Technogel Mantegel 20 Parts list manual

I

IN

NS

ST

TR

RU

UC

CT

TI

IO

ON

NS

S

F

FO

OR

R

I

IN

NS

ST

TA

AL

LL

LA

AT

TI

IO

ON

N,

,

U

US

SE

E

A

AN

ND

D

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

E

ED

D.

.

0

01

1-

-0

08

8

G

GB

B

M

MA

AN

NT

TE

EG

GE

EL

L

2

20

0

-

-

3

30

0

-

-

5

50

0

–

–

7

70

0

Condenser “ Water”

Condenser “ Air”

Condenser “ Air/Water”

Dispositive “ Granita”

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

2

EDITION 01-08 –This manual is the exclusive property of TECHNOGEL spa.

Any unauthorized reproduction of part or whole of this document is prohibited

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

3

Introduction

Thank you for choosing our product. For best results, we recommend that you read this instruction

manual carefully.

The descriptions and illustrations contained in this manual are not binding. TECHNOGEL reserves the

right to modify and improve, without notice and at any point, machine parts where deemed necessary

for construction and/or commercial motives.

Persons qualified to carry out the work depending on the type of work involved

Please note the symbols given at the side of each operation described for installation, use and

maintenance:

= Technician = User

Where the symbol of the Technician is indicated (an electrician, plumber or mechanic) this means that

the operations described can be carried out exclusively by these people. If the user attemps to carry

out these operations this could prove dangerous and he/she must refrain from doing so.

Installation and first start-up

The installation and first startup of this machine must be carried out by a TECHNOGEL

technician or one with TECHNOGEL authorization.

TECHNOGEL spa DECLINES ALL LIABILITY FOR INSTALLATIONS OR

STARTUPS CARRIED OUT BY UNAUTHORIZED PERSONS.

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

4

How to unpack the machine

GROSS WEIGHT A B C

MANTEGEL 20 = KG. 280 mm. 730 1030 1730

MANTEGEL 30 = KG. 310 mm. 730 1030 1730

MANTEGEL 50 = KG. 355 mm. 730 1100 1730

MANTEGEL 70 = KG. 525 mm. 730 1320 1730

ATTENTION : DUE TO ITS NARROW AND HIGH SHAPE, THE MACHINE

MAY BE UNSTABLE DURING HOISTING.

Remove all the side and top wooden panels

Lift the machine using a fork lift truck, inserting the forks between the

machine base and the crate base

Under the crate base unscrew the four bolts that hold the machine

tightly in position

ATTENTION:

After removing these bolts, the base of the crate will drop to the

ground.

After removing the crate base, lower the fork lift truck and place the

machine on the ground.

The machine can now be moved by means of the handles.

THE TYPE OF WOOD USED FOR THE PACKING CRATE IS NATURAL SPRUCE,

NOT CHEMICALLY TREATED SO THAT IT CAN BE PERFECTLY RECYCLED.

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

5

Hoisting the machine

NET WEIGHT A B C

MANTEGEL 20 = KG. 190 mm.490 620 1305

MANTEGEL 30 = KG. 220 mm.490 600 1330

MANTEGEL 50 = KG. 260 mm.490 740 1330

MANTEGEL 70 = KG. 435 mm.490 940 1400

ATTENTION: DUE TO ITS NARROW AND HIGH SHAPE, THE MACHINE

MAY BE UNSTABLE DURING HOISTING.

Lift the machine using a fork lift truck, inserting the forks from the side,

between the front and rear wheels.

Hoist the machine with belts near the front and rear wheels (as in

drawing).

The tie rod lifting the machine must be at the exact centre of the

machine.

Move the machine by holding the flange handle in one hand and the

corner of the machine in the other.

After positioning the machine, use your feet to lock with the front wheel

brakes.

NEVER USE YOUR HANDS

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

6

Machine identification

Every machine is given a plate bearing:

machine type

electrical power

serial number

gas type and quantity

voltage and hertz ratings

This plate is found at the back of the machine. Below is the serial plate for this machine.

