Techno CNC Systems WinCNC User manual

2Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

TABLE OF CONTENTS

I. Safety Information

Forklift Guide ........................................................ Page 3

Plasma Safety Instructions ............................................ Page 4

II. Techno CNC Plasma Installation

Machine and Controller Connections ................................ Page 6

Plasma Torch Connections ............................................ Page 7

III. Controller Functionality .........................................................Page 8

IV. Controller Screen Layout .........................................................Page 9

V. Controller Button Functions

Toolbar / Axis Window .............................................Page 10

Jog and Incremental Buttons .............................................Page 11

Viewer .....................................................................Page 12

Function Buttons .............................................Page 13

StatusIndicator/THCQuickCong .................................Page14

THCCongWindow .............................................Page15

VI. Using Cut Charts .....................................................................Page 16

VII. Plasma Quick Start Guide .........................................................Page 18

VIII. Pen Quick Start Guide .........................................................Page 20

IX. Supported Code .....................................................................Page 22

X. Error Codes .................................................................................Page 23

XI. Machine Lubrication .........................................................Page 24

XII. Diagrams

PCandControllerInterfaceConnections .....................Page25

Machine Diagram .........................................................Page 26

XIII. Cut Quality .................................................................................Page 27

XIV. Consumables .................................................................................Page 31

XV. Warranty .................................................................................Page 34

3Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

PLASMA FORKLIFT GUIDE

II. MEASURING FORKS AND FORKLIFTING MACHINE

2.1

Fig. 2.1

Measuring the distance between the forks.

(shown in Fig 2.1).

NOTE: Forklift capacity must be

adequate to safely lift the machine.

I.

SAFETY

WARNING:

DO NOT LIFT OR

MOVE MACHINE

USING GANTRY

1.1

Be very careful not to damage the wiring and/

or the plumbing underneath the machine.

It is recommended that you have professional riggers conclude the installation if you are uncomfortable with this method.

For safety and to prevent damage to the machine

and cables, Lift Machine Using Forklift Tubes ONLY

Forklift your machine up from the

oor and remove the wooden pallet.

2.2

Fig. 2.2

Take care not to damage the

machine. Slowly move in close to the

machine.

Front of Machine

Rear of Machine

1

3

2

4

Right SideLeft Side

1 2

43

Please note the 4 Forklift Tubes on

the front and rear of the machine.

Fig. 1.1

If required, there are 4 Forklift Tubes

on the sides of the machine.

28"

23"

23"

SAFETY INFORMATION

Techno CNC Systems’ cutting equipment is engineered and designed with safety as top priority.

However, the overall safety of the operator will drastically increase by proper installation and

operation.

WARNING -

Do not install, operate, or repair the CNC, or torch equipment without reading the safety warnings

within this manual.

Be very careful when maintaining, troubleshooting and operating this equipment.

THE PLASMA TORCH CAN SCORCH SKIN AND CAUSE PERMANENT DAMAGE OR DEATH

FUMES AND GASES CAN BE DANGEROUS

• PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

• KEEP CHILDEN AWAY

• IF OPERATING WITH A PACEMAKER, IT IS IMPERATIVE YOU CONSULT WITH YOUR

DOCTOR PRIOR TO USING THE MACHINE OR ANY OF ITS ACCESSORIES.

• ENSURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR

PROCEDURES ARE DONE ONLY BY QUALIFIED INDIVIDUALS.

• The biproduct of plasma cutting produces fumes and gases that may be hazardous to

health. Avoid breathing these fumes and gases. Keep your head out and away from the

fumes.

• Use the appropriate amount of ventilation, water, and/or exhaust at the plasma arc to keep

fumes and gases away from your breathing zone.

• Use an air-supplied respirator if water and ventilation is not enough to remove all fumes.

• When plasma cutting lead, or cadmium plated steel and other metals or coatings which

produce toxic fumes, keep your exposure to a minimum within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or mechanical ventilation. In conned spaces, or, but

not advised, outdoors, a respirator may be required.

• Disconnect the power source from all devices before performing any service or

maintenance. When power sources are active, during operation, voltages in excess of

250V are produced. This creates the potential for serious electrical shock, or possible

death.

