Technomark M4 inline User manual

Page 1of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Maintenance manual

Type

Original version from 22/08/2014

Revision

1.3

Revision date

27/04/2016

Drafted by

FT

Validated by

SJ

3 Allée Michaël FARADAY

Parc d’Activités STELYTEC

42400 SAINT-CHAMOND

FRANCE

www.technomark-marking.com

Tel.: +33 (0)4 77 22 25 91

Fax: +33 (0)4 77 22 38 91

Page 2of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Before we start the TECHNOMARK company would like to warmly thank you for your confidence. You have chosen the

M4 inline, the first intelligent marking tool (IDI track & mark) that is dedicated to marking integration for ensuring

your products' identification. More than just a marking machine, we offer a complete solution which addresses all of

your traceability requirements. Our customer service is at your disposal for any further information.

And so now, enjoy your marking…

CONTENTS

1. Introduction. ______________________________________________________________________________ 3

2. Manuals __________________________________________________________________________________ 3

3. Customer Service Team. _____________________________________________________________________ 4

4. Identity of your marking equipment ____________________________________________________________ 5

5. Components and wear parts.__________________________________________________________________ 6

6. Preventive maintenance: Maintenance timetable. _________________________________________________ 9

6.1. General_______________________________________________________________________________ 9

6.2. Machine information ___________________________________________________________________11

6.3. Sharpening the stylus___________________________________________________________________ 12

6.4. The spring____________________________________________________________________________13

7. Compatibility with Integrated Multi4 V3 (NMI0-IE). _______________________________________________ 13

8. Remedial maintenance: Error detection.________________________________________________________ 14

8.1. Malfunctions _________________________________________________________________________14

8.2. Error codes___________________________________________________________________________16

9. List of illustrations _________________________________________________________________________ 22

Page 3of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

1.Introduction.

TECHNOMARK reserves the right to change the information and specifications contained in this manual without prior

notice. You should consult TECHNOMARK to learn of any changes that may have been made.

Under no circumstances may TECHNOMARK be held responsible for any direct or indirect incident related to damages,

even if exceptional, including, but not limited to, financial losses related to the use of information contained in this

manual. This clause also applies in cases where TECHNOMARK has been informed and/or had prior knowledge of

possible risks associated with the use of the equipment.

The TECHNOMARK guarantee of the equipment it manufactures is defined in its terms and conditions. Unless

specifically stated otherwise on our acknowledgement of order receipt, our equipment is guaranteed for 1 (ONE) year

from the delivery date of the equipment. This guarantee consists in our replacement, free of charge, of any defective

parts, except with regard to externally supplied sub-assemblies, in which case the supplier's warranty is applied. This

warranty does not cover defects resulting from normal wear of the products, incorrect use, maintenance not

performed in accordance with standard trade practices, inadequate storage conditions, an inappropriate product

environment, excessive use of the equipment or failure to follow the instructions for use and/or connection. Under

no circumstances will any repair work covered by the guarantee that causes a loss of time or profit result in an

extension of the said guarantee.

The following are excluded from the cover:

-Stylus

-Spring

-Stylus guide

-Core

-The outer part of the cable between the control unit and the marking head or an accessory.

The information contained in this manual is confidential and remains the property of the TECHNOMARK company.

2.Manuals

The information that is required throughout your machine's lifespan is available in the following manuals:

