Techno CNC Systems HD series User manual

Call: 1-631-648-7481 or Visit: support.technocnc.com 1

HD WinCNC Manual

(HTT0674)

This document will provide a quick guide to the set up and operating

procedure of the Techno HD Mini CNC Router and the Techno HD Series CNC

Router with a WinCNC Controller.

The Techno HD Mini CNC Router and the HD CNC Routers are powered by

high precision stepper motors and controlled by a PC with a WinCNC Control

System. Files are transferred from a Cam system via a USB memory stick.

Techno CNC Systems, LLC. ©2015 (06/17)

2Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

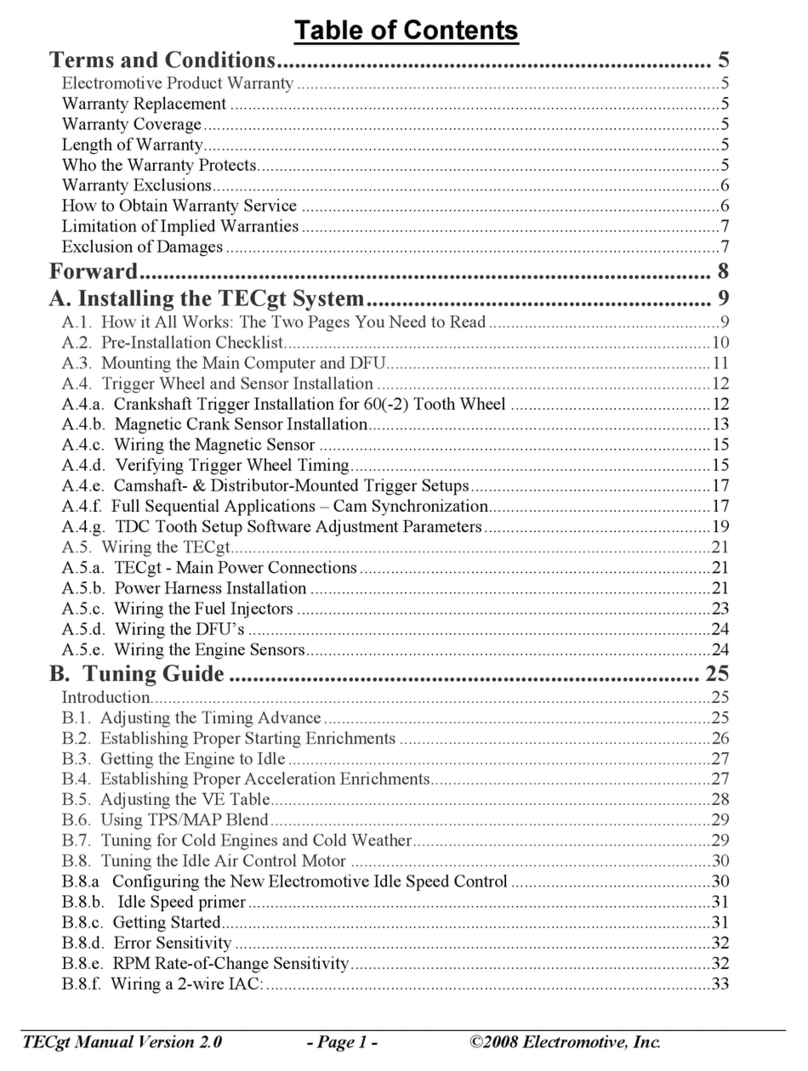

TABLE OF CONTENTS

I Forklift Guide ............................................................... Page 3

Safety Instructions ............................................................... Page 4

Colleting Guidelines ............................................................... Page 5

HD Mini Setup Instructions .................................................. Page 6

HD Series Setup Instructions .................................................. Page 9

HD Series Vacuum Pump Setup.................................................. Page 10

HD Series Installation .................................................. Page 11

II Controller Functionality

2.1- HD Mini Control Panel Functions ..................................................... Page 7

2.2- HD Mini Enabling the Machine 2.3- HD Mini Start Up/Home.........Page 8

2.1- HD Series Control Panel Functions ..................................................... Page 14

2.2- HD Series Enabling the Machine 2.3- HD Series Start Up/Home......Page 15

2.4- WinCNC Controller Overview ..................................................... Page 16

