Techsage SpinJet 1000 User manual

Service guide March 2001 1

SpinJet 1000

Service Guide

Safety precautions

SpinJet 1000 is intended for use on the large format printer HP

DesignJet 1050C/1055CM (referred to as the printer) only. The in-

structions for installation and operation of both printer and SpinJet

1000 must be followed.

SpinJet is intended for permanent installation on the above mentioned

printer type. Normal single-sided printing is possible without removing

or tilting down the SpinJet 1000.

SpinJet 1000 is intended for operation with installed top cover and

mounted side covers.

The operator may remove the top cover during a jam removal. Only

specially trained personnel should carry out tasks for test or service

purposes, requiring operation in otherwise open and/or dismounted

condition.

The routines of inspection and replacement of wear and spare parts

must be followed. Always disconnect Power Mains before

disconnecting cables and electrical parts.

Connect SpinJet to Power Mains 100-120VAC or 200-240VAC,

50/60Hz, one phase and earth. Apply a Power Cord according to local

Voltages and Plugs. A UL Listed Power Cord rated minimum 10A,

125V is provided with SpinJet in areas where this apply.

Service guide March 2001 2

Table of Contents:

1. General .......................................................................................3

1.1 Functional test ............................................................................... 3

1.2 Fault finding ................................................................................... 3

Error codes ...................................................................................................3

Other trouble shooting ....................................................................................4

2. Wear and Spare Part replacement procedures ..................................8

2.1 General ......................................................................................... 8

2.2 Covers .......................................................................................... 9

5550 112 Cover 1 ........................................................................................9

5550 034 Assy, Cover 3 w/badge ...................................................................9

5550 035 Assy, Cover 2 w/keypad ..................................................................9

2.3 Drive and sensor components......................................................... 10

5551 004 Timing belt...................................................................................10

5551 066 Timing belt...................................................................................10

5550 005 Assy, motor w/pulley and connector ................................................11

5550 007 Assy, sensor/connector (PS01) ......................................................12

5551 001 Photo sensor (PS02) ....................................................................13

5551 001 Photo sensor (PS03) ....................................................................13

5550 026 Assy, harness #6 connector PCB to PS02-03.................................14

5551 062 Photo sensor left (PS04)...............................................................14

5551 063 Photo sensor right (PS05).............................................................14

5550 028 Assy, harness #10 connector PCB to PS04-05...............................14

2.4 Control system components ........................................................... 15

5551 073 Fuse ...........................................................................................15

5551 088 Fuse holder cap............................................................................15

5550 032 Assy, control system ....................................................................15

5550 048 PIC, programmed .........................................................................15

5550 197 Connector PCB............................................................................16

5550 027 Assy, harness #7 connector PCB to keypad ....................................16

5550 025 Assy, harness #5 connector PCB to motor 2 or 3 ...........................16

5550 038 Assy, harness #4 and #11 in supporting arm. .................................16

5550 030 Assy, harness #12 RS232 printer communication............................17

2.5 Mechanical components ................................................................. 17

5551 018 Gas spring...................................................................................17

5551 019 Bumper.......................................................................................17

5550 200 Bushing 4....................................................................................18

5550 166 Guide 5 .......................................................................................18

5550 021 Assy, Guide 6 ..............................................................................18

5550 196 Tool 1.........................................................................................18

5550 186 Flap ............................................................................................18

5550 199 Foil .............................................................................................19

5551 055 Tape ...........................................................................................19

5551 056 Tape ...........................................................................................19

5551 023 Spring.........................................................................................19

5550 174 Retainer 1 ...................................................................................19

5550 008 Pulley with clutch ..........................................................................19

5550 181 Encoder ......................................................................................20

1453 007 Bearing (on shafts) .......................................................................20

5550 020 Assy, hub with set screws (upper shaft) ..........................................20

5550 020 Assy, hub with set screws (lower shaft) ...........................................21

1453 007 Bearing (inside roller).....................................................................22

5550 011 Pulley with clutch ..........................................................................23

5550 055 Assy, Standoff with vibration damper .............................................23

5550 019 Boom guide with standoffs.............................................................23

5550 212 Spring guide 1 .............................................................................23

5550 036 Assy, Drum with spring, right ........................................................24

5550 037 Assy, Drum with spring, left ..........................................................24

1453 013 Bearing .......................................................................................25

5550 014 Brake with clutch..........................................................................26

5550 195 Bushing 2....................................................................................26

5550 208 Bushing 5....................................................................................26

5550 047 Assy, foot extension set................................................................26

3. Wear and Spare Parts list ........................................................... 27

Service guide March 2001 3

1. General

For information on installation procedure: Please see SpinJet Installation

Guide.

For information on specifications, normal use and operation: Please see

SpinJet Operator’s manual.

1.1 Functional test

In order to establish the existence of a possible problem and later the

effect of the corrective action taken, test the SpinJet as follows:

Connect the SpinJet control box to a power outlet.

Switch the box on with the rocker switch. A red light in the button

indicates that the control box is “on”.

Switch on the SpinJet by pressing the power button of the SpinJet

keyboard. Verify that the motors initialise and bring the system into the

“Single” state.

Press the mode button. Verify that the system switches to the

“Double” state and raises the flipper gate.

Install a SpinJet approved paper roll according to the user guide.

Run the test jobs of the software supplied with the product. Verify that

both sides are printed and the required front to back match is achieved.

If the match is inadequate, repeat the procedure of loosening the four

screws securing the printer to the printer base, moving the printer

slightly on its base and tightening the four screws again. Repeat until a

satisfactory result is achieved.

