6

Operating instructions

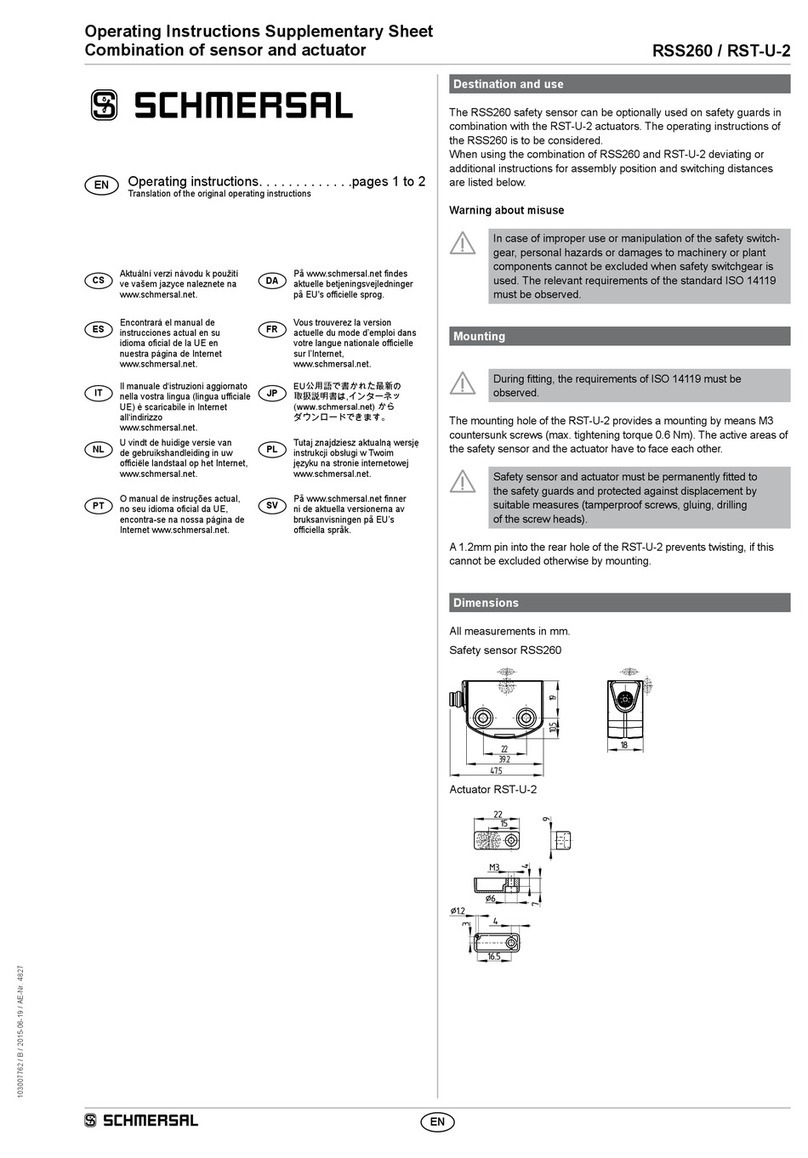

Safety sensor RSS260

EN

4. Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition.

The safety outputs can be integrated into the safety circuit of the control

system. For applications of PL e / control category 4 to ISO 13849-1,

the safety outputs of the safety sensor or sensor of the chain must be

wired to a safety monitoring module of the same control category .

Protection is not required when pilot wires are laid. The cables however

must be separated from the supply and energy cables. The max. fuse

rate for a sensor chain depends on the section of the connecting cable

of the sensor.

Requirements for the connected safety-monitoring module

• Dual-channel safety input, suitable for p-type sensors with NO function

Information for the selection of suitable safety-monitoring

modules can be found in the Schmersal catalogues or in the

online catalogue on the Internet: products.schmersal.com.

As an alternative to a safety-monitoring module, the safety sensors of

the CSS 34F0 or CSS 34F1 series can also be used as first sensor

of a series-wired chain for the direct control and monitoring of safety

contactors (refer to operating manual of CSS 34F0 / CSS 34F1).