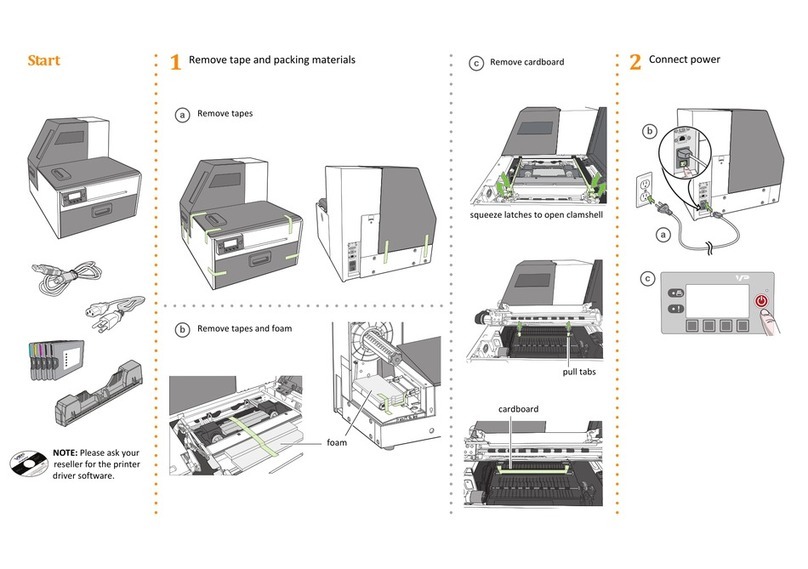

M4 inline Installation Manual: Contains information on unpacking and installing your equipment.

M4 inline Software Manual: Contains the necessary information for configuring and using your marking

machine.

Interfacing instructions for M4 inline: Contains the necessary information for establishing communication with

your equipment (RS232, Ethernet, 16-way).

M4 inline Maintenance Manual: Contains information about servicing your machine.

Information essential for the safety of the user.

Information essential for the safety of the machine.

does not indicate a malfunction or fault.Additional information.Complementary information

Page 4of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

3.Customer Service Team.

The TECHNOMARK dot peen marking machine requires only minimal maintenance. The role of our after-

sales customer service team is to help you to keep your equipment in good condition and prevent

malfunctions linked to the use of your machine.

We strive to be proactive and are constantly seeking new solutions to improve the services we offer to our

customers.

In order to achieve this, TECHNOMARK offers the following services:

Telephone assistance

TECHNOMARK provides personalised assistance. Whatever your question, a specialised technician

will be ready with the answers you need.

Factory maintenance contract

In order to ensure that your marking equipment is in perfect working order, TECHNOMARK offers a

regular upkeep service for your marking equipment. All you need to do is send us your machine

periodically and we will give it a complete service.

On-site maintenance contract

TECHNOMARK can send a specialised technician for regular site visits to ensure the maintenance of

your marking equipment at your own plant.

Product training tailored to your needs

As an approved training body, TECHNOMARK can provide a complete training package, so you can

quickly and effectively get to grips with your new equipment.

Tailored solutions

If required, TECHNOMARK can provide you with a machine free of charge while we deal with your

equipment.

You can get in touch with our customer service team via:

E-mail: [email protected]

Telephone: 04 77 22 25 91

Opening times: 8:30 a.m. to 5:30 p.m.

Our technicians will help you to detect and resolve malfunctions as quickly as possible.

Page 5of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

4.Identity of your marking equipment

When contacting the After-Sales Customer Service Team, please provide us with the identity of your equipment.

You will find this information on the nameplate on the control unit (located on the rear) and the quality plate delivered

with the marking head (attached to the cable).

See the format below:

Illustration 1: Control unit nameplate.

Illustration 2: 50x55 marking head nameplate.

Illustration 3: 120x55 marking head nameplate.

Page 6of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

5.Components and wear parts.

Illustration 4: Exploded view –50x55 marking head.

Page 7of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

1

V3-C-2001

Top connector

11

V3-M-0016

Plastic bushing for translation

screw

2

V3-M-1007

Main body

12

V3-M-1005

Right-hand flange

3

V3-M-2002

Drive pulley X

13

V3-V-0020

Set screw

4

V3-M-1004

Left-hand flange

14

V3-M-2006

Pulley spline shaft

5

MTV2-M-0010

Engine belt X

15

MTV2-M-0005

Drive pulley Y

6

V3-M-4001

Side cover

16

MTV2-M-0002

Stepper motor

7

V3-M-2001

Pulley translation screw

17

V3-M-2021

Ø12 axis

8

NAI0-7003

Flexible protection cover

18

V3-M-4002

Front cover

9

Subset

Impact unit

(see illustration 5)

19

V3-M-0023

Cover attachment clip

10

Subset

Slide unit

(see illustration 6)

20

V3-M-2011

Guiding bar

Illustration 5: Exploded view –Impact unit parts

1

TKF053A-60

Coil base

2

TKF054A-A

Core

3

TKF053A-60

Standard stylus

4

MTV2-M-0003

Spring

5

TKF052A-60

Stylus guide

6

TKF051A-A

Knurled nut

Page 8of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Illustration 6: Exploded view –valve sub-assembly/Moving part - 50x55 window.

