Schweitzer Engineering Laboratories, Inc. SEL-451-5-Based Autosynchronizer Data Sheet

5

Control Functions

Successfully synchronizing a generator requires that

three parameters be within close acceptance criteria.

➤Slip (frequency difference) in acceptance band

➤Voltage difference in acceptance band

➤Angle difference near zero

The heart of an autosynchronizer is the slip-compensated

advanced angle close function that compensates for the

breaker mechanism delay and energizes the synchroniz-

ing breaker close coil at the precise instant to cause the

main contacts to make contact at zero degrees angle dif-

ference.

Additionally, the A25A has features to control the gener-

ator to match frequency and voltage by pulsing the refer-

ence points of the governor and voltage regulator

controls, respectively, to bring these parameters into the

synchronizing acceptance bands.

Start Sync Process Mode

Before a circuit breaker can be closed, the circuit breaker

must be selected by asserting one of the circuit breaker

selection inputs on the back of the control. Selecting a

breaker loads all the settings associated with that breaker.

One of two modes can be used to initiate the synchroniz-

ing process.

Start/Stop on Initiate and Abort Mode

When Start/Stop on Initiate and Abort mode is enabled,

the operator must select a circuit breaker for autosyn-

chronization. The synchronizing close process can be

initiated, or the circuit breaker can be closed by initiating

the autosynchronizer when one of the three close permis-

sive conditions is asserted (synchronizing close, parallel

close, dead-bus close).

Start/Stop on Circuit Breaker Selected Mode

When Start/Stop on Circuit Breaker Selected mode is

enabled, the operator must select a circuit breaker for

autosynchronization. The circuit breaker will close

immediately, or the autosynchronizing process will start

when one of the three close permissive conditions

asserts.

Frequency Matching

The A25A can adjust the generator frequency to match

the frequency of the bus. When isolated from the system,

the governor control operates in isosynchronous (fre-

quency control) mode. The control raises or lowers the

frequency reference point on the governor control via

pulsing contacts. The user can select between OFF, Fixed

Pulse Mode, and Proportional Pulse Mode.

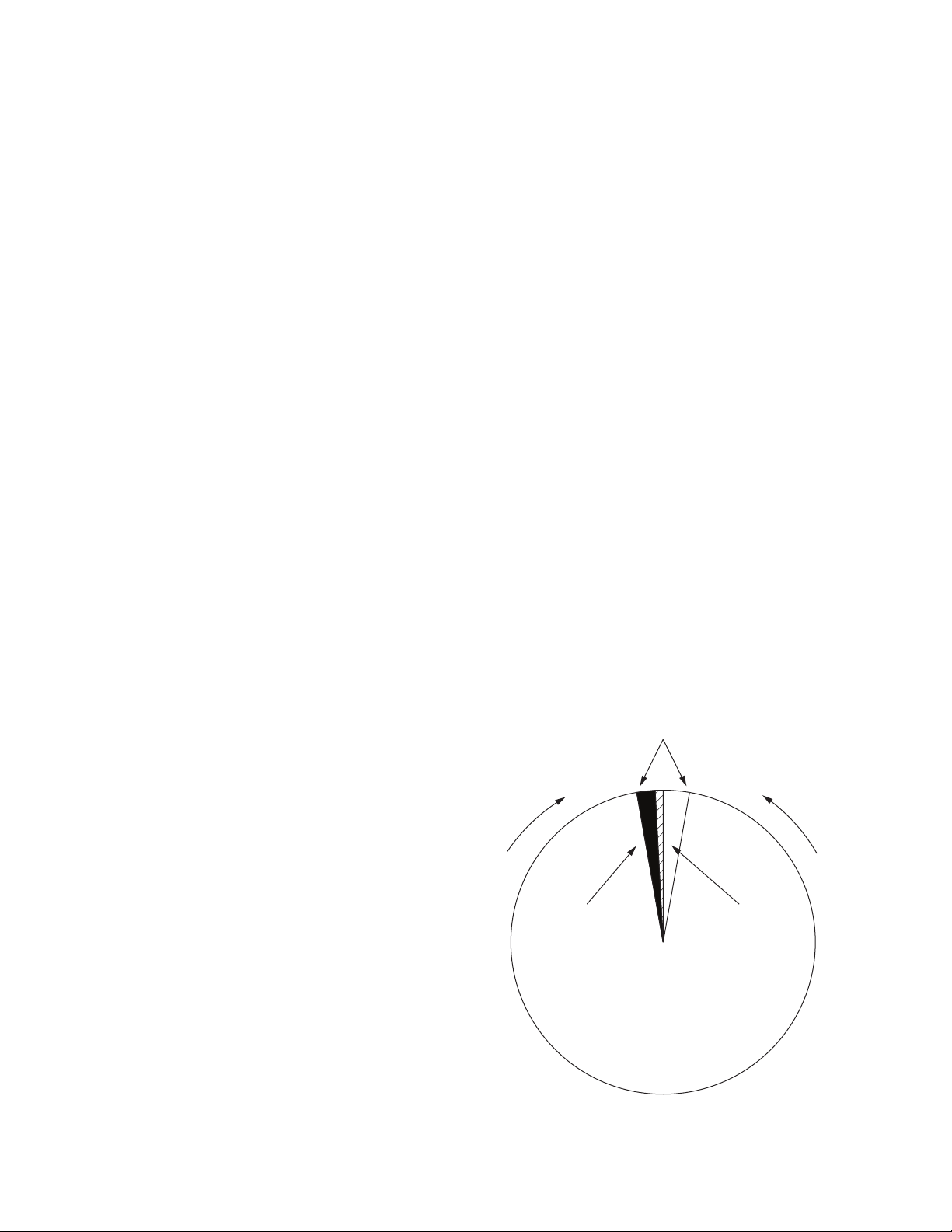

Figure 3 shows the proportional pulse control character-

istic when the GF > BF (antimotoring) feature is enabled.

Figure 4 shows the control characteristic when the

GF > BF feature is disabled.

At zero slip, the generator angle will not rotate into phase

with the power system and a close cannot occur. When

GF > BF is not enabled, zero slip is inside the control

dead band, and no correction pulses will be sent to the

governor to change the slip rate off of zero. Figure 4

shows that the proportional pulse characteristic is modi-

fied by addition of a dead-scope band. If the frequency is

within the dead-scope band of ±20 mHz, a frequency

raise correction pulse will be output to move the slip rate

off of zero.

The following user settings define the control

characteristic:

➤Slip allowed (hertz)

➤Pulse width (seconds) (fixed pulse mode)

➤Proportional pulse slope (seconds/hertz) (propor-

tional pulse mode)

➤Pulse interval (seconds)

➤Enable/disable GF > BF

The pulse interval defines the time between the rising

edges of consecutive correction pulses. This time should

be greater than the settle time of the generator frequency

after each correction pulse.

The width of each correction pulse is proportional to the

deviation of the frequency from the center of the correc-

tion dead band when Proportional Pulse Mode is

enabled. As the frequency approaches the center of the

dead band, the correction pulses become shorter to pre-

vent hunting.

When GF > BF is enabled, the control ensures that the

allowable slip is positive (generator frequency greater

than bus frequency) so that power flow is out of the gen-

erator upon initial synchronization. This feature is rec-

ommended for applications that have prime movers with

extremely sensitive reverse power protection. The center

of the dead band is offset in the positive direction from

zero slip by one half of the slip allowed setting.

The correction dead band is fixed with a 20 percent mar-

gin inside the slip allowed synchronism acceptance set-

ting.