• Insulate yourself from work and ground by using dry insulation. Always wear gloves and

clothing that covers any exposed skin. Take extreme care when the work environment is

moist or damp.

• The electrode and work (ground) circuits are electrically active, or “hot”, when the power

source is on. Do not touch these active parts with bare skin or wet clothing. Dry gloves

and clothing without holes must be worn at all times during operation.

• Always ensure that the work ground makes a good electrical connection with the metal

being cut. The connection should be as close as possible to the material being cut.

• Ground the metal substrate being cut to a good electrical, earth ground.

• Always replace damaged or worn insulation and consumables.

• Arc Rays produced by the plasma torch can injure your eyes and burn your skin. The arcing

process produces very bright infrared and ultraviolet rays. These rays will damage your eyes

and burn your skin if the proper safety eyewear and clothing are not worn.

• Use safety glasses and a shield to protect your eyes from sparks and arc rays when operating

or observing any plasma cutting.

• Use clothing suitable for plasma cutting or gouging, including, but not limited to, durable,

ame resistant gloves and jacket.

• Protect those around the machine with suitable, non-ammable outer protection and/or warn

them not to gaze at the arc or expose themselves to the arc rays and metal spatter.

ARC RAYS WILL BURN

CUTTING FLAME AND SPARKS CAN CAUSE EXPLOSION FIRE

• Fires and explosions can be caused by oxygen fueled cutting ame, plasma arc, hot slag and

sparks.

• A re extinguisher should be ALWAYS readily available. When working in areas where re

hazard may exist, always provide a re watch.

• When the machine is not in use, or not cutting, ensure that no part of the electrode circuit is

touching the work ground. Accidental contact can cause overheating and create a re hazard.

• Be sure there are no combustible or ammable materials near the workplace. Any material

that can’t be removed, must be protected.

• Sparks and hot slag from cutting can easily go through small cracks and openings to adjacent

areas.

• Avoid cutting near hydraulic lines.

• Do not cut or burn through tanks, drums, or containers until proper steps have been taken to

ensure that these processes will not cause ammable or toxic vapors from substances inside.

• Vent hollow castings or containers before heating or cutting. They may explode.

• Do not add fuel to engine driven equipment near an area where plasma cutting is being

conducted.

• Connect the work cable ground as close to the cutting area as possible.

• Hydrogen gas may form and be trapped under aluminum work pieces when they are cut

while using a water table. DO NOT cut aluminum alloys with the water table unless the

hydrogen gas can be eliminated. Hydrogen gas that is trapped can ignite and cause an

explosion.

• TURN OFF input power using the power disconnect at the machine as well as the switch at

the main fuse box before working on the equipment.

• Install equipment in accordance with the U.S. National Electrical Code and manufacturer’s

recommendations.

• Ground the equipment in accordance with the U.S. National Electrical Code and the

manufacturer’s recommendations.

WORKING WITH ELECTRICALLY POWERED EQUIPMENT

PLASMA ARC CAN INJURE

• Keep your body away from the plasma nozzle and plasma arc.

• Operate the pilot arc with extreme caution. The arc is capable of burning the operator and

others around.

• An EMF (Electric and Magnetic Field) is caused when an electric current ows through any

conductor. An arc ray current creates EMF elds around torch cables and cutting machine.

• EMF elds may interfere with some pacemakers. Operators with a pacemaker, or other

bioelectrical device should consult with their physician before using the plasma cutter.

• Exposure to EMF elds during cutting may have other health eects which are not known.

• Any and all operators should follow these procedures in order to minimize exposure to EMF

elds from an arc ray circuit:

• Route the torch and work cables together – Secure them with electrical tape

or zip-ties when possible.

• NEVER wrap or coil the torch and work cables around your body.

• DO NOT place your body between the torch and work cables.

• Connect the work cable to the workpiece as close as possible to the area

being cut.

• Do not work next to the cutting power source.

WHILE OPERATING THE CNC MACHINE

ELECTRICAL AND MAGNETIC FIELDS MAY BE DANGEROUS

• WEAR THE PROPER EYE, EAR, FACE, AND BODY PROTECTION.