1

V3-M-1001

Valve

10

V3-M-0012

Ball bearing

2

MTV2-M-

0015

Linear guideway

11

V3-M-3004

Spline shaft sheet block

3

V3-M-3005

Detection sheet Y

12

V3-M-0018

Spline shaft plastic bushing

4

V3-M-2032

Coil housing

13

V3-M-0005

Spline shaft + pulley

5

V3-M-3008

Belt base Y

14

V3-M-0019

Valve plastic bushing

6

V3-M-0013

Cylindrical pin

15

V3-M-0001

Translation screw

7

V3-M-2005

Idle pulley

16

V3-C-0002

Detection card

8

V3-M-0011

Belt Y

17

V3-M-0022

Spacer for detection card

9

V3-M-3007

Belt clip Y

18

V3-M-0017

Detection magnets

Page 9of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

6.Preventive maintenance: Maintenance timetable.

6.1.General

The control panel on the welcome screen of the control unit has a maintenance indicator:

Maintenance indicator: The LED turns red when a maintenance operation is required.

For more information, refer to the ‘Maintenance’ chapter in the Inline-user-maintenance-

software)

The timetable for the operations required for the preventive maintenance of your marking device is shown for

illustrative purposes only. Carrying out this preventive maintenance will extend the life of your marking machine.

This timetable has been drawn up according to the following reference settings:

2,000 markings per day, based on 24h worked per day, 3x8 (complete cycle of 43s).

Marking of 10 characters on two lines, height of characters 4mm, and 5x7 matrix.

Position of lines in X=10 / Y=10 and 15 mm

Medium marking force, level 3/6 + standard marking speed, level 3/5.

The other settings are standard.

Average results (depends on the characters marked): Marking time of 9s / 152 impacts per marking / 0.11m

displacement on the X axis and 0.10m displacement on the Y axis.

In the case of more intensive use (greater force/speed/number of impacts) or a difficult environment (chips of materials,

considerable amount of fluid and dust), the preventive maintenance frequencies listed below should be shortened, to

ensure that your device continues to function correctly.

In the event of intensive use, the active part of the machine (coil body) may reach a temperature of

over 70°C. Do not conduct any operations on this element without suitable protection and/or allow

this part to cool before handling it.

The maintenance and upkeep operations must be conducted with the machine

SWITCHED OFF. The power cable must be disconnected.

The knurled nut on the striker unit must be tightened/loosened manually. Never use

tools, as this could cause serious damage. The quality of your machine will be

impaired.

Page 10 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Frequency

Maintenance operations to be carried out

/ week

-Check the general condition of the machine and the impact unit in particular. Clean the internal

components of the impact unit (core, stylus, guide) and lubricate the stylus.

/ month

-Clean the guides and internal parts of the machine. Use, as a minimum, a damp rag and, if possible,

a (dry) air blow gun.

-Check the condition of the marking head cable visually.

-Check the length of the spring (see chapter 5.2).

-Check the tip of the stylus. This may affect the quality of the marking. If chipped or rounded,

sharpen the tip or change the stylus (see chapter 5.1).

/ 6 months

-Check the clearance between the guide and the stylus (see illustration 7). If the clearance is too

great, change the stylus guide.

-Check (always with the control unit disconnected) that the axes of the X/Y have no hard points. To

do this, move the internal part of the machine, using the guides for grip.

DO NOT MOVE BY PUSHING THE IMPACT UNIT

/ year

-Ask the TECHNOMARK team, or an authorised dealer, to service the machine.

This service will include:

Changing all the bushings and joints.

Full cleaning of the machine and its guidance elements.

Checking the condition and operation of all the machine’s electronic elements and cables.

Testing the operation of the impact unit.

Full test of the machine, as on the day it left the factory.

Should a fault be detected on the marking head, the defective part will be replaced.

The spline shaft and ball bearing must not be lubricated with Vaseline oil. The spline shaft has a self-

lubricating coating, which can be affected by the use of such oils.

When using your machine, you may notice a black deposit coming from the spline shaft. This is normal and

Page 11 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Illustration 7: Movements to check the stylus guide clearance.