2.5- WinCNC Program Operation ..................................................... Page 17

III Operating Tutorials

3.1- Jogging the Machine and . ......................... Page 38

3.2- Adjusting the XYZ Position/WCS/User Origin ....................... Page 39

IV Advanced Tutorials

4.1- Alternating between Override and Programmed Feedrates .. Page 41

4.2-SettingOverridespeedforaG-codele................................Page42

4.3- Setting the Table Size ...................................... Page 43

4.4- Command Reference ...................................... Page 44

V HD Mini Machine Lubrication ................. Page 72 and Page 73

HD Machine Lubrication ...................................... Page 74

VI ERROR MESSAGES ................................................................ Page 75 - 80

VII Appendix

Becker Vacuum Pump Manual ......................... Page 81 - 85

Becker Vacuum Pump Filter Inspection ......................... Page 86 - 89

Becker Vacuum Pump Greasing Process ......................... Page 90 - 93

VIII Warranty ......................... Page 94

Call: 1-631-648-7481 or Visit: support.technocnc.com 3

HD WinCNC Manual

(HTT0674)

www.technocnc.com (HTT06081112)

All Techno machines are shipped assembled and secured to a wooden pallet.

Unpack all items that shipped

with your machine. Check the

items against the packing slip

to be sure nothing was left out.

Notify Techno immediately if

you are missing any pieces of

your shipment.

1.1

I. UNPACKING AND MACHINE IDENTIFICATIONS

Please note the 4 Forklift Tubes on

the front and rear of the machine.

II. MEASURING FORKS AND FORKLIFTING MACHINE

Front of Machine

Rear of Machine

1 2

43

Fig. 1.1

Care must be taken not to damage the

valves on the front of the machine.

Slowly move in close to the machine.

2.3

Fig. 2.3 Forklift your machine up from the

oor and remove the wooden pallet.

2.4

Fig. 2.4

Forks must be centered in the front

of the machine (shown in Fig 2.1).

2.1

Fig. 2.1

Measure the distance

between the forks.

(shown in Fig 2.2).

2.2

Fig. 2.2

For safety and to prevent damage to the machine

and cables, Lift Machine Using Forklift Tubes ONLY

If required, there are 4 Forklift Tubes

on the sides of the machine.

SAFETY WARNING: DO NOT LIFT OR MOVE MACHINE USING GANTRY

Depending on machine size — SEE QUOTE FOR MACHINE WEIGHT

NOTE: Forklift capacity must be adequate to safely lift the machine.

It is recommended to have Fork Lift Extensions to better support load.

FORKLIFT GUIDE

4Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

1. Keepngers,hands,andallotherobjects

awayfrommachinewhilepowerison.

2. Disconnectpowertoallsystemcomponents

whennotinuse,whenchangingaccessories,

andbeforeservicing.

3. Donotloosen,remove,oradjustmachine

partsorcableswhilepowerison.

4. Exercisecarewithmachinecontrolsand

aroundkeyboardtoavoidunintentional

starting.

5. Makesurevoltagesuppliedisappropriateto

specicationsofcomponents.

6. Machinesmustbepluggedintothree-

prongedgroundedoutlets.Donotremove

thegroundingplugorconnectintoan

ungroundedextensioncord.

7. Keepcablesandcordsawayfromheat,oil,

andsharpedges.Donotoverstretchor

runthemunderotherobjectsoroverwork

surfaces.

8. Useproperxturesandclampstosecure

work.Neverusehandstosecurework.

9. Donotattempttoexceedlimitsofmachine.

10. Donotattempttousemachineforpurposes

otherthanwhatisintended.

11. Usemachineonlyinclean,well-litareas

freefromammableliquidsandexcessive

moisture.

12. Stayalertatalltimeswhenoperatingthe

machine.

13. Alwayswearsafetygoggles.

14. Donotwearloose-ttingclothingwhen

operatingmachine.Longhairshouldbe

protected.

15. Alwaysmaintainproperbalanceandfooting

whenworkingaroundthemachine.

16. Maintainequipmentwithcare.Keepcutting

toolscleanandsharp.Lubricateandchange

accessorieswhennecessary.Cablesand

cordsshouldbeinspectedregularly.Keep

controlscleananddry.

17. Beforeusing,checkfordamagedparts.An

authorizedservicecentershouldperform

allrepairs.Onlyidenticalorauthorized

replacementpartsshouldbeused.

