Tecmec Sirio HH Series User manual

Sirio HH

Use and maintenance manual

Page 1of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

Sirio HH

Use and maintenance manual

Sirio HH

Use and maintenance manual

Page 2of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

Contents

1GENERAL INFORMATION 4

1.1 MANUFACTURER IDENTIFICATION 4

1.2 PRODUCT IDENTIFICATION 4

1.3 CE DECLARATION 5

1.4 REFERENCE STANDARDS 6

1.5 WARRANTY 6

2EQUIPMENT DESCRIPTION 7

3SAFETY 8

3.1 SAFETY RULES 8

3.2 ELECTRICAL POWER SUPPLY 8

3.3 WORKING ZONES 9

3.4 COMPONENTS AND SAFETY DEVICES 9

3.5 RESIDUAL RISKS 9

3.6 SYMBOLS SHOWN ON THE EQIUPMET 10

3.7 INTENDED USE OF THE EQUIPMENT 10

3.8 NON INTENDED USE 10

4TRANSPORT AND HANDLING 11

5INSTALLATION 12

6USE 18

6.1 OPERATION INSTRUCTION AND ELECTRICAL PANEL SETTINGS 18

6.2 COSTUMIZED AGITATION AND PAUSE SETTINGS 19

6.3 LOADING AND UNLOADING OF CANS 19

7MAINTENANCE 20

7.1 ORDINARY MAINTENANCE 20

7.2 NON USE PERIODS 20

8TROUBLESHOOTING 21

9TECHNICAL FEATURES 22

9.1 TECHNICAL FEATURES OF THE STANDARD MODEL 22

9.2 TECHNICAL FEATURES OF THE ATEX MODEL 23

10 WIRING DIAGRAMS 24

10.1 WIRING ELECTRICAL PANEL STANDARD MOTOR SINGLE PHASE 24

10.2 WIRING ATEX SINGLE PHASE MOTOR 25

11 DISPOSAL 26

Sirio HH

Use and maintenance manual

Page 4of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

1 GENERAL INFORMATION

1.1 Manufacturer Identification

TECMEC S.r.l.

Località Faustina, 63

20080 Albairate (MI) –Italy

Tel: +39 02 9469871

Fax: +39 02 94698741

e-mail: tecmec@tecmec.com

web: www.tecmec.com

1.2 Product identification

The identification label, is located on the left side of the structure, with the below mentioned data:

Safety and Health Requirements Symbols

Manufacturer Data

CE Mark

Production Year

Serial Number

Univocal Machine Code

Motor Protection Class

Electrical Characteristics

Sirio HH

Use and maintenance manual

Page 5of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

1.3 CE Declaration

Sirio HH

Use and maintenance manual

Page 6of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

1.4 Reference standards

2006/42/CE Machine Directive

2014/95/CE Low Voltage Directive

2014/30/UE Electromagnetic Compatibility Directive

UNI EN ISO 12100:2010 Safety Machinery - General Principles for Design - Risk reduction and

assessment

CEI EN 60204-1 Electrical Equipment of Machines

1.5 Warranty

The warranty covers free of charge the repair or replacement of the components with manufacturing

defects.

For the warranty conditions, please refer to the document containing the warranty terms inside the CD

supplied with the equipment.

In particular, the warranty will not cover any damage due to the transport, or non compliance with the

installation and operating instructions, or usage by unauthorized personnel, or for reasons not caused by the

manufacturer.

Sirio HH

Use and maintenance manual

Page 7of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

2 EQUIPMENT DESCRIPTION

The timed dispenser Sirio HH, is an equipment designed for the professional sector.

The unique feature of this equipment is to maintain homogeneous, over time, the colorants contained in the

cans (provided with suitable lids provided separately from Tecmec).

In order to avoid accidents or injury to person, or and things, the equippment have to be used by trained

personnel.

Sirio HH

Use and maintenance manual

Page 8of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

3 SAFETY

3.1 Safety rules

The products of the series Sirio HH, must be included in the assessment of company risk and requires the

applicable laws on safety at work to be complied.