When ordering spare parts and requesting technical assistance, always quote the information given on

the serial plate:

MACHINE TYPE

MANTEGEL

SERIAL NUMBER

VOLTAGE

VOLT HZ

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

7

P

PO

OS

SI

IT

TI

IO

ON

NE

EM

ME

EN

NT

T

M

MA

AC

CH

HI

IN

NE

E

C

CO

ON

ND

DE

EN

NS

SE

ER

R

F

FO

OR

R

W

WA

AT

TE

ER

R

C

CO

ON

NN

NE

EC

CT

TI

IO

ON

N

W

WA

AT

TE

ER

R

E

EN

ND

D

E

EL

LE

EC

CT

TR

RI

IC

CA

AL

L

technician qualificate:

ELECTRICIAN PLUMBER

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

8

Dimensions and different facilities: MANTEGEL 20

Dimensions and weight:

A–width

B–depth

C

H–height

Weight

19” 3/8

490 mm.

24” 7/16

620 mm.

7” 7/8

200 mm.

51” 3/8

1305 mm.

419 Lb.

190 Kg.

WARNING:

For the good functioning, the machine does not have to be anchored to the floor, neither some

particular technical precaution are to be taken to limit the vibration transmission.

The installation requires the following operations:

Around the machine perimeter, leave an operat ive space of at least 10” (25 cm) necessary to carry

out the works smoothly.

Make sure the machine is steady by blocking the brakes (F) of the front wheels using the feet (DO

NOT USE THE HANDS).

Connect the hidro-system with the water inlet and outlet (see above picture point W). For the

pressure and consumption data refer to page 12 (MANTEGEL 20).

Connect the electric system (see above picture point E). For the power and absorption data refer to

page 10 (Table A - MANTEGEL 20).

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

9

Dimensions and different facilities: MANTEGEL 30

Dimensions and weight:

A–width

B–depth

C

H–height

Weight

19” 3/8

490 mm.

24” 7/16

620 mm.

7” 7/8

200 mm.

52” 3/8

1330 mm.

485 Lb.

220 Kg.

WARNING:

For the good functioning, the machine does not have to be anchored to the floor, neither some

particular technical precaution are to be taken to limit the vibration transmission.

The installation requires the following operations:

Around the machine perimeter, leave an operative space of at least 10” (25 cm) necessary t o carry

out the works smoothly.

Make sure the machine is steady by blocking the brakes (F) of the front wheels using the feet (DO

NOT USE THE HANDS).

Connect the hidro-system with the water inlet and outlet (see above picture point W). For the

pressure and consumption data refer to page 12(MANTEGEL 30). Connect, also, the washing

water (L) cold or hot according to the availability.

Connect the electric system (see above picture point E). For the power and absorption data refer to

page 10 (Table A - MANTEGEL 30).

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

10

Dimensions and different facilities: MANTEGEL 50

Dimensions and weight:

A–width

B–depth

C

H–height

Weight

19” 3/8

490 mm.

29” 1/2

750 mm.

7” 7/8

200 mm.

52” 3/8

1330 mm.

640 Lb.

290 Kg.

WARNING:

For the good functioning, the machine does not have to be anchored to the floor, neither some

particular technical precaution are to be taken to limit the vibration transmission.

The installation requires the following operations:

Around the machine perimeter, leave an operat ive space of at least 10” (25 cm) necessary to carry

out the works smoothly.

Make sure the machine is steady by blocking the brakes (F) of the front wheels using the feet (DO

NOT USE THE HANDS).

Connect the hidro-system with the water inlet and outlet (see above picture point W). For the

pressure and consumption data refer to page 12 (MANTEGEL 50). Connect, also, the washing

water (L) cold or hot according to the availability.

Connect the electric system (see above picture point E). For the power and absorption data refer to

page 10 (Table A - MANTEGEL 50).

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

11

Dimensions and different facilities: MANTEGEL 70

Dimensions and weight:

A–width

B–depth

C

H–height

Weight

19” 3/8

490 mm.

37”

940 mm.

7” 7/8

200 mm.

55”

1400 mm.

960 Lb.

435 Kg.

WARNING:

For the good functioning, the machine does not have to be anchored to the floor, neither some

particular technical precaution are to be taken to limit the vibration transmission.

