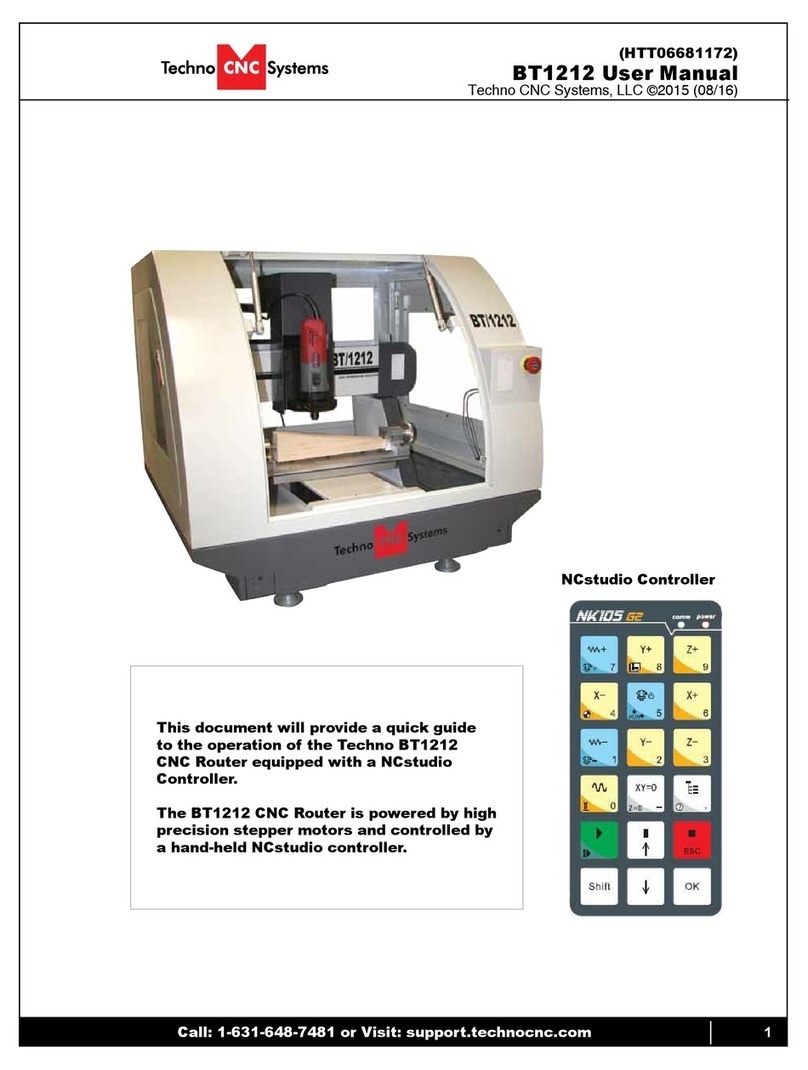

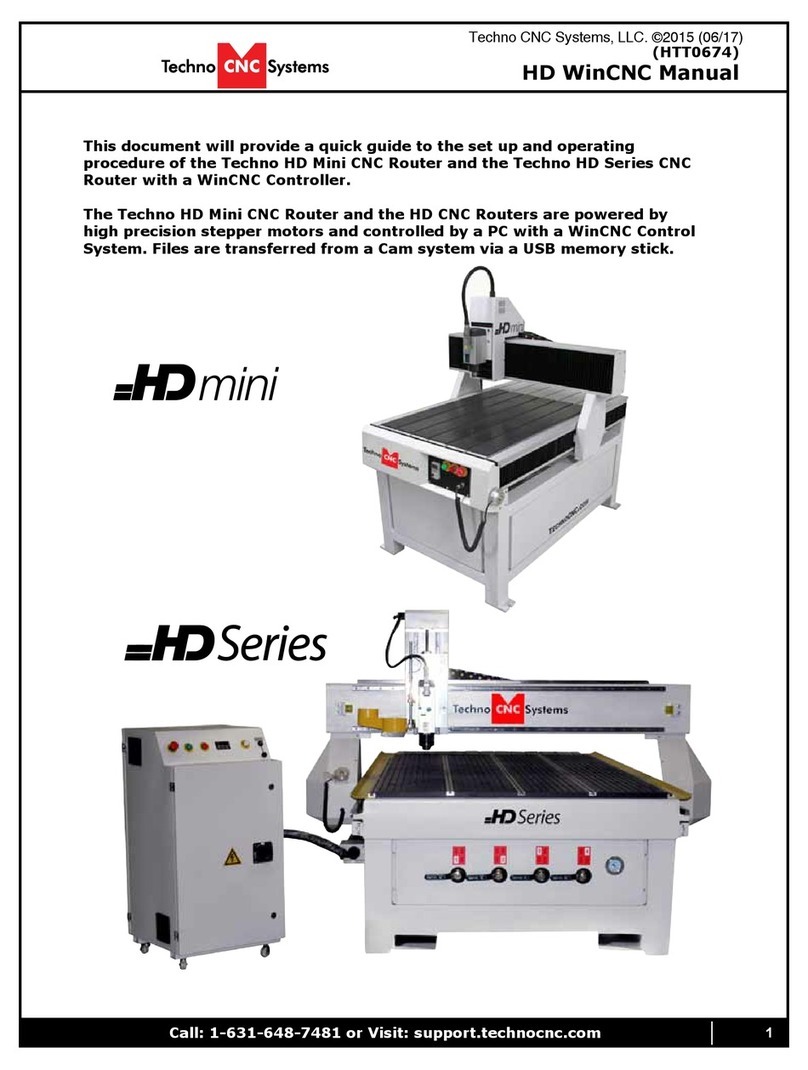

Techno CNC Systems Venture Series User manual

1For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

This manual will provide unpacking, maintenance, and user guide for running the Techno Venture Series

and Venture Plus Series CNC Routers.

It is suggested that the operator keep this manual by the machine. This will provide the most important

information pertaining to the operation of this machine.

©2017 (05/08/2017)

WARNING: DO NOT OPERATE THIS MACHINE WITHOUT PROPER

TRAINING! Improper or unsafe operation of the machine will

result in personal injury and/or damage to the equipment.

Series CNC Router

User Manual

2For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

TABLE OF CONTENTS

I......General Installation Instructions.

1.1 Forklift guide and unpacking instructions. ............................. Page 3

1.2 Safety Instructions. ............................. Page 4

1.3 Correct Colleting. ............................. Page 5

1.3.5 Toolstand 1.3.6 Spindle Warmup ............................. Page 6

1.4 Electrical and Pneumatic connections. ............................. Page 7 - 8

1.5 Vacuum Pump connections. ............................. Page 9

II.....Machine Start-Up and Screen Functionality.

2.1- Start up Procedure. ............................. Page 10 - 12

2.2- Screen Callouts. ............................. Page 13 - 25

2.3- File System-Network. ............................. Page 26

III... Operating Tutorials

3.1- Jogging the Machine. ............................. Page 27 - 28

3.2- Learning Tool lengths. ............................. Page 29 - 30

3.3- Saving an Origin | Setting XYZ Zero Position ............................. Page 31 - 32

