Technoplus multiflex 80280 User manual

multiflex

OPERATING INSTRUCTIONS

technoplus Verarbeitungstechnik GmbH As of:

12.12.2007

6923 Lauterach / AUSTRIA Version:

1.0

Retain for future reference!

2 Version 1.0

Version 1.0 3

Identification data

Identification data manufacturer

technoplus Verarbeitungstechnik GmbH

Lerchenauerstraße 69

6923 Lauterach / AUSTRIA

Telephone: +43 (0) 5574 76178-0

Fax: +43 (0) 5574 76178-2

Internet: www.technoplus.eu

Identification data marketing company

Grass GmbH

Grass Platz 1

6973 Höchst / AUSTRIA

Telephone: +43 (0) 5578 701-0

Fax: +43 (0) 5578 701-59

Email: info@grass.at

Internet: www.grass.at

Identification data product

Product: Drilling and inserting machine

Type : multiflex

Item number: 80280

Serial number: …………

Year of manufacture: …………

Legal information relating to operating instructions

These operating instructions and the information contained therein have been compiled

with all due care and attention. However, technoplus Verarbeitungstechnik GmbH

accepts no liability for printing errors, other forms of error, or any damage resulting from

such.

technoplus Verarbeitungstechnik GmbH reserves the right to undertake changes to

their products which serve to facilitate their technical advancement. Such amendments

may not necessarily be documented individually in each case.

The copyright to these documents remains the sole property of the manufacturer. All

manner of reproduction, including excerpts, is only permitted with the permission of the

manufacturer. The only exception to this is where the copying of instructions is required

for the operation of the product.

© Copyright technoplus Verarbeitungstechnik GmbH 2007. All rights reserved.

4 Version 1.0

Table of Contents

1.

General user information 6

1.1. Purpose of the document ................................................................................... 6

1.2. Positional information in the documentation....................................................... 6

1.3. Figures used ...................................................................................................... 7

1.4. Symbols used..................................................................................................... 8

2.

Basic safety instructions 9

2.1. General safety instructions................................................................................. 9

2.2. Obligations of the operating company.............................................................. 10

2.3. Obligations of the personnel ............................................................................ 10

2.4. Proper use ....................................................................................................... 10

2.5. Reasonably foreseeable misuse ...................................................................... 10

2.6. Safety equipment ............................................................................................. 11

2.7. Personal protective equipment......................................................................... 11

2.8. Hazards and safety measures ......................................................................... 12

2.9. Residual risk according to EN ISO 12100 parts 1+2 ........................................ 13

3.

Product information 14

3.1. Overview of machine with component descriptions.......................................... 14

3.2. Technical Data ................................................................................................. 15

3.3. Machine identification....................................................................................... 17

4.

Permissible tools 18

4.1. Vertical boring mill............................................................................................ 18

4.2. Horizontal boring mill........................................................................................ 18

5.

Permissible workpieces 19

5.1. Permissible materials ....................................................................................... 19

5.2. Permissible workpiece dimensions .................................................................. 19

6.

Unpacking and scope of delivery 20

6.1. Unpacking ........................................................................................................ 20

6.2. Scope of delivery.............................................................................................. 20

7.

Transport, Storage and Erection 21

7.1. Transport and storage conditions..................................................................... 21

7.2. Space requirements and ambient conditions ................................................... 21

7.3. Requirements for the foundations .................................................................... 21

7.4. Erection at final site.......................................................................................... 22

8.

Installation and commissioning 23

8.1. Pneumatic connection...................................................................................... 23

8.2. Electrical connection ........................................................................................ 23

8.3. Dust extraction connection............................................................................... 23

Version 1.0 5

9.

Working with the machine 24

9.1. Clamping the drill bit into the quick-change chuck........................................... 24

9.2. Mounting the quick-change chuck on the boring head .................................... 24

9.3. Attaching a table extension.............................................................................. 25

9.4. Mounting the insertion matrices on the insertion frame ................................... 25

10.

Settings on the machine 26

10.1. Setting the vertical bore depth ......................................................................... 26

10.2. Setting the vertical bore spacing...................................................................... 26

10.3. Setting the horizontal bore depth..................................................................... 27

10.4. Setting the horizontal bore height .................................................................... 27

10.5. Adjust the drilling speed................................................................................... 28

11.

Troubleshooting and fault recovery 29

12.

Maintenance 30

12.1. Maintenance schedule..................................................................................... 30

12.2. Cleaning instructions ....................................................................................... 31

13.