18. Removeanyadjustingkeysandwrenches

beforeturningmachineon.

19.Donotoperatethemachineunattended.

20.Followallsafetyinstructionsandprocessing

instructionsintheMSDSforthematerial

beingprocessed.

21. Useproperprecautionswithdustcollection

systemstopreventsparksandrehazards.

22.Makesuretohaveproperreextinguishing

equipmentonhandatalltimes.

WARNING: IMPROPER OR UNSAFE OPERATION OF THE MACHINE WILL

RESULT IN PERSONAL INJURY AND/OR DAMAGE TO THE EQUIPMENT.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE OPERATING MACHINE.

DO NOT OPERATE MACHINE IF YOU ARE UNFAMILIAR WITH THESE SAFE

OPERATING INSTRUCTIONS. DO NOT OPERATE MACHINE WITHOUT

KNOWING WHERE THE EMERGENCY STOP SWITCH IS LOCATED.

PREVENT FIRE HAZARDS by using the proper feeds, speeds, and tooling while

operating your Techno machine. For example, setting feeds and speeds too low

and/or using dull tool bits creates friction at the material. The friction generates

heat which can result in a re that can be drawn through the vacuum table or

dust collector without warning. Fire hazard from friction heating caused by dull

tools is possible when cutting certain materials, especially composite material

such as wood composites, MDF and Particleboard. © 2012

Safety Instructions

Call: 1-631-648-7481 or Visit: support.technocnc.com 5

HD WinCNC Manual

(HTT0674)

WARNING!

THE SPINDLE WILL BE DAMAGED

IF UNBALANCED EQUIPMENT IS USED.

AIR SUPPLY MUST BE FILTERED AND DRY.

6Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

The Techno HD Mini

Router is powered by

220 Volt AC and the

electronics require Single

Phase power.

When unpacking the machine,

avoid twisting any of the cables.

(Fig 1.1a and Fig 1.1b)

1.1

1.2

I. TECHNO HD MINI SETUP

The power cable is supplied without a plug.

You will need to supply your own plug.

Haveasuitablyqualiedpersonattachthecorrectplug

in compliance with the wiring standards in your area.

The machine must be connected to a 220V,

single phase, 15A circuit.

The cable that we supply will be one of two types.

It may either be a cable with a brown, blue, and green/yellow wire

or a cable with a black, white, and green wire. (Fig 1.2)

Power is connected as follows:

Cable type 1:

Brown - hot

Blue - hot

Green/yellow - ground

Cable type 2:

Black - hot

White - hot

Green - ground

Fig. 1.2

Fig. 1.1

Call: 1-631-648-7481 or Visit: support.technocnc.com 7

HD WinCNC Manual

(HTT0674)

2.1 Control Panel Functions.

Once the electrical connections have been made, the machine is powered on by pressing the green

POWER button on the front of the machine. Figure 2.1a shows the buttons and their functions.

The front panel also contains the Spindle Inverter Readout.

The number on this display multiplied by 60 gives the spindle speed in RPM.

The potentiometer and buttons on this display should NOT be touched.

The spindle is controlled by the WinCNC controller on your PC.

Emergency

Stop Power

Enable

Power

Disable

Spindle Inverter

Readout

USB

Port

Fig.2.1a

Tool

Calibration

Block

WinCNC Controller

WinCNC Users Guide Page 10

Screen Display

The following section contains a sample of the WinCNC software

display. Common components are labeled to provide clarity.

NOTE : This screen may differ from your screen layout, as it is

highly customizable and may have been altered by the CNC ma-

chine manufacturer.

Screen Display Component Breakdown

Menu Bar

The Menu Bar contains many of the main features of the WinCNC

software. It is broken down into several generalized sections, as

shown below. The menu bar selections are described in the follow-

ing pages. If a menu option has a shortcut key, the shortcut key

combination is listed in parenthesis () after the name of the menu

option.

Program Operation

Turn on the Spindle Vary the spindle speed

The spindle speed should change uniformly, 1 on

LCD=50 on inverter,6=300

If looking down the spindle from above, tool should be

turning Clockwise.

Check rotation of the spindle.

II. WinCNC Controller: Functionality

Once the main power switch has been engaged the controller is activated by pressing the

green on switch on the front of the controller.

8Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

2.2 Enabling The

Machine.

When the machine is plugged in,

the red POWER button will light up

indicating the machine is powered,

but motors are not yet powered.

Fig 2.2a

Activate the machine by pressing the

green POWER button.

Power is now applied to the machine.

The green light will now light up and the

red light will go off. Fig 2.2b Fig.2.2b

Fig.2.2a

(Note that the red POWER button will light up if the Emergency Stop is pressed during operation.)

2.3 Start-Up/Home

Homing the Machine

WhenWinCNCControllerisstartedthedisplayissettothelastknownposition.Ifthemachine

hasbeenmovedmanuallyorhasdriftedwhilepowereddown,thispositionwillnotbeaccurate.

TheG28commandmustbeusedtohomethemachine.G28movestheWZmotorsuptothe

highlimits,thenmovestheXYmotorstotheirlowlimits.Theheadsarethenmovedawayfrom

thelimitsbythevaluesspeciedinWINCNC.INIandeachaxisissettozero.Thispositionis

MachineZero.

ItisimportanttouseG28tosetMachineZerosincemanyWinCNCfeaturesarecalculatedfrom

thisposition.SoftLimitsandBoundariescannotbeusedifMachineZeroisnotproperlyset.G28

willsearchforthelimitsat50”perminute.The“lim_step=”settinginWINCNC.INIcanhelp

minimizetheimpacttothemachinewhenstoppingatthelimitswitches.

G28canalsobeusedtohomeonlyspeciedaxis.(i.e.G28ZhomesonlytheZaxis).

NormalmachineoperationusingWinCNCControllerwouldbe:

Starttheprogram.

EnterG28.PushENTER.(MachineGoesHome)

Enterpartprogramtocut.PushENTER.(Jobleruns)

Call: 1-631-648-7481 or Visit: support.technocnc.com 9

HD WinCNC Manual

(HTT0674)

L1 L2 L3

Fig. 1.1

Enclosure

The Techno HD Series Router is powered by 220 Volt AC. Unless specially requested,

the electronics require 3-phase power.

The Electronics are housed in the large Nema

enclosure as shown in Figure 1.1. When unpacking

the machine avoid twisting the cable carrier that

guides the cables to the motors.

Haveasuitablyqualied

person connect the

220V to the terminals.

Make sure that all local

electrical codes are

obeyed. For single phase

machine, connect power

to L1 and L3 only.

1.1

1.4

I. TECHNO HD SETUP

Open the

back of the

enclosure

(shown in

Fig 1.2) with

the key

provided.

1.2

Fig. 1.2

Fig. 1.4

Guide the cable through the hole

on the side of the enclosure and

attach the hand-held controller to

the DB 15 terminal.

(shown in Fig. 1.6).

1.5

Fig. 1.5

The electronics will now be

visibleandidentiableandwill

be identical or like depending

on the model issued. (shown in

Fig. 1.3).

The terminals for the

220 volt connection are located

at the bottom of the box

(shown in Fig.1.4).

1.3

Fig. 1.3

B

A

C

D

A -Controller Board

B -Stepper Driver

C -24 Volt PSU

D -220 Volt In

1.6

If the machine has a vacuum

hold down pump, there is a

matching connector that will

plug into the controller box

(shown in Fig.1.7).

Vacuum Starter

Connection

Fig. 1.6

10 Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

Control Box Front Panel

(for Vacuum System)

The

highlighted above come

standard if the Vacuum Table

is purchased with the machine.

Vacuum Pump Switch

WARNING: Direction of Pump Rotation is critical.

Briey start Pump and check rotation (arrow on casing).

Exchange phases if rotation is incorrect.

IF YOU RUN THE PUMP/BLOWER CONTINUOUSLY

IN THE WRONG DIRECTION,

THE VANES WILL BE DAMAGED.

NOTE:

The cover was

removed from

Motor Starter.

HD VACUUM PUMP SETUP: SINGLE PHASE & 3 PHASE

If a Vacuum Pump/Blower was part of your order, you

will have an electrical starter box that looks like this.

You should not need to wire the Vacuum Pump/Blower

Motor, it has been wired and tested at the factory.

You will need to have the electrician connect

AC power (220 or 440VAC)asspecied

on the unit here to the Motor Starter.