3.4- Preparing a G-Code File. ............................. Page 33 - 34

3.5- Running a G-Code File. ............................. Page 35 - 36

3.6-MachineOrigin,WorkingOrigin,&Osets .............................Page37

IV.....Advanced Tutorials

4.1- Using Block to Block Function. ............................. Page 38

4.2-MemSearch. 4.3-ReturntoProle. .............................Page39

4.4- Setup Parameters. ............................. Page 40 - 43

4.5- Backing up Parameters. ............................. Page 44 - 46

V......Machine Lubrication ............................. Page 47

VI....Appendix

6.0- HSD Aggregate Tool Setup. ............................. Page 48 - 49

6.1- Service and Maintenance Guide ............................. Page 50 - 54

6.2- Fault Finding/Error Messages. ............................. Page 55 - 59

Becker Vacuum Pump Manual ............................... Page 60 - 64

Becker Vacuum Pump Filter Inspection ............................... Page 65 - 67

Becker Vacuum Pump Greasing Process ............................... Page 68 - 72

Warranty .......................... Page 73

3For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

Techno CNC Systems Venture Series Forklift Guide

SAFETY WARNING:

DO NOT LIFT MACHINE OR MOVE MACHINE BY THE GANTRY

For safety and to prevent damage to the machine, Lift Machine Using The Frame ONLY

** Some Venture Series CNC Routers do NOT have forklift tubes. **

If so, make sure forklift blades enter through the frame of the machine only. Use blocks when lifting

machine to prevent damage to the vacuum table plumbing **

1. Unpack all items that shipped with your machine. Check the items on your slip to be sure nothing was left out. Notify Techno if you have any missing

pieces of your shipment.