Circuit diagrams 32

13.1. Pneumatic Diagram ......................................................................................... 32

13.2. Pneumatic components ................................................................................... 33

13.3. Electrical circuit diagram.................................................................................. 34

13.4. Electrical components...................................................................................... 35

14.

Decommissioning and disposal 36

14.1. Decommissioning ............................................................................................ 36

14.2. Disposal........................................................................................................... 36

15.

Warranty conditions 37

16.

Miscellaneous 39

16.1. Declaration of conformity ................................................................................. 39

16.2. Resale sheet.................................................................................................... 41

16.3. Questionnaire 1 - Reason for purchasing the multifflex ................................... 43

16.4. Questionnaire 2 - Satisfaction.......................................................................... 45

17.

Personal notes 47

GENERAL USER INFORMATION

Version 1.0 6

1. General user information

1.1. Purpose of the document

These operating instructions serve to describe the operational processes and

maintenance of the machine as well as to provide important information required for

the safe and efficient handling of the machine.

1.2. Positional information in the documentation

All directional and positional information in these operating instructions relate to the

operating position of the user.

Rear side of the machine

L

e

f

t

R

i

g

h

t

Front side of the machine

Operating position of the user

GENERAL USER INFORMATION

Version 1.0 7

1.3. Figures used

Instructions and system reactions

Operating steps that are to be undertaken by operating personnel are depicted as

numbered lists. The order of the steps is to be maintained. The reactions to the

respective operations are marked by means of an arrow. Example:

1. Operation 1

Reaction to operation 1

2. Operation 2

Reaction to operation 2

Lists

Lists that do not have a set order are depicted as lists with dashes. Example:

– Dash 1

– Dash 2

Numbering in figures

Numbering in figures is shown within quotation marks. Example:

”1“

”2“

GENERAL USER INFORMATION

8 Version 1.0

1.4. Symbols used

Important!

The symbols serve the purposes of safety and may not be removed or damaged

under any circumstances. Observe all warning and safety signs attached to the

machine.

Danger! Immediate impending danger which will lead to serious injury

or death.

Warning! Possibly dangerous situation which could lead to serious injury

or death.

Caution! Possibly dangerous situation which could lead to minor injury.

Also warning of property damage.

Important! Potentially damaging situation which could cause either the

product or property in its vicinity to be damaged.

Note! For operational information and other useful information. Not to

be used for dangerous or potentially damaging situations.

Warning signs Risk of injury due to crushing the hands and fingers.

Prohibition signs The machine may only be operated by one person.

Mandatory signs Wear eye protection

Mandatory signs Wear ear protection

Mandatory signs Wear protective gloves

Mandatory signs Wear protective shoes

CE marks

Designates conformity with the valid EU directives which are

applicable to the product and which prescribe a CE

identification.

Note! Observe the operating instructions

Note! Note regarding lowering the drilling unit even with the motor

switched off

BASIC SAFETY INSTRUCTIONS

Version 1.0 9

2. Basic safety instructions

2.1. General safety instructions

– The deployment and application of the drilling and inserting machine may only be

undertaken as described in these operating instructions.

– The operating company of the drilling and inserting machine is responsible for

maintenance of application-related national and international health, work and

safety regulations. In addition, the operating company is obliged to ensure that all

operating personnel have been trained in the operation of the machine.

– Work on the electrical equipment may only be undertaken by authorised specialist

electricians.

– Protect yourself from electric shocks.

– The pneumatic and electrical connection lines are to be laid in an orderly fashion

and are to be protected against damage (e.g. inside cable ducts).

– Before beginning each working day, all safety equipment is to be checked for

completeness and function.

– Only replace damaged parts with original replacement parts!

– The machine is always to be separated from the electrical mains as well as from the

pneumatic compressed air supply for all maintenance, repair and adjustment tasks.

– The electrical master switch must always be set to 0 and the EMERGENCY STOP

button pressed after completion of work, before changing tools, when changing

gears, or for all work in the area of the tools.

– It is to be secured against re-starting by unauthorised persons.

– The permissible tools are described in chapter 4. For your own safety, only use

tools of correspond strength from the manufacturer's supply portfolio.

– Particular care is to be taken with large workpieces which project over the edges of

the machine table. It is necessary to mount a larger rest (accessories - table

extension) or to use additional supports for the workpieces.

