BIKERACE: Service & Maintenance Manual -rev. 1.1

Page ii

7.8. DISASSEMBLING THE ALTERNATOR.................................................................................................................7.10

7.9. DISASSEMBLING THE BELT..............................................................................................................................7.11

7.10.DISASSEMBLING THE CHAIN............................................................................................................................7.13

7.11.DISASSEMBLING THE PULLEY..........................................................................................................................7.14

7.12.DISASSEMBLING THE PEDAL CRANK GROUP....................................................................................................7.15

7.13.DISASSEMBLING THE ALTERNATOR BRUSHES .................................................................................................7.16

8. ADJUSTMENTS....................................................................................................................................................8.1

8.1. ALIGNING THE BELT..........................................................................................................................................8.1

8.2. BELT TENSION ..................................................................................................................................................8.2

8.3. CHAIN ALIGNMENT ...........................................................................................................................................8.3

8.4. CHAIN TENSION ................................................................................................................................................8.5

8.5. PLAY OF SADDLE STEM.....................................................................................................................................8.6

8.6. WEAR OF ALTERNATOR BRUSHES .....................................................................................................................8.7

8.7.PLAY OF THE PEDAL GROUP ..............................................................................................................................8.8

8.8. ADJUSTING THE LCD BACKLIGHTING...............................................................................................................8.9

8.9. ADJUSTING THE BUZZER TONE........................................................................................................................8.10

9. CONFIGURING THE MACHINE ......................................................................................................................9.1