2. A toolbox and other accessories, such as vacuum hosing and leveling feet, may be packed under the machine during shipping.

3. Forklift your machine up from the oor and remove the wooden pallet (if it was shipped on a wooden pallet).

4For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

1.2 SAFETY INFORMATION!

1. Keepngers,hands,andallotherobjectsawayfrom

machinewhilepowerison.

2. Disconnectpowertoallsystemcomponentswhen

notinuse,whenchangingaccessories,andbefore

servicing.

3. Donotloosen,remove,oradjustmachinepartsor

cableswhilepowerison.

4. Exercisecarewithmachinecontrolsandaround

keyboardtoavoidunintentionalstarting.

5. Makesurevoltagesuppliedisappropriateto

specicationsofcomponents.

6. Machinesmustbepluggedintofour-pronged

groundedoutlets.Donotremovethegrounding

plugorconnectintoanungroundedextension

cord.

7. Keepcablesandcordsawayfromheat,oil,and

sharpedges.Donotoverstretchorrunthem

underotherobjectsoroverworksurfaces.

8. Useproperxturesandclampstosecurework.

Neverusehandstosecurework.

9. Donotattempttoexceedlimitsofmachine.

10. Donotattempttousemachineforpurposesother

thanwhatisintended.

11. Usemachineonlyinclean,well-litareasfreefrom

ammableliquidsandexcessivemoisture.

12. Stayalertatalltimeswhenoperatingthemachine.

13. Alwayswearsafetygoggles.

14. Donotwearjewelryorloose-ttingclothingwhen

operatingmachine.Longhairshouldbeprotected.

15. Alwaysmaintainproperbalanceandfootingwhen

workingaroundthemachine.

16. Maintainequipmentwithcare.Keepcutting

toolscleanandsharp.Lubricateandchange

accessorieswhennecessary.Cablesandcords

shouldbeinspectedregularly.Keepcontrols

cleananddry.

17. Beforeusing,checkfordamagedparts.An

authorizedservicecentershouldperformall

repairs.Onlyidenticalorauthorizedreplacement

partsshouldbeused.

18. Removeanyadjustingkeysandwrenchesbefore

turningmachineon.

19. Donotoperatethemachineunattended.

20. Followallsafetyinstructionsandprocessing

instructionsintheMSDSforthematerialbeing

processed.

21. Useproperprecautionswithdustcollection

systemstopreventsparksandrehazards.

Read these instructions thoroughly before operating

machine. DO NOT operate machine if you are unfamiliar with

these safe operating instructions. DO NOT operate machine

without knowing where the emergency stop switch is located.

PREVENTFIREHAZARDSbyusingtheproperfeeds,speeds,andtoolingwhileoperatingyourTechnomachine.

Forexample,settingfeedsandspeedstoolowand/orusingdulltoolbitscreatesfrictionatthematerial.The

frictiongeneratesheatwhichcanresultinarethatcanbedrawnthroughthevacuumtableordustcollector

withoutwarning.Firehazardfromfrictionheatingcausedbydulltoolsispossiblewhencuttingcertainmaterials,

especiallycompositematerialsuchaswoodcomposites,MDFandParticleboard. ©2015

5For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

WARNING!

THE SPINDLE WILL BE DAMAGED

IF UNBALANCED EQUIPMENT IS USED.

AIR SUPPLY MUST BE FILTERED AND DRY.

1.3 Correct Colleting:

Read these instructions thoroughly

BEFORE operating machine.

6For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

1.3.5 Tool Stand Diagram - Proper Placement

ReadtheseinstructionsthoroughlyBEFOREoperatingmachine.

1.3.6 —HSD

Spindle Warmup

Read these instructions thoroughly BEFORE operating machine.

USE AND ADJUSTMENT

PREHEATING

HSD S.p.A. uses high-precision angular contact bearing pairs, pre-loaded and lubricated for life

with special grease for high speeds.

When the machine is switched on for the first time every day, allow the electrospindle to perform a

brief preheating cycle in order to allow the bearings to gradually attain a uniform operating

temperature, and hence to obtain a uniform expansion of the bearing races and the correct preload

and rigidity.

The following cycle is recommended, without machining operations:

50 %of the maximum rated speed for 2minutes.

75 %of the maximum rated speed for 2minutes.

100 %of the maximum rated speed for 1minute.