1.2 Fault finding

Error codes

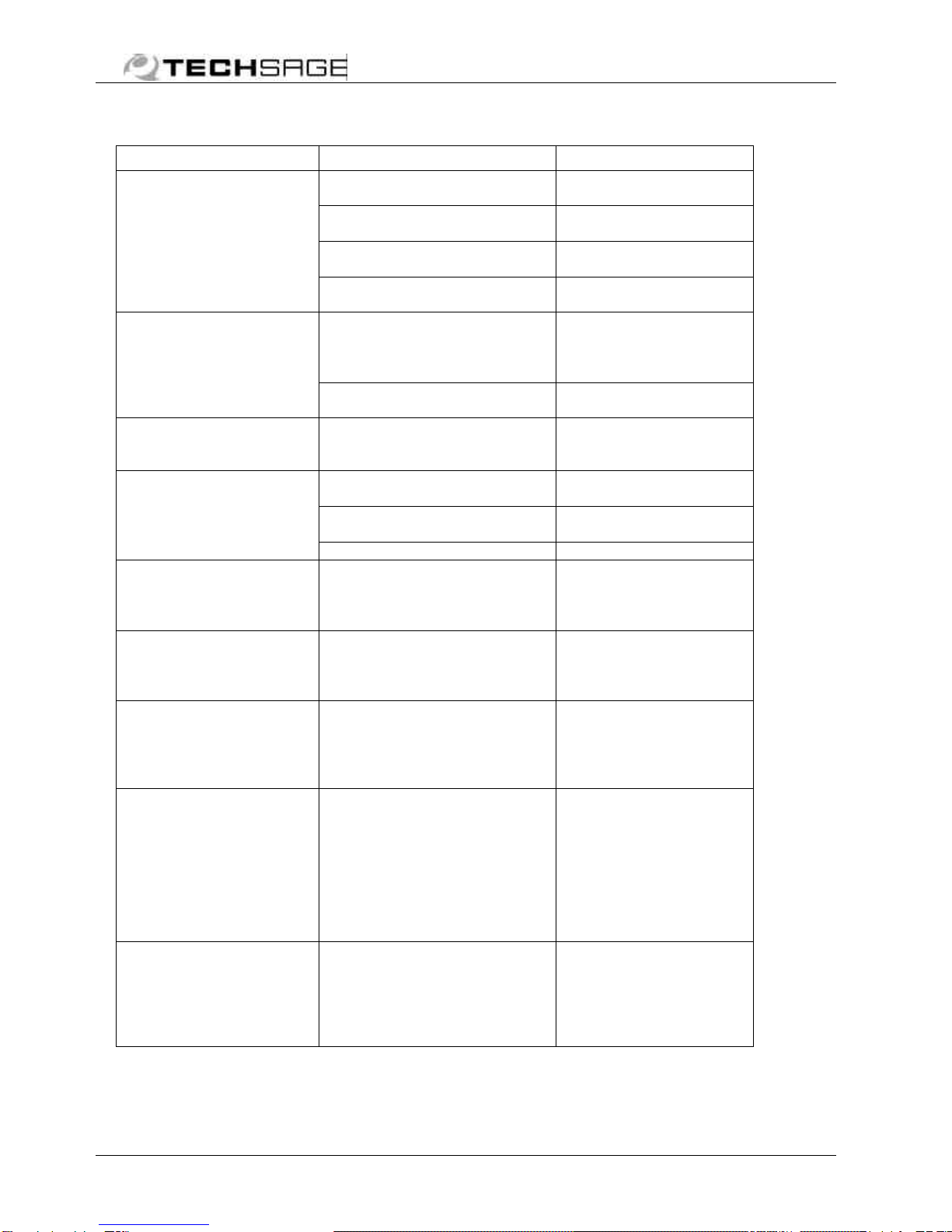

Error

codeOccurs when Possible causes

Error01 Medium sensor on

when leaving OFF

state

Blocking object

Attenuator offset or rotated relative

to light emitter

Emitter defective

Receiver defective

Sensor harness defective

Harness #11 defective

Service guide March 2001 4

Error

codeOccurs when Possible causes

Error02 Gate sensor not on

in time

Motor 2 defective

Motor 2 harness #5 defective

Belt defective

Sensor defective

Sensor harness #6 defective

Harness #4 or #11 defective

Error03 Gate sensor not off

in time

Sensor defective

Sensor harness defective

Harness #4 or #11 defective

Error04 Boom sensor not on

in time

Motor 3 defective

Motor 3 harness #5 defective

Belt defective

Sensor defective

Sensor harness #6 defective

Harness #4 or #11 defective

Error05 Boom sensor not

off in time

Motor 3 defective

Motor 3 harness #5 defective

Belt defective

One way clutch defective

Sensor defective

Sensor harness #6 defective

Harness #4 or #11 defective

Error06 Paper feed encoder

does not reach

preset count value

in time

Sensor (right or left) defective

Sensor harness #10 defective

Harness #4 or #11 defective

Motor 1 defective

Belt defective

Other trouble shooting

SymptomsPossible causesRemedies

No light in control

box switch

Melted main fuse Replace fuse at inlet

module

Harness #11 defective

ReplaceNone of the LEDs

are lit in the SpinJet

keypad

and

Light in control box

switch

Control box component

failure

Replace control box

SpinJet does not

respond to the signal

from the printer to

go into double mode

Harness #12 defective Replace

Service guide March 2001 5

Symptoms Possible causes Remedies

The guide system

(leading to the sensor

light line) is damagedor

has a burr, which

obstructs the paper path

Find and remove

burr/damage

Roller/tire system has

too much friction or

resistance to rotate

Check bearings or

possible

interferences

Medium does not

reach paper sensor

Gate closes too tight on

Guide 2

or

The metal flag on the

right end of the gate is

bent

Straighten long leg

of the flag

Boom does not

maintain proper loop

shape of the sheet

during the first side

printing

and

Motor 3 runs

Suspension spring(s) is

damaged thus producing

friction in boom guides

Replace spring(s)