3 Phase Control Box

Single Phase Control Box

Pump/Blower Motor

Starter Box & Connector

Vacuum Hoses

Vacuum Hose Kit

Use the

T-Connector

to connect the

Blue Hose to

the 2 Vacuum

Hoses to the

Machine.

Call: 1-631-648-7481 or Visit: support.technocnc.com 11

HD WinCNC Manual

(HTT0674)

I. Techno HD Installation

The Techno HD series Router is powered

by 220 Volts AC.

Unless specially requested the electronics

require 3 phase power.

1.1 The Electronics are housed in the large

controllerboxasshowningure1.1.When

unpacking the machine avoid twisting the

cable carrier that guides the cables to the

motors.

Fig.1.1

Controllerbox

1.2 Open the back of the controller box (shown in Fig 1.2a) with the key provided.

TheelectronicswillnowbeexposedandcomponentsidentiedinFig1.2b.

Fig.1.2a

Fig.1.2b

A

C

B

A- Controller Board.

B- 24Volt PSU.

C- Stepper Driver.

D- 220Volt In.

D

12 Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

Fig.1.3

1.3

Haveaqualiedelectricianattach220Voltsto

theterminalonthebottomofthebox(g1.4.)

Unlessspecicallyrequestedbytheuser,

3 Phase 220Volt is needed.

Ifthemachinehasbeenmodiedforsingle

phase operation, then L1, L3 and GND are

used, and nothing is attached to L2. Fig.1.4

1.4

If the machine has a vacuum table the Vacuum

Pump should be wired to 220V or 440V

(dependingonwhatisspeciedontheUnit,)by

aqualiedElectrician.

Fig 1.5a

Voltage In

Fig.1.5a

Fig.1.5b

Fig.1.5c

The starter box will have a round silver

connector attached to a grey cable coming

outofit,g1.5b.

This connector plugs into the socket on the

sideofthemachine,g1.5c.

This cable provides 220volts to the starter coil

to turn on the vacuum.

Very Important! Install the 37 pin cable from the control box

into the daughter card (BLUE) connector, not the PCI (BLACK) connector.

The cards have different power and ground pins and the cards will be

damaged if connected incorrectly.

Make sure the PCI-7200 card is using its own IRQ. IRQ settings must be

alteredfromtheBIOStoinsurenoconictsoccurbetweenthePCI-7200

card and other system resources. Changing these settings from within

Windows alone will not insure this.

After installing your PCI-7200 card and the extra connector, boot up your

computer for driver and software installation.

**Note: When your computer boots up, you may get a hardware installation

wizard. Close it. You will be installing the driver after the software is installed.

Call: 1-631-648-7481 or Visit: support.technocnc.com 13

HD WinCNC Manual

(HTT0674)

WARNING: Direction of Pump Rotation is critical.

Briey start Pump and check rotation (arrow on casing).

Exchange phases if rotation is incorrect.

IF YOU RUN THE PUMP/BLOWER CONTINUOUSLY

IN THE WRONG DIRECTION,

THE VANES WILL BE DAMAGED.

1.6

Use the T-connector to connect the blue

hose to the two hoses from the bottom

of the machine (Fig 1.6a) and attach the

other end of the blue hose to the pump.

(Fig 1.6b) Fig.1.6a

Fig.1.6b

1.7

Once power is connected, turn the

machine on by turning the main

power control switch.

Fig 1.7a

Fig.1.7a

Fig.1.7c

Press the green button to apply

power to the controller and

enable the motors. Fig 1.7c

Vacuum switch.

Press the vacuum switch to turn

on the vacuum pump.

Fig 1.7d

The Vacuum zones are

controlled by the manifolds on

the front of the machine. Fig

1.7e

Fig.1.7d

Fig.1.7e

Fig.1.7b

Power is now applied to the

controller box. The red light will

now light up indicating the machine

is powered, but motors are not yet

enabled. Fig 1.7b

(Note that the red POWER button will light up if the Emergency Stop is pressed during operation.)

Vacuum Hoses

T-connector

end of Blue Hose

14 Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

2.1 Control Panel Functions.

Once the electrical connections have been made, controller is

powered by turning the main power switch, on the front of the

machine, to the ON position

(as shown in Fig. 2.1a).