The preheating cycle should also be performed every time that the machine is inoperative long

enough for the electrospindle to cool down to room temperature.

Only for HSK versions:

it is forbidden to run the electrospindle without the tool-holder inserted.

While the machine is operating, the spindle can reach high temperatures. Be very careful

not to touch it without due precautions.

Spindle Warm-up:

7For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

1.4.2

AlltheelectronicsfortheVenturemachineare

locatedinthehousingcabinet.Donotopen

thesedoorswhenpowerisappliedtothe

machine.

1.4.3

Therearetworoundedconnectorsonthesideofthe

controller,theseconnectorsprovide220voltsforthe

vacuumpumpstartercontactors.

Leadthecablefor3phase220voltsthatwillbeusedto

powermachinethroughtheholeonthebottomofthe

cabinet.

Fig1.4.2

220Vinfor

powering

machine

220VOut

forVacuumPump

Network

Connection

Motor/

Encoder

Fig1.4.3.

1.4 Electrical and Pneumatic connections.

TheTechnoVentureseriesmachineispoweredbythreephase220

volts.Theamperagerequirementsforthismachineare40amps.

1.4.1

Whenthemachinehasbeenunpacked,itwill

benecessarytoattachthekeyboardshelftothe

frontofthemachine.

Whentheshelfisinplace,leadthemouseand

keyboardcablesthroughthesmallholeinthe

fontofthemachine.Plugthecablesintoan

availableUSBconnectiononthePC.

Screwstoattach

shelf

Fig1.4.1

Holeformouseand

keyboardcable

WARNING: Ensure that all electrical connections are

carried out by a qualied electrician.

Improper electrical connections can result in

damage to the equipment, re and death.

8For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

1.4.4

Attachthethreephasesandthegroundtothe

connectionsshowning1.4.4aor1.4.4b

Yourmachinemaycomewithaterminalblock

(shownin1.4.4a)oryoumachinemaycomewith

noterminalblockandmustbewiredtothepower

switchshowningure1.4.4b

1.4.5

Variouscomponentsonthemachinerequireair

pressure.of90psiandneedstobesuppliedtothe

machineatalltimesforittofunctioncorrectly.

Attachanairhosetotheairinputonthebackofthe

machine.Seeg1.4.5.

Ifyourshophosedoesnotttheadaptorsupplied,the

adaptercanberemovedandasuitableoneattached.

3 phase

220V in

WARNING: Ensure that all electrical connections are

carried out by a qualied electrician.

Improper electrical connections can result in damage

to the equipment, re and death.

Fig1.4.5

Should read

90 psi

1.4.6

Removethefourbracketsusedtostabilizethegantry

duringshippingusingmetricallenwrenchs.Theremay

bebracketsattachedtotheXandZaxis,aswell.

Fig1.4.6

Fig1.4.4a.

Fig1.4.4.b

3 phase

220V in

9For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

1.5 Vacuum Pump connections

YouwillneedtohaveanelectricianconnectACpower

(220or440VAC)asspeciedontheunittothemotor

starter.

TakethesilverconnectorfromtheStarterBoxand

connectittothefemaleconnectoronthemain

electronicunit.

Attachthesilverconnector

fromthestarterboxhere.

Attachthehosesfromthemachinetothe

T-connectorsandattachthemtothepump.

WARNING: Direction of Rotation is critical.

Briey start motion and check rotation (arrow on casing).

Exchange phases if rotation is incorrect.

IF YOU RUN THE PUMP/BLOWER CONTINUOUSLY IN THE WRONG

DIRECTION, THE VANES WILL BE DAMAGED

Turnonindividualsectionsofthe

vacuumtablebyturningthemanifold

handlesinthefrontofthemachine.

Vacuum on and off functions are

controlled by the Osai controller

and can only be turned on from

the computer screen.

To test the motor, press the

reset button on the starter box

once all connections are made.

1

2

4

3

10 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

11 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

Section II: Machine Start-Up | Screen Functionality

2.1.1Turn the Main power switch to the ON

Position.220Voltsshould havebeenran to

themachinebyanelectrician.220Visgoing

to be attached to the back of the switch

(below)orattachedtotheterminal(below)

*E-Stop may have been pushed in for

shippingpurposes*

2.1.2

Theredlightonthefrontofthe

machinewilllightup.Thisindicates

that220voltsiscomingintothe

machine.

ThePowerONlightwilllightup

indicatingthatpowerhasbeen

appliedtothecontrollersystemand

themotors.