• PROTECT your eyes and face with welding goggles and/or helmet. These items should have

the proper grade of lter plate.

• PROTECT your body from welding slag/spatter and arc ash with protective clothing

including woolen clothing, ame-proof apron and gloves, leather leggings and high boots.

• Where ear protection when necessary.

• ENSURE that all protective clothing and eyewear is in good, working condition.

• Ensure that there is adequate lighting in the area of the machine.

• Safety Glasses should be worn in work area at all times.

• DO NOT CLIMB ON MACHINE. The machine is not intended to be used as a ladder or to

support anything other then the material being cut. By climbing onto the machine, there is risk

of falling which can result in injury or de

ELECTRICAL AND MAGNETIC FIELDS MAY BE DANGEROUS

7Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

The Techno CNC Plasma

System is powered by 220 volt

single phase power.

Make sure the Ground Clamp

(Work Lead) is connected to

the material being cut, or the steel slats

that the material is resting on.

Have a licensed electrician perform

all electrical connections based on

your electrical codes!

Please make sure the CNC Plasma

is properly grounded using the

grounding lug provided on the rear

leg of the machine.

8Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

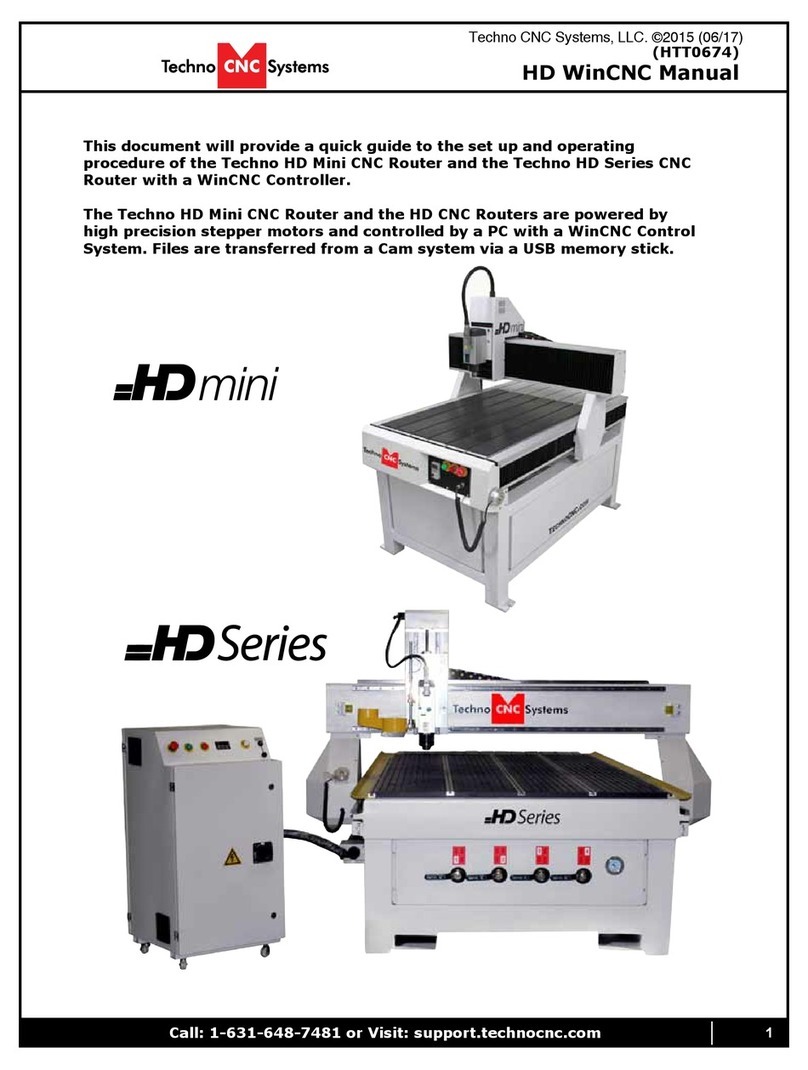

1.3 Unpack the computer and monitor and mount them on the

controller.ThePCtsonthesideshelfandthemonitorrestsontop.