6.2.Machine information

In “Information” menu appears general information linked to file system, mechanical system (marking statistics and

displacement), hardware (temperature and serial number) and last marking (cycle time and marking time).

Illustration 8 : Information window

Reference: 5mm

from the tip of the

stylus

Stylus guide

Clearance of less than 0.2mm between the guide

adjustment and the stylus when moved at the reference

height.

Stylus head

Tip

Page 12 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

In “Maintenance” window appears details of monitoring points.

Illustration 9 : Maintenance window

6.3.Sharpening the stylus

The stylus is a wear part of the TECHNOMARK machine.

Repeated markings (especially on hard materials) will blunt the tip. The quality of the impact points (circularity, depth)

is thus reduced over time.

In addition, a lateral impact on a hard material may leave the tip chipped and result in poor quality marking.

All styluses provided with your TECHNOMARK machine (whether the standard model or with optional extras) are solid

carbide. As a result, it is possible to sharpen them using a suitable wheel.

The standard styluses are sharpened to 90° with a projecting tip. This configuration has the best marking

quality/service life ratio. However, we offer the option of different tips for specific applications (60°, 120°, aeronautics

with a tip radius of 0.2mm).

Check the initial sharpening angle of your stylus before you decide to resharpen it.

The stylus may rotate within its guide. Non-concentric sharpening will certainly cause

poor quality marking.

Page 13 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

6.4.The spring

The stylus is a wear part of the TECHNOMARK machine.

The spring plays a crucial role in marking quality. In fact, a ‘tired’ spring will not allow the stylus to return to its original

position quickly and the impacts may be too slight or not properly spaced. If you notice this fault, change the spring.

Use the same procedure as for lubricating the stylus to dismantle the impact unit.

The service life of the spring is linked to the course of the stylus, the frequency of vibration and the operating

temperature of the impact unit.

7.Compatibility with Integrated Multi4 V3 (NMI0-IE).

The M4 inline machine is technologically compatible with a machine from the Integrated Multi4 V3 range. This

compatibility is achieved through the use of the same connector between the marking head and the control unit on

the two ranges of products. This has been made possible for the use of backup machines for industrial sites already

equipped with the two ranges of machine: Integrated Multi4 V3 and M4 inline. It enables:

- the replacement of a M4 inline marking head by a Multi4 V3 marking head (with the M4 inline control unit)

- or the replacement of a Multi4 V3 marking head by a M4 inline marking head (with the Multi4 V3 control unit)

Important: this has been made possible for the sole purpose of avoiding production stops.

This is a temporary back-up solution, the time to repair the original machine.

In this specific case, the capacities of the following machine functions may be affected and not ensured:

-IDI Mark&Track.

-Self-diagnosis.

-Graphical overview settings.

-Marking depths and speeds.

-Originals grip settings.

-Easyshift.

-Load factor.

-In/out settings.

Note the slight marking window difference (Y axis) between the M4 inline marking head and that of Multi4 V3:

M4 inline: Compact: 50x55 and standard: 120x55

For Multi 4 V3: Compact: 50x60 and standard: 120x60

N.B.: the usage possibilities in slave mode are very different. It may be impossible to replace one control unit range

with the other while keeping identical In/Out cables.

Normal free length of the spring: 53.5mm.

A spring is considered ‘tired’ when this length falls below 51mm.

Accessories from the two ranges are not compatible.

Page 14 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

8.Remedial maintenance: Error detection.

8.1.Malfunctions

Symptom

1st level troubleshooting

Remedial action

- The control unit screen does

not work.

- The control unit is not getting

any power.

- The screen or ribbon cable

does not work.

- Check the condition and

connection of the power cord.

- Check the position of the on/off

switch.

- Contact the After-Sales Customer

Service Team.

- The marking depth is not

sufficient and/or constant.

- The stylus is worn and/or

chipped.

- The stylus is dirty and/or partly

stuck in the guide.

- The spring is worn.

- The distance between the

stylus and the part is almost

10mm and the ripples on the

part mean that the stylus is

sometimes blocked.

Sharpen or replace the stylus.

Clean and lubricate the stylus.

Change the stylus return spring.

Move the machine closer to the part

to be marked.

- There is not impact during

marking.

- A test is carried out rather

than the start of a cycle.

- The stylus is stuck and/or does

not return to its original

position, is not lowered.