The installation requires the following operations:

Around the machine perimeter, leave an operat ive space of at least 10” (25 cm) necessary to carry

out the works smoothly.

Make sure the machine is steady by blocking the brakes (F) of the front wheels using the feet (DO

NOT USE THE HANDS).

Connect the hidro-system with the water inlet and outlet (see above picture point W). For the

pressure and consumption data refer to page 12 (MANTEGEL 70). Connect, also, the washing

water (L) cold or hot according to the availability.

Connect the electric system (see above picture point E). For the power and absorption data refer to

page 10 (Table A - MANTEGEL 70).

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

12

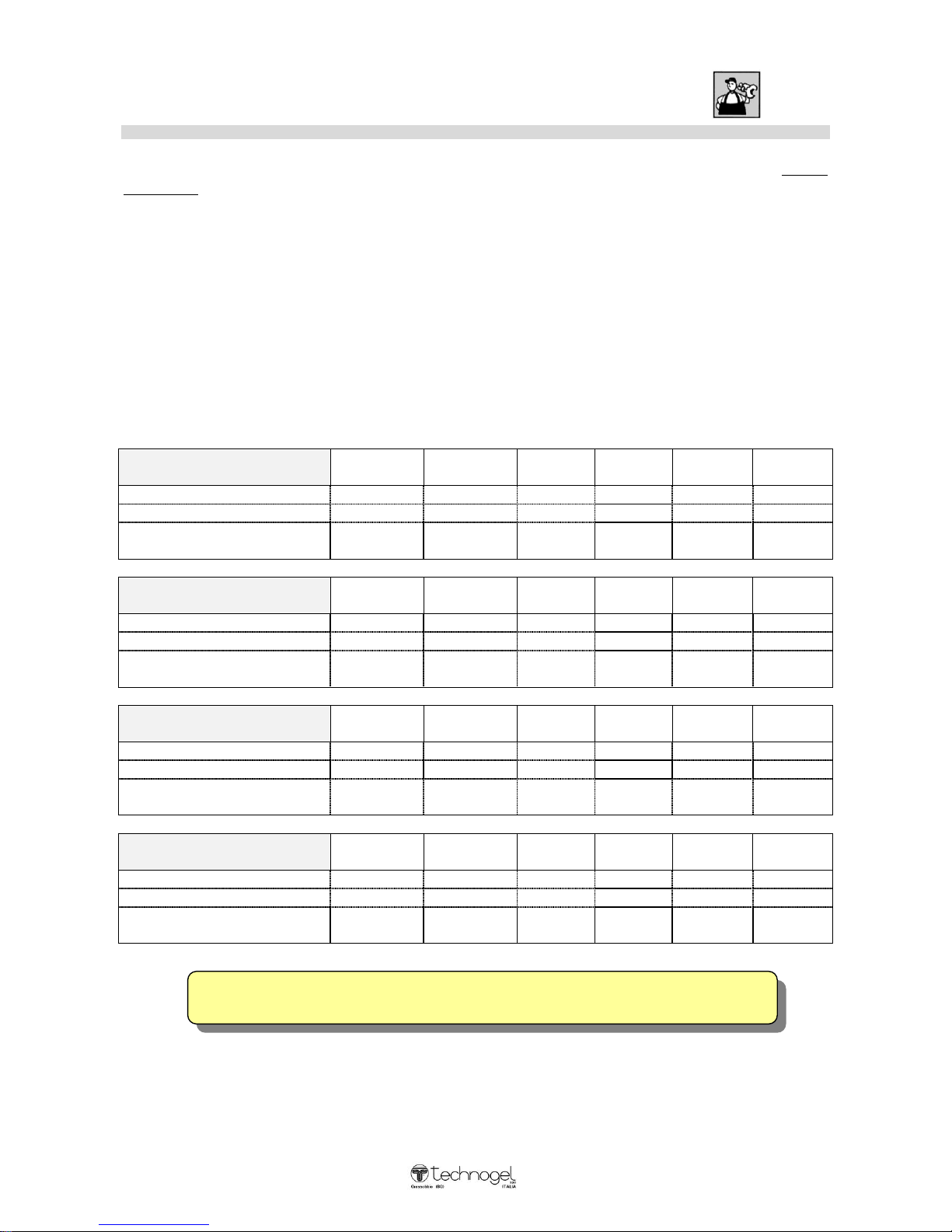

Electrics installation

The electrical installation, which the machine is connected to, must be carried out by a skilled

electrician according to regulations and observing the Laws in force. An efficient electrical

installation with earthing is the most important thing in order for your machine to work

perfectly.