2.1- Start up Procedure.

Power

O

Power

ON

OSAI

Power

Switch

MUST

BEON!

PC

Power

E-stop:

Turnso

controller,

motorand

spindle

USB

Port

1

2

4

3

Fig2.1.2

PressthePowerONbuttontostart

thesystem.

PresstheComputerPowerbutton

tostartthePC.Thismayonlylight

temporarily.ThePCwillstarttoboot.

5

Terminal

12 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

2.1.4Softwarestartup.

OncethePChasstarted,theBootControllersoftwarewillstartautomatically.Ifitdoesnot,doubleclick

ontheBootControllerIcon(Itlookslikearocketship)onthedesktop.Ifnotextappearsinthebox,after30

seconds,checkthatthelightforthecontrollerisonandthatthenetworkcablefromPCtoOsaicontrolleris

connected.Ifnoconnectionoccurs,seetheFaultFindingsectionintheAppendix.

IftheBootControllerdoesnotstartafteraminuteandthemessageCNCiswaitingforaBOOTmodedirective

appearsonthescreen,thennormalmodeneedstobeselected.

Bootcontrollerloaded

andconnectingto

machine

Controlleriswaiting

foramode.

Ifthemachineisstarting

fromafreshPCboot,

thenNormalmodewill

automaticallybeselected.

192.168.0.1

192.168.0.1

* Otherwise,itwill

automaticallygointo

normalmodeafterafew

seconds.

13 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

2.1.5InterfaceStarts:

TheTechnointerfacescreen

willnowopen.Therewillbe

awarningmessagesaying

EmergencyStopActive.

ClickontheE-stopReset

Buttontoremovethis

warning.

TheAxisnotreferencederrorwillappear.

Clickon“HomeAll”andalltheaxeswillmovetotheirhomeposition.Ifanyerrorsremainonthescreen(i.e.Low

AirPressure,)rectifytheproblemandclickon“ResetErrors”or“RESET”toremovethemessage.

Themachineisnowreadytobejogged.

HomeAll

ResetErrors

Note:PressingHomeAll

willmovethemachine

tothefrontleftcornerof

thetable.

Thismustbedoneevery

timethemachineboots

up.

Oncethemachineisin

theHomeposition,it

hasareferencepoint

fromwhichitcanpickup

toolsandlocateosets.

14 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

2.2 Screen Callouts

AboveisthemainscreenoftheTechnoVentureinterface.

Tohelpunderstandthefunctionsofthebuttonstheywillbebrokendownintothefollowingcategories:

A-Joggingfunctions.

B-HomingFunctionsandClearancePosition

C-PneumaticandElectricalControls.

D-MenuSystems.

E-CoordinateSystems.

F-OriginFunctions.

G-SaveOriginMenu

H-SpindleandCoolantcontrol.

I-LoadG-codeFile.

J-ProgramFunctions.

K-ToolMenu

L-OsetMenu.

A

B

C

D

E

F

G

H

J

K

L

15 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

Themachinewillnotmoveunlessajogmodeisselected.Clickonthebuttonbesidethetext

toselectamode.

A-Handwheel:

Inthismode,themachinewilloperateviatheMPG/Handwheel.PleaseseeHandwheel

operationformoreinformation.Allotherfunctionsaredisabledwhenthisisactive.

B-Continuous:

Also,knownasJogMode.Themachinewillmovesmoothlyandcontinuouslywhenthe

userclicksonthedirectionalarrowassociatedwitheachaxis.SpeediscontrolledbyJog

speedandisapercentageofthemaxjogspeed(800ipm)formanualjogmode.(Ex:[50%of

800=400IPM])

C-Step:

Also,knownasIncrementalJogMode.Themachinewillmovebyanexactamount,as

speciedbyJogStepvariablewhenthearrowbuttonishelddownwithleftclick.[Example:if

jogstepissetto.05andIclickX+.machinemoves.05toright]

D-MDI:

ManualDataInput,thisfeatureallowstheusertomanuallyenterandexecutealineofG-code.

[Ex:(M3S1800:spindleturnsonat18,000rpm)]

E-JoggingArrows:

Byleftclickingonthesearrowsthemachinewillmoveinthecorrespondingdirection.These

arrowsareonlyfunctionalifContinuousorStepmodeisactive.

F-ResetErrors:Thiswillremoveanywarning/errormessagesthatappearonthescreen.

