Techno CNC Systems Titan Series User manual

1Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

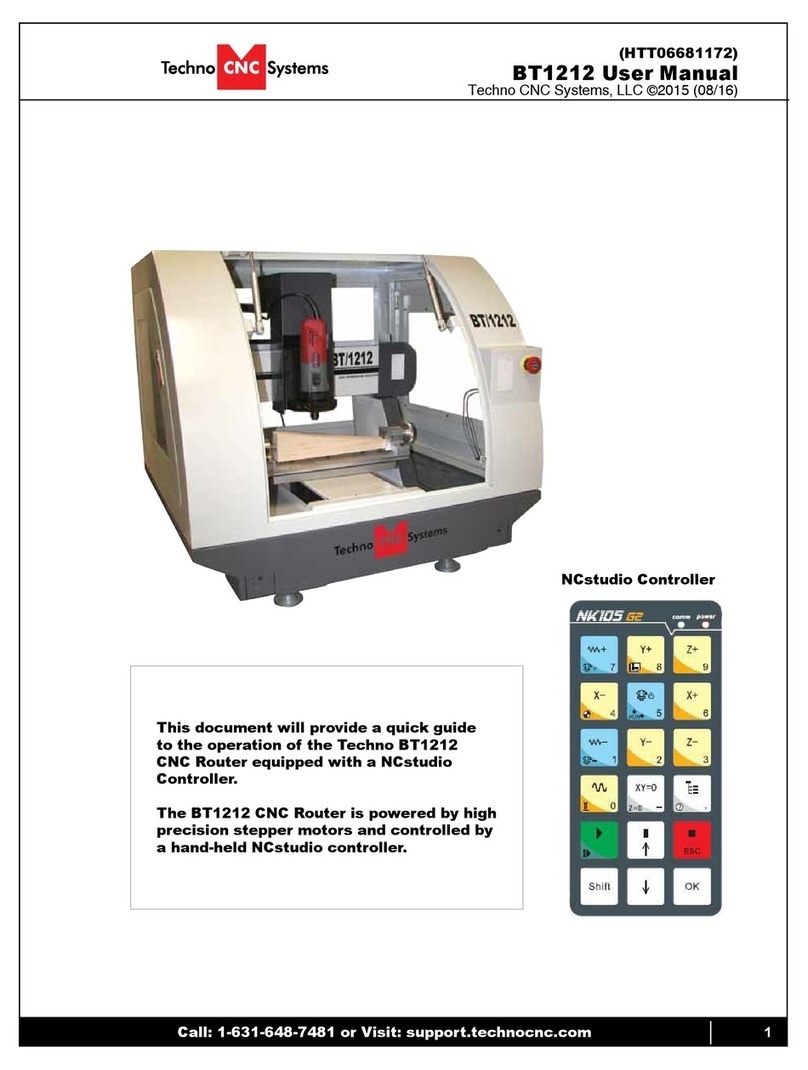

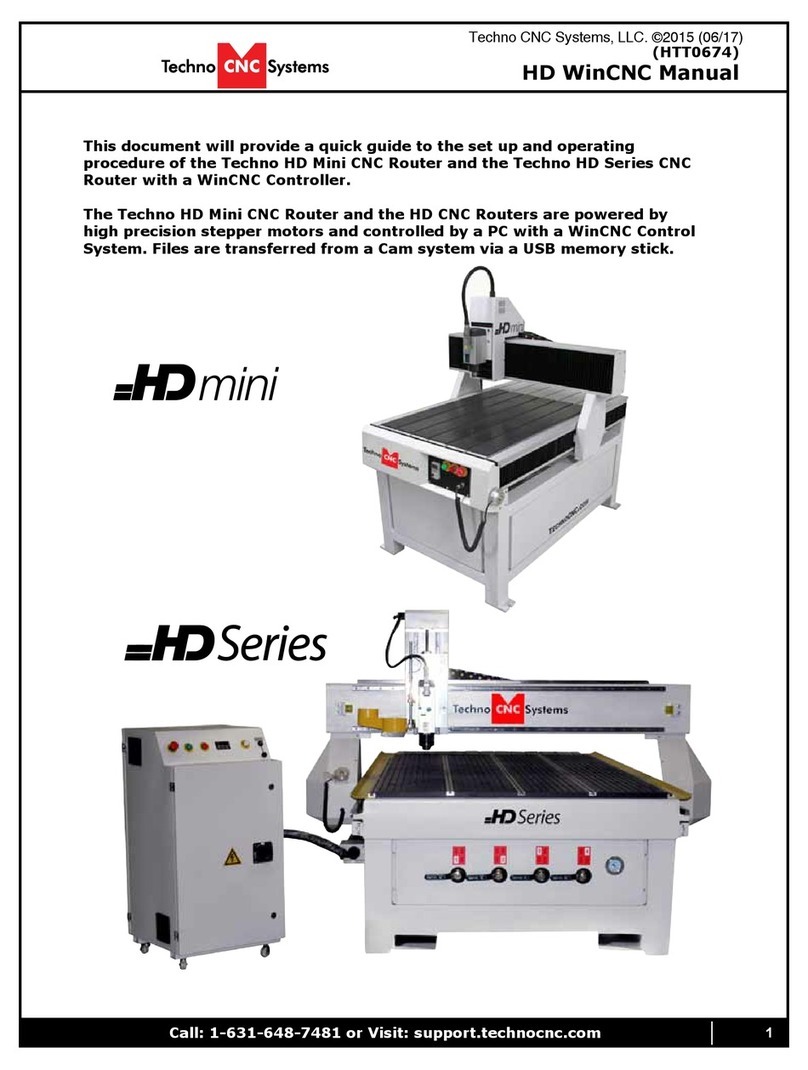

This document will provide a quick guide to the set up and operating

procedure of the Techno Titan CNC Router with a WinCNC Controller.

The Techno Titan CNC Router is powered by high precision stepper motors

and controlled by a PC with a WinCNC Control System.

Techno CNC Systems, LLC. ©2015 (06/17)

2Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

TABLE OF CONTENTS

Forklift Guide .........................................................................Page 3

Safety Instructions ...............................................................Page 4

Colleting Guidelines ...............................................................Page 5

IInitial Setup

1.1 Titan Series Series Installation .................................Page 6

1.2 Titan Series Series Installation .................................Page 10

II Controller Functionality

2.1 Control Panel Functions .....................................................Page 12

2.2 Enabling the Machine ...........................................Page 13

2.3 Software Overview .....................................................Page 15

2.4 Program Shortcuts .....................................................Page 26

III Operating Tutorials

3.1 - Machine Startup - Homing ...........................................Page 28

3.2 - Manaul Operation .....................................................Page 28

3.3 - Axis Window ...............................................................Page 29

3.4 - Park Position ...............................................................Page 29

3.5 - Functions ...............................................................Page 30

3.6 - Adjusting the XYZ Position/WCS/User Origin .......................Page 32

3.7 - Running a G-code File .....................................................Page 34

IV Advanced Tutorials

4.1 Tool Changes ...............................................................Page 35

4.2 Measuring Tool Lengths .....................................................Page 35

4.3 Learning Pocket Positions ...........................................Page 38

4.4 4th axis .........................................................................Page 40

V Controller Commands (G, M and L codes) ......................Page 41

VI Error Messages ..............................................................Page 69

VII Maintainence ........................................................................Page 75

VIII Warranty ........................................................................Page 89

3Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

4Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

1. Keepngers,hands,andallotherobjects

away from machine while power is on.

2. Disconnect power to all system components

when not in use, when changing accessories,

and before servicing.

3. Do not loosen, remove, or adjust machine

parts or cables while power is on.

4. Exercise care with machine controls and

around keyboard to avoid unintentional

starting.

5. Make sure voltage supplied is appropriate to

specicationsofcomponents.

