Technogel MIXGEL 30 Parts list manual

I

IN

NS

ST

TR

RU

UC

CT

TI

IO

ON

NS

S

F

FO

OR

R

I

IN

NS

ST

TA

AL

LL

LA

AT

TI

IO

ON

N,

,

U

US

SE

E

A

AN

ND

D

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

Ed 04/08

GB

M

MI

IX

XG

GE

EL

L

3

30

0

-

-

M

MI

IX

XG

GE

EL

L

5

50

0

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

2

EDITION 07-06 –This manual is the exclusive property of TECHNOGEL spa.

Any unauthorized reproduction of part or whole of this document is prohibited

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

3

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

4

Introduction

Thank you for choosing our product. We strongly advise you to read this instruction manual carefully

so as to ensure trouble-free machine performance.

The descriptions and illustrations in this manual are not to be taken as binding; TECHNOGEL spa,

therefore, reserves the right, at any time and without prior warning, to make changes to parts of the

machine if they should they be considered necessary for any reason, whether it be for production or

commercial purposes.

Persons qualified to carry out the work depending on the type of work involved

Please note the symbols given at the side of each operation described for installation, use and

maintenance:

= Technician = User

Where the symbol of the Technician is indicated (an electrician, plumber or mechanic) this

means that the operations described can be carried out exclusively by these people. If the

user attemps to carry out these operations this could prove dangerous and he/she must refrain

from doing so.

Installation and first start-up

The installation and first startup of this machine must be carried out by a TECHNOGEL

technician or one with TECHNOGEL authorization.

TECHNOGEL spa DECLINES ALL LIABILITY FOR INSTALLATIONS OR

STARTUP CARRIED OUT BY UNAUTHORIZED PERSONS.

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

5

How to unpack the machine

GROSS WEIGHT A B C

MIXGEL 30 = 390 kg mm. 730 1030 1730

MIXGEL 50 = 444 kg mm. 730 1100 1730

ATTENTION : OWING TO ITS TALL, NARROW SHAPE, THE

MACHINE MAY BE UNSTABLE DURING HOISTING.

Remove all the side and top wooden panels

Lift the machine using a fork lift truck, inserting the forks

between the machine base and the crate base

.

Under the crate base unscrew the four bolts that hold the

machine tightly in position

ATTENTION:

After removing these bolts, the base of the crate will drop to the

ground.

After removing the crate base, lower the fork lift truck and place

the machine on the ground.

The machine can now be moved by means the handles.

THE TYPE OF WOOD USED FOR THE PACKING CRATE IS NATURAL SPRUCE, IT HAS

NOT BEEN CHEMICALLY TREATED SO IT IS PERFECTLY SUITED FOR RECYCLING.

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

6

Hoisting the machine

NET WEIGHT A B C

MIXGEL 30 = 290 kg mm. 490 800 1350

MIXGEL 50 = 339 kg mm. 490 940 1435

CAUTION: OWING TO ITS TALL, NARROW SHAPE, THE

MACHINE MAY BE UNSTABLE DURING HOISTING.

Lift the machine using a fork lift truck, inserting the forks from

the side, between the front and rear wheels.

Hoist the machine with belts near the front and rear wheels

(as indicated in the drawing).

The tie rod lifting the machine must be at the exact centre of

the machine.

Move the machine by holding the flange handle in one hand

and the corner of the machine in the other.

After positioning the machine, use your feet to lock with the

front wheel brakes.

NEVER USE YOUR HANDS

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

7

Machine identification

Every machine is given a plate bearing:

machine type

electrical power

serial number

gas type and quantity

voltage and hertz ratings

This plate is located at the back of the machine. Below is the serial plate for this machine.

When ordering spare parts and requesting technical assistance, always quote the information given on

the serial plate:

MACHINE TYPE

MIXGEL

SERIAL NUMBER

VOLTAGE

VOLT HZ

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

8

M

MA

AC

CH

HI

IN

NE

E

P

PO

OS

SI

IT

TI

IO

ON

NI

IN

NG

G

A

AN

ND

D

U

UT

TI

IL

LI

IT

TI

IE

ES

S

People authorized only:

ELECTRICIAN PLUMBER

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

9

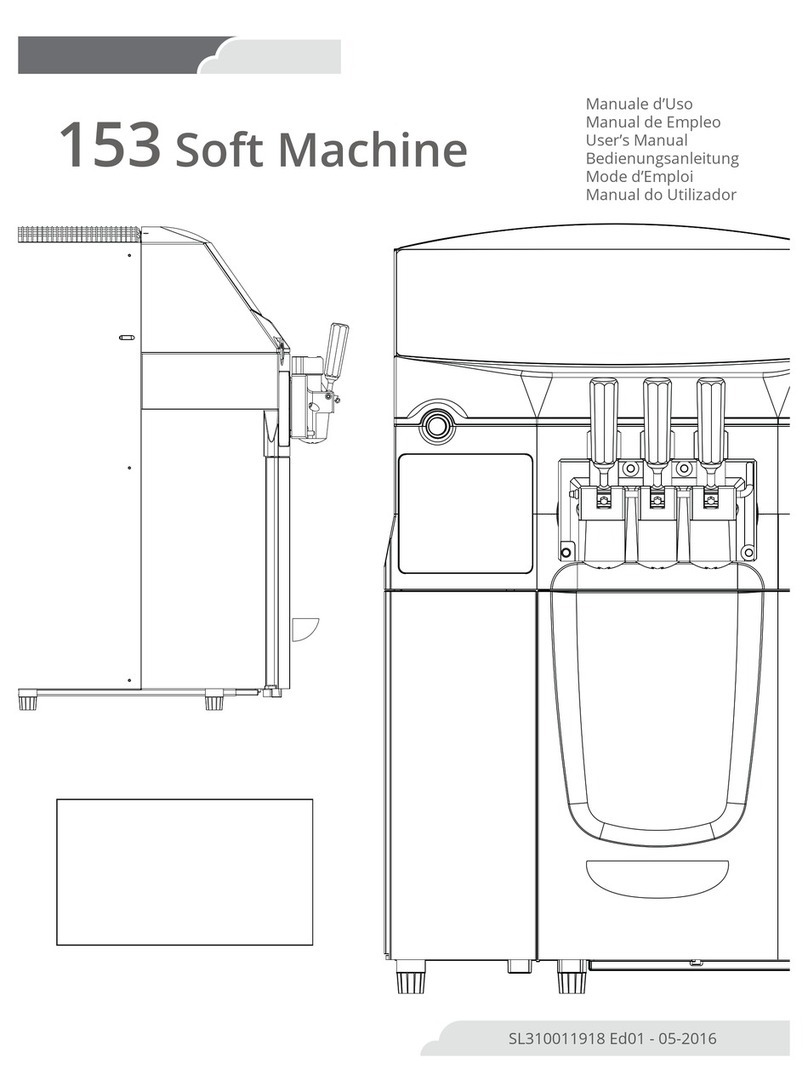

Dimensions and different facilities :

M

MI

IX

XG

GE

EL

L

3

30

0

Dimensions and weight:

A–width

B–depth

C

H–height

Weight

490 mm.

600 mm.

200 mm.

1350 mm.

290 Kg.

WARNING:

The machine does not have to be anchored to the floor to ensure satisfactory operation. No particular

technical precautions need be taken to limit transmission of vibrations.

The installation requires the following operations:

A space of at least 10” (25 cm) must be left round the machine to ensure any mauntenance w ork

can be carried out easily.

Make sure the machine is steady by blocking the brakes (F) of the front wheels using the feet (DO

NOT USE THE HANDS).

Connect the hidro-system with the water inlet and outlet (see diagram above point W). For the

pressure and consumption data please see page 11 (MIXGEL 30).

Connect the electric system (see diagram above point E). For the power and absorption data

please see page 10 (Table A –MIXGEL 30).

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

10

Dimensions and different facilities :

M

MI

IX

XG

GE

EL

L

5

50

0

Dimensions and weight:

A–width

B–depth

C

H–height

Weight

490 mm.

740 mm.

200 mm.

1435 mm.

339 Kg.

WARNING:

The machine does not have to be anchored to the floor to ensure satisfactory operation. No particular

technical precautions need be taken to limit transmission of vibrations.

The installation requires the following operations:

A space of at least 10” (25 cm) must be left round the machine to ensure any mauntenance w ork

can be carried out easily.

Make sure the machine is steady by blocking the brakes (F) of the front wheels using the feet (DO

NOT USE THE HANDS).

Connect the hidro-system with the water inlet and outlet (see diagram above point W). For the

pressure and consumption data please see page 11 (MIXGEL 50).

Connect the electric system (see diagram above point E). For the power and absorption data

please see page 10 (Table A –MIXGEL 50).

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

11

Electric installation

The electrical installation, which the machine is connected to, must be carried out by a skilled

electrician in compliance with regulations and the Laws in force. An efficient electrical

installation with earthing is most important to ensure your machine works perfectly.

Fit a suitable wall switch: we strongly recommend fitting an automatic differential switch. See table

(A) for power rating and absorption details.

Check that the mains voltage is the same as the machine rating, shown on the serial number plate

(see page 6).

The line cable of the machine has 4 wires when the machine is 220 V: and 5 wires when it is 380V.

or 415 V.

When the cable has 4wires, the yellow/green wire is the earth and the other three are the three

phases.

When the cable has 5wires, the yellow/green wire is the earth - the blue wire is neutral - the other

three are the three phases.

- TABLE -A-

MIXGEL 30

V.220

50 HZ

V.220

60 HZ

V.200

50/60HZ

V.400

50 HZ

Total power kW

7.15

8

7.15

7.15

Max. Absorp. A

25

29

25

15

Line cable

N° of wires & cross sections

4 x 6 mm²

4 x 6 mm²

4x6 mm²

5x4 mm²

MIXGEL 50

Total power kW

9,3

9,3

9,3

Max. Absorp. A

32

32

21,5

Line cable

N° of wires & cross sections

4 x 6 mm².

4 x 6 mm².

5 x 4 mm².

