Techspan Clean Box Ultrasonic User manual

Techspan Group, Ph: 1-800 148 791 Ph: ++64 9 827-6567 Fax1-800 148 799 Fax ++64 9 827 6596 sales@techspanonline.com

Operating Instructions

Techspan Clean Box Ultrasonic Cleaning Unit

www.techspanonline.com

Content

2

BA/ECB/GB/0505©

1 General....................................................................... 3

2Important safety warnings .......................................... 3

3 Product description..................................................... 4

3.1 CE conformity ...............................................................4

3.2 Techspan.Clean Box product features...........................4

3.3 Functioning ...................................................................4

3.4 Technical details ...........................................................5

3.5 Description of the unit ...................................................5

3.6 Accessories...................................................................7

3.7 Operating elements.......................................................8

4 Initial operation ........................................................... 8

4.1 Filling of the unit............................................................9

4.2 Cleaning......................................................................10

4.3 Placement of cleaning items .......................................10

4.4 Start-up of the cleaning process .................................10

5 Cleaning media ........................................................ 11

5.1 Suitable cleaning media..............................................12

6 Maintenance............................................................. 12

6.1 Maintenance / Care.....................................................12

6.2 Repair .........................................................................13

6.3 Troubleshooting ..........................................................13

7 Putting out of action and waste disposal .................. 14

8Distributor's contact address.................................... 14

General

© BA/ECB/GB/0505

3

1 General

The present Operating Instructions are part of the delivered

equipment. They must be ready for use at any time and remain

with the unit in case of resale.

Carefully read the Operating Instructions before use of the unit

and operate the electrical appliance according to the

instructions only.

We reserve the right to carry out technical modifications on the

unit due to advanced development.

Reprints, translations and copying of any kind, including of parts

of the document, must be authorized by the editor.

The copy right remains with the editor.

2 Important safety warnings

Read before initial operation!

The present Techspan ultrasonic cleaning unit has been designed

for the treatment of items and liquids only.

Check the unit for transport damages. In case of visible

damages do not put the unit into operation.

The mains plug must be connected to an easily accessible

socket only, as it serves as interrupting device. The unit can be

operated at a mains voltage of 100 – 240 Vac.

Place the unit at a dry and sufficiently ventilated workplace.

Protect the unit from entering humidity! Do not hose or put

under water. Keep workplace, housing and operating elements

dry.

Do not open the housing. The unit must be opened by

authorized specialized personnel only.

For cleaning, maintenance and care of the unit, in case of

suspected humidity inside the unit or in case of malfunctions

and after operation pull the mains plug.

Fill the unit with a sufficient quantity of cleaning liquid before

switch-on. Do not treat flammable liquids in an ultrasonic

cleaning bath. Risk of fire and explosion!

Section 5: Cleaning media

Intended use

Check for damages

Mains connection

Placement

Prevention o

f

electrical accidents

Pull the mains plug

Cleaning liquid

Product description

4

BA/ECB/GB/0505©

3 Product description

3.1 CE conformity

The present ultrasonic unit is in compliance with the CE

marking criteria according to the EMC directive 89/336/EEC,

and the low voltage directive 73/23/EEC.

The declaration of conformity is available from the

manufacturer.

3.2 Techspan Clean Box product features

Techspan Clean Box – High technology „Made in Germany“

x compact ultrasonic unit for professional ultrasonic cleaning

x cleaning frequency 46.000 vibrations/sec

x piezoceramic frequency transducer

x easy operation

x practical design

x wide range of useful accessories

x for connection to mains voltages of 100 Vac - 240 Vac

3.3 Functioning

Today, cleaning by ultrasound is the most modern fine cleaning

method.

The electric high-frequency energy created by an ultrasonic

generator is transformed into mechanical energy by piezo-

electrical transducer systems and is then transmitted into the

bath.

This process creates millions of tiny vacuum bubbles, which

implode due to the variations of pressure caused by the

ultrasonic activity. Highly energetic liquid jets are created. These

jets remove dirt particles from surfaces and even from the

smallest grooves and bores.