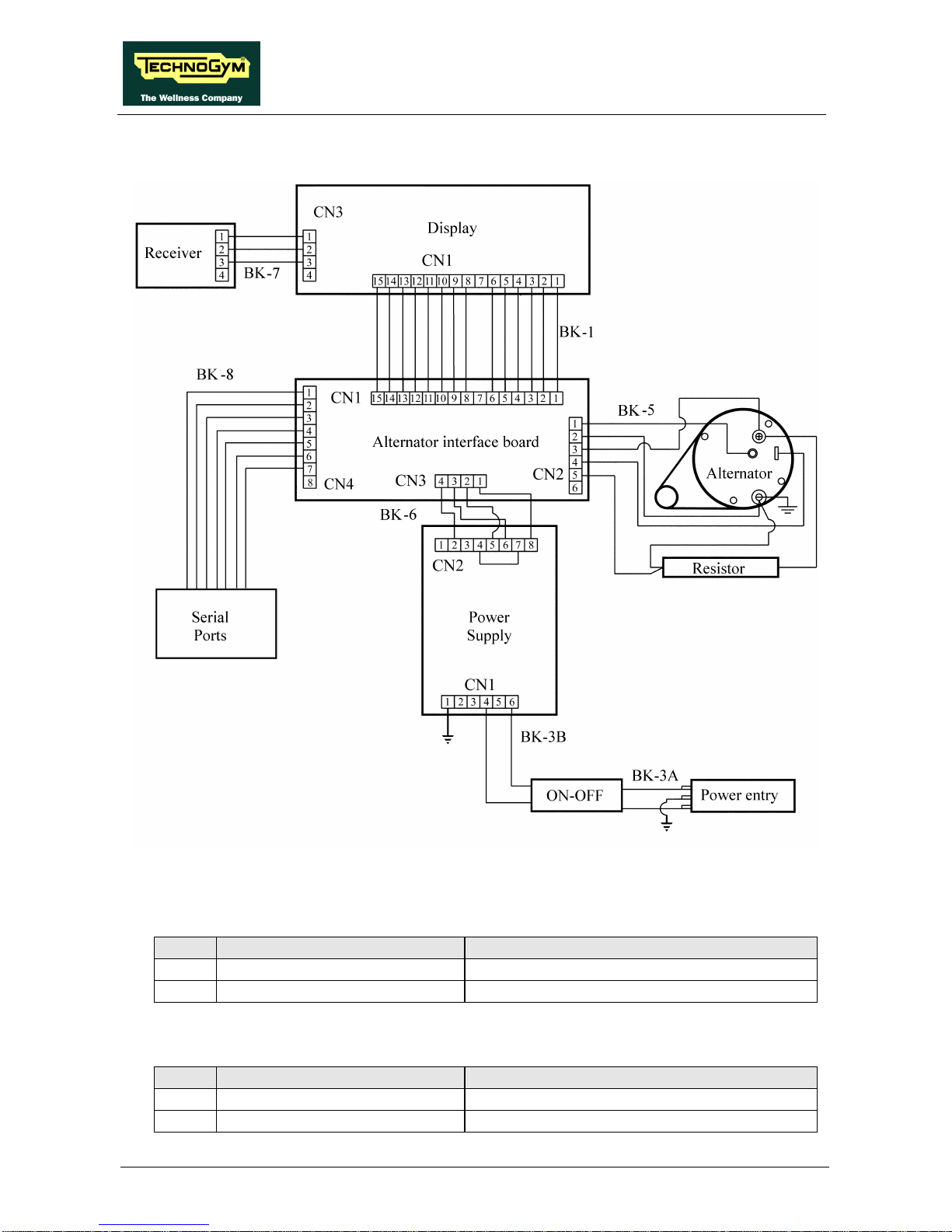

9.1. MACHINE HW CONFIGURATION .......................................................................................................................9.1

9.1.1. Machine No. configuration...............................................................................................................9.1

9.1.2. Alternator configuration...................................................................................................................9.1

10.SCHEDULED MAINTENANCE.......................................................................................................................10.1

10.1.EXTERNAL CLEANING OPERATIONS.................................................................................................................10.1

10.1.1. Setting up the operation ..................................................................................................................10.1

10.1.2. Cleaning operations........................................................................................................................10.1

10.2.INTERNAL CLEANING OPERATIONS..................................................................................................................10.2

10.2.1. Setting up the operation ..................................................................................................................10.2

10.2.2. Cleaning operations........................................................................................................................10.2

10.3.SPECIAL MAINTENANCE OPERATIONS..............................................................................................................10.3

10.3.1. Setting up the operation ..................................................................................................................10.3

10.3.2. Checking the working conditions ....................................................................................................10.3

10.3.3. Checking the wiring and connections..............................................................................................10.3

10.3.4. Checking the display........................................................................................................................10.3

10.3.5. Checking the wear of the rubber handlebar cover..........................................................................10.3

10.3.6. Checking the state of wear of the chain...........................................................................................10.4

10.3.7. Lubrication......................................................................................................................................10.4

10.3.8. Checking the state of wear of the alternator belt.............................................................................10.4

10.3.9. Checking the play of the saddle stem...............................................................................................10.4

10.3.10. Checking the operation of the cardio receiver................................................................................10.4

10.3.11. Checking the resistance setting .......................................................................................................10.4

10.3.12. Checking the noise of the brushes ...................................................................................................10.4

11.APPENDIX...........................................................................................................................................................11.1

11.1.TECHNICAL NOTES ON CARDIO RECEIVERS .....................................................................................................11.1

11.1.1. Type of ASIC....................................................................................................................................11.2

11.1.2. Presence of electromagnetic fields..................................................................................................11.2

11.1.3. Reducing receiver sensitivity...........................................................................................................11.3

11.1.4. Mechanical vibrations.....................................................................................................................11.4

11.1.5. Position of the receiver....................................................................................................................11.4

11.1.6. Routing of cables.............................................................................................................................11.5

11.2.PERSONAL CODED DEVICE.............................................................................................................................11.6

11.2.1. Operating modes .............................................................................................................................11.6

11.2.2. Upgrade of machines already installed...........................................................................................11.7

11.3.SPECIAL FUNCTIONS .......................................................................................................................................11.8

11.3.1. Displaying the selected type of alternator.......................................................................................11.8