Tecnoma RAMPE VITIFIX Guide

Adjusting, Using and Maintenance

Read carefully before to use the sprayer

RAMPE VITIFIX

99920EN July-2015

Indice C

JULY-2015 3

99920EN

INDEX

1 - IDENTIFICATION

1.1 - SEAL OF THE AUTHORIZED DEALER Tecnoma ....................................................................................................................................................................... 5

1.2 - BRAND PLATE............................................................................................................................................................................................................................. 5

1.3 - CONSTRUCTER’S ADDRESS .................................................................................................................................................................................................... 5

2 - GENERAL INFORMATION

2.1 - FOREWORD ................................................................................................................................................................................................................................ 7

2.2 - THE USER INSTRUCTIONS ....................................................................................................................................................................................................... 7

2.2.1- Product improvements ...............................................................................................................................7

2.2.2- User warning..............................................................................................................................................7

2.3 - GENERAL COMMUNICATIONS .................................................................................................................................................................................................. 7

2.3.1 - Denitions ..................................................................................................................................................7

2.3.2- Conventions used ......................................................................................................................................8

2.4 - EXPECTED USAGE CONDITIONS............................................................................................................................................................................................ 8

2.4.1- Machine functions .....................................................................................................................................8

2.4.2 - Operator qualications ...............................................................................................................................9

2.5 - INFORMATION FROM AUTHORISED DEALER ......................................................................................................................................................................... 9

2.6 - INFORMATION ON OWNER ....................................................................................................................................................................................................... 9

2.7 -APPENDIX ................................................................................................................................................................................................................................. 10

3 - GENERAL SAFETY

3.1 - FOREWORD ...............................................................................................................................................................................................................................11

3.2 - USE OF AN AGRICULTURAL MACHINE. ..................................................................................................................................................................................11

3.3 - USING CROP TREATMENT PRODUCTS ..................................................................................................................................................................................11

3.4 - CONVENTIONS RELATING TO SAFETY SYMBOLS ............................................................................................................................................................... 12

3.5 - RECOMMENDATIONS PRIOR TO USE.................................................................................................................................................................................... 13

3.5.1-The user instructions................................................................................................................................13

3.5.2- Person protection.....................................................................................................................................13

3.6 - WARNING PICTOGRAMS AND OTHER MARKINGS............................................................................................................................................................... 14

3.6.1- Description of warning pictograms ..........................................................................................................14

3.7 - GENERIC RISKS ....................................................................................................................................................................................................................... 14

3.8 - CLEANING, MAINTENANCE AND REPAIR .............................................................................................................................................................................. 14

3.9 - ENVIRONMENTAL PROTECTION ............................................................................................................................................................................................ 14

4 - DESCRIPTION OF THE BOOM

4.1 - GENERAL CHARACTERISTICS ............................................................................................................................................................................................... 15

4.1.1 - Vitix boom...............................................................................................................................................15

4.2 - CONFORMITY ........................................................................................................................................................................................................................... 15

4.3 - EQUIPMENT FOR ROAD TRAVEL............................................................................................................................................................................................ 15

4.4 - TECHNICAL CHARACTERISTICS ............................................................................................................................................................................................ 16

4.4.1 - Dimensions and weight of the boom........................................................................................................16

5 - COMMISIONING

5.1 - DELIVERY OF THE MACHINE .................................................................................................................................................................................................. 17

5.1.1- Delivery inspection...................................................................................................................................17

5.2 - COMMISSIONING ..................................................................................................................................................................................................................... 17

5.1.2 - Operator qualication...............................................................................................................................17

5.1.3- Check on the required tractor characteristics ..........................................................................................17

5.3 -ADDITIONAL DOCUMENTATION.............................................................................................................................................................................................. 17

5.4 - PREPARATION .......................................................................................................................................................................................................................... 17

5.5 - ELECTRICAL CONNECTION .................................................................................................................................................................................................... 17