6. Machines must be plugged into three-

pronged grounded outlets. Do not remove

the grounding plug or connect into an

ungrounded extension cord.

7. Keep cables and cords away from heat, oil,

and sharp edges. Do not overstretch or

run them under other objects or over work

surfaces.

8. Useproperxturesandclampstosecure

work. Never use hands to secure work.

9. Do not attempt to exceed limits of machine.

10. Do not attempt to use machine for purposes

other than what is intended.

11. Use machine only in clean, well-lit areas

freefromammableliquidsandexcessive

moisture.

12. Stay alert at all times when operating the

machine.

13. Always wear safety goggles.

14. Donotwearloose-ttingclothingwhen

operating machine. Long hair should be

protected.

15. Always maintain proper balance and footing

when working around the machine.

16. Maintainequipmentwithcare.Keepcutting

tools clean and sharp. Lubricate and change

accessories when necessary. Cables and

cords should be inspected regularly. Keep

controls clean and dry.

17. Before using, check for damaged parts. An

authorized service center should perform

all repairs. Only identical or authorized

replacement parts should be used.

18. Remove any adjusting keys and wrenches

before turning machine on.

19. Do not operate the machine unattended.

20. Follow all safety instructions and processing

instructions in the MSDS for the material

being processed.

21. Use proper precautions with dust collection

systemstopreventsparksandrehazards.

22.Makesuretohaveproperreextinguishing

equipmentonhandatalltimes.

WARNING: IMPROPER OR UNSAFE OPERATION OF THE MACHINE WILL

RESULT IN PERSONAL INJURY AND/OR DAMAGE TO THE EQUIPMENT.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE OPERATING MACHINE.

DO NOT OPERATE MACHINE IF YOU ARE UNFAMILIAR WITH THESE SAFE

OPERATING INSTRUCTIONS. DO NOT OPERATE MACHINE WITHOUT

KNOWING WHERE THE EMERGENCY STOP SWITCH IS LOCATED.

PREVENT FIRE HAZARDS by using the proper feeds, speeds, and tooling while

operating your Techno machine. For example, setting feeds and speeds too low

and/or using dull tool bits creates friction at the material. The friction generates

heat which can result in a re that can be drawn through the vacuum table or

dust collector without warning. Fire hazard from friction heating caused by dull

tools is possible when cutting certain materials, especially composite material

such as wood composites, MDF and Particleboard. © 2012

Safety Instructions

5Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

WARNING!

THE SPINDLE WILL BE DAMAGED

IF UNBALANCED EQUIPMENT IS USED.

AIR SUPPLY MUST BE FILTERED AND DRY.

6Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

I. Initial Setup

Remove the controller and place it on the oor to the left of the machine.

When unpacking the controller, avoid twisting the cable carrier that guides the cables to the motors.

Carefully remove the Titan from its wood pallet. Be sure to remove the bolts from its four leveling feet

insertion holes, as well as anything stowed under the Titan during shipping.

Remove all bubble wrap, foam and strapping from the machine.

Attached the provided leveling feet to the six legs and adjust accordingly until the table is level.

Remove the four brackets used to stabilize

the gantry during shipping using metric allen

wrenchs.