In order to achieve efficient cleaning results the liquid in the

cleaning bath must contain a suitable cleaning chemical.

Product description

© BA/ECB/GB/0505 5

3.4 Technical details

Mains voltage (Vac) 100 - 240

Mains frequency (Hz) 50 / 60

Power consumption (Watt) 40

Ultrasonic frequency (kHz) 46

Outer dimensions unit W / D /H (mm) 212 / 122 / 130

Inner dimensions tank W / D / H (mm) 194 / 84 / 60

Max. filling volume tank (liter) 0,9

Inner dimensions basket W / D / H (mm) 178 / 80 / 47

Mesh size basket (mm) 6

Weight (kg) 1,0

Material tank stainless steel

Material housing PC-ABS

3.5 Description of the unit

Illustration 3.1

A

B

E

D

C

Product description

6BA/ECB/GB/0505 ©

Illustration 3.2

Plastic basket

Stainless-steel cleaning tank

PC-ABS plastic housing

LED display

Operating key on/off

Cable coil

can also be used for hooking the unit onto the wall support

Wall support

for the practical placement, e.g. in the bathroom.

The Techspan Clean Box can be fixed to the wall by means of

special wall support. For mounting the support to the wall only a

screw is required. The unit can easily be hooked to the wall

support and removed.

F

G

A

B

C

D

E

F

G

Product description

© BA/ECB/GB/0505 7

3.6 Accessories

Illustration 3.3

Illustration 3.4

translucent unit cover – to be used both as cover for the tank

and practical drop-off collecting basin (Illustration 3.4)

cleaning basket – for the gentle storing of sensitive items during

the cleaning process

forceps – for the easy removal of small items from the cleaning

bath

cleaning beakers blue and white including cover – specially

designed for the discreet cleaning of dentures and braces in the

Elmasonic

wall support – description see Illustration 3.2; page 6

Useful accessories

included in delivery

A

B

EDC

B

A

A

B

C

D

E

Initial operation

8BA/ECB/GB/0505 ©

3.7 Operating elements

Key for turning the ultrasound on and off.

Keep the key pressed for a short time: the unit starts a cleaning

cycle of 7 minutes. The cleaning process can be stopped at any

time by pressing the on/off key again. For further cleaning

cycles press the key again.

Indicates the operating mode of the unit:

The operating modes are indicated as follows:

The green LED lamp is on – the mains plug is connected to the

socket, the unit is in stand-by operating mode. The ultrasound

can be switched on by pressing the on/off key.

The green LED lamp is flashing – the ultrasound is switched on.

Operating elements

on/off key

LED display

Green lamp is on

Green lamp flashing

4 Initial operation

Check the Techspan ultrasonic cleaner for possible transport

damage before initial operation.

In case of visible damages do not connect the unit to the

mains. Contact your supplier and forwarding agent.

For operation, place the unit on a dry and solid surface or hook

it to the wall support included in the delivery. Ensure that the

workplace is sufficiently ventilated!

Check for transport

damages

Placement

Wall support

Risk of electrocution due to humidity inside the unit!

Protect the unit from entering humidity.

The unit inside is splashwater-proof. Keep workplace and

housing dry in order to prevent electrical accidents and

damages on the unit.

CAUTION

Initial operation

© BA/ECB/G B /050 5 9

Allowed ambient temperature +5°C - +40°C

Ambient conditions

x Allowed relative humidity of air up to 30°C: 80%

x Allowed relative humidity of air up to 40°C: 50%

x No condensation

Connect the unit to an easily accessible socket as the mains

plug serves as interrupting device!

The Techspan ultrasonic cleaner can be connected within a

range of 100Vac to 240Vac.

Connect the unit to

the mains

Voltage range

100Vac – 240Vac

4.1 Filling of the unit

Fill the cleaning tank with a sufficient quantity of a suitable

cleaning liquid before operation.

Observe filling level

Dry running of the transducer tank can cause damage to the

unit.

Ensure that the cleaning tank is filled to the optimum level

during operation (2/3 filling level).