Fit a suitable wall switch: we strongly recommend fitting an automatic differential switch. See table

(A) for power rating and absorption details.

Check taht the mains voltage rate is the same as the machine rating, shown on the serial number plate

(see page 5).

The power cable has 4 wires: the yellow/green wire is the earth wire, the other three are for the three

phases.

Table (A):

MANTEGEL 20

V.220

50HZ

V.220

60HZ

V.200

50/60HZ

V.380

50HZ

V.380

60HZ

V.415

50HZ

Total power KW

2,6

2,6

4

2,6

2,6

2,6

Max. absorp. A.

10,5

10,5

19

6,5

7,5

6,5

Power cable

Wires & section

4 x 2,5

mm²

4 x 2,5

mm²

4 x 4

mm²

4 x 1,5

mm²

4 x 2,5

mm²

4 x 1,5

mm²

MANTEGEL 30

V.220

50HZ

V.220

60HZ

V.200

50/60HZ

V.380

50HZ

V.380

60HZ

V.415

50HZ

Total power KW

4,2

4,2

4,2

4,2

4,2

Max. absorp. A.

11,2

11,2

19,5

7

8

6,5

Power cable

Wires & section

4 x 4

mm²

4 x 4

mm²

4 x 4

mm²

4 x 2,5

mm²

4 x 2,5

mm²

4 x 2,5

mm²

MANTEGEL 50

V.220

50HZ

V.220

60HZ

V.200

50/60HZ

V.380

50HZ

V.380

60HZ

V.415

50HZ

Total power KW

6

6

6

6

Max. absorp. A.

20

20

13

12

Power cable

Wires & section

4 x 6

mm²

4 x 6

mm²

4 x 4

mm²

4 x 4

mm²

MANTEGEL 70

V.220

50HZ

V.220

60HZ

V.200

50/60HZ

V.380

50HZ

V.380

60HZ

V.415

50HZ

Total power KW

11,2

11,2

11,2

11,2

11,2

Max. absorp. A.

36

36

45

21

20

Power cable

Wires & section

4 x 10

mm²

4 x 10

mm²

4 x 10

mm²

4 x 6

mm²

4 x 6

mm²

TECHNOGEL CANNOT BE HELD LIABLE FOR ANY DAMAGE ARISING FROM

INCORRECT INSTALLATION OR MAINS DEFECTS.

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

13

Water connection

The refrigeration system has a water-cooled condenser. A connection for the hot or cold water pipe

exists. It is useful for washing the machine. Its tap and nozzle are in the front of the machine.

Connect the mains hose to the fitting that reads " ENTRATA ACQUA- WATER INLET ".

The drain hose must be connected to the fitting that reads " USCITA ACQUA-WATER OUTLET ".

The connection plates and fittings are inside the machine: to access these, remove the rear panel.

To connect the machine to the mains, we recommend using a rubber hose suitable for up to 10 bars

with an inside diameter of about 15 mm (matching the fittings supplied with the machine).

If, for any reason, the plates indicating water inlet and outlet are illegible, please note that the water

inlet hose is fitted to the pressure-switch valve.

WATER PRESSURE AND CONSUMPTION

If the machine is using mains water, check that the incoming water has a pressure of at least 1 bar.

If the water pressure is more than 5 bar, fit a pressure reducer to the system, to reduce this to 4 bar.

Average water consumption (when the refrigerating unit is on) is:

- MANTEGEL 20 = 80/100 litres/hours*

- MANTEGEL 30 = 100/190 litres/hour*

- MANTEGEL 50 = 150/250 litres/hours*

- MANTEGEL 70 = 300/450 litres/hours*

* depending on the temperature of the incoming water.

If the water contains impurities, fit a purifying filter to avoid scaling and/or damage to the

pressure-switch valve.