It is advisable to check the efficiency of your electricity supply , especially the earth and

safety systems.

TECHNOGEL spa CANNOT ASSUME ANY RESPONSIBILITY FOR ACCIDENTS

CAUSED BY IMPROPER INSTALLATION OR FAULTY WIRING

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

12

Water connection

The refrigeration system has a water-cooled condenser. A connection for the hot or cold water pipe

exists. It is useful for washing the machine. Its tap and nozzle are on the front of the machine.

Connect the mains hose to the fitting that reads " ENTRATA ACQUA - WATER INLET ".

The drain hose must be connected to the fitting that reads " USCITA ACQUA - WATER OUTLET ".

The connection plates and fittings are inside the machine: to access these, remove the rear panel.

To connect the machine to the mains, we recommend using a rubber hose suitable for pressure of up

to 10 bars with an internal diameter of about 15 mm (matching the fittings supplied with the

machine).

If, for any reason, the plates indicating water inlet and outlet are illegible, please note that the water

inlet hose is fitted to the pressure-switch valve.

WATER PRESSURE AND CONSUMPTION

If the machine is using mains water, check that the incoming water has a pressure of at least 1,5 bar.

If the water pressure is more than 5 bar, fit a pressure reducer to the system, to reduce this to 4 bar.

Average water consumption (when the refrigerating unit is on) is:

MIXGEL 30 = 150/180 litres/hours *

MIXGEL 50 = 200/230 litres/hours *

* depending on the temperature of the incoming water.

If the water contains impurities, fit a purifying filter to avoid scaling and/or damage to the

pressure-switch valve.

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

13

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

14

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

15

A

AC

CC

CE

EP

PT

TA

AB

BL

LE

E

A

AN

ND

D

U

UN

NA

AC

CC

CE

EP

PT

TA

AB

BL

LE

E

U

US

SA

AG

GE

E

M

MA

AC

CH

HI

IN

NE

E

O

OP

PE

ER

RA

AT

TI

IO

ON

N

C

CO

ON

ND

DI

IT

TI

IO

ON

NS

S

S

SA

AF

FE

ET

TY

Y

W

WA

AR

RN

NI

IN

NG

G

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

16

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

17

ACCEPTABLE AND UNACCEPTABLE USAGE

All pasteuriser /mixer machines in TECHNOGEL's MIXGEL series have been designed

exclusively for mixing ice-cream.

Use of these machines for any products other than those intended is entirely at the

Customer's own risk.

Machine operation conditions

Here below are the minimum and maximum doses of mixture that the different machines are able to

process; the doses are expressed as litres of mixture to put into the machine each time:

Minimum load

Maximum load

MIXGEL 30

3 litres

6 litres

MIXGEL 50

3 litres

8 litres

WE STRONGLY ADVISE YOU TO OBSERVE THE MINIMUM AND MAXIMUM

DOSES GIVEN ABOVE SO THAT YOUR MACHINE WILL MAKE

AN EXCELLENT PRODUCT IN TOTAL SAFETY.

TECHNOGEL spa CANNOT BE HELD LIABLE FOR DAMAGE CAUSED

BY EXCEEDING THE MAXIMUM RECOMMENDED DOSES

Initial start-up

CAUTION IMPORTANT

TO CARRY OUT INITIAL START-UP, PRESS THE “START”

BUTTON AND THEN WAIT FOR AT LEAST 60 MINUTES BEFORE

ACTIVATING THE REFRIGERATOR COMPRESSOR.

IF THE MACHINE IS DISCONNECTED FROM THE POWER SUPPLY

FOR ONE DAY OR MORE, AFTER PRESSING THE “START”

BUTTON, IT IS NECESSARY TO WAIT FOR AT LEAST 60 MINUTES

BEFORE ACTIVATING THE REFRIGERATOR COMPRESSOR.

IF THE MACHINE IS NEVER DISCONNECTED FROM THE POWER

SUPPLY NO WAITING PERIOD IS NECESSARY.

COMPRESS

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

18

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

19

Safety warning

Before starting the machine, check that the safety devices (1) (hopper protection grill) and (2) (exit

protection grill) are mounted and working.

When the machine is in use, do not touch the edge of the tank (4) with the hands or any other part

of the body as it is extremely hot. The boiler cap must be raised by means of the handle (2).

CAUTION: when the lid (3) is raised while the machine is in operation, the stirrer inside the heater

must stop. Check that it does so.

WARNING

Tampering or reducing safety devices (1) and (2),

can cause serious injury to the operator

While the machine is operating:

NEVER introduce foreign bodies into the hopper when this is in use, eg. scrapers -

knives - hose piping, etc., as these can damage the machine and may

injure the operator.

Never insert scrapers or knives between the bars in the exit while the

ice-cream is flowing out.

TECHNOGEL CANNOT BE HELD LIABLE FOR DAMAGE AS A RESULT OF

TAMPERING WITH THE MACHINE SAFETY DEVICES.

C:\Users\jamie\AppData\Local\Temp\notes97E53A\~3769474.doc

20

This manual suits for next models

1

Table of contents

Other Technogel Ice Cream Maker manuals