Boom suspension

springs curls during

first side printing

One way clutch defective Replace pulley/clutch

assembly of spring

drum shaft

One way clutch defective Replace pulley/clutch

assembly of feed

shaft

Sheet dropped by

SpinJet before being

fed into printer

Coil spring holding

central roller shaft

disengaged/lost

Reinstall/replace

Paper does not feed

into printer

and

Motor does not try

to feed

and

No error signal

Distance between right

and left encoder sensor

too long

Loosen, hold

together and fasten

Harness #4 defective

ReplacePaper does not feed

into printer

and

Motor does not try

to feed

and

Error code 06

displayed

Motor 1 defective Replace

One way clutch defective Replace pulley/clutch

assembly of feed

shaft

Paper does not feed

into printer

and

Motor does try to

feed

and

Tires do not run

and

Error code 06

displayed

Belt defective Replace

Service guide March 2001 6

Symptoms Possible causes Remedies

Sheet lead edge caught

by notches of Guide 1

Find and remove

burr/damage

Damage to foil on Guide

2

Find and remove

burr/damage

Faulty position of foil on

Guide 2

Paper does not feed

into printer

and

Motor and tires do

try to feed

Tires worn to too small

diameter

Replace hub/tire

assembly (8 pcs.)

Front unit too far away

from printer

Check and correct

position of the two

rubber bumpers

defining the distance

Sheet does not

reach blue line

Tires worn to too small

diameter

Replace hub/tire

assembly (8 pcs.)

Sheet overshoots

blue line by small

amount

Tire surface glazed or

contaminated (loss of

friction)

Replace hub/tire

assembly (8 pcs.)

Encoder sensor (right or

left) defective

Replace

Encoder sensor harness

#10 defective

Replace

Sheet overshoots

blue line by

approximately 50mm

Harness #11 defective Replace

Printer does not

respond to signal

from SpinJet to go

into sheet mode

Harness #12 defective Replace

Sheet pulled out of

printer again after

printer vacuum is

applied

One way clutch defectiveReplace pulley/clutch

assembly of feed

shaft

Printer unable to pull

in sheet from

SpinJet after printer

vacuum is applied

Printer vacuum too low Check printer

vacuum level and

vacuum system

seals

Insufficient pressure

from SpinJet against

printer platen

and

The last part of the

tilting to the lower

position achieved by

gravity (without

pushing)

Loss of pressure in gas

spring(s)

Identify spring(s),

which does not

produce 500N and

replace

Noisy drives Wrong belt tension Readjust belt

tension according to

replacement

procedures for

5551 004 and 066

in section 2.3.

Service guide March 2001 7

Where possible, verify the hypothesis regarding the cause of an

experienced problem by trying to replace the suspect part or system.

Make only onereplacement between these tests and go back to the

originally fitted part or system, when there is no effect of the

replacement.

All sensors are using an optical principle, where the effect is that of a

light path being intersected by a moving part or by the medium. All

sensors are equipped with monitoring LED’s with the following functions:

PS01: Green LED on means that the signal is stable and

unambiguous.

Red/orange LED on means light path is cut by an object

(“dark”).

PS02-05: A red LED means, that the light path is not cut by an

object (opposite of “dark”).

These functions serve to help identifying certain sensor related faults

before trying to replace the sensor itself.