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

14

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

15

M

MA

AC

CH

HI

IN

NE

E

P

PO

OS

SI

IT

TI

IO

ON

NI

IN

NG

G

C

CO

ON

ND

DE

EN

NS

SE

ER

R

F

FO

OR

R

A

AI

IR

R

O

O

A

AI

IR

R

/

/

W

WA

AT

TE

ER

R

C

CO

ON

NN

NE

EC

CT

TI

IO

ON

NS

S

Technician qualificate:

ELECTRICIAN PLUMBER

IF The machine works with isolate condenser,you’ ll have to contact the:

REFRIGERATOR TECHNICIAN

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

16

TECHNOGEL spa CANNOT BE HELD RESPONSIBLE FOR ANY DAMAGE CAUSED BY

INCORRECT POSITIONING OF THE MACHINE IN AN UNSUITABLE PLACE. THE

COMPANY IS ALSO UNABLE TO ASSUME ANY RESPONSIBILITY FOR INADEQUATE

PERFORMANCE OF THE MACHINE OWING TO OPERATING CONDITIONS BEING

BEYOND THE LIMITS OF ACCEPTABILITY.

Positioning of machine with fixed air condenser

VALID FOR MACHINES WITH EITHER AIR CONDENSATION OR AIR/WATER COMBINED

It is extremely important that the machine should be installed in a spacious room with doors

and windows so the air heated by the machine can be changed regularly.

The rear of the machine must be place at a distance of at least 0.5 metres from the wall.

During operation of the machine, the doors and windows in the room must be left open

otherwise the air heated by the machine will become extremely hot and could reach

temperatures of around 50°C. If the machine is allowed to operate in these conditions the

main components (refrigerator compressor and turbine motor) could well overheat over the

long term and this could jeopardize correct operation of the machine and cause damage which

would be costly to repair. It would also mean an increase in running costs owing to the high

consumption of electricity w hile the machine’ s performance w ould be reduced by 50% .

IDEAL POSITIONING OF THE MACHINE

As shown in the diagram, the air coming in through the door (1) is sucked in and heated

during condensation of the ventilators (2) and is pushed in the direction of the window (3)

and thus outside.

The ideal solution, though not always easy to put into practice, is to make holes in the wall

(4) opposite the ventilators (2). The air can therefore flow out freely without any problem and

the machine’ s performance w ill alw ays be excellent.

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

17

Positioning of the machine with remote air condenser

In order to combat problems of overheating of the air, whenever possible the remote air condenser

should be mounted.

CAUTION:

Copper or flexible piping (T) transporting the refrigerant gas from the machine to the condenser and

vice versa,

Should not exceed 4 metres in length.

The condenser must be fixed to wall brackets positioned high up so that they are beyond the reach of

people of average height.

As illustrated in the diagram, the condenser must be positioned at least 200 mm from the wall so that

air can be sucked in without any problem. It is also advisable to install protective roofing over the

equipment to protect it from rain water.

with remote air condenser

The machine must be installed by a Refrigeration Technician who after connecting the equipment will

check that the quantity of gas inside the machine is correct for optimum operation.

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

18

Cooling Machine fixed

Dimension / Weigh MANTEGEL 20 Air

A- Width

B–Depth

C–Console Table

H–Height

Weight

490 mm

1120 mm

200 mm.

1305

220 Kg.

Dimension / Weigh MANTEGEL 30 Air

490 mm

1120 mm

200 mm.

1305

250 Kg.

Dimension / Weigh MANTEGEL 50 Air

490 mm

1300 mm

200 mm.

1305

290 Kg.

WARNINGS:

After positioning the machine and locking the front wheels by pressing on the brake with the feet (do

not use the hands for this operation), check that the feet (P) both rest on the floor. If the feet (P) are

not level, during operation the condenser could move around owing to movement of the ventilators.

If the machine operates in contact with other machines, make sure there is a space of at least 25

cm between them.

Carry out the electrical connections of the machine and make sure that the electric cable (E) comes

from above and is not laid on the floor where it could be crushed. For data on power and

absorption please see page 22 Table A under the specific machine reference.

For the MANTEGEL 30 and MANTEGEL 50 machines, it is possible to connect hot or cold water

for washing purposes to the rear of the machine.