To ensure the highest possible degree of safety in the correct use of the machine, all measures deemed

necessary in the design, construction, testing and installation have been adopted.

For a proper use, the machin has to be used by trained personnel, in order to avoid accidents.

The used components is in accordance with the applicable standards.

The dispenser Sirio HH Compact must be located in a special tank / container, suitable to contain any

accidental products leaks.

To avoid that the equipment have instability issues, it's necessary to verify both the perfect

leveling of the feets locaded in the bottom part of the structure and the fixing to the wall, as

per the assembly instructions.

3.2 Electrical power supply

Determined the installation area, the following prerequisites have to be implemented:

The main power supply have to be provided through an electrical panel, placed on the wall close to the

equipment.

The maximun expected power is 0.75Kw.

The section of each conductor must be a minimum of 1,5 mm².

The main power supply line, must be fitted with an efficient ground connection, and complies with all

the requirements in force.

The electrical power supply panel have to consist in a residual current device (IΔn=0,03A) with voltage

and phase compatible with the agitation motor (single phase).

To ensure a complete safe operation for the operator and the equipment, it's very important, during the

assembly of the electrical panel, to use the above mentioned type of switch, due to the fact that the switch

will have a protective function against possible direct or accidentals voltage hazard down to ground.

It's important to make the necessary assessment of the site, and follow the requiring and characteristic rules

of the electrical system, to ensure that they are not a cause of accidents or injuries.

Sirio HH

Use and maintenance manual

Page 9of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

3.3 Working zones

The zones where improper use and not allowed intervention may present risks are the below mentioned :

Operator Zone

Maintenace Zone

3.4 Components and safety devices

The machine is equipped with an red emergency button, placed on the control panel.

A pressing action of this button cause an immediately emergency stop, classified as category 0, the power to

the motor will be interrupted, and will interrupt the agitation movement.

Once the emergency situation is resolved, release the emergency button to restore the normal operation:

Release the emergency button

Press the START button

3.5 Residual risks

In spite of precaution adopted in the design of the equipment, to ensure safe use there may be reasonably

foreseeable situation for which it has only been possible to reduce the risk without completely eliminating it.

Risk

Precaution

Injuries and or crushing during the loading and or

unloading of the cans.

Use protective gloves and safety shoes during loading and

unloading of the cans.

Eyes damage due to paint splashes.

Use protective glasses.

Improper actions during the agitation cycle.

Don't load or unload cans during the agitation.

Don't put your hands, or tools / items, in the agitation zone

during the normal operation cycle.

The dispenser is designed to handle colorant / pastes of various types. Prior to their use, follow

the instructions warning and safety instruction on each individual can / package, and on the

data sheet issued by the producer.

MAINTENANCE ZONE

0.5MT

.

1.4M

T.

0.5MT

.

OPERATOR ZONE

(DRIVER PROGRAMMING)

OPERATOR ZONE

LOADING AND UNLOADING

0.2MT.

1.4M

T.

0.5MT

.

Sirio HH

Use and maintenance manual

Page 10 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

3.6 Symbols shown on the eqiupmet

Danger electrical hazard.

Is forbidden to carry out work on the equipment under voltage.

Is forbidden to operate on the electrical system without authorizations.

Danger gear in movements.

Forbidden to load or unload the cans during the agitation cycle.

It is mandatory to read carefully the instruction manual, before carry out any operations on the

equipment.

It is mandatory to provide the grounding of the electrical system.

3.7 Intended use of the equipment

The unique feature of this equipment is to maintain homogeneous, over time, the colorants contained in the

cans (provided with suitable lids provided separately from Tecmec).

3.8 Non intended use

Any other use of this equipment that are not described in this manual are considered improper and therefore

prohibited.

In particular it is forbidden:

Load or unload the cans during the agitation cycle / process.

During this process the Led warning is clearly visible on the control panel.

Any kind of manumission or unauthorized intervention on the electrical control panel.

Access the motor compartment by unauthorized personnel, and in any case when the plug for the main

power is connected.

