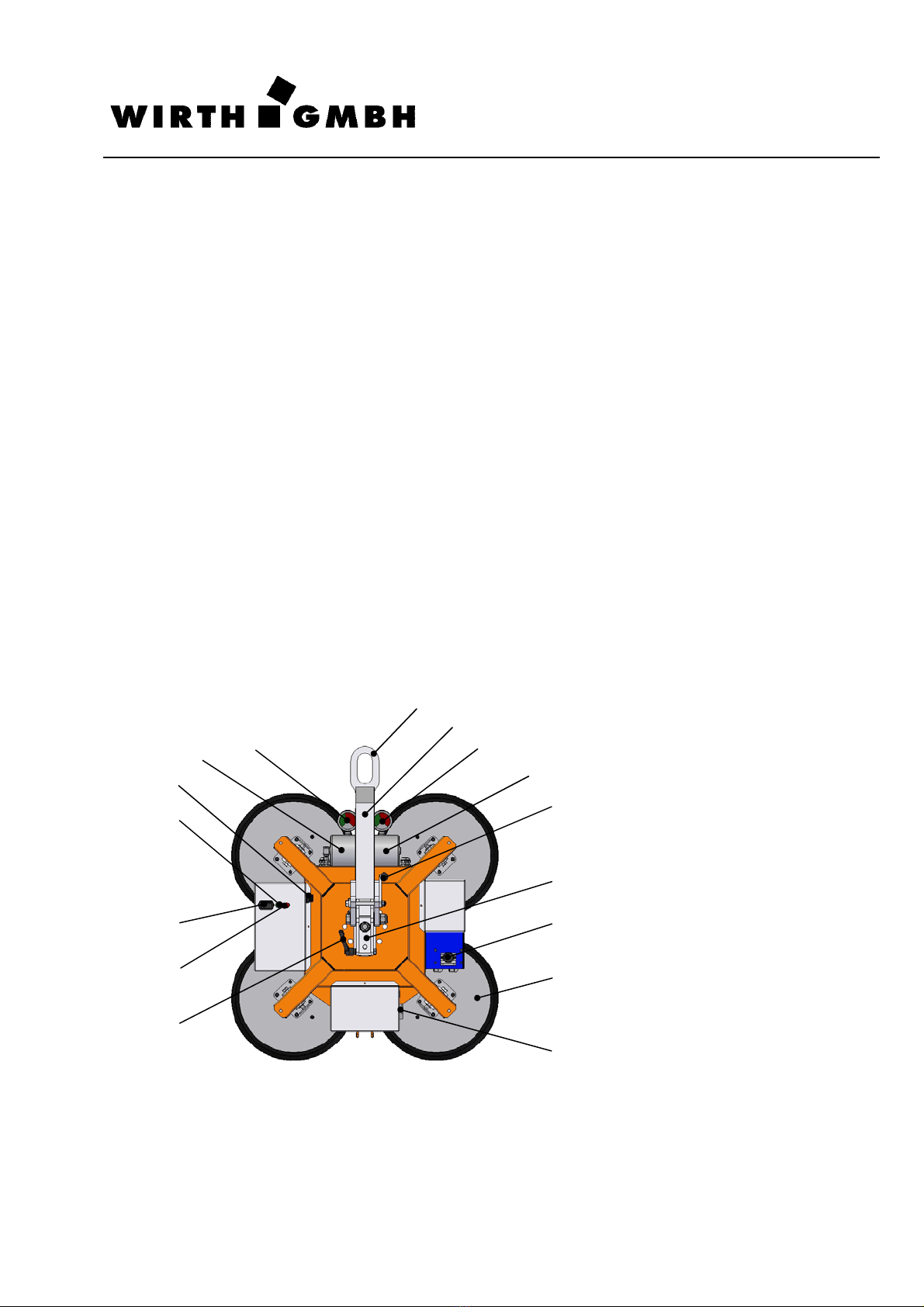

Operating Instructions

OKTOPUSGL-R600

Technical documentation

1 98 900 002 a

Page 6 of 26

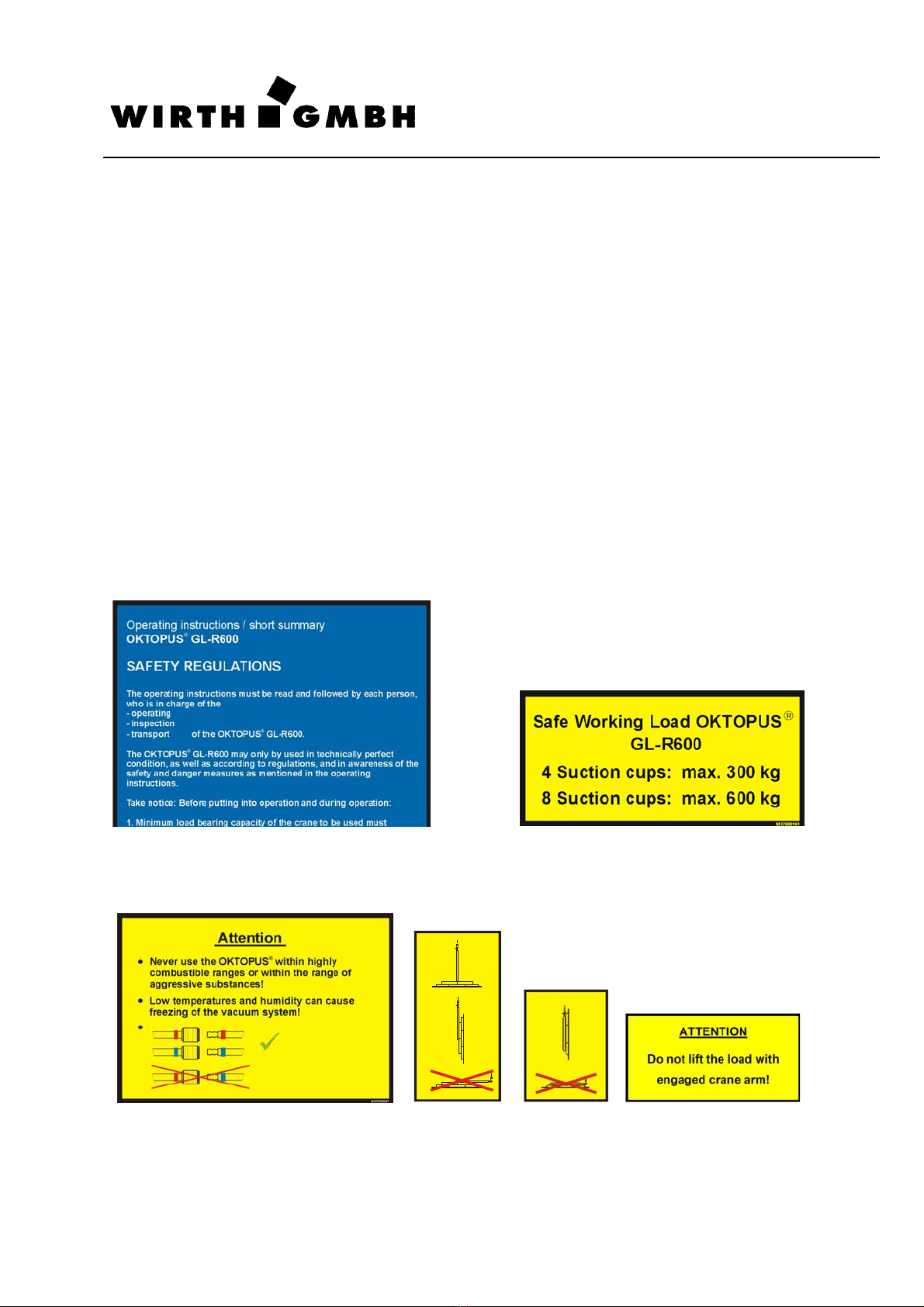

2.2 Safety instructions

(1) Only use cranes with a CE mark and a load bearing capacity exceeding the live

load of the OKTOPUS®GL-R600 in all working positions by at least 100 kg!

(2) Never use a damaged, not fully functional or not complete OKTOPUS®.

(3) Before using the crane/OKTOPUS®working arrangement for the first time always the

units have to be checked by an expert and this inspection has to be documented!

(4) Only operate the crane if you hold a suitable licence!

(5) Only operate the OKTOPUS®and the crane, if you are familiar with the control and

display elements as well as the operating instructions. You need to be aware of

the impact a function can have on the entire equipment.

(6) Before using the OKTOPUS®and the crane check the function of the operating and

indicating elements as well as the alarm features!

(7) Make sure that the crane operator has a sufficient view over the sling and assembly

location.

(8) Arrange hand signals with the installer and fitter for the necessary crane operations!

(9) Consider absolutely the maximum load-bearing capacities of the OKTOPUS®GL-R600

described in this section under the point Information Signs! The data are valid only for a

working height which corresponds to the sea level!

(10) Should be protection hoods on the suction heads, the protection hoods must remove

before start-up!

(11) Only work in wind strengths of less than 36 km/h, else the load is endangered of