Service guide March 2001 8

2. Wear and Spare Part replacement

procedures

2.1 General

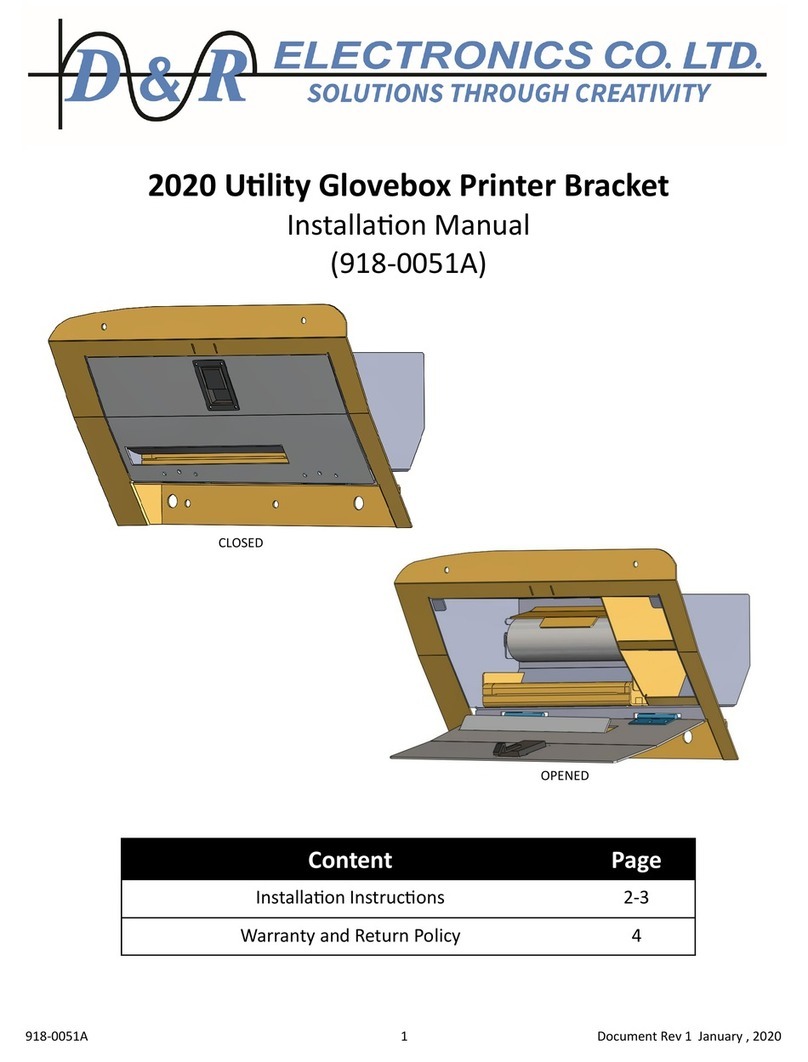

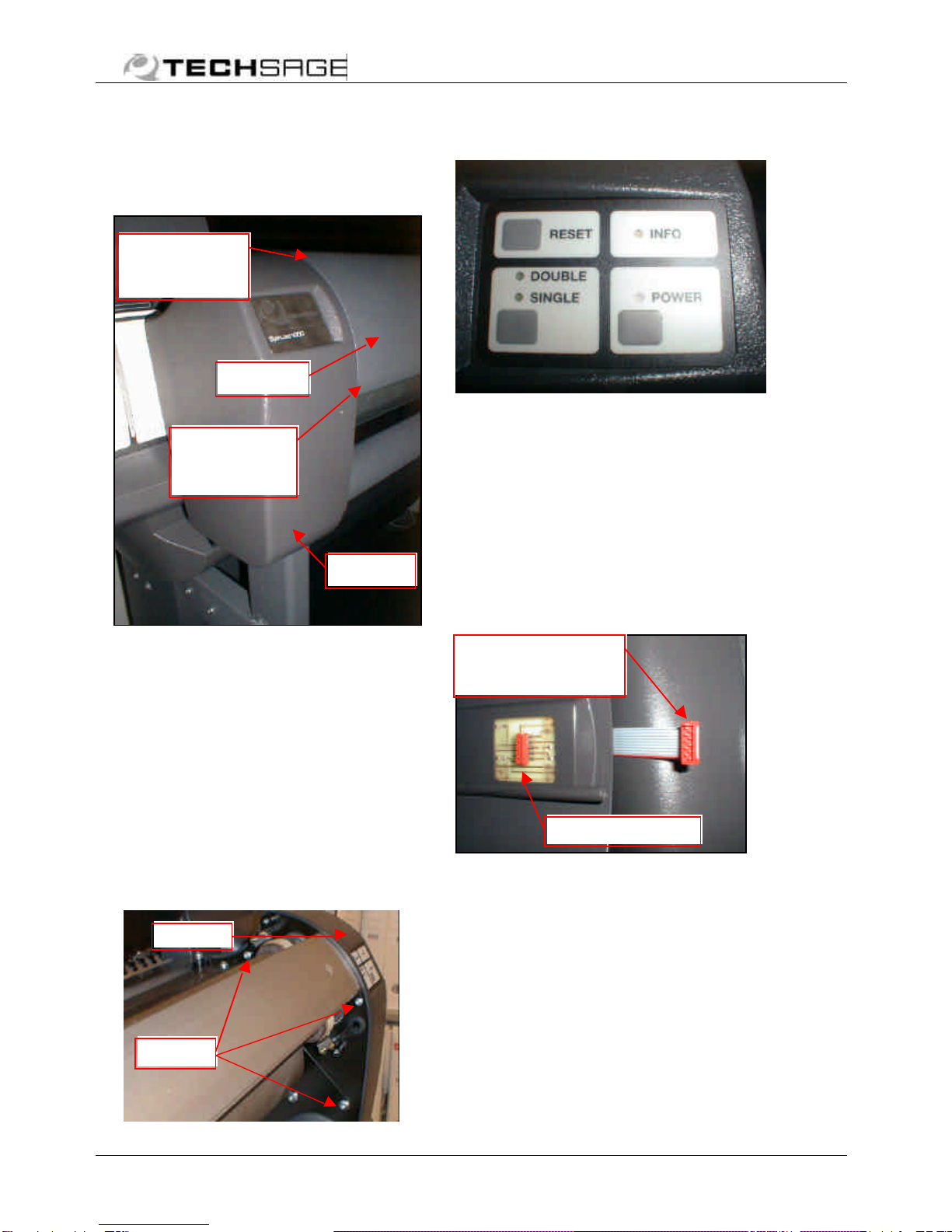

Replacement procedures require

that the SpinJet is mounted on a

printer or supported similarly. In

general replacements require

covers to be removed first.

Further for general reference,

Guide 2 and Guide 5 are identified

in picture below.

In order to maintain internal

accuracy of the unit, the screws

of Beam 1 and Guide 1 should

never be loosened.

Recommended tools:

§Torx screwdrivers T10, T15

and T20

§T25 (provided with HP

Printer)

§Straight blade screwdrivers

(small sizes)

§Thin blade knife

§Pair of pliers (pointed)

§Soft head hammer

§M5 screw, length 12 mm

min. (provided with the

SpinJet)

§PIC extractor

§Antistatic wristband

Guide 1

Beam 1

Cover 1

Cover

3

Cover 2

Guide

5

Guide 2

Service guide March 2001 9

2.2 Covers

5550 112 Cover 1

Release at lower studs first by

gently pulling outwards and lift off

at upper studs. Install in reverse

order.

5550 034 Assy, Cover 3

w/badge

5550 035 Assy, Cover 2

w/keypad

The side covers are fastened with

3 screws each (see picture).