Removing the protection from the motor compartment, if so only during the maintenance phase done

only by expert personnel.

In any case it is absolutely mandatory to remove the plug from the main electrical /power line

before executing any kind of maintenance.

Sirio HH

Use and maintenance manual

Page 11 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

4 TRANSPORT AND HANDLING

The equipment are packed in special cardboard boxes and transported on pallets.

Each box is labeled with: type of module, code, production order.

The identification label with the symbols, and the risks and residual risks is located on the front side of the

motor module panel.

In case of needs to move an operating equipment please follow the below points:

Always operate by following the instruction provided by existing accident prevention regulation.

Remove the shelf's, and place all the colorants cans in a appropriated place.

Place the dispenser on a pallet.

Move the pallets with appropriated means to the new destination.

Install the equipment by following the instructions.

For obvious safety reason it is forbidden to move the assembled equipment.

For movement over long distance, the equipment MUST be packed and secured on pallets, as

when it was delivered.

Sirio HH

Use and maintenance manual

Page 12 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

5 INSTALLATION

Warning

Consider the size and weights of the various components that will be moved.

Is fundamental constraint that the below mentioned installation steps are

carried out by two (2) person.

A

Remove the module from the box.

B

To avoid scratches lay down the

modue on the carton box.

C

Secure the extension support using

the M8 screws and nuts.

Screw without over tighten the 4 feet

and nuts.

Secure the control panel to the control

panel using the M4 screws.

Sirio HH

Use and maintenance manual

Page 13 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

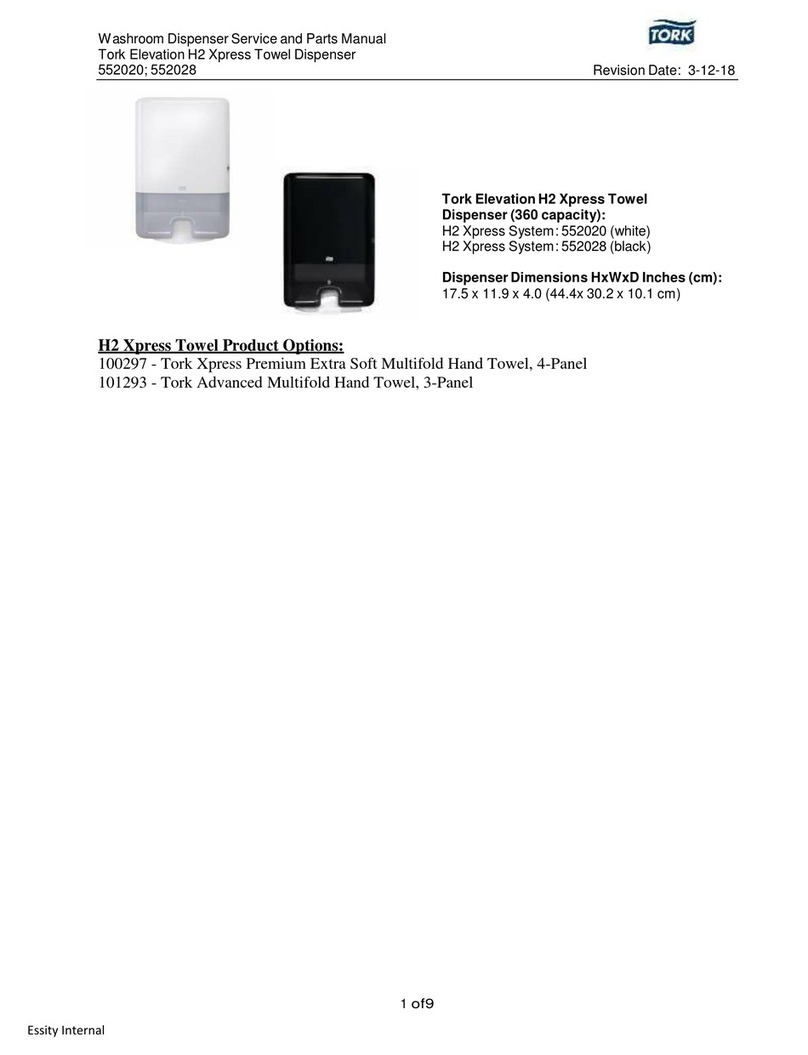

D

Place the basement approximately 40

- 50Cm from the wall.