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

19

Cooling Machine Arranged air water

Dimension / Weigh MANTEGEL 20 Air / Water

A- Width

B–Depth

C–Console Table

H–Height

Weight

490 mm

1120 mm

200 mm.

1305

230 Kg.

Dimension / Weigh MANTEGEL 30 Air / Water

490 mm

1120 mm

200 mm.

1305

260 Kg.

Dimension / Weigh MANTEGEL 50 Air / Water

490 mm

1300 mm

200 mm.

1305

300 Kg.

FIXED COOLING AIR / WATER MACHINE

WARNINGS:

After positioning the machine and locking the front wheels by pressing on the brake with the feet (do

not use the hands for this operation), check that the feet (P) both rest on the floor. If the feet (P) are

not level, during operation the condenser could move around owing to movement of the ventilators.

If the machine operates in contact with other machines, make sure there is a space of at least 25

cm between them.

Carry out the electrical connections of the machine and make sure that the electric cable (E) comes

from above and is not laid on the floor where it could be crushed. For data on power and

absorption please see page 22 Table A under the specific machine reference.

Connect the water supply (W) to the machine with inlet and outlet for the condensation from the

refrigerating unit. For instructions on how to connect the machine, please see pages 8, 9 or 10

depending on the type of machine. For data on pressure and consumption, please see page 15.

(Page 19 only).

For the MANTEGEL 30 and MANTEGEL 50 machines, it is possible to connect hot or cold water

for washing purposes to the rear of the machine.

C:\Documents and Settings\mconti.TECHNOGEL-USA\My Documents\MACCHINE\ARTESAN\ART

MANUALS\Mantegel\Inglese\MG 2V Istruzioni Inglese 01-08.doc

20

TECHNOGEL spa CANNOT ASSUME ANY RESPONSIBILITY FOR ACCIDENTS

CAUSED BY IMPROPER INSTALLATION OR FAULTY WIRING

Electric installation

COOLING MACHINE AIR O AIR / WATER

The electrical installation, which the machine is connected to, must be carried out by a skilled

electrician in compliance with regulations and the Laws in force. An efficient electrical

installation with earthing is most important to ensure your machine works perfectly.

Fit a suitable wall switch: we strongly recommend fitting an automatic differential switch. See table

(A) for power rating and absorption details.

Check that the mains voltage is the same as the machine rating, shown on the serial number plate

(see page 6).

When the cable has 4wires, the yellow/green wire is the earth and the other three are the three

phases.

When the cable has 5wires, the yellow/green wire is the earth - the blue wire is neutral - the other

three are the three phases.

- TABLE -A-

MANTEGEL 20 Air

V.220

50 HZ

V.220

60 HZ

V.400

50 HZ

V.380

60 HZ

Total power KW.

3

3

3

Absorbtion edge A.

12

12

8

Wire line

Branch screw

4 x 2,5mm²

4 x 2,5mm²

4 x 1,5mm²

MANTEGEL 30 Air

V.220

50 HZ

V.220

60 HZ

V.400

50 HZ

V.380

60 HZ

Total power KW.

3,2

3,2

3,2

Absorbtion edge A.

13

13

8,5

Wire line

Branch screw

4 x 4mm²

4 x 4mm²

4 x 2,5mm²

MANTEGEL 50 Air

V.220

50 HZ

V.220

60 HZ

V.400

50 HZ

V.380

60 HZ

Total power KW.

5,2

5,2

5,2

Absorbtion edge A.

21

21

14,5

Wire line

Branch screw

4 x 6mm²

4 x 6mm²

4 x 4mm²

This manual suits for next models

3

Table of contents

Other Technogel Ice Cream Maker manuals

Popular Ice Cream Maker manuals by other brands

Ninja

Ninja CREAMI quick start guide

Taylor

Taylor Freezemaster 336 Original operating instructions

Vollrath

Vollrath Stoelting CC101A Operator's manual

Kambrook

Kambrook Little Chefs Soft Scoops KLCIA4 Instruction booklet

Cuisinart

Cuisinart ICE31U manual

Vollrath

Vollrath Stoelting CBB Series Operator's manual