II. WinCNC Controller: Functionality

Fig.2.1a

Once the main power switch has been engaged the controller is activated by pressing the

green on switch on the front of the controller.

The front panel also contains the spindle speed readout. The number on this display

multiplied by 60 gives the spindle speed in RPM. The potentiometer and buttons on this display should NOT be

touched.

The spindle is controlled by the WinCNC controller on your PC.

Figure 2.1b shows the buttons and their functions.

Emergency

Stop

Power

Enable

Power

Disable

Spindle Inverter

Readout

Vacuum

Controls

USB

Port

Fig.2.1b

WinCNC Controller

WinCNC Users Guide Page 10

Screen Display

The following section contains a sample of the WinCNC software

display. Common components are labeled to provide clarity.

NOTE : This screen may differ from your screen layout, as it is

highly customizable and may have been altered by the CNC ma-

chine manufacturer.

Screen Display Component Breakdown

Menu Bar

The Menu Bar contains many of the main features of the WinCNC

software. It is broken down into several generalized sections, as

shown below. The menu bar selections are described in the follow-

ing pages. If a menu option has a shortcut key, the shortcut key

combination is listed in parenthesis () after the name of the menu

option.

Program Operation

Turn on the Spindle Vary the spindle speed

The spindle speed should change uniformly, 1 on

LCD=50 on inverter,6=300

If looking down the spindle from above, tool should be

turning Clockwise.

Check rotation of the spindle.

Call: 1-631-648-7481 or Visit: support.technocnc.com 15

HD WinCNC Manual

(HTT0674)

2.2 Enabling The

Machine.

Turnthemachineonbyturn-

ingthemainpowercontrol

switch.

Fig2.2a

Fig.2.2a

Fig.2.2c

Powerisnowappliedtothe

controllerbox.Theredlight

willnowlightupindicating

themachineispowered,but

motorsarenotyetenabled.

Fig2.2b

Pressthegreenbuttontoap-

plypowertothecontrollerand

enablethemotors.Fig2.2c

Fig.2.2b

2.3 Start-Up/Home

(Note that the red POWER button will light up if the Emergency Stop is pressed during operation.)

Homing the Machine

WhenWinCNCControllerisstartedthedisplayissettothelastknownposition.Ifthemachine

hasbeenmovedmanuallyorhasdriftedwhilepowereddown,thispositionwillnotbeaccurate.

TheG28commandmustbeusedtohomethemachine.G28movestheWZmotorsuptothe

highlimits,thenmovestheXYmotorstotheirlowlimits.Theheadsarethenmovedawayfrom

thelimitsbythevaluesspeciedinWINCNC.INIandeachaxisissettozero.Thispositionis

MachineZero.

ItisimportanttouseG28tosetMachineZerosincemanyWinCNCfeaturesarecalculatedfrom

thisposition.SoftLimitsandBoundariescannotbeusedifMachineZeroisnotproperlyset.G28

willsearchforthelimitsat50”perminute.The“lim_step=”settinginWINCNC.INIcanhelp

minimizetheimpacttothemachinewhenstoppingatthelimitswitches.

G28canalsobeusedtohomeonlyspeciedaxis.(i.e.G28ZhomesonlytheZaxis).

NormalmachineoperationusingWinCNCControllerwouldbe:

Starttheprogram.

EnterG28.PushENTER.(MachineGoesHome)

Enterpartprogramtocut.PushENTER.(Jobleruns)

16 Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

II. WinCNC Controller: Overview

WinCNC Controller has advanced features to provide the smoothest possible

cuts. G-Code input is constantly buffered to ‘vector match’ moves. This means

your machine only slows down when it needs to and then only as much as

needed to stay within the acceleration parameters programmed. WinCNC

Controller also does S-Curve acceleration through arcs and matches arc

tangential velocities with straight moves to provide smooth arc moves. The

result of these features is simply smoother cuts and less need for finishing

operations. WinCNC Controller has a highly customizable, user-friendly

interface that lets you take control of your machine, providing features

previously only found on custom industrial controllers.

The intuitive user interface is easy to learn and convenient to use. All the

features you need and expect are readily accessible via industry standard

G-Codes. Simple keystrokes provide the ability to start, pause, restart, jog,

and rapid transit any axis without navigating multiple screens and windows.

Programs may be run from any line as needed. The programmed feed rates

may be adjusted from 1% to 200% without stopping machine motion.