Verify that the floor is as flat as

possible, in case of differences use the

adjustable feet.

If this procedure is not carried out, the result could lead to noise, malfunctions, abnormal wear

of moving parts, and pose risks to the end user.

E

Introduce the shaft with the joint in

the reducer seat / location.

F

Introduce the drive shaft in to the

gear placed on the shelf, and then in

to the reducer joint crossing the

plastic protections.

Tighten the grain / screw of the joint

with the supplied key.

Slide the protections between them,

until they go in contact with the

structure.

Sirio HH

Use and maintenance manual

Page 14 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

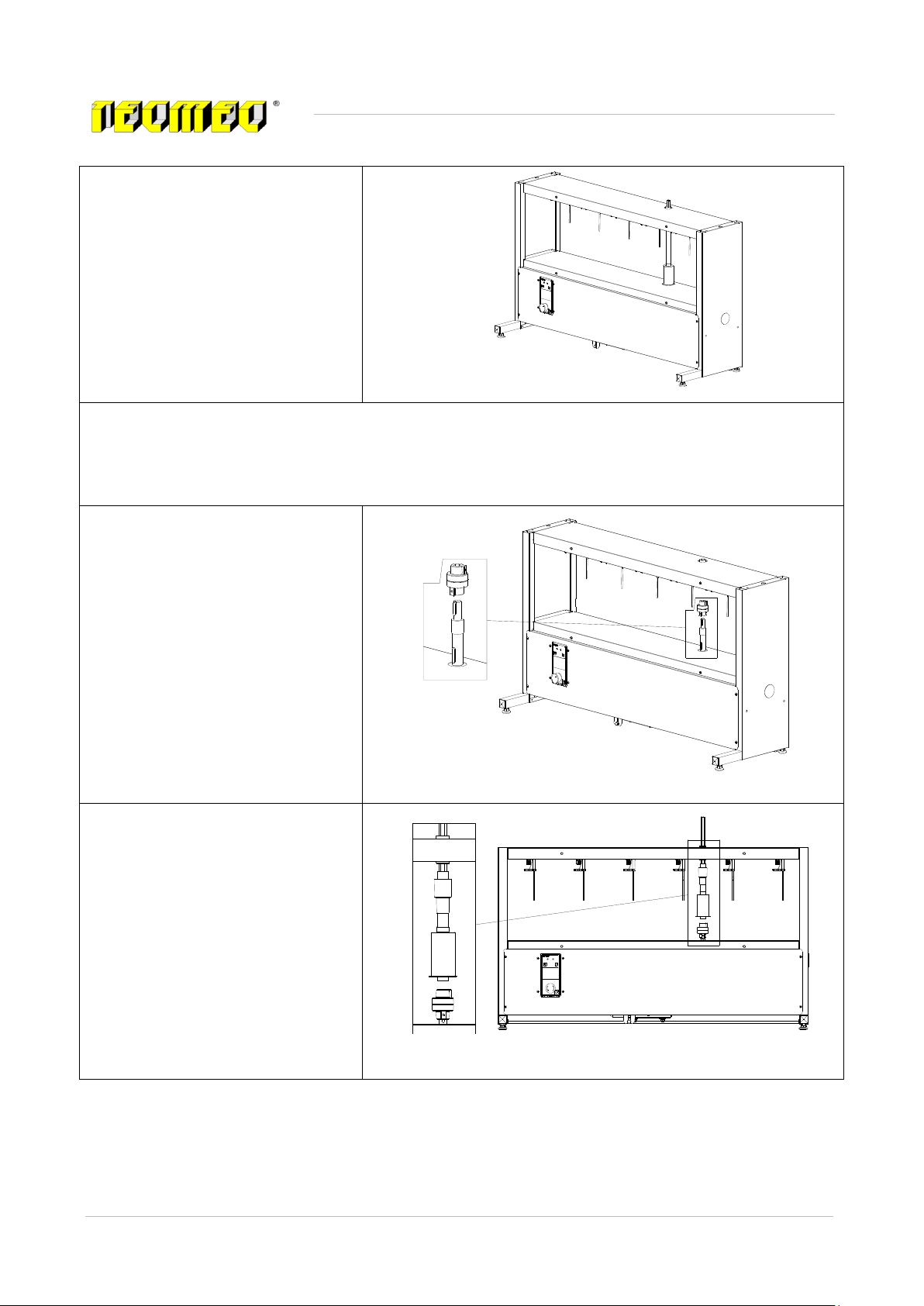

G

Overlap the modules that make up the

machine.

Fit /imbed the tabs in the lower

structure, and secure with the M6

screw and washer.

H

Connect the transmission shaft, in the

same way as for the basement.

Repeat the operation H for all the agitated modules.

I

Connect on the rear part of the

dispenser the various structure

modules, with the ground plate.

Sirio HH

Use and maintenance manual

Page 15 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

L*

Place the dispenser against a wall, or

or a similar structure to support the

wieght, and prevents overturning.

Verify the feets, and that the

dispenser is leveled, use a bubble

level.

If not, use the adjustment feets, once

done secure the feets with the nuts.

*If the dispenser contains more than

1 agitated column, go to point O.

M

Secure the structure against the wall

with the supplied brackets and

anchors.

It is mandatory to execute this operation.

Not performing the above operation carries risks for the end user.

N

Secure the frontpanel (optional) at the

top of the last module.