Remove Cover 1 to get access to

the two upper screws.

Cover 3 comes with the badge

and Cover 2 with the keypad.

5550 027, Assembly, harness

#7, connector PCB to keypad

(not included in 5550 035) must

be disconnected from the keypad

in order to allow Cover 2 to be

put aside.

Note the little orientation tab of

the connector when refitting.

Take care to fit harnesses well

inside when installing covers.

Lower stud

inside side

plate

Upper stud

inside side

plate

Cover 1

Cover 3

Inside of keypad

Tail of 5550 027

(orientation tab indi-

cated by the arrow)

Cover 2

3 screws

Service guide March 2001 10

2.3 Drive and sensor components

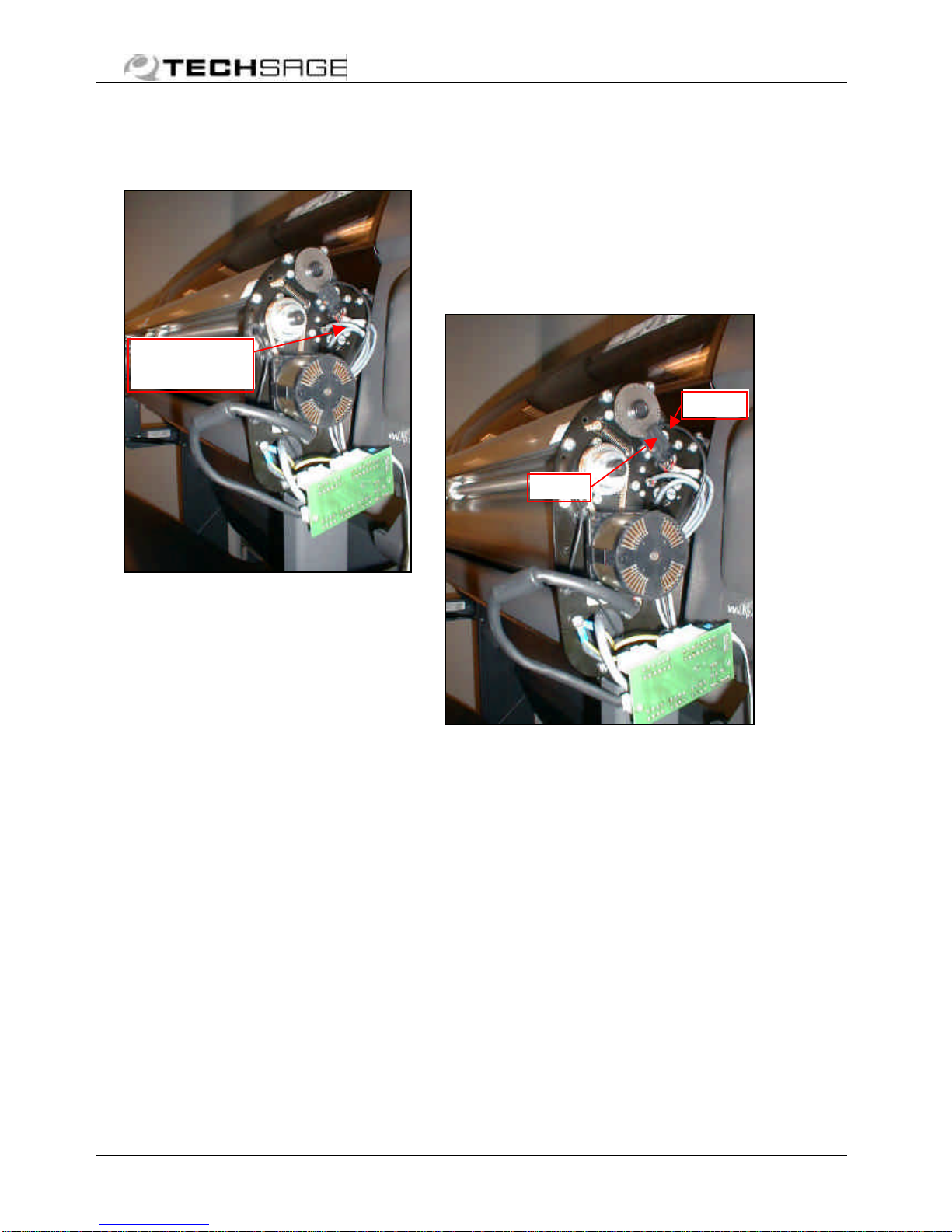

5551 004 Timing belt

5551 066 Timing belt

WARNING!

Always support and lower the

boom (picture) by hand when

loosening and removing timing

belt ofmotor 3.

Remember to loosen the 3 motor

standoff screws (picture) before

replacement. Reapply correct

timing belt tension according to

below procedures.

Motor 1 and 2

Adjustment of timing belt

5551 004:

With the motor turned off and

all 3 motor standoff screws

loosened apply a load of 2N

near the tip of the screwdriver

engaging the TOP screw and

tighten screw (picture). Then

tighten the 2 other screws.

The load can be provided by a

spring balance or by hanging a

200g mass load (e.g. a stack of

sheets)on the screwdriver.

Make sure the belt is not

transmitting torque during the

procedure.

55551 066

(motor 3)

55551 004

(motor 1+2)

55551 066

(motor 3)

55551 004

(motor 1+2)

Load 2N (200 g)

Motor standoff

screw

Lowered boom

Service guide March 2001 11

Motor 3

Adjustment of timing belt

5551 066:

Make sure the belt is not

transmitting torque during the

procedure (lower the Boom to

the bottom position).

With the motor turned off

loosen all 3 motor standoff

screws (inside the side plate).