1.1 Techno Titan Series Installation

7Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

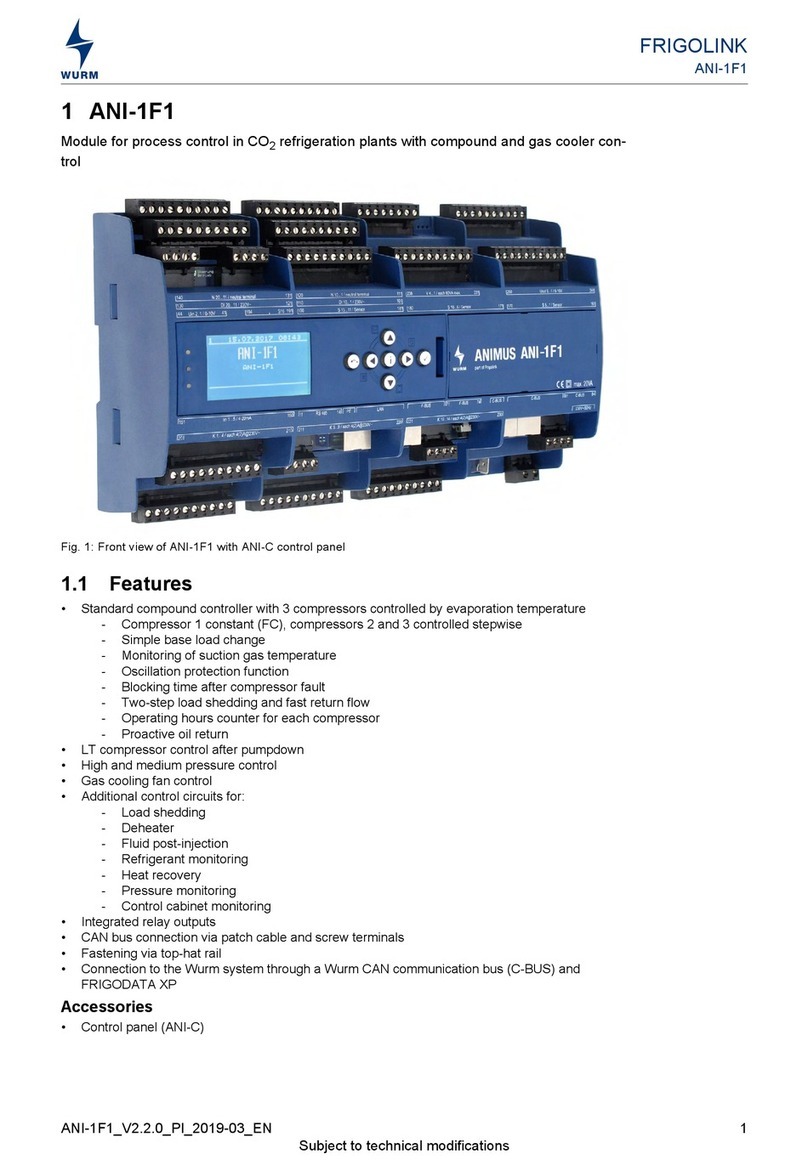

L1 L2 L3

Fig. 1.2a

Enclosure

The Electronics are housed in the large NEMA enclosure

as shown in Fig. 1..2a. When unpacking the machine avoid

twisting the cable carrier that guides the cables to the

motors.

Have a suitably qualied

person connect the 220V

to the shown terminals.

Make sure that all local

electrical codes are obeyed.

For single phase machine,

connect power to L1 and L3

only.

Fig. 1.2c

Open the rear of the controller

using the provided key located

around the emergency stop

button or inside of the tool box.

You will now have access to the

electronics that drive the CNC.

They will be identical or like

depending on the model issued.

(shown in Fig. 1..2b).

The terminals for the

220 volt connection are located

at the bottom of the box

(shown in Fig. 1..2c)

Fig. 1.2b

A- Controller Board.

B- 24Volt PSU.

C- Stepper Driver.

D- 220Volt In.

A B

C

D

8Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

Install the 37 pin cable from the control box into the rear of the PC.

The cable from the WinCNC board must go to the BLUE

connector.

Unpack the PC, monitor, keyboard and mouse and began

mountingtheequipment.Attachthemonitortotheprovided

mount, place the PC in the side tray and connect both to a

110VAC power source.

Rout keyboard and mouse to PC and make sure the monitor

is also connected.

9Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

10 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

1.2 Vacuum Pump Installation

11 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

12 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

2.1 Control Panel Functions

Emergency Stop - This button will cut power to the entire machine. Used in

emergency situation to completely stop the machine.

Power Enable - Once the main power breaker has been engaged, the controller is

turned on by pressing this green button.