Sirio HH

Use and maintenance manual

Page 16 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

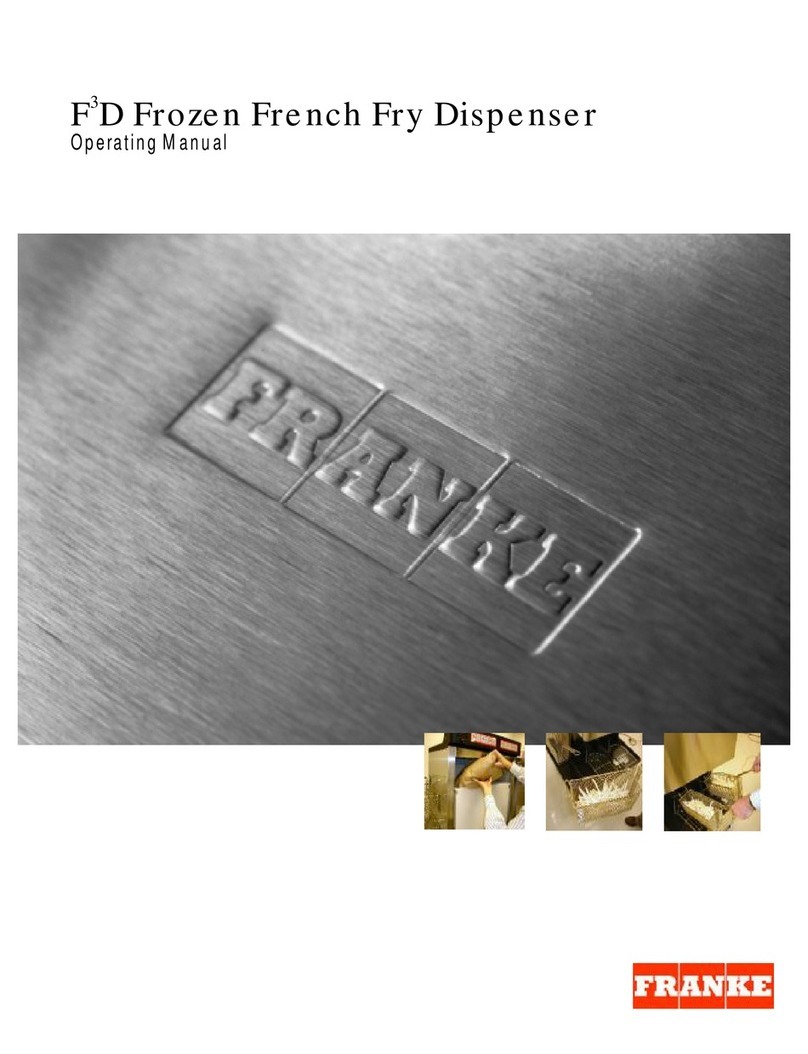

Additional operations for dispenser with 2 or more columns

O

Remove the plastic cap located on the

right side of the motor module.

Fit the over turning extensions on the

module without the motor.

Locate , place side by side the

module without the motor, to the one

with the motor already secured

against the wall.

P

Remove the front panel of the

basement

Secure the two structure using

toothed washer and M6 srews.

Q

Connect the reducers through the

shaft and transmission joints.

R

Overlap and secure the successive

modules as step G-H-I-L.

Sirio HH

Use and maintenance manual

Page 17 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

S

Connect the two columns with the M6

screws and nuts, using the holes in

the module posts.

T

Complete the installation by

performing points Mand N.

Sirio HH

Use and maintenance manual

Page 18 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

6 USE

6.1 Operation instruction and electrical panel settings

The mixing machine is controlled by a electrical panel with internal CPU, that will generate the signal / input

to the agitation motor. The control panel is located in the right shoulder of the machine.

START BUTTON

Enables to start the motor in the cyclical function

based on the setted time (default: 20 min. ON, 240

min OFF)

STOP BUTTON

Stops the motor and the cyclical function.

EMERGENCY BUTTON

Will stop the motor, but will maintain the electrical

panel powered. To restart the motor and the cyclical

function, turn the emergency button clockwise, and

press the start button.

LiGHT INDICATION

Green Led = Dispenser powered ( tension present )

Red Led flashing and Green Led off = Motore in rotazione e macchina in fase di agitazione

Red and Green Led fixed light = Cycle mode active ( agitation motor off ready to start )

Note:

To restart the motor during the pause period, press the red STOP button, wait a few seconds