Move the unit until the timing

belt has no preload and

minimum slack (picture) and

tighten the screws.

Test the tension by turning on

the SpinJet, switch it to the

Double mode and intersect the

beam of PS01. Motor 3 will

now lower the boom until the

Reset-button is activated.

Too much tension gives more

noise and possibly stalling

motor during lowering.

Too much slack will cause the

belt to disengage the teeth of

the motor pulley at a slight load

of the Boom during raising.

Repeat the positioning if

required.

5550 005 Assy, motor

w/pulley and connector

Motor 1, 2 and 3 are identical.

Motor with

pulley and

harness

Timing belt

5551 066

(motor 3)

with

appropriate

slack

Timing belt

5551 066

(motor 3)

with too

much

slack.

Service guide March 2001 12

To disconnect motor 2 or 3 (left

side of unit) first disconnect

motor harness at connector PCB

(right side), then pull the harness

just enough to gain access to the

connectors.

Make sure to lower boom before

removing timing belt on motor 3.

Loosen 3 screws on the motor

flange and remove the timing belt.

Replace motor, tighten 3 screws

on motor flange and reconnect

motor harnesses.

Adjust timing belt tension as

described in previous section.

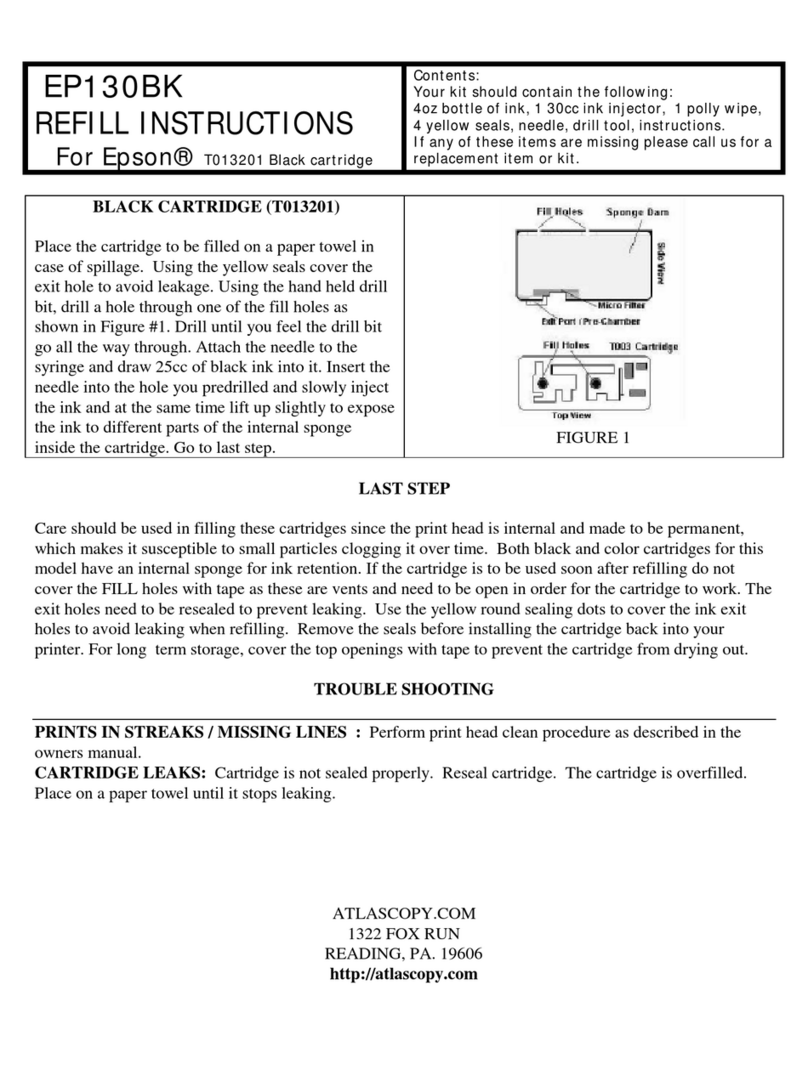

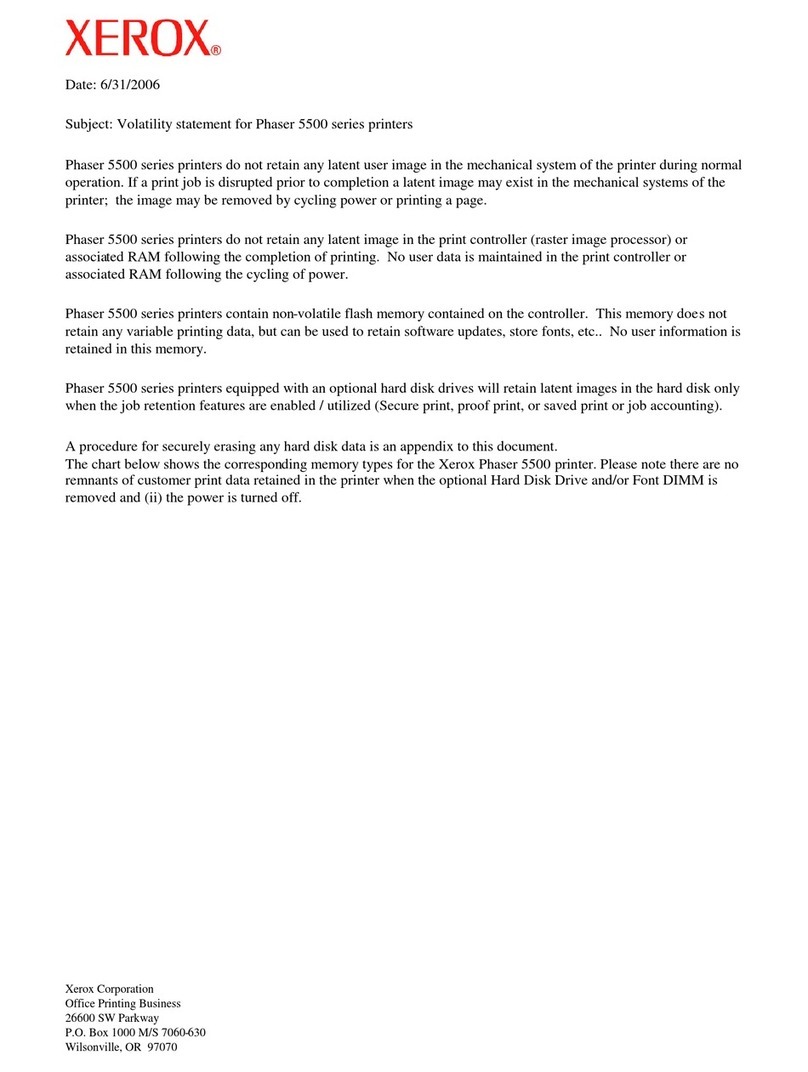

5550 007 Assy,

sensor/connector (PS01)

Disconnect assy from the

connector PCB, loosen screws of

emitter and receiver and remove

the hole grommets and the assy.

Reassemblein reverse order. Make

sure to position holes (ø0.5 and

ø1) of sensitivity attenuators

according to above picture.

Motor

flange

screw

Motor

2

Motor

3

Hole ø

0.5 mm

Receiver

Unscrew

this side

Emitter

Hole ø

1 mm

Service guide March 2001 13

5551 001 Photo sensor

(PS02)

Dismount Guides 2 and Guide 5 as

well as Console 2 (picture).

Dismounting of the boom shaft

pulley on the left side is required.

Refer to section 5550 008 (pulley)

and 5550 066.

Swing down Guide 4, loosen,

remove and disconnect PS02.

Reassemble in reverse order. Make

sure to adjust to correct timing

belt tension as previously

described.

5551 001 Photo sensor

(PS03)

Lower boom by hand and

dismount the boom guide. Loosen

and remove PS03 with its pillar.

Disconnect and replace PS03.

Reassemble in reverse order.

PS03.

Screws of

pillar are

outside side

plate.

PS 02

Console 2

PS 02

located

inside

Guide 4

Boom

guide

Service guide March 2001 14

5550 026 Assy, harness #6

connector PCB to PS02-03

Disassemble PS02 or 03 as

described in the previous

sections.

Unscrew connector PCB,

disconnect harness and withdraw

it through the side plate.

Reassemble in reverse order.

Make sure to reconnect EMC

ground straps with the same

connector board securing screw.

5551 062 Photo sensor left

(PS04)

5551 063 Photo sensor