– Shavings may not be blown-off, rather, they are to be extracted by means of

suitable equipment.

– Always keep the working area and the machine clean, untidiness and obstructed

working areas increase the risk of injury.

– Only use the machine in clean rooms, do not leave the machine outdoors,

especially never leave it outside in the rain.

– Wear tight-fitting working clothes when working with the machine and use a hairnet

if you have long hair. In addition, the personal protection equipment is to be adhered

to and worn, see chapter 2.7.

– These operating instructions must be available to the operating personnel at all

times.

– Modifications and amendments as well as interfering with the electrical systems of

the drilling and inserting machine can lead to serious injury and are forbidden.

– The machine must always be shut-down immediately in the event of danger by

means of pressing the EMERGENCY STOP button.

– The machine may only be operated by one person.

– It is only permitted to operate the machine when standing in an upright position.

– Machine parts may not be used as props for the body.

– It is not permitted to reach into the running machine. When working, ensure that the

hands are kept out of the working range of the tools and the inserting frame.

BASIC SAFETY INSTRUCTIONS

10 Version 1.0

2.2. Obligations of the operating company

The operating company is obliged to allow only those persons to work on the machine

who:

– are familiar with the basic regulations relating to working safety and accident

prevention,

– have been trained to work with the machine,

– have read these operating instructions and have signed them to confirm that they

have been understood.

The requirements of the EC directive for the usage of tools 89/655/EEC is to be

maintained.

2.3. Obligations of the personnel

Before beginning work, all persons who have been commissioned to work with the

machine are obliged to:

– observe the basic regulations relating to working safety and accident prevention,

– read the safety chapter and the warning information contained in these operating

instructions and to sign to confirm that they have been understood.

Please contact the manufacturer in the event of unresolved queries.

2.4. Proper use

Warning!

The machine is to be used solely in accordance with its proper use and is only to

be operated when in technically perfect working order!

The drilling and inserting machine is intended exclusively for drilling in solid wood or

wood-like materials (wood-based composite materials) and the inserting of fittings.

Only those tools may be used that are expressly detailed in chapter 4 may be used.

– Proper use also includes the following:

– the observance of the operating instructions and safety instructions

– the undertaking of cleaning and maintenance tasks.

2.5. Reasonably foreseeable misuse

Warning!

Dangerous situations can arise in the event of misuse!

All applications that are not specified under "proper use" or applications which exceed

these shall be considered as improper use!

The operator is responsible

– for any damage resulting from such,

– and the manufacturer accepts no liability.

The following misuse is not permissible:

– Drilling and inserting with materials which are not in accordance with the regulations

– Drilling and inserting of workpieces which are not in accordance with the regulations

– Simultaneous usage of the machine by more than one person.

BASIC SAFETY INSTRUCTIONS

Version 1.0 11

2.5.1. Modifications or amendments

Unauthorised modifications or amendments to the machine shall void all manufacturer

liability and guarantee!

For this reason, do not make changes or additions to the machine without first seeking

the agreement and written permission of the manufacturer.

2.5.2. Replacement and wearing parts as well as auxiliary materials

The use of replacement and wearing parts from third-party manufacturers can be

dangerous. Only use original parts or parts that have been released for use by the

manufacturer. The manufacturer accepts no liability for damage caused by the usage

of replacement and wearing parts that have not been released by the manufacturer.

2.6. Safety equipment

Important!

Safety equipment, warning signs, etc., serve the purposes of safety and may not

be removed or damaged or deactivated under any circumstances.

– Lockable electrical master switch to secure against unauthorised starting and to

switch the machine off when setting up and adjusting.

– Lockable pneumatic EMERGENCY STOP switch to secure against unauthorised

starting and to switch the machine off when setting up and adjusting.

– Compressed air filter pressure-reducing-valve to prevent mechanical overloading of

the machine, see Pneumatic diagram chapter 13.1

– Thermal overload protection for the electromotor, see Electrical circuit diagram

chapter 13.3

– Controllable back-pressure valve, directly on the master cylinder prevents the

machine from lowering in the event of pressure loss, the valve is only opened when

the start button is pressed, see Pneumatic diagram chapter 13.1

– Motors only run when the start button is pressed. After the start button has been

released, the motors start up after a delay. The delay duration can be adjusted in

the electrical switching cabinet.

– The motor does not run during the insertion process.

– Integrated dust extraction system to protect the operating personnel from fine

particulate matter.