Fig. 1.4

1.4 Plug the labelled cables

into their proper places. 2

labelled interface cables, 1

monitor and 2 USB for mouse

and keyboard.

II. Techno CNC Plasma Installation

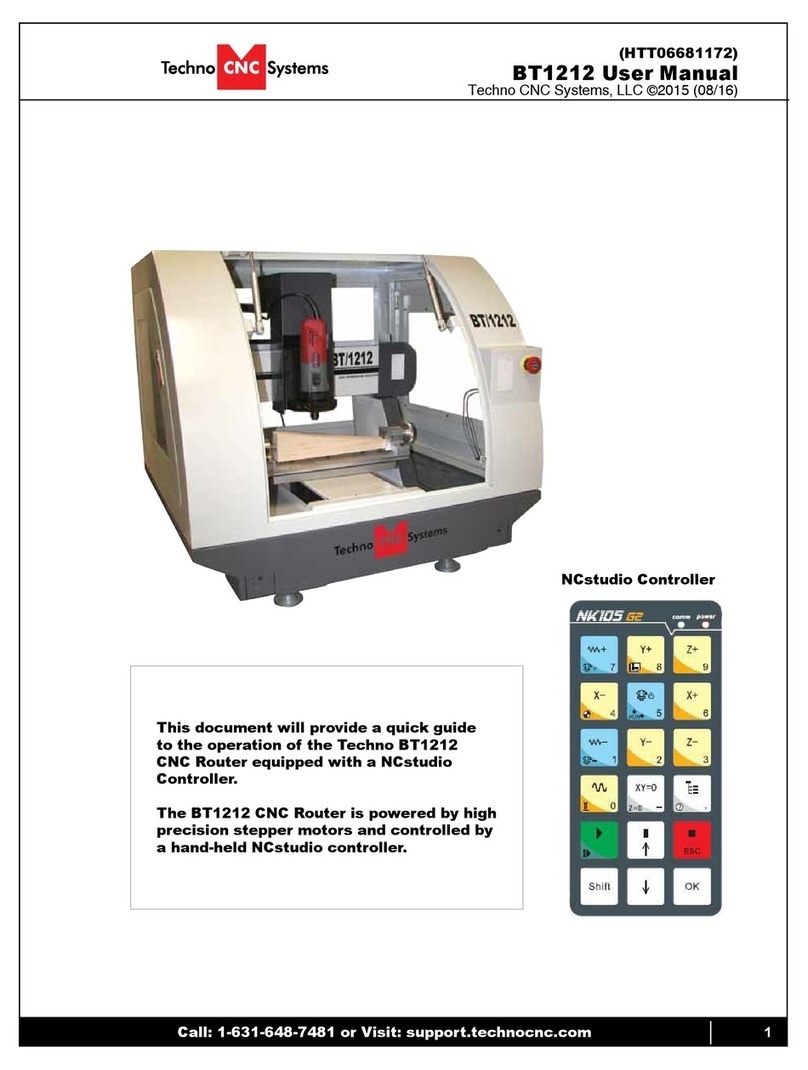

1.1 The Electronics are housed in the large controller box as shown in

Figure 1.1. When unpacking the machine, avoid twisting the plastic conduit

that guides the cables to the motors.

1.2 Open the front and back of the controller box

See PC and Controller Interface Connections on page 25.

Machine and Controller Connections

1.5 The terminal for the 220 volt connection

is located at the bottom front of the box.

Fig. 1.1

Have a suitably qualied person connect the 220V to the

terminals. Make sure that all local electrical codes are obeyed.

For single phase machine, connect power to L1 and L3 only.

Fig. 1.3

9Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

When hooking up the plasma torch, be sure to use appropriate

power. See Hypertherm documentation or refer to quote for

details.

Please read and understand the Hypertherm torch manual before

operating the machine.

IIb. Plasma Torch Connections

TheHyperthermtorchrequiresaclean,dry,non-uctuating90

psi compressed air source to operate. Do not atempt to operate

plasma with the air connected.

The error “check torch” will also appear when the torch is not in

its correct position. This acts as an e-stop if the torch knocks into

something while in motion.

Make sure the torch and grounding clamp are plugged in.