JULY-2015 4

5.6 -ADJUSTING THE BOOM .......................................................................................................................................................................................................... 18

5.1.4- MANUALLY SETTING THE HEIGHT OF THE FRAME...........................................................................18

6 - USE

6.1 - RECOMMENDATIONS PRIOR TO USE.................................................................................................................................................................................... 19

6.2 - POSITIONING THE BOOM........................................................................................................................................................................................................ 20

6.2.1-Adjusting the height..................................................................................................................................20

6.2.2 - Adjusting the width of the boom ..............................................................................................................20

6.2.3- BOOM POSITION FOR TRANSPORT ....................................................................................................20

6.3 - POSITION OF THE SPRAYER PARTS...................................................................................................................................................................................... 21

6.3.1-Adjusting the position of the spray guns .................................................................................................21

6.3.2-ADJUSTING THE UPPER HANDS..........................................................................................................22

6.3.3- adjusting the position of the lower hands.................................................................................................22

6.4 - BOOM CONTROLS AND MOVEMENTS................................................................................................................................................................................... 24

6.4.1-TWO SOLENOID VALVE ELECTRICAL CONTROL AND CIRCUIT SELECTOR ...................................24

6.4.2-TWO SOLENOID VALVE ELECTRICAL CONTROL AND TELESIT AND COMPRESSOR OPTION .....24

6.4.3- FOUR SOLENOID VALVE ELECTRICAL CONTROL AND TELESIT AND COMPRESSOR OPTION ...25

6.4 - USING NOZAL NOZZLES.......................................................................................................................................................................................................... 27

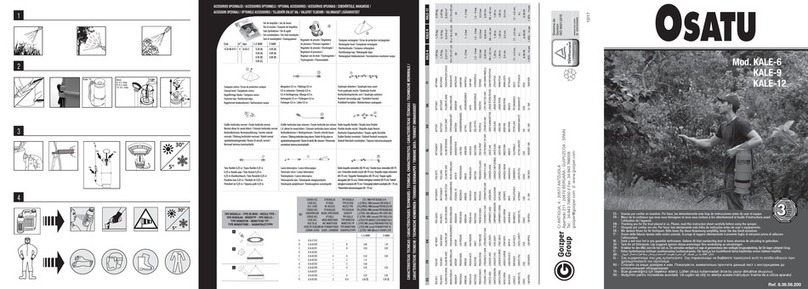

6.4.1- NOZZLE FLOW RATE TABLE ABX NOZAL ............................................................................................27

6.4.2- NOZZLE FLOW RATE TABLE : RFX NOZAL..........................................................................................28

6.4.3- NOZZLE FLOW RATE TABLE : AFX NOZAL ..........................................................................................29

6.4.4- NOZZLE FLOW RATE TABLE : RDX NOZAL..........................................................................................30

6.4.5- NOZZLE FLOW RATE TABLE : ADX NOZAL..........................................................................................31

6.4.6- NOZZLE FLOW RATE TABLE : ATX NOZAL...........................................................................................32

6.4.7- NOZZLE FLOW RATE TABLE : RRX NOZAL..........................................................................................32

6.4.8- NOZZLE FLOW RATE TABLE : ARX NOZAL..........................................................................................33

6.4.9- NOZZLE FLOW RATE TABLE : TRIFILET...............................................................................................34

6.4.10- NOZZLE FLOW RATE TABLE : R5X NOZAL ........................................................................................35

6.4.11 - Calculation of ow rate for different tables .............................................................................................36

6.4.12- NOZAL ranger........................................................................................................................................36

7 - SERVICING

7.1 - CLEANING ................................................................................................................................................................................................................................ 37

7.2 - GENERAL SERVICING.............................................................................................................................................................................................................. 37

7.2.1- Spare parts ..............................................................................................................................................37

7.2.2- Hydraulic and spray circuits .....................................................................................................................37

7.3 - VERIFYING THE SETTINGS ON THE BOOM .......................................................................................................................................................................... 39