– Various protective covers to protect against contact with the drill

2.7. Personal protective equipment

The operator must provide the following protective equipment.

Wear protective gloves

Wear protective shoes

Wear eye protection

Wear ear protection

BASIC SAFETY INSTRUCTIONS

12 Version 1.0

2.8. Hazards and safety measures

Hazards and adverse effects can occur during the application of the machine,

– which can represent a risk to life and limb for the user or third-parties,

– for the machine itself, or

– to other property and ancillary materials.

In this case, the manufacturer accepts no liability.

The basis for safe handling and fault-free operation of this machine is the knowledge

of the safety and operating instructions contained within this documentation.

Hazard Safety measure

Release tool Chuck with clamping screw

Tool - breakage

only branded products from the manufacturer's

supply portfolio. The personal protection equipment

have to be worn

Tool - contact All tools behind a transparent cover

Tool - machine contact Safety drilling depth stop

Workpiece ejection Workpiece stops

Advance mechanism No automatic advancing movements

Workpiece clamping

mechanism Icon on hold-down device (= insertion frame)

Risk of impact Non-existent due to slow lifting motion

Drives Direct drive in completely closed transmission

housing

Tool unit

Advance for lifting movement via buttons with collar

and without latching; maintenance of safety

margins according to EN 294 in relation to risk

Control, unexpected tool start

Control, unexpected lift

activation

Electrical control with PE converter, button with

collar and without latching

Control, tool-start during

insertion Query of insertion frame with pneumatic valve

Electricity Equipment according to EN 60204 part 1, VDE

0100 and IEC 384

Noise The personal protection equipment have to be worn

Dust Dust extraction system

BASIC SAFETY INSTRUCTIONS

Version 1.0 13

2.9. Residual risk according to EN ISO 12100 parts 1+2

Important!

The machine has been built according to the current state-of-the-art and

recognised safety-relevant regulations.

However, danger to life and limb for the user or third-parties or adverse effects

to the machine or other property can occur during its operation.

Residual risks comprise:

– Caution, even when the electrical master switch is turned off, the machine will

move in the event that the start button is pressed, insofar as it is supplied with

compressed air.

– In the event of operation by unqualified personnel

– In the event of operation without the required safety and protective equipment

– in the event of improper tooling or improper tool attachment

– In the event of processing large workpieces without additional workpiece supports

– In the event of drilling, insertion or clamping movements of machine parts for the

2nd hand of the operating personnel

– In the event of additional persons in the working area

– In the event of interfering with the machine if it has not been properly secured