WARNING: Read this setup thoroughly before running the machine. Have a licensed

electrician perform all electrical connections based on your local codes!

Hypertherm Machine Interface Cable from

Controller box

10 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

III. Controller Functionality

Machine Controls

Emergency Stop -

Cuts off the power

to the machine.

Power Button - Turns the machine on and

off when the machine has power and the

power breaker is in the on position.

Power Indicator Light - Light on

indicates power to the machine.

Power Breaker

The power breaker is used as a safety feature. The machine will only power up when the

breaker is in the vertical “ON” position. Spin the selector clockwise from “OFF” to “ON” in order to

enable the machine and lock out access to the high powered electronics inside the controller cabinet

“OFF” Position “ON” Position

Fan On Fan Off

11 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

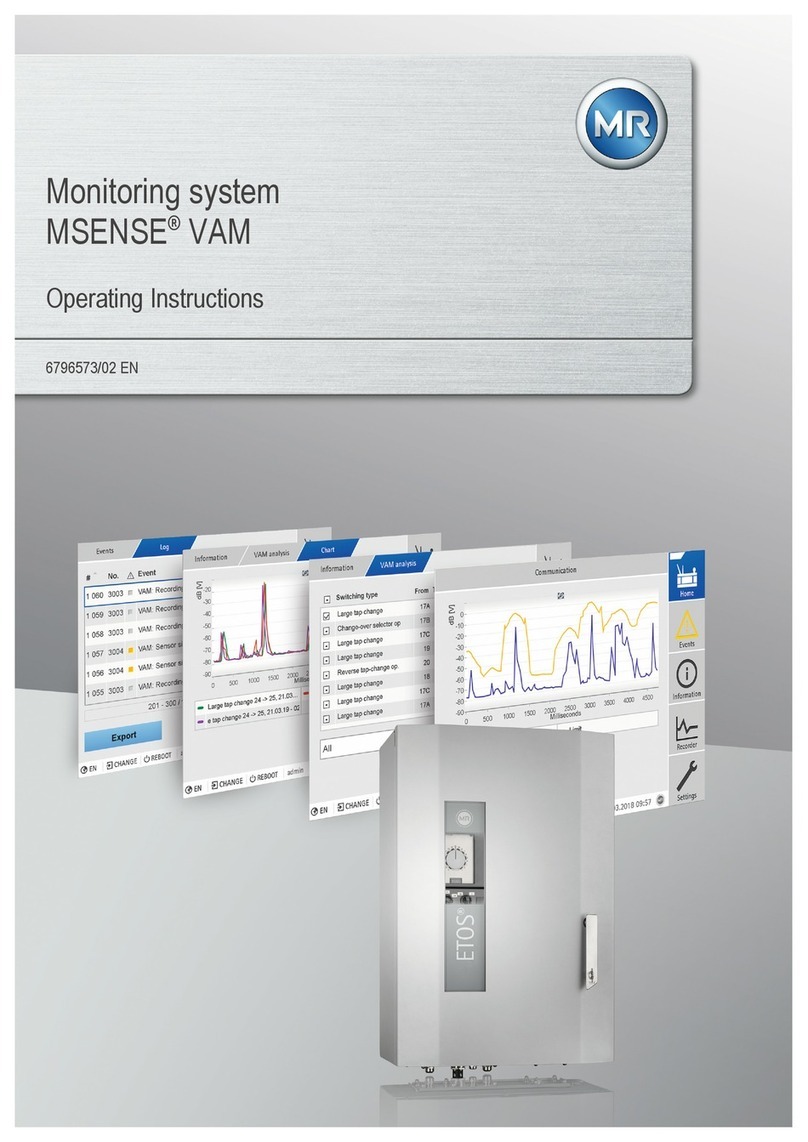

IV. Controller Screen Layout

Main Layout Controls and Description

Command Box and History Viewer

Live View and Toolpath Viewer

Jog / Transit Direction, Speed,

Step Size Buttons

Axis Window

Custom Functions

THC Conguration

Window

Status Indicators

Tool Bar

12 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

Tool Bar

V. Controller Button Functions

START

Execute

command line

or job

RESTART / SKIP

Restarts a job at a

given line number

SINGLE STEP MODE

Allows you to execute

single lines of a g-code

leatatime.