swinging uncontrollably.

(12) Check the suction pads daily for damage; if necessary replace with new pads.

(13) Clean the suction surfaces on the elements. Do not place the suction pads on protec-

tive film, but remove the film beforehand, at least at the contact areas of the suction

pads.

(14) Never stand or walk under the suspended load!

(15) Ensure that no-one attempts to mount or ride on the OKTOPUS®GL-R600 or the

suspended construction elements.

(16) Stop work immediately when the acoustic alarm sounds and the warning light

lights up! In this case there are the danger of a grave damage to the system and fal-

ling of the sucked load. Use the elevating machine to put down the OKTOPUS®and

the sucked load carefully. Find and remove the cause for the alarm. In case the defects

cannot be removed, finish working with the OKTOPUS®immediately. The OKTOPUS®

has to be secured against further use.

(17) In the event of faults and during servicing and maintenance work always switch the

OKTOPUS®off. Turn therefor the main switch to the OFF position!

(18) Please note, low temperatures and humidity can cause freezing of the vacuum

system!

(19) Never use the OKTOPUS®within highly combustible ranges or within the range of

aggressive substances!

(20) Wet components must not be sucked in, because:

a. this reduces the load bearing capacity considerably and

b. the vacuum system and/ or the control system of the OKTOPUS®might be dam-

aged!

(21) Never attempt to lift damaged glass or facade elements.

(22) After use protect the suction cups of the OKTOPUS®against damage by using protec-

tion hoods!