If the safety sensor is wired to relays or to non-safety relevant control

components, a new risk analysis must be carried out.

The sensors cyclically switch off the safety output to test them. The safe

The switch-off times must be tolerated by the safety-monitoring module.

The switch -off time of the safety sensor is additionally extended

depending on the cable length and the capacity of the cable used.

Typically, a switch-off time of 250 μs is reached with a 30-m connecting

cable.

Configuration of the safety-monitoring module

If the safety sensor is connected to electronic safety-

monitoring modules, we recommend that you set a

discrepancy time of min. 100 ms.

The safety inputs of the safety-monitoring module must be

able blanking a test impulse of approx. 1 ms.

The safety-monitoring module does not need to have a cross-

wire short monitoring function, if necessary, the cross-wire

short monitoring function must be disabled.

4.2 Serial diagnostic -SD

(only 8-pin version)

Cable design in case of serial diagnostics

On wiring SD devices, please pay attention to the voltage

drop on the cables and the current carrying capacity of the

individual components.

The wiring capacitance of the connecting cable of the safety sensor

must not exceed 50 nF.

Depending on the strand structure, normal unshielded 30 m long control

cables LIYY 0.25 (0.14) mm2to 1.5 mm2have a wiring capacitance of

approx. 3 - 7 nF.

Accessories for the series-wiring

For convenient wiring and series-wiring of SD components,

the SD junction boxes PFB-SD-4M12-SD (variant for the

field) and PDM-SD-4CC-SD (variant for control cabinet on

carrier rail) are available along with additional comprehensive

accessories.

Detailed information is available on the Internet, products.

schmersal.com.

5. Operating principles and coding

5.1 Mode of operation of the safety outputs

The safety outputs can be integrated into the safety circuit of the control

system. The opening of a safety guard, i.e. the actuator is removed

out of the active zone of the sensor, will immediately disable the safety

outputs of the sensor (switching distances refer to technical data).

Any error that does not immediately affect the functionality of the safety

sensor (e.g. too high the ambient temperature, interference potential

at a safety output, cross-wire short) will lead to a warning message,

the disabling of the diagnostic output and the delayed shut-down of the

safety outputs. safety outputs are disabled if the error warning is active

for 30 minutes.

The signal combination, diagnostic output disabled and safety channels

still enabled, can be used to stop the production process in a controlled

manner.

After fault rectification, the error message is reset by opening and re-

closing the corresponding safety guard. The safety outputs enable and

allow a restart.

For devices with serial diagnostic, a bit can be set/deleted in the call

telegram to reset the fault.

5.2 Coding

Safety sensors with standard coding are ready to use upon delivery.

Individually coded safety sensors and actuators will require the

following "teach-in" procedure:

1. Switch the safety sensor's voltage supply off and back on.

2. Introduce the actuator in the detection range. The teach-in procedure is

signalled at the safety sensor, red LED on, yellow LED flashes (1 Hz).

3. After 10 seconds, brief cyclic flashes (3 Hz) request the switch-off

of the operating voltage of the safety sensor. (If the voltage is not

switched off within 5 minutes, the safety sensor cancels the "teach-

in" procedure and signals a false actuator by 5 red flashes).

4. After the operating voltage is switched back on, the actuator must be

detected once more in order to activate the taught actuator code. In

this way, the activated code is definitively saved!

For ordering suffix -I1, the thus executed allocation of safety sensor and

actuator is irreversible.

For ordering suffix -I2, the "teach-in" procedure for a new actuator can

be repeated an unlimited number of times . When a new actuator is

taught, the code, which was applicable until that moment, becomes

invalid. Subsequent to that, an enabling inhibit will be active for ten

minutes, thus providing for an increased protection against tampering.

The green LED will flash until the expiration of the time of the enabling

inhibit and the detection of the new actuator.

The 10-minutes protection time will subsequently restart in case of a

power failure during the lapse of time.