NOTE

Ensure that the chosen cleaning chemical is suitable for

treatment in an ultrasonic bath and observe the instructions on

dosage and compatibility of the material.

We recommend the use of the cleaning agents listed in section

5.1.

Caution! Flammable products are not allowed for use in an

ultrasonic bath. Observe the instructions given in section 5

(cleaning media).

Restrictions concerning further cleaning media are also

indicated in the instructions given in section 5.

For queries please contact the manufacturer or your supplier.

Freshly mixed cleaning liquids are saturated with air which

lessens the cleaning effect of the ultrasonic activity. By

sounding the liquid over a period of several minutes before the

cleaning process the tiny air bubbles in the liquid are

eliminated.

Suitable cleaning

agents

Prohibited cleaning

agents

Degassing of liquids

Initial operation

10 BA/ECB/GB/0505 ©

4.2 Cleaning

The items to be cleaned must be covered completely in the

cleaning liquid.

Place the items in the bath with the contaminated side down.

Cleaning instructions

4.3 Placement of cleaning items

Caution! Do not place the cleaning items directly on the bottom

of the transducer tank as this might lead to damages on the

unit.

Use suitable accessories:

Use the plastic cleaning basket for big items.

Suitable for dentures, braces and small items. For cleaning, fill

the beaker with a suitable cleaning chemical.

Insert the loaded dental beaker in the transducer tank which

must be filled with liquid up to approx. 50%. Add a few drops of

a cleaning chemical to the water in the transducer tank.

With the forceps the cleaned items can be taken out of the unit

or items can be held into the liquid for cleaning.

Cleaning basket

Dental beake

r

Forceps

4.4 Start-up of the cleaning process

Do not reach inside the tank during ultrasonic operation!

Cell walls can be damaged by prolonged exposure to ultrasonic

activity.

For taking out the cleaning items switch off the unit or use the

forceps (included in delivery).

NOTE

Press the on/off key in the operating panel of the unit (see also

section 3.7). The unit starts a cleaning cycle which switches off

automatically after 7 minutes.

This process can be repeated as often as required.

After the cleaning process thoroughly rinse the cleaned items in

running water and wipe dry with a cloth.

Press on/off key.

After-treatment o

f

items: rinsing/drying

Cleaning media

© BA/ECB/GB/0505 11

5 Cleaning media

For more efficient cleaning results it is required to add a

suitable cleaning chemical to the liquid in the cleaning bath.

When choosing the cleaning chemical ensure that the product

is suitable for the use in an ultrasonic bath; products that are

not suitable can cause damage to the transducer tank. When

using other chemicals than the ones recommended please

observe the instructions given on the label, in particular

concerning the use in an ultrasonic bath.

Risk of fire and explosion!

Never use flammable liquids or solvents directly in the

ultrasonic cleaning tank.

We recommend to use the cleaning media listed in section 5.1.

CAUTION

Ultrasound increases the vapourisation of liquids and creates

finest vapours which can easily catch fire at ignition sources.

Risk of damage to the transducer tank!

Do not use acid cleaners (pH value below 7) directly in the

stainless-steel tank if the items to be cleaned carry

contaminations containing halogenides (fluorides, chlorides or

bromides).

The same applies to salt solutions (NaCl).

We recommend to use the cleaning media listed in section 5.1.

NOTE

The stainless-steel tank can be destroyed by crevice corrosion

within a very short period. Substances causing crevice

corrosion can be contained in household cleaners.

The manufacturer cannot be held responsible for damages

caused by crevice corrosion.

For queries please contact the manufacturer or your supplier.

Maintenance

12 BA/ECB/GB/0505 ©

5.1 Suitable cleaning media

Techspan has a large range of suitable cleaning products developed

by chemical engineers in the laboratory in Germany. Please contact

your supplier.

Cleaning solution for the cleaning of glasses and optical

equipment.

For instructions on application see product label.

Ammoniacal cleaner, brightening effect for precious metals and

jewellery.

For instructions on application see product label.

Cleaner for dentures and braces with activated oxygen. Also

suitable for the cleaning of feeding-bottles and accessories.

For instructions on application see product label.

