search for iron parts (clips,

screws, etc.) along the visual

level indicator with a magnet and

remove or replace them.

Gauge level different to surface of

the liquid (variation)

-Deviation of a few centimetres

or millimetres

Unavoidable deviation with float.

Incorrect float being used.

Immersion depth of the magnet in

the float incorrectly calibrated.

See data sheet.

Check whether the correct float

has been used.

Shift the magnet in the flat by

tapping the float on a soft pad

(rubber mat).

This manual suits for next models

56

Table of contents

Popular Measuring Instrument manuals by other brands

koban

koban KPAW-01A manual

Field Scout

Field Scout CM 1000 product manual

McCrometer

McCrometer FPI Mag 394 Installation, operation and maintenance manual

Baumer

Baumer Hubner Berlin TDPZ 0,2+ESL Installation and operating instructions

VWR International

VWR International 634-6002 instruction manual

DeWalt

DeWalt DW0165 user manual