Check the control of the machine by

the master device.

Clean the stylus, check the condition

of the return spring and the

presence of the core. Tighten the

knurled nut manually.

Page 15 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

-The distance between the

stylus and the part is greater

than 10mm.

Ensure that the part is in the right

position and check the distance

between the stylus and the part.

- The machine is making

strange noises.

- The drive and/or guidance

systems are clogged.

- Clean the mechanics according to

the instructions in the maintenance

manual.

Problem with the marking

quality:

- The impacts are not properly

aligned.

- The impacts are irregular (in

terms of depth).

- The part to be marked is

inadequately secured or the

machine is not properly locked

over the part.

- The marking speed is too high

in relation to the height of the

characters.

- The depth of the impacts is too

high in relation to the height of

the characters and their matrix.

- Clamp the part or keep the

machine locked onto the smoothest

possible face of the part to be

marked.

- Reduce the marking speed,

increase the height of the

characters.

- Reduce the marking force, use a

looser matrix, increase the height of

the characters or change the height

of the stylus/part according to the

chosen force*.

*Reminder:

The depth of the marking depends on the impact force, but also the distance between the stylus and the part.

For the M4 inline machine, the recommended distance is 3mm. With this setting, a gradual 1 to 6 force depth is

obtained.

When installing the machine, it may be necessary to modify the stylus/part distance. The usage ranges for each force

are as follows:

Force 1: from 1mm to 4mm

Force 2: from 2mm to 6mm

Force 3: from 2mm to 8mm

Force 4: from 2mm to 8mm

Force 5: from 2mm to 8mm

Force 6: from 2mm to 8mm

Respecting the stylus/part distances is essential to ensure the required depth, with optimum marking quality.

At lower forces (1, 2 and 3), if the stylus is too far away, it will not actually touch the part during marking.

At higher forces (4, 5 and 6), the further away the stylus (within the limits of its potential 9mm course), the stronger

the impact.

N.B.: marking small characters at a high force may render the marking illegible.

Page 16 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

8.2.Error codes

The TECHNOMARK machine can help you detect potential malfunctions. If a problem is detected, error codes will

appear on the screen.

The window disappears when you click .

Refer to the following table to identify the issue.

Error code

1st level

troubleshooting

Remedial action

Error code 1: Memory error.

Restart the control unit.

If the problem persists, contact

the After-Sales Customer

Service Team.

Error code 2: File error.

The current file is corrupted.

No more space available to

save the file.

Restart the control unit.

Recreate an identical file and

delete the defective file.

Delete certain files from the

control unit.

Contact the After-Sales

Customer Service Team.

Error code 3: Font error.

The file font does not exist in

the machine.

Change the font of the file you

wish to open.

Error code 4: Matrix error.

The matrix of the text in the file

does not exist in the machine.

Change the matrix of the text.

Error code 7: DATAMATRIX

error.

Problem in calculating the

coding of the data matrix

Delete and recreate the data

matrix, checking the data and

settings to encode.

Error code 8: Stylus short-

circuit.

The striker unit cable has been

damaged.

Check the condition of the

impact unit cable and restart

the control unit.

Page 17 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Error code

1st level

troubleshooting

Remedial action

The impact unit connector has

been damaged.

Check the impact unit

connector and restart the

control unit.

The marking head cable has

been damaged.

Check the condition of the

marking head cable and restart

the control unit.

If the problem persists, contact

the After-Sales Customer

Service Team.

Error code 9: Open circuit.

The impact unit cable has been

cut or damaged.

Check the condition of the

impact unit cable and restart

the control unit.

The impact unit connector has

been damaged or is not

properly connected.

Check the impact unit

connector and restart the

control unit.

The marking head cable has

been cut or damaged.

Check the condition of the

marking head cable and restart

the control unit.

Contact the After-Sales

Customer Service Team.

Error code 10: Weak current.

The impact unit cable has been

damaged.

Check the condition of the

impact unit cable and restart

the control unit.

The impact unit connector has

been damaged or is not

properly connected.

Check the impact unit

connector and restart the

control unit.

Contact the After-Sales

Customer Service Team.

Error code 11: No impact.

No measuring impact.

Check stylus/part distance.

Contact the After-Sales

Customer Service Team.