7.3.1- General information .................................................................................................................................39

7.3 - SPECIFIC MAINTENANCE OPERATIONS ON THE BOOM..................................................................................................................................................... 39

7.3.1- Greasing ..................................................................................................................................................39

7.3.2 - Stops, plastic and rubber rollers .............................................................................................................39

7.3.3- Filtering ...................................................................................................................................................39

8 - ENVIRONMENTAL PROTECTION

8.1 - REMINDER ................................................................................................................................................................................................................................ 41

8.1.1 -Preventive measure .................................................................................................................................41

8.1.2- Spraying...................................................................................................................................................41

8.1.3 -Operating conditions ................................................................................................................................41

8.1.4- COMPATIBLE NOZZLES AND FILTERS ................................................................................................42

9 - PERSONAL NOTES

10 - INDEX

1 - IDENTIFICATION

1.1-SEAL OF THE AUTHORIZED DEALER Tecnoma

Refer to chapter

IDENTIFICATION of the sprayer’s using manual of your machine.

1.2-BRAND PLATE

Refer to chapter

IDENTIFICATION of the sprayer’s using manual of your machine

1.3-CONSTRUCTER’S ADDRESS

Tecnoma Technologies

54, rue Marcel Paul

51206 Epernay - France

Tel: 03.26.51.99.99

Fax: 03.26.51.83.51

Email: [email protected]

Site: www.tecnoma.com

July-2015 5

990232

July-2015 6

– IDENTIFICATION –

July-2015 7

Chapter 2

2.1-FOREWORD

We recommend that the dealers of this new or used machine and/or equipment keep a written proof that this

sheet was indeed supplied with this machine and/or equipment (Phytomieux Chart).

2.2-THE USER INSTRUCTIONS

The original user manual is written and published in French. All foreign language versions are translations of

the original. In the event of contradiction, inaccuracy or digression between the original version in French and

versions in other languages, the original in French shall prevail.

•Description of machine or equipment operation and maintenance methods

•Provides instructions for a perfectly safe use of the machinery

•It is an integral part of the machine.

•Should be kept in the tractor cabin

•Must be thoroughly read by all machine users

If, in spite of the information provided in this manual, some points remain unclear, contact your Authorized

Tecnoma Dealer or, if not possible, contact Tecnoma see chapter MACHINE IDENTIFICATION

. Tecnoma

has paid due diligence to the writing of this manual in order to make it as complete and precise as possible, and

shall not be held liable for any possible omissions or imprecision.

2.2.1 - PRODUCT IMPROVEMENTS

Tecnoma continuously strives to improve its products and therefore reserves the right to perform the

modications deemed necessary for improvement without prior warning and without being required to perform

modications or improvements on machines or equipment that has already been sold.

Any modication on Tecnoma machines and/or equipment is prohibited , except for modications expressly

authorized in writing by After Sales Services or Tecnoma Technical Department.

2.2.2 - USER WARNING

We regularly updated our instructions and are open to your suggestions for improvements of our documents.

2.3-GENERAL COMMUNICATIONS

2.3.1 - DEFINITIONS

2.3.1.1 Hazardous area

All areas inside and/or in the vicinity of a machine in which there is a risk for the safety or health of an exposed

individual.

2.3.1.2 Exposed person

Any individual partially or completely present in the dangerous zone.

2.3.1.3 Operator - Driver

The individual or individuals responsible for the installation, operation, adjustments, cleaning, repair of breakdowns

and transportation of a machine.

2.3.1.4 Authorised dealer

Any individual who has benetted from an agreement with Tecnoma regarding the specic training that has

been provided by Tecnoma.