STOP / ABORT Stops

a running command

or job

PAUSE

Pauses a running

command or job

VIEW HISTORY

Opens Job history

browser

OPEN

Opens Explorer

toopenajoble

EDIT

Opens Notepad

toeditajoble

SIMULATE

Simulatesaleto

check for errors and

run time

VIEW

Displays the current

job in the viewer

window

SOFT LIMITS

Enables/Disables

soft limit features

Axis Window

Green Box

Indicates an origin

offset is applied

Blue Box

Indicates a workspace offset is

applied

Red Triangle

Indicates a triggered limit switch

(left low, right high)

Slider Bar

Controls feed rate

override

The axis window is the primary display for current information about each axis on your machine.

The current positions and velocities for each axis are displayed in the text boxes.

Thetoolbarisacollectionofshortcutbuttonsthatperformspecicactions.

Machine Status

Displays current units,

active modes and

current feed rate

override percentage

13 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

Jog and Incremental Buttons

These buttons are what allow you to initiate a manual jog or incremental movement. In jog mode,

holding the button down will continuously move the machine. In incremental mode, each time a

button is pressed the machine will move according to the jog increment that has been selected.

Holding the button down in incremental mode will move the machine only once.

Jog Increment Buttons

When pressed, these buttons allow the

machine to move in steps of the selected

increment.

Jog Speed Buttons

When pressed, these buttons

allow the machine to move

at predetermined continuous

speeds.

Movement Direction Buttons

When pressed, these buttons allow the

machine to move in selected direction in

the selected mode.

(Jog or Incremental)

14 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

Viewer

WinCNCcontainsabuiltinviewerwindowthatwillallowyoutodisplaytheoutputofG-Codelesbeforethe

jobisactuallyrun.Bydefault,theviewercanalsodisplayaG-Codelelinebylineasitisrun.

G0 rapid moves are shown as a black dashed line. G1 feedrate moves are displayed as a solid blue line.

Toviewalebeforeyourunit,opentheleinthecommandlineandthenpresstheviewerbuttononthe

toolbar.

Once the object is loaded into the viewer the following controls can be used:

Zoom In - click the left mouse button.

Zoom Out - click the right mouse button.

Selected Zoom - hold down the left mouse button and drag the box around the area to zoom in on.

Pan or Re-Center Object - hold CTRL and click either mouse button.

Reset Image - hold shift and click either mouse button

Origin

Where red vertical and

horizontal lines intersect

Current Position

Shows the current position

of the plasma torch

(Shown as red circle)

15 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

Function Buttons

These buttons perform preset functions. They are used as shortcuts for many G-code operations.

Seek Limits

Finds the machine’s

limit switches. Should be

performed at start-up.

Set XY

Sets the XY origin at the

current position

Set Z

Sets the Z origin at the

current position.

Not necessary for Plasma jobs.

Go to XY

Raises Z to its high limit

and sends the machine to

XY=0

Touch Top

Starts automatic

touch off cycle to set

Z=0

Park

Sends the machine to a

pre programmed park

position. Usually, by

default, at the back of

the machine.

Clear

Clears all offsets.

16 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

Torch Height Control (THC) Quick View

ThiswindowallowstheusertoselectpreconguredTHCmodesaswellasperformbasiccommands.

Quick Cong Select

Shows the currently selected THC

conguration.Dropdownmenu

shows other options.

THC / Auto

Enables / Disables Automatic THC

Enables / Disables Autosense

Cong

Opens a window to create a new

THCcongurationprole.

(See Next Section)

Target Voltage

Sets the target

voltage (height) for

the given job

Arc Voltage

Shows the actual (real

time) voltage

Torch

Turns the torch on or off.

Indicator

Green is torch on

Red is torch off

Status Indicators

This window shows certain machine inputs and outputs.

Arc Present

Green indicates that arc

has successfully transferred

17 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

THC Conguration Window

ThiswindowallowstheusertosaveTHCprolesforfutureusage.Werecommendsavinganew

congurationproleforeachmaterialtypeandthicknessused.

The highlighted variables should always be used. All values are taken directly from the Hyperthem

Manual’s Cut Charts.