Power Disable - Once the machine has been turned on, the controller is turned off

by this red button.

Gate Valve(s) - If using a vacuum pump, this controls the gate valve(s) to control

vacuum to the machine.

Spindle Inverter Readout - This displays the actual spindle RPM in hertz.

USB Port - This is used as an extension port for the PC

Vacuum Control(s) - These buttons will remotely turn the vacuum pumps on and

off

Emergency

Stop

Power

Enable

Power

Disable

Spindle Inverter

Readout

Vacuum

Control(s)

USB

Port

Gate

Valve(s)

II. Control Functionality

13 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

Power is now applied to the

controller box. The red light

will now light up indicating

the machine is powered, but

motors are not yet enabled. Fig

2.2b

Press the green button to ap-

ply power to the controller and

enable the motors. Fig 2.2c

Fig. 2.2b

Once the electrical connections have been made,

controller is powered by turning the main power

switch, on the front of the machine, to the ON

position (as shown in Fig. 2.2a).

Both the front and rear access doors must be closed

Fig. 2.2a

NOTE: If the red button stays lit and the green button does not stay ON, please

check to make sure that the Emergency Stop button is not pressed. Twist the

Emergency stop button to release.

2.2 Enabling The Machine

Make sure you have your

clean, dry air with at least 90

psi connected at the rear of

the machine.

Fig. 2.2c

14 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

Oncethemachinehasbeenpoweredupandadequateairpressurehasbeen

applied, the PC and monitor may be turned on and booted up.

WhenthePCnishesloading,theTechnoCNCInterfacemaynowbelauched.

Run the program by double clicking the Techno CNC

Interface icon on your Windows desktop.

Techno CNC Interface

15 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

2.3 Techno CNC Software Controller: Overview

The Techno CNC Controller has advanced features to provide the

smoothest possible cuts. G-Code input is constantly buffered to

‘vector match’ moves. This means your machine only slows down

when it needs to and then only as much as needed to stay within the

acceleration parameters programmed. The Techno CNC Controller

also does S-Curve acceleration through arcs and matches arc

tangential velocities with straight moves to provide smooth arc

moves. The result of these features is simply smoother cuts and less

needfornishingoperations.TheTechnoCNCControllerhasahighly

customizable, user-friendly interface that lets you take control of

your machine, providing features previously only found on custom

industrial controllers.

The intuitive user interface is easy to learn and convenient to use. All

the features you need and expect are readily accessible via industry

standard G-Codes. Simple keystrokes provide the ability to start,

pause, restart, jog, and rapid transit any axis without navigating

multiple screens and windows. Programs may be run from any line

as needed. The programmed feed rates may be adjusted from 1% to

200% without stopping machine motion.

16 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

WinCNC Controller

WinCNC Users Guide Page 10

Screen Display

The following section contains a sample of the WinCNC software

display. Common components are labeled to provide clarity.

NOTE : This screen may differ from your screen layout, as it is

highly customizable and may have been altered by the CNC ma-

chine manufacturer.

Screen Display Component Breakdown

Menu Bar

The Menu Bar contains many of the main features of the WinCNC

software. It is broken down into several generalized sections, as

shown below. The menu bar selections are described in the follow-

ing pages. If a menu option has a shortcut key, the shortcut key

combination is listed in parenthesis () after the name of the menu

option.

Program Operation

Program Operation: Overview

ThissectionoutlinesthetasksrequiredtooperationyourTechnoTitanSeriesCNC

RouterequippedwiththeWinCNCControlSystem

17 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

Tool Bar

START

Execute

command

line or job

RESTART / SKIP

Restarts a job at a

given line number

SINGLE STEP MODE

Allows you to execute

single lines of a g-code

leatatime.