right (PS05)

5550 028 Assy, harness #10

connector PCB to PS04-05

Replacement of encoder sensors

PS04 and 05 requires removing of

the sensor fastening screws.

Common harness #10 is plugged

into sensor.

It is easier to disconnect the

connector from the sensor, when

the sensor is removed from the

pillar.

Important: Keep the two sensors

in close contact with each other

when re-installing.

To replace harness, first loosen

screws of the connector PCB.

Make sure to reconnect EMC

ground straps when reassembling.

PS04

PS05

Harness #6

(2 pcs.)

Service guide March 2001 15

2.4 Control system

components

5551 073 Fuse

5551 088 Fuse holder cap

Turn fuse cap with screwdriver

and remove fuse and cap.Replace

with fuse rated “250V 3.15A T

(ø5 x 20 mm) only!

5550 032 Assy, control

system

Disconnect all harnesses before

removal. Control box is fastened

to printer by 2 screws below box.

Reconnect as described in

installation guide (male/female

coding makes it impossible to

interchange the two 15-pin

connectors).

5550 048 PIC, programmed

Component safety precautions

Handling:

•Avoid touching the legs,

which are susceptible to

static electricity

•Keep the legs mutually

“grounded” with conductive

material for storing/shipping

Exchange:

Note the position of the half-circle

notch on the body of the PIC: It

should be pointing downwards in

the control box when mounted on

the printer.

Before replacement switch off

power completely by removing the

supply cord. Replace the PIC

using a PIC extractor (tool) as

shown in picture.

Especially if tool is unavailable,

take care to lever out and install

the PIC as parallel as possible,

thus avoiding bending of the legs.

Fuse

holder

PIC,

programm

ed

Take hold of

both ends

with the PIC

extractor

Service guide March 2001 16

5550 197 Connector PCB

Replace connector PCB by

loosening it from the 2 standoffs

and disconnect all harnesses

(picture below).

Make sure to reconnect EMC

ground strap from harness #4

and #11 with same connector

board securing screw when

reassembling.

5550 027 Assy, harness #7

connector PCB to keypad

Dismount connector PCB and

replace harness. The keypad is

part of the cover spare part

(5550 035).

5550 025 Assy, harness #5

connector PCB to motor 2 or

3

Dismount connector PCB and

disconnect harness #5.Withdraw

it through the beam and disconnect

at motor end (connectors are

located inside beam when

assembled). Reassemble in reverse

order.

5550 038 Assy, harness #4

and #11 in supporting arm.

Assembly comprises assembled

pillar, console and gas spring with

motor and signal harnesses:

§5550 024 Assy, harness #4

main PCB to connector PCB,

motor

§5550 029 Assy, harness #11

main PCB to connector PCB,

signal

Replacement requires removal of

the entire mechanical unit.