Run the program by double clicking the WinCNC icon

on your Windows desktop.

Program options may be selected from the pull down menu using the mouse,

ALT+ menu key, or function keys while the machine is stopped. Files can either

be typed into the command line or you can use the File menu’s open option to

bring the file name to the command line. Using the open command does not

automatically run the file, it just brings the name to the command line.

Call: 1-631-648-7481 or Visit: support.technocnc.com 17

HD WinCNC Manual

(HTT0674)

WinCNC Controller

WinCNC Users Guide Page 10

Screen Display

The following section contains a sample of the WinCNC software

display. Common components are labeled to provide clarity.

NOTE : This screen may differ from your screen layout, as it is

highly customizable and may have been altered by the CNC ma-

chine manufacturer.

Screen Display Component Breakdown

Menu Bar

The Menu Bar contains many of the main features of the WinCNC

software. It is broken down into several generalized sections, as

shown below. The menu bar selections are described in the follow-

ing pages. If a menu option has a shortcut key, the shortcut key

combination is listed in parenthesis () after the name of the menu

option.

Program Operation

18 Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

WinCNC Controller

WinCNC Users Guide Page 10

Screen Display

The following section contains a sample of the WinCNC software

display. Common components are labeled to provide clarity.

NOTE : This screen may differ from your screen layout, as it is

highly customizable and may have been altered by the CNC ma-

chine manufacturer.

Screen Display Component Breakdown

Menu Bar

The Menu Bar contains many of the main features of the WinCNC

software. It is broken down into several generalized sections, as

shown below. The menu bar selections are described in the follow-

ing pages. If a menu option has a shortcut key, the shortcut key

combination is listed in parenthesis () after the name of the menu

option.

Program Operation

2.4 Program Operation: Overview and Short Cuts

Transit Menu

Slow (F2) - Sets the transit speed to slow.

Medium (F3) - Sets the transit speed to medium

Fast (F4) - Sets the transit speed to fast.

Keyboard (CTRL+K) -

Enable/Disable the keyboard transit/jog

control used to move the machine with

the keyboard.

This section outlines the tasks required to operation

your Techno HD CNC Router equipped with the

WinCNC Control System

Call: 1-631-648-7481 or Visit: support.technocnc.com 19

HD WinCNC Manual

(HTT0674)

WinCNC Controller

WinCNC Users Guide Page 11

File Menu

Open (CTRL+O) - Opens a le.

Edit (CTRL+E) - Opens the editor. If a lename is in the command

line, the editor opens that le.

Simulate (CTRL+S) - Simulates a le running to check for errors and

estimate run time.

View (CTRL+V) - Views a le in the viewer window.

Restart (CTRL+R) - Opens the le restart dialog box to restart a le.

Create Home File (CTRL+H) - Creates a home le at the current

machine position.

Import => DXF - Allows the user to import DXF (Drawing Exchange

Format) le.

Import => HPGL - Allows the user to import HPGL (Hewlett-Packard

Graphics Language) le.

*Note: The DXF and HPGL import feature is intended for cutting

simple designs. WinCNC does not compensate for tool diameter

when converting these les. For more complicated design, where

intelligent tool pathing is important, please use a compatible CAD/

CAM program.

Digitize => Manual - Enable/Disable the Manual Digitizing Toolbar.

Digitize => Automatic - Automatic digitizing (L802, L803).

Digitize => Frame - Skeletal Digitizing (L810). This scanning

method scans a center line or spine, and horizontal lines or ribs of

the object.

Digitize => Outline - Creates an outline trace around an object.

Program Operation

20 Call: 1-631-648-7481 or Visit: support.technocnc.com

HD WinCNC Manual

(HTT0674)

WinCNC Controller

WinCNC Users Guide Page 12

Digitize => Laser => Run Scan - Opens the laser digitization dialog

box to set up laser scanning parameters.

Digitize => Laser => Reprocess Data - Opens a data le from a

previous laser scan used to re-generate a 3D object with different

ltering options to improve the quality of the 3D object.

Exit - Closes WinCNC.

Conguration Menu

D/A Calibration - Calibration Settings for D/A (Digital to Analog)

spindle speed control. This can only be used if D/A has been acti-

vated in the WinCNC Program.