STOP / ABORT

Stops a running

command or job

PAUSE

Pauses a running

command or job

VIEW HISTORY

Opens Job history

browser

OPEN

Opens Explorer

to open a job

le

EDIT

Opens Notepad

toeditajoble

SIMULATE

Simulatesaleto

check for errors

and run time

VIEW

Displays the current

job in the viewer

window

SOFT LIMITS

Enables/Disables

soft limit features

Axis Window

Green Box

Indicates an origin

offset is applied

Blue Box

Indicates a workspace offset

or tool length is applied

Red Triangle

Indicates a triggered limit

switch (left low, right high)

Slider Bar

Controls feed

rate override

The axis window is the primary display for current information about each

axis on your machine.

The current positions and velocities for each axis are displayed in the text

boxes.

Machine Status

Displays current

units, active modes

and current feed rate

override percentage

Thetoolbarisacollectionofshortcutbuttonsthatperformspecicactions.

18 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

Viewer

WinCNCcontainsabuiltinviewerwindowthatwillallowyoutodisplaytheoutputofG-Codeles

beforethejobisactuallyrun.Bydefault,theviewercanalsodisplayaG-Codelelinebylineasit

is run.

G0 rapid moves are shown as a black dashed line. G1 feedrate moves are displayed as a solid blue

line.

Toviewalebeforeyourunit,opentheleinthecommandlineandthenpresstheviewerbutton

on the toolbar.

Once the object is loaded into the viewer the following controls can be used:

Zoom In - click the left mouse button.

Zoom Out - click the right mouse button.

Selected Zoom - hold down the left mouse button and drag the box around the area to zoom in

on.

Pan or Re-Center Object - hold CTRL and click either mouse button.

Reset Image - hold shift and click either mouse button

Origin

Where red vertical and

horizontal lines intersect

Current Position

Shows the current

position of the plasma

torch

(Shown as red circle)

19 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

Function Buttons

These buttons perform preset functions. They are used as shortcuts for many

G-code operations.

Home All

Finds the machine’s limit

switches. Should be

performed at start-up. Set XY

Sets the XY origin at

the current position

Man. Z=0

Sets the Z origin at the

current position.

Go XY0

Raises Z to its high limit

and sends the machine

to XY=0

Auto Z=0

Starts automatic

touch off cycle to

set Z=0

Clear

Clears all offsets.

Park

Moves the machine to a

clearance position

20 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

WinCNC Controller

WinCNC Users Guide Page 11

File Menu

Open (CTRL+O) - Opens a le.

Edit (CTRL+E) - Opens the editor. If a lename is in the command

line, the editor opens that le.

Simulate (CTRL+S) - Simulates a le running to check for errors and

estimate run time.

View (CTRL+V) - Views a le in the viewer window.

Restart (CTRL+R) - Opens the le restart dialog box to restart a le.

Create Home File (CTRL+H) - Creates a home le at the current

machine position.

Import => DXF - Allows the user to import DXF (Drawing Exchange

Format) le.

Import => HPGL - Allows the user to import HPGL (Hewlett-Packard

Graphics Language) le.

*Note: The DXF and HPGL import feature is intended for cutting

simple designs. WinCNC does not compensate for tool diameter

when converting these les. For more complicated design, where

intelligent tool pathing is important, please use a compatible CAD/

CAM program.

Digitize => Manual - Enable/Disable the Manual Digitizing Toolbar.

Digitize => Automatic - Automatic digitizing (L802, L803).

Digitize => Frame - Skeletal Digitizing (L810). This scanning

method scans a center line or spine, and horizontal lines or ribs of

the object.

Digitize => Outline - Creates an outline trace around an object.

Program Operation

This manual suits for next models

1

Table of contents

Other Techno CNC Systems Control System manuals

Popular Control System manuals by other brands

LS ELECTRIC

LS ELECTRIC XGT Series user manual

Burk

Burk ARC Plus SL instruction manual

BACHMANN EUROPE Plc

BACHMANN EUROPE Plc E-Z COMMAND DIGITAL COMMAND CONTROL SYSTEM user manual

Carel

Carel m chiller user guide

Tekmar

Tekmar 364 Data brochure

Interspace Industries

Interspace Industries FiliBuster user manual