and press the green START button.

Led

Green

Led

Red

Start

Stop

Emergency

Sirio HH

Use and maintenance manual

Page 19 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

6.2 Costumized agitation and pause settings

The factory setting is setted as follow: 20 minutes agitation 240 minutes pause.

In case of necessity to modify the jumper on the electrical board see below

Availables agitation times : 10-15-25 min

Availables pauses times : 60-120-180-300-360-420-480 min

6.3 Loading and unloading of cans

Add or remove the cans from the respective location only when the machined is turned off.

When placing the can make sure that the lid is properly positioned. The reference point are 2: the spout

against the anti rotation "nail", and the fork against the reference points.

Sirio HH

Use and maintenance manual

Page 20 of 28

Instruction n° 192 - Rev. 02 of 06/07/2016

EN

Copyright © 2016 Tecmec S.r.l. Translated from the original instructions

7 MAINTENANCE

7.1 Ordinary maintenance

To extend the life time of the equipment, the Siro HH needs some flew precaution:

Verify every morning that the power lights in ON.

Verify that all the lids of the cans / tins are properly placed in the agitation zone.

In case of liquids spill, disconnect the equipment from the main electrical line, clean immediately the

area by using the proper products.

Leave the equipment in always operation mode, even during the evening and weekends , in order to

keep the products always ready to be used.

Verify every six months the correct tightening of the transmission, transmission joints, and the

proper tension of the motor belt.

Verify every months the functionality of the emergency button by following the below steps:

1- Press the button during any operation phase, verify that the lights on the control panel are

switched off, and in case of agitation that the motor will stop.

2- Once the procedure is done, restore the equipment by pressing the START button.

For any other kind of issues, or doubts, please contact the Customer Service Dep. in Tecmec.