– In the event of failure to observe the regulations for proper use

– In the event of control system failure

PRODUCT INFORMATION

14 Version 1.0

3. Product information

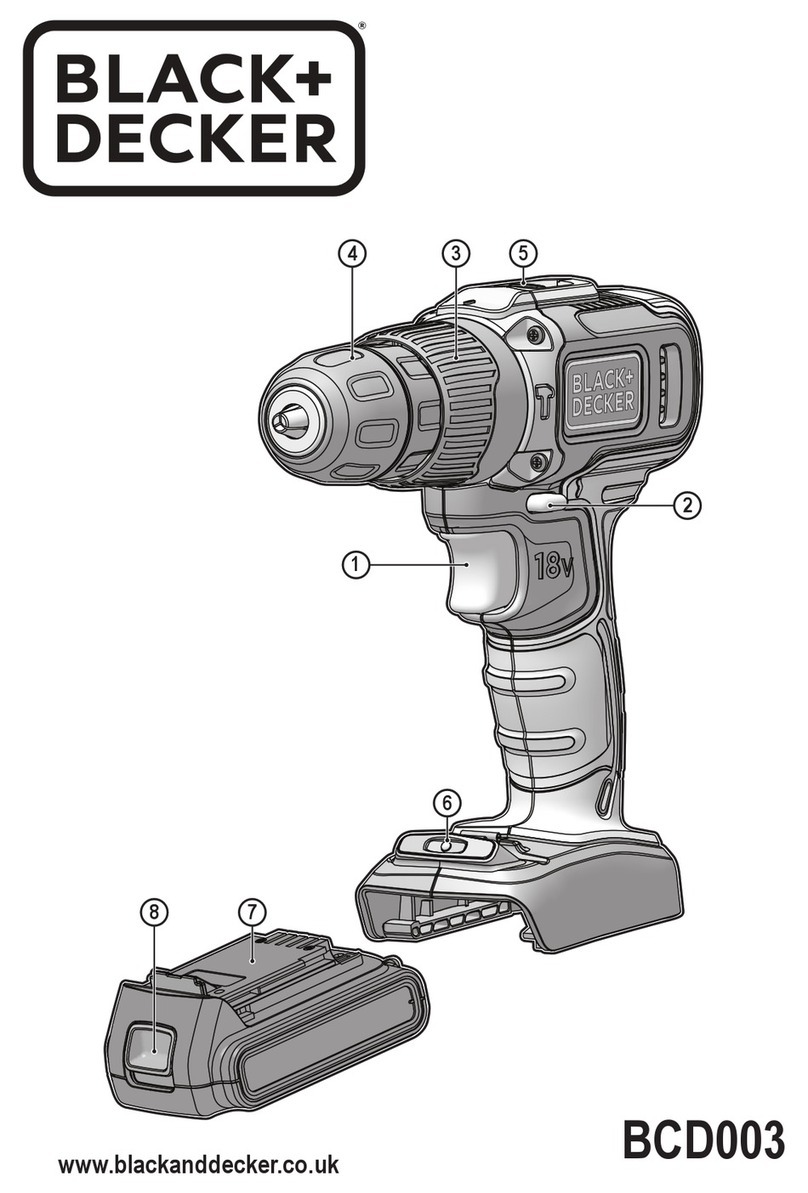

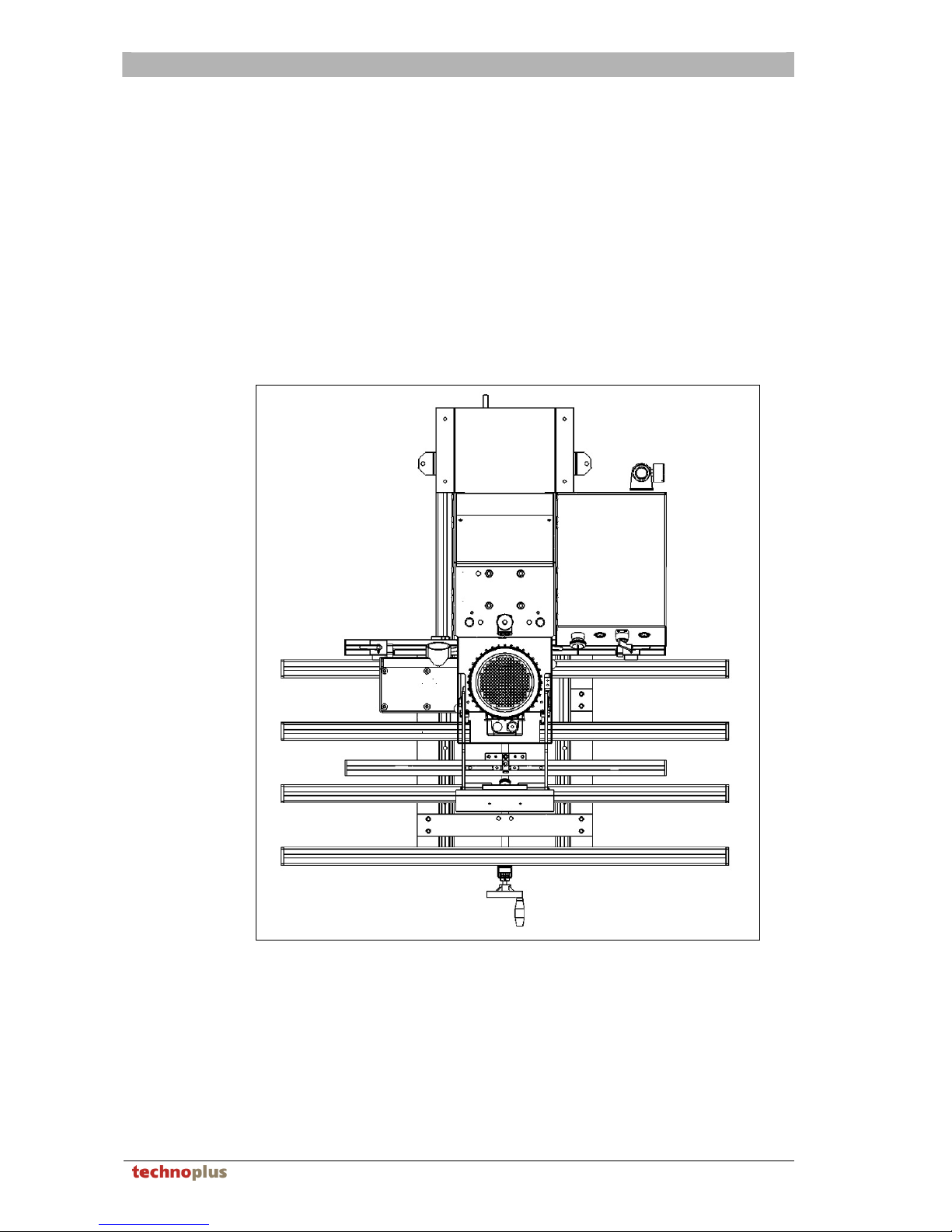

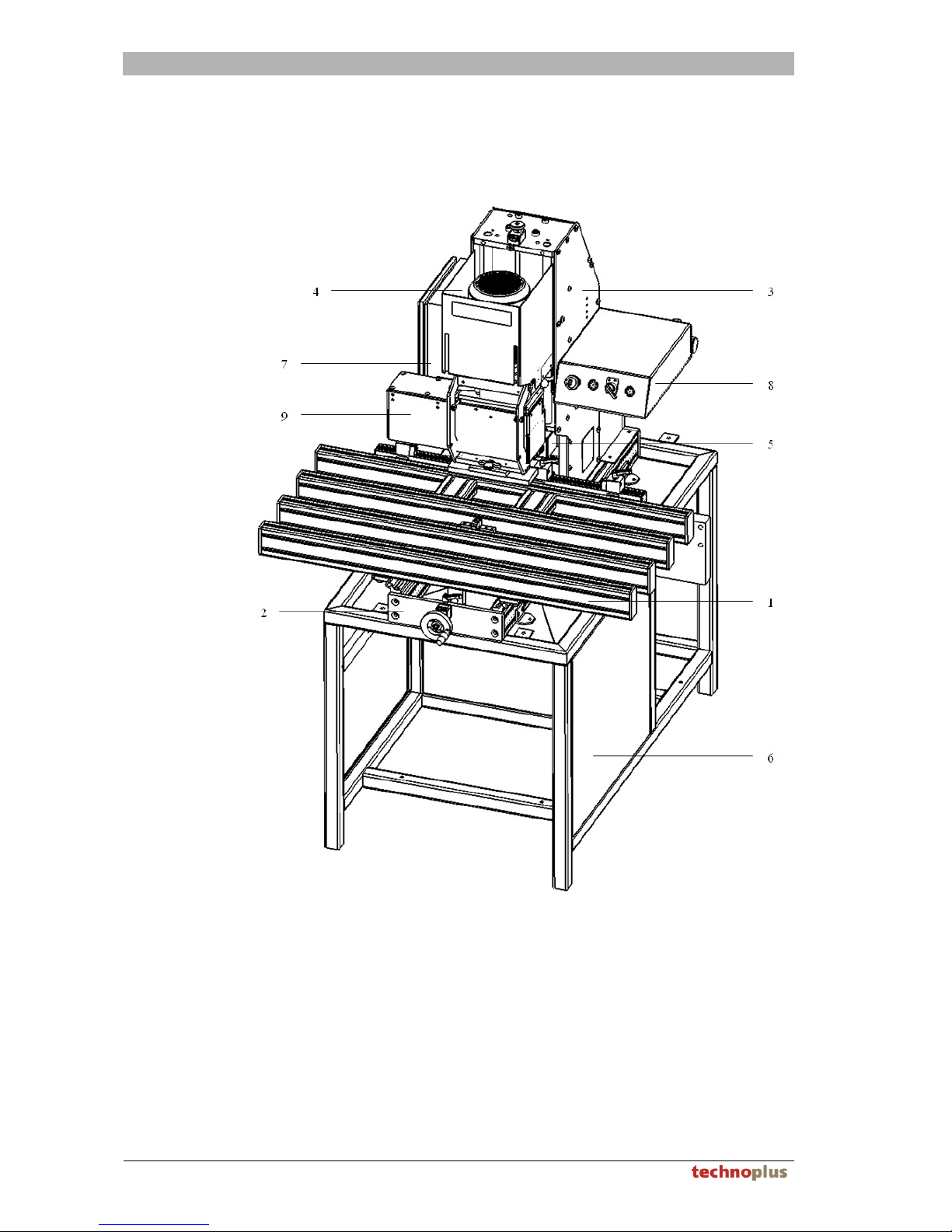

3.1. Overview of machine with component descriptions

”1“ Machine table

”2“ Base frames with guidance columns for horizontal movement

”3“ Base frames with guidance columns for vertical movement

”4“ Vertical boring mill

”5“ Horizontal boring mill

”6“ Machine foundation (=accessory)