Disconnect harnesses at control

box and detach them from the an-

chors on the clamp.

Connector

PCB

Harness

#5 (2 pcs.)

Harness #4

and #11

strapped on

clamp.

Supporting

arm assy

Location

of screws

(4 pcs.

T20)

Service guide March 2001 17

Remove the 4 screws holding the

SpinJet to the clamps(picture)

and lift off the unit.

Dismount connector PCB,

disconnect harnesses and

unscrew supporting arm assembly

from side plate.

Reassemble in reverse order,

adjust and test the unit according

to section 4 and 6 of the

Installation Guide.

5550 030 Assy, harness

#12 RS232 printer

communication

Replacement follows directly from

the picture. Assure that both

SpinJet and Printer are turned off

during replacement.

2.5 Mechanical compo-

nents

5551 018 Gas spring

Replace one gas spring at a time

only. Keep SpinJet in upright

position and release retainers at

both ends. Depress gas spring

slightly with a cramp/clamp to

unload the bearing. Reassemble in

reverse order.

Caution: Depressing gas spring

requires a force of 500 Newton!

5551 019 Bumper

Support at

printer front

(2 pcs.)

Depress ends

with clamp or

vice.

Harness #12

Service guide March 2001 18

Two bumpers are located on the

unit at points of contact with the

printer front and one at the gate.

Unscrew and reinstall bumpers by

hand.

5550 200 Bushing 4

5550 166 Guide 5

See picture for replacement.

5550 021 Assy, Guide 6

5550 196 Tool 1

Guide 6 is located on lower edge

of the printer window.

The spare part comes supported

by a wooden installation rail. Keep

Guide 6 in the rail during handling.

Tool 1 isused for control of the

gap under the guide.

For information on installation

procedure: Please see SpinJet

Installation Guide.

5550 186 Flap

The transparent flap, supplied with

an adhesive strip, is located on the

inside of the gate.

Replace flap by gently pulling it off,

cleaning gate with ethanol and

apply new flap. Assure flap

protrudesfrom gate as shown, is

aligned with the flag at the right

end and is firmly pressed to the

surface of the gate.

Flap

must

protrude

11.8±1.5 mm

from gate

Flag

Gate

Guide 5

Bushing 4

Adhesive strip

Installation rail

Guide 6

Service guide March 2001 19

5550 199 Foil

The foil is located on Guide 4,

where the sheet exitsthe unit.

Spare part is supplied with an

adhesive strip.

Replace foil by gently pulling it off,

cleaning guide with ethanol and

apply new foil as specified on

picture.

5551 055 Tape

5551 056 Tape

5551 055 is a common 19 mm

3M Scotch Magic Tape and is not

supplied as a spare part. 5551

056 is supplied to a pre-cut

length.

For information on installation

procedure: Please see SpinJet

Installation Guide.

5551 023 Spring

Springs are located at both roller

ends (see next picture).

Important: Do not remove or

reinstall springs by grabbing the

body of the spring, as this may

damage the preload (no visible

damage!)

Replace by gently lifting the spring

eyelet off the stud and the shaft

end, using a pair of pliers (pointed).

Roller is retained by clearance

holes in side plates.

5550 174 Retainer 1

The press fit retainers are located

on the shafts for the one way

clutches, one on the right side (see

next picture) and two on the left

side of unit. Pull off with an M5-

screw and reinstall by gently

tapping on the end of the retainer.

5550 008 Pulley with clutch

Foil

No

t to exceed

end edge

Press the adhesive

strip

firmly on

Foil must

protrude 9.1±0.5

mm

from

G

uide 4

5551 055

5551 056

Spring

Retainer 1

M5-hole in

center

5550 008

Service guide March 2001 20

This pulley is located on the paper

feed shaft end close to motor 1.

Remove retainer and timing belt

as described in previous sections.

Replace pulley, reinstall retainer

and timing belt and readjust timing

belt tension as described in

previous section.

5550 181 Encoder

Remove sensors PS04 and PS05

(refer to earlier section).

If only the disc needs

replacement, slide off the retainer

and the encoder using a thin blade

and thin screwdrivers.

Press on new encoder disc and

retainer and reinstall sensors.

If the assembly including the hub

is to be removed, see the

following.

1453 007 Bearing (on

shafts)

Dismount springs from roller ends

(previously described under

5551023).

To get access to the upper shaft,

first remove encoder unit located

on right side plate. Insert two

screwdrivers in the groove of the

encoder hub (picture) and lever off

the encoder disc assembly (with

hub).

To get access to the lower shaft,

first remove the pulley on the

right shaft end (refer to earlier

section, 5550 008). Also remove

pulley 4 on the roller shaft

(picture above) in order to get

access to the screwsofHousing

2.

Loosen and remove Housing 2

and/or 3 with bearing from shaft

end and side plate. Slide bearing

out of Housing. Reinstall in

reverse order.

5550 020 Assy, hub with

set screws (upper shaft)

Bearing

Housing 3

Housing 2

Shaft 8

Roller end

Pulley 4

Hub

Encoder

Encoder

PS04 + 05

Table of contents

Other Techsage Printer Accessories manuals

Popular Printer Accessories manuals by other brands

Xerox

Xerox 5500DN - Phaser B/W Laser Printer manual

Konica Minolta

Konica Minolta HT-502 installation manual

NEC

NEC SUPERSCRIPT 4400 SERIES user guide

Kodak

Kodak XLS 8600 PS user guide

Lexmark

Lexmark 20T3600 - T 620 B/W Laser Printer quick reference

HP

HP Designjet 8000s Take-Up Reel Kit installation guide