A

B

CD

E

F

A-Jogging Functions

16 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

A-HomeAll:

Sendsthemachinetothehomeposition.(AbsoluteXYZ=0).TheZaxiswillrstmoveuptoits

limit,thentheXandYaxeswillmovesimultaneously.

B-SINGLEAXISHOME:

Whenthisbuttonisleftclicked,eachaxiscanbehomedseparately.Whenthebuttonisactive,

theuserthenclicksonthearrowkeyfortheaxistobehomedtoenabletheoperation.[Ex:

clicksingleaxishome,clickX-,machinewillhomethex-axisonly]

C-CLEARANCEPOSITION:

Whenthisbuttonisleftclicked,themachinewillruntowardstheback,inordertoloadand

unloadwork

B-Homing Functions

A

B

C

17 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

C-Pneumatic and Electrical Controls

Thesectionshighlightedbelowarethebuttonsthatcontrolthepneumaticandelectrical

outputsforthecontroller.

A

B

C

D

A-ShroudUp/Down:

Thisbuttonwillraiseorlowerthedustshroudonthespindle.

B-PinsUp/Down:

Thisbuttonwillraiseorlowerthepop-uppinsonthesidesofthetable.

C-Vacuum1On/O:

ThisbuttonwillturnVacuum1onando,ifitisconnected.

D-Vacuum2On/O:

ThisbuttonwillturnVacuum2onando,ifitisconnected.

ShroudUp/DownandPinsUp/Downwillonlyfunctionif90lbs.ofcompressedairconnectedtothe

machine

Vacuum1on/oandVacuum2on/osend220voltstothestartercoilofthevacuumpump,thus

activatingthepump.

Down Up

Down Up

18 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

A

B

C

D-Menu Screens

ThesectionshighlightedbelowaretheMenuScreenoptionsoftheinterface.Theusercan

switchtothesescreensbyclickingonthecorrespondingbutton.

A-Osets:

OpenstheOsetMenu.Inthismenutheusercansavemultipleosets/origins

andapplythemtothecoordinatesystem.

B-I/O:

OpenstheInputandOutputscreendiagnostics.Thesescreenswillshowthe

statesoftheinputsandoutputs.

C-Tool:

OpenstheToolMenu.Inthismenutheusercanstoretoollengthsandchange

toolnumbers.

19 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

E-Coordinate System

A

B

C

D

A-XYZCoordinates:

Thisdisplaysthelocationofthemachine.IftheOriginNoiszero,thenumbersdisplayed

arethedistancefromtheHomeposition(AbsoluteXYZ=0).IfthereisanOriginNumber

active,thenumbersdisplayedarethedistancefromthatoriginszeroposition.

B-Tool:

Thisdisplaysthetoolthatiscurrentlyinthespindle.Ifthenumberreadsasingledigitthen

thereisnoosetappliedtothattoolatthistime.WhentheTooldisplays1.1,or2.2,or5.5

etcthentheZ-osetisactive.TheZ-osetneedstobeactivewhensettingtheorigin.

C-OriginNo:

Thisdisplaystheactiveorigin/coordinatesystem.Whenitreads0,nooriginisactiveand

thecoordinatesystemdisplayedisthefromtheHomeposition.Thesystemissetupto

accommodate8origins,butmanymorecanbemadeavailable.

D-ZOset:

ThisistheamountofZ-osetbeingappliedtothetool.Z-osetisthedistancefromthe

homepositionanditissetintheToolmenuusingthetoolcalibrationblock.

20 For Support Visit· www.technocnc.com and click Support or Call: (631) 648-7481

(HTT0673)

Venture Series

F-Origin Functions

A

B

C

A-APPLYORI1:

LeftclickingonthisbuttonactivatesOrigin1forthecoordinatesystem.

B-GOTOXY0ORI1:

LeftclickingonthisbuttonmovestheZaxistothehomepositionand

theXYaxestotheX-zero,Y-zeroforOrigin1.(XY=0)

C-SaveOrigin:

LeftclickingonthisbuttonopenstheSaveOriginScreenSafeMode

Option.Inthisscreentheusercansavethepositionofthemachine

astheOrigin.ThisiswheretheusersetsXYZzero.ThisSafeMode

Optionwillprovideadditionalwarningsandopportunitiesfortheuser

toensurethattheoriginissavedcorrectly.

Origincanalso

becalledtheXYZ

zeropoint.

Other Techno CNC Systems Control System manuals