”7“ Electrical switching cabinet

”8“ Pneumatic console

”9“ Vertical boring transmission

PRODUCT INFORMATION

Version 1.0 15

3.2. Technical Data

Main dimensions of the machine

Machine table width 1,000 mm

Machine table depth at 20mm boring gap 500 mm

Machine table height with foundation (=accessory) 950 mm

Machine table height without foundation 200 mm

Machine table overall height with foundation 1,650 mm

Machine table overall height without foundation 910 mm

Machine overall depth 1,010 mm

Setting ranges for the machine

Vertical boring mill

Drill lengths - maximum possible length 57 mm

Drill diameter - maximum permissible drill diameter at pot spindle 35 mm

Drill diameter - maximum permissible drill diameter on all other

spindles 15 mm

Bore row - greatest possible spacing 200 mm

Bore row - smallest possible spacing 0 mm

Furniture hinges - greatest possible pot spacing (central boring) 50 mm

Furniture hinges - smallest possible pot spacing (central boring) 9 mm

Horizontal boring mill

Drill lengths - maximum possible length 150 mm

Drill bit diameter - maximum permissible drill bit diameter 16 mm

Boring height - maximum possible boring height 5 mm

Boring height - minimum possible boring height 40 mm

Bore depth - maximum bore depth Approx.120mm

Overall weight of the machine

Overall weight of the machine vertical / horizontal 14/03 with foundation Approx.220kg

Overall weight of the machine vertical / horizontal 14/03 without

foundation Approx.160kg

Ambient conditions

Temperature in operation +10 to +30 °C

Temperature in storage -10 to +40 °C

Humidity in operation or storage, not condensation! 10 to 80 %

PRODUCT INFORMATION

16 Version 1.0

Electrical connection

Supply voltage according to type plate ..... V

Frequency according to type plate ….. Hz

Installed load for 3-phase motors 1.8 kW

Rating of the supply is to correspond with local regulations, however, minimum 1.5mm²

fused supply with max. 1.5x nominal current according to type plate, max. 10 A.

H07RN-F5G1.5 or equivalent

Pneumatic connection

Dust, water and oil-free compressed air min. 5.5 bar

Max. working pressure max. 6 bar

Max. permissible pressure in supply line max. 10 bar

Compressed air consumption per bore stroke 6 bar Approx. 1.2 l

Compressed air consumption per bore stroke, suction performancefor compressor Approx. 7.5 l

Pressing force at 0.6 MPa (6bar) Approx. 3,000 N

Dust extraction connection

The machine must be connected to an extraction system in accordance with the

interface description. The connection lines are to be designed to be flame-resistant. If it

is necessary to connect the machine to the extraction plant electrically, the

manufacture offers a volumetric flow rate monitor as optional equipment, which can be

connected to the interface shown on the electrical circuit diagram, chapter 4-007.

The dust and shavings collection elements of the machine are to be designed in such

a way as that the value remains safely below the technical guideline concentration limit

value for wood dust. (Connection to a plant according to the interface description, test

protocols by an independent institution available).

Thread diameter for dust extraction vertical bore head Ø 80 mm

Thread diameter for dust extraction horizontal bore head Ø 80 mm

Thread diameter for dust extraction machine foundation Ø 80 mm

Required extraction performance per connection Approx. 360 m³/h

Mean air speed 20 m/sec

Static negative pressure vertical bore head 1500 Pa

Static negative pressure horizontal bore head 500 Pa

Static negative pressure machine foundation 500 Pa

PRODUCT INFORMATION

Version 1.0 17

Noise emission values

According to DIN EN ISO 11202 supplemented by CEN -TC 142, the

workplace emission value L

pA

amounts to:

idle running .......... dB(A)

Working noise 84.5 dB(A)

According to EN ISO 3746 supplemented by CEN -TC 142, the

sound power level L

WA

amounts to:

Idle running ...........dB(A)

Working noise 94.7 dB(A)

The measurement uncertainty constant K amounts to 4 dB(A).

The following supplements specified by CEN - TC142 in order to achieve an accuracy

class better than 3 dB were taken into consideration:

– The environmental corrective factors K

2A

and K

3A

amount to ≤4 dB.