7.2 Non use periods

In case that the equipment will be switched off, due to a prolonged period of non-use, to avoid a overload

issues on the motor it is necessary to proceed as follow:

Remove all the cans/tins from the shelf's, execute a mixing trough a mixer / shaker or in alternative

a manual mixing, and verify any eventual consistency problem.

In group of 2-3 locate the cans on the equipment, and mix them for at least 5 minutes.

Stop the agitation, and add other cans/tints for the mixing cycle.

Proceed as above until all the cans/tins are stored in the equipment.

In case of power failure, verify the reason, once restored the situation, restart the agitation cycle by pressing

the START button, in order to always ensure a good homogenization of the product.

During the loading and unloading of the cans, stop the agitation cycle by pressing the red STOP button.

This manual suits for next models

2

Table of contents

Other Tecmec Dispenser manuals

Popular Dispenser manuals by other brands

Bosch

Bosch THD2023 operating instructions

Parker

Parker SciLog LabTec Series Installation, Operation & Maintenance Instruction Manual

Nordson

Nordson freedom product manual

Franke

Franke SD3200 installation guide

Franke

Franke F3D Frozen French Fry Dispenser operating manual

Dispense-Rite

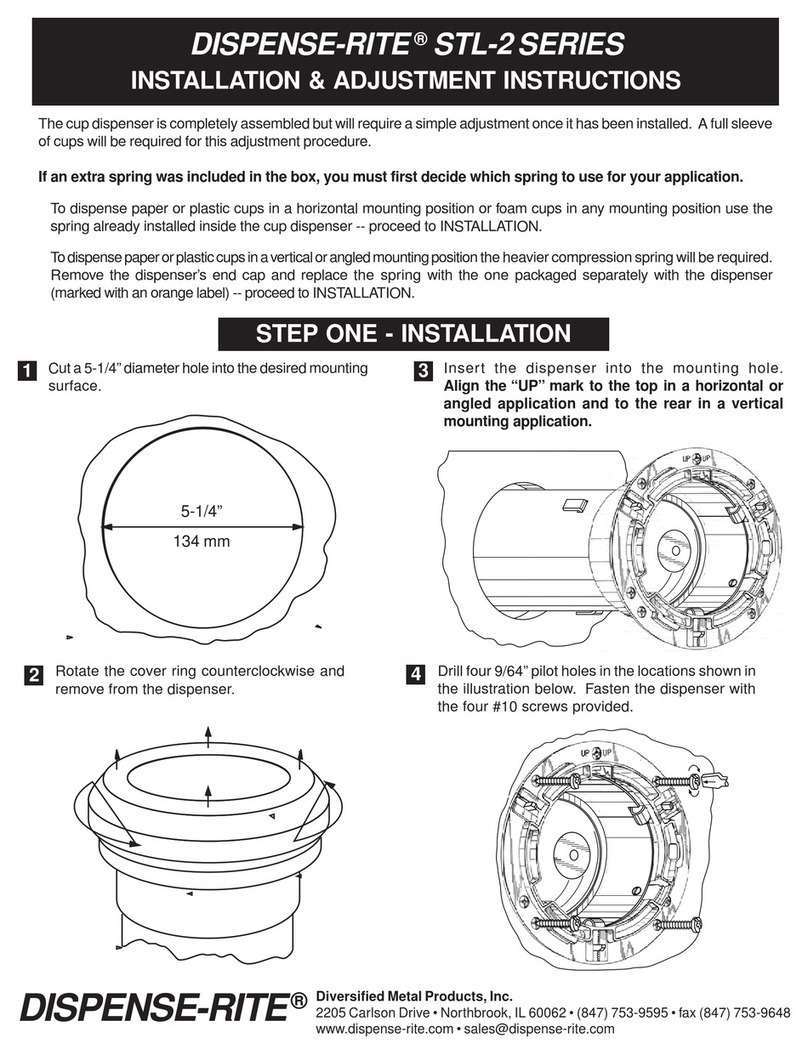

Dispense-Rite STL-2 Series Installation & adjustment instructions