Please note: Shop conditions vary from user to user. For this reason, we recommend disabling

THC for new materials, so tests can be run and arc voltage can be read, which will allow the user to

accurately set a target voltage.

Material Name

Congurationname

Torch Amps

Piercing Height Cutting Height

Cong List

Shows a list of THC

proles.Selectone

to edit it.

THC Mode

3 Options

Disabled-NoTHC,maintainsaxedheight

Automatic-THCOn,maintainsaxedheightabovethematerialbasedonvoltage(recommended)

AutoSense-Usesvoltagefrominitialtouchoffasxedheight

Feed Rate

Target Voltage

Pierce Delay

18 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

Setting the Plasma Cut Parameters:

Please refer to your Hypertherm Powermax Manual’s cut chart to ensure proper settings

Maximum cut speeds are the fastest speeds possible to cut material without regard to cut quality.

Recommendedcutspeedsareagoodstartingpointforndingthebestqualitycut.Youwillneedto

adjust the speeds for your application and your table to obtain the desired cut quality.

VI. Using the Cut Charts

19 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

The cut chart on the previous page is being used as an example. It is from the Hypertherm

PowerMax manual. It represents the cut chart for shielded consumables on Mild Steel with English

Units.

In this example, we will be cutting 16 Ga mild steel and we will use the recommended settings. These are

merely recommended settings, you will need to adjust accordingly.

We will use the cut chart from left to right.

First,weneedtoopentheCNCInterfaceandopentheTHCcongwindow.

NametheMaterial“16Ga-45amps”

Wewillstartwith“TorchAmps”.Forourgivensetup,wewillbeusing45amps.Input45intothe“TorchAmps”

boxandmakesuretheHyperthermtorchissetto45usingthefrontknob.Ifyouhaveamorepowerfulunit,

plug in the amperage that your torch will be set to.

Next, we choose our material thickness. In this example, we will be using 16 Ga.

As we move from left to right, we can use and set various parameters.

Torch-to-work distance is our “Cutting Height” value. Enable “Cutting Height” and set the value to .06”

InitialPierceHeightisour“PiercingHeight”value.Enable“PiercingHeight”andsetthevalueto.15”

Now we will set our Pierce delay, under “Pierce Delay” enter 0.0.

For the best cut results, we will use the “Recommended” settings for feed rate and voltage.

Ourcutspeedwillbe350inchesperminute.Put350inthespotmarked“FeedRate”

Our voltage will be 116. Put 116 in the spot marked “Target Volts”

Finally,chooseaTHCmode.Incasesofatsheetmaterial,youcanchoose“disabled”.Iftheremaybeany

chance of variation of material thickness or height or the material may be warped, choose “Automatic”

Click“Save”tosavetheproleand“Done”toexit

Please note: When saving, if the “material name” has any symbols, the conguration will not be

saved correctly. Ensure that you spell out the full name, i.e)

20 Call: 1-631-648-7481 or Visit: support.technocnc.com

Plasma User Manual

WinCNC

Step 2 - Seek Limits

Once powered up, please choose “Seek Limits”

from the controller screen. This will move the

machine to its limit switches, ensuring accurate

positioning.

WARNING: BEFORE SEEKING LIMITS, ENSURE

THAT THE PLASMA TABLE IS FREE FROM

OBSTRUCTION

Step 3 - Setting the Origin

Jog the machine to the desired X/Y start position by

pressing the X and Y directional key, or use the arrow

keys on the keyboard. “Page up” and “page down”

control the z-axis.

Once located, press “Set XY”.

The display should now show X and Y coordinate values

of 0.000 with green boxes as indicators that the origin

has been set.

Z may have a non zero number, as the z-axis lifts up to

its “pierce height” after it touches off the meter.

Step 1 - Power Up

Turn on power to the machine, plasma torch

and PC. Ensure the torch and machine have an

adequate air supply and the ground clamp is

properly on the material being cut.

VII. Plasma Quick Start Guide

This guide will assume all machine, controller, plasma and

PCconnectionshavebeenmadeandthatyouarereadytorunale.

Table of contents

Other Techno CNC Systems Control System manuals