– The difference between the foreign noise sound pressure level and the noise sound

pressure level at all measuring points is ≥6 dB.

– K

3A

is calculated according to appendix A, DIN EN ISO 11204.

– A rectangular enveloping measurement surface with 9 measuring points of

1.0 m from the reference surface is used.

Under consideration of ISO 7960 sections 0 to 4, the machine-specific conditions of

measurement were as follows:

Drill bit: 1xconcealedhinge drill bit

d=35mm; t=13mm n=2750 min

-1

2x dowel drill bits d= 8mm; t=13mm n=2750 min

-1

Workpiece: Uncoated chipboard

Microphone position: 1m distance form the centre of the bore axis at a height of 1.5m.

Note

The values given here are emission values and may not simultaneously represent safe

working area values. As there is no correlation between emission values and working

area values, these cannot be reliably used in order to determine whether or not

additional precautions are required. Factors which could affect the current working

area values include the duration of the influence, the characteristics of the working

space, other sources of noise, the number of machines and other neighbouring

influences. The reliable working area values can also vary from one country to another.

However, this information should enable the operator to make a better estimation of

the potential hazards and risks.

3.3. Machine identification

The machine is equipped with a type plate which details the following:

– machine type

– machine number

– year of manufacture

– weight

– the required compressed air.

PERMISSIBLE TOOLS

18 Version 1.0

4. Permissible tools

Warning!

Hazards for both the machine and its users can occur in the event that

impermissible tools are used!

The operator is responsible

– for any damage resulting from such,

– and the manufacturer accepts no liability.

4.1. Vertical boring mill

Only commercially-available hard metal or HSS drill bits may be used with dimensions

as given in the following table. We recommend only using tools of correspond

strength from the manufacturer's supply portfolio.

– Body diameter max. 10 mm

– Overall length of the drill bit max. 57 mm

– Drill bit diameter drive spindle max. Ø 35 mm

– Drill bit diameter residual spindles max. Ø 16 mm

4.2. Horizontal boring mill

Only commercially-available hard metal or HSS drill bits may be used with dimensions

as given in the following table. We recommend only using tools of correspond

strength from the manufacturer's supply portfolio.

– Body diameter max. 10 mm

– Overall length of the drill bit max. 100 mm

– Drill bit diameter drive spindle max. Ø 19 mm

– Drill bit diameter residual spindles max. Ø 16 mm

PERMISSIBLE WORKPIECES

Version 1.0 19

5. Permissible workpieces

Warning!

Hazards for both the machine and its users can occur in the event that

impermissible workpieces are used!

The operator is responsible

– for any damage resulting from such,

– and the manufacturer accepts no liability.

5.1. Permissible materials

Only workpieces made from

– wood (solid wood) or

– wood-like materials (wood-based composite materials) may be processed.

Other materials may not be processed.

5.2. Permissible workpiece dimensions

The workpieces must be laid stably and securely on the machine table, without the

need for the operator to hold onto the workpieces in order to prevent them from falling

down. This unconstrained positioning (without being held by the user) is a requirement

for the safe operation of the machine and must be ensured by means of the user.

– The maximum workpiece thickness is 40 mm.

– If the workpieces are larger than 300 x 300 mm, then they must be positioned on

bolsters placed next to the machine such as supports or similar devices.

The manufacturer offers table and guide extensions as optional accessories for this

purpose.

UNPACKING AND SCOPE OF DELIVERY

20 Version 1.0

6. Unpacking and scope of delivery

6.1. Unpacking

When unpacking the drilling and inserting machine, the paperboard packaging should

be removed in the upward direction. The machine body is protected against corrosion

by means of sprayed oil.

The sprayed oil can be left on the machine in order to protect against corrosion.

After unpacking, the machine is to be checked for possible damage. Damage is to be

reported immediately to the haulage company and the supplier, both by telephone and

in writing.

6.2. Scope of delivery

The scope of delivery, especially the optional equipment, must be checked against the

delivery notes for completeness immediately after unpacking.

Any incorrect parts are to be reported to the supplier immediately.

The basic equipment comprises:

– 14 Spindle gear drive with chuck (without drill bit)

– Insertion frame to mount the insertion matrices

– 2 Connections for dust extraction system

– 2 mounted lifting eye bolts in order to be able to lift the machine.

– Operating tools

– Operating Instructions

Table of contents