Settings Menu

Positions - Opens the positions dialog box with options to view and

edit stored positions. (Ex: G53 P# to call position in G-Code)

Home Positions - Opens the positions dialog box with options to

view and edit stored home positions. (Ex: G0 H# to call home pos.)

Tool Positions - Opens the tool positions dialog box with options to

view and edit stored tool positions for use with automatic tool chang-

ers. (This requires an additional software feature to be enabled)

Tool Library - Edits and views the dened tool library.

Local Coordinates - View XYZ coordinates.

View Menu

Resolution - View current resolution settings for each axis.

Acceleration - View current acceleration settings for each axis.

Limits - View current limit settings for each axis.

Inputs - Views real-time input states.

Outputs - Views real-time output states.

Program Operation

This manual suits for next models

1

Table of contents

Other Techno CNC Systems Control System manuals

Popular Control System manuals by other brands

Krom Schroder

Krom Schroder FCU 500 technical information

Meteo Control

Meteo Control WEB’LOG RESIDENTIAL quick start guide

Electro motive

Electro motive TECgt user manual

Little Giant

Little Giant OA1S Series owner's manual

flakt woods

flakt woods FICO FCLA-128 Installation, use and maintenance handbook

Aqua Logic

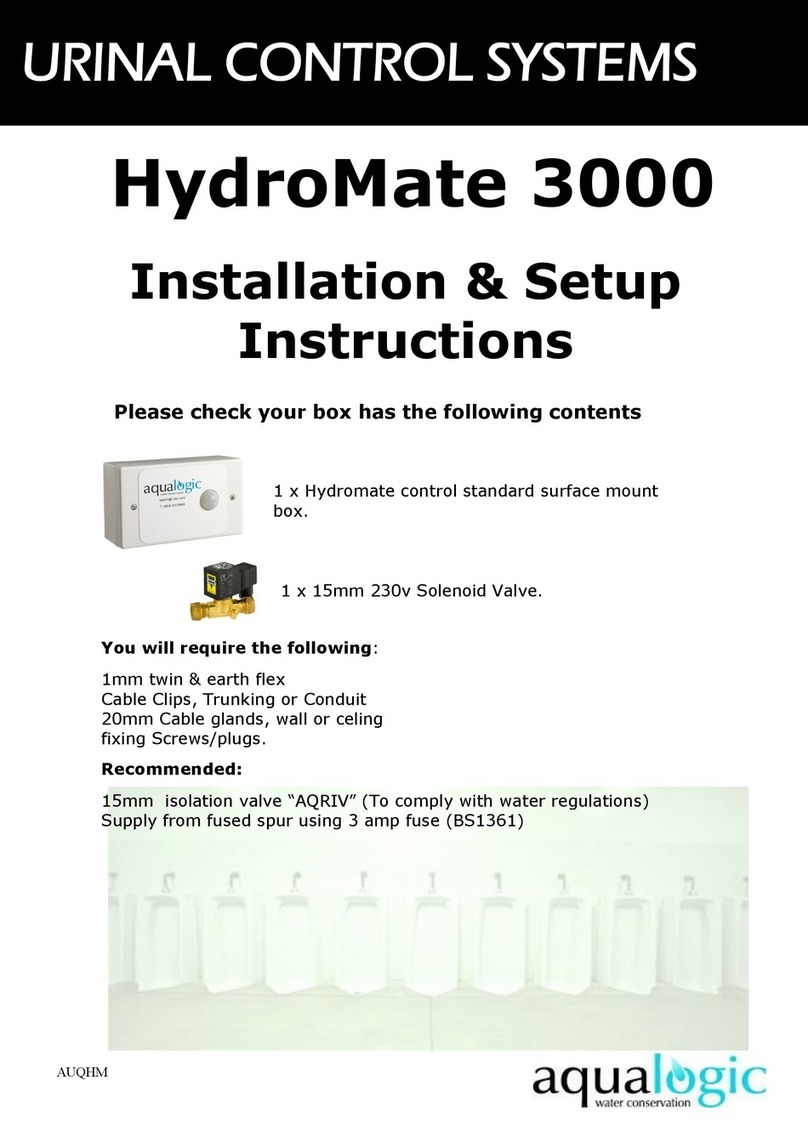

Aqua Logic HydroMate 3000 Installation & setup instructions