Page 18 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Error code

1st level

troubleshooting

Remedial action

Error code 12: Abandonment.

The current marking operation

has been interrupted.

Restart the marking and check

at which point it was

interrupted.

Error code 13: No marking

head.

The marking head has not been

correctly connected to the

control unit.

Check that the head has been

connected correctly and that

the connector is locked and and

restart the control unit.

The marking head cable is

broken.

Check the condition of the

cable.

This may only occur when

initialising the marking control

unit.

A mechanical blockage is

preventing the machine from

moving to its original position.

Check that there is no object

blocking the trajectory of the

impact unit and restart the

control unit.

Turn the power off and check

that the machine can move to

its original position without any

problem.

The detection card is defective.

Contact the After-Sales

Customer Service Team.

Error code 14: X and Y origin

error.

The impact unit has been

mechanically blocked by an

external element.

Check that there is no object

blocking the trajectory of the

impact unit and restart the

control unit.

May occur only after an initial

or nth marking.

The detection elements are

defective.

Issue with the sequences or

machine settings.

Check that the detection pins

are not twisted and thus unable

to pass through the sensors.

Restart the control unit.

Check the status of the I/O

configured in the control unit

and the condition of the

sensors.

The detection card is defective.

Contact the After-Sales

Customer Service Team.

Page 19 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Error code

1st level

troubleshooting

Remedial action

Error code 15: X origin error.

The impact unit has been

mechanically blocked by an

external element.

Check that there is no object

blocking the trajectory of the

impact unit and restart the

control unit.

May occur on start-up, after an

initial or nth marking.

The detection element X is

defective.

Check that the detection pin X

is not twisted and thus unable

to pass through the sensor and

restart the control unit.

The detection card is defective.

Contact the After-Sales

Customer Service Team.

Error code 16: Y origin error.

The impact unit has been

mechanically blocked by an

external element.

Check that there is no object

blocking the trajectory of the

impact unit and restart the

control unit.

May occur on start-up, after an

initial or nth marking.

The detection element Y is

defective.

Check that the detection pin Y

is not twisted and thus unable

to pass through the sensor and

restart the control unit.

The detection card is defective.

Contact the After-Sales

Customer Service Team.

Error codes 39, 40, 41, 42:

EEPROM errors.

Contact the After-Sales

Customer Service Team.

Error codes 43, 44, 45, 46: USB

stick errors.

The USB stick used is defective.

Try with another USB stick.

Restart the control unit.

Internal control unit issue.

Contact the After-Sales

Customer Service Team.

Error code 49: Window error.

A marking point is outside the

window.

Check that there is no flag

indicating marking outside of

the window in the marking

overview. Reposition the text.

If the problem persists, contact

the After-Sales Customer

Service Team.

Page 20 of 22

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Model from 14/04/2016

TECHNOMARK

3 Allée Michaël FARADAY

Parc d’activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Error code

1st level

troubleshooting

Remedial action

Error 50: Temperature error.

The machine has been in ‘test

position’ for too long and the

motors have been powered up

for too long.

Turn the control unit off for

around ten minutes and

restart.

The ambient temperature is

outside the usage ranges.

Turn the control unit off for

around ten minutes and

restart.

If the problem persists, contact

the After-Sales Customer

Service Team.

Successive marking of a

number of files with a large

number of characters and using

a tight matrix.

Reduce the number of impacts

by using another font.

Reduce the marking speed.

Reduce the marking force.

If the problem persists, contact

the After-Sales Customer

Service Team.

Error code 51: Marking busy.

The requested task cannot be

launched because the machine

is already busy.

Wait for the current task to end

or stop it.

Error 57: TechnoMATRIX

licence error.

The necessary licence is not

present in the control unit.

Contact the After-Sales

Customer Service Team.

Error 58: TechnoLOG licence

error.

The necessary licence is not

present in the control unit.

Contact the After-Sales

Customer Service Team.

Error 59: 16-way line error.

Configuration issue for the file

line with regard to the 16-way

card.

Check the configuration of the

16-way card.

Contact the After-Sales

Customer Service Team.

Error 64: 16- way card error.

Card not detected.

Contact the After-Sales

Customer Service Team.

Other manuals for M4 inline

3

Table of contents

Other Technomark Label Maker manuals