Mild cleaning concentrate for the careful cleaning of medical

and dental instruments (also suitable for aluminium alloys).

For instructions on application see product label.

Alkaline cleaning solution for the intensive cleaning of medical

and dental instruments (not suitable for aluminium alloys).

For instructions on application see product label.

elma opto clean

elma super clean

elma denta clean

elma clean 10

elma aquasonic

6 Maintenance

6.1 Maintenance / Care

Pull the mains plug before carrying out any maintenance works.

The Techspan ultrasonic cleaner is maintenance-free.

Check the housing and the mains cable for damage regularly in

order to prevent electrical accidents.

Caution! Do not use acids or solvents for cleaning the plastic

parts.

In order to prolong the service life of the transducer tank,

remove the cleaning residues regularly, in particular metal

particles.

Lime deposits on the stainless-steel tank can be cleaned gently

e.g. with elma clean 40 or elma clean 115C.

Maintenance

Care of housing

Care of transduce

r

tank

Maintenance

© BA/ECB/GB/0505 13

For this, fill the cleaning chemical at the recommended

concentration in the ultrasonic bath and operate for several

minutes. Then empty the unit and wipe the tank walls clean.

For reasons of hygiene, we recommend to disinfect the

transducer tank and the edge of the tank regularly. (Household

disinfectants)

6.2 Repair

In case of any damage please contact your supplier or the

manufacturer of the unit.

Repair works require special know how and must be carried out

by specialized personnel only.

Use original spare parts only.

The mark of CE conformity may lose its validity due to

unauthorized opening of the unit.

The manufacturer cannot be held responsible for any damage

caused by unauthorized opening of the unit.

Opening by

authorized

specialized

personnel only

CAUTION

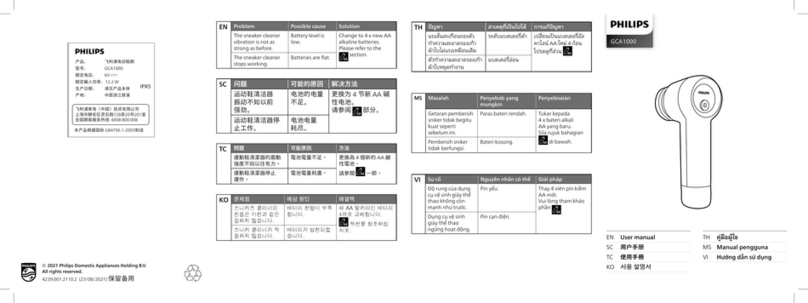

6.3 Troubleshooting

Before returning the unit to the supplier or manufacturer for

repair, please check the following possible causes:

Malfunction Possible cause Remedy

no function;

LED dark

x mains plug not connected

x mains cable damaged /

interrupted

x plug in the mains plug

x return unit to manufacturer /

supplier

no function;

LED is on, no flashing of

LED

x on/off key has not been

pressed correctly

x faulty electronics

x press on/off key again

x return unit to manufacturer /

supplier

no function;

LED flashes green

x faulty electronics x return unit to manufacturer /

supplier

cleaning result not

satisfactory

x no cleaning chemical or

unsuitable cleaning chemical

has been used

x cleaning interval too short

x use suitable cleaning

chemical

x repeat cleaning interval

housing or mains cable

damaged

x possibly by third party x return unit to manufacturer /

supplier

Putting out of action and waste disposal

14 BA/ECB/GB/0505 ©

7 Putting out of action and waste disposal

The unit components can be taken to metal, plastics and

electronics recycling stations.

8 Distributor's contact address

Techspan Group

P O Box 15-262, New Lynn, Auckland, New Zealand

P O Box 1012, Mascot, NSW 1460, Australia

Ph: +64 (0) 9 827-6567 Australia: Ph: 1-800 148 791

e-mail: [email protected]

Homepage: www.techspanonline.com

Technical Support

Phone 1-800 148 791 or +64 (0) 9 827-6567

Fax 1-800 148 799 or +64 (0) 9 827-6596

e-mail: [email protected]

Subject to technical and visual modifications. ch_0505

Table of contents