2 - GENERAL INFORMATION

July-2015 8

– GENERAL INFORMATION –

2.3.1.5 Right Side - Left Side

All indications of direction in the instruction manual are provided in relation to the direction of travel

2.3.1.6 Machine

Generic term to refer to the sprayer

2.3.2 - CONVENTIONS USED

2.3.2.1 Operation recommendations, reactions

The operations are shown in the form of a numbered list which it is advisable

to comply with, the precise operator action can be described (►), the

resulting reaction resulting from the application of the operation or of the

action is shown, where necessary, by an arrow ( → ) for example :

1. Operation 1

1► Action 1 of the operator

→ Result

2. Operation 2

→ Result

2.3.2.2 Illustrations

As Tecnoma is constantly developing its machines, the assembly variations are numerous, the diagrams,

sketches and photos which illustrate these instructions are not contractually binding.

2.3.2.3 References in the illustrations

The bracketed numbers show positions in the illustration, for example (1)

or even (1/g2) refer 1 to illustration 2 of the chapter in question.

2.4- EXPECTED USAGE CONDITIONS

2.4.1 - MACHINE FUNCTIONS

This machine is exclusively intended to be used for current agricultural, forestry or wine making activities, namely

the spreading of phytosanitary products in accordance with environmental regulations

Any other use is considered contrary to normal use and is therefore prohibited.

The consequences of the use of certain phytosanitary products

Beware, certain products can be damaging due to their action on the materials used in the

manufacture of the sprayer. In order to limit the action of these products on the integrity of your

machine it is advisable to :

•Avoid prolonged contacts (approx. 20 hours)

•Never used unauthorised mixtures obtained starting from different phytosanitary products

•Do not use products that have a tendency to solidify or gum up.

•Empty and rinse the equipment immediately after treatment

Your machine is compatible with the use of liquid fertilizers

The sprayer's pump membranes have been designed by Tecnoma, and are resistant to a wide

range of products.

If you have doubts, please contact your Authorized Dealer.

Direction of movement

Left side Right side

Fig.1

July-2015 9

– GENERAL INFORMATION –

2.4.2 - OPERATOR QUALIFICATIONS

• The machine can only be used, serviced and repaired by individuals fully conversant

with its mode of operation and safety procedures.

• Before using your machine, insure that you are familiar with all its controls and correct

use.

2.5-INFORMATION FROM AUTHORISED DEALER

The Authorized Dealer must perform certain procedures when supplying a new Tecnoma machine and/or

equipment.

The machines are made roadworthy under the responsibility of the Authorised Tecnoma. Dealer.

•Check that the machine delivered is compliant with the purchase order.

•Read the Operation and Servicing Manual and all Safety Instructions for the machines.

•Insure that the information indicated on the control lists before delivery and upon delivery are thoroughly

checked and are compliant before delivering Tecnoma Technologies machines to their owners.

•The Authorized Dealer must give his customer complete instructions of the basic principles, operation and

servicing of the machine and the operating limits beyond which safety conditions would be hazardous and

inevitably become a danger to the user.

•The Dealer must give the customer the manuals of the machine.

2.6-INFORMATION ON OWNER

Tecnoma thanks you for purchasing one of its sprayers

The machine is designed and constructed to offer several years of satisfactory operations. However, its operation

and life cycle depend in part on the manner in which it is used and serviced.

•Comply with the recommended safety requirements indicated throughout the manual. Refer to chapter

GENERAL SAFETY

(into the manual of the machine)

•Use the equipment as instructed in this manual.

Refer to chapter MACHINE USE

•Maintain this equipment on a daily basis and as instructed in this manual

Refer to chapter MACHINE MAINTENANCE

Use only Tecnoma original parts if you wish to maintain the

validity of the warranty.

•Do not modify the machine.

•Do not use the machine with protection or safety systems that are faulty, poorly installed or not certied by

Tecnoma.

•Do not install optional equipment that is not allowed or out of production.

•Check that the details of your machine or equipment appear in the "MACHINE MAINTENANCE" chapter.

This information will be useful when ordering spare parts from your approved reseller.

CAUTION

•Failure to comply with these rules :

•Can make your machine dangerous

It frees the manufacturer of all responsibility in case of damages or injuries.

•If you have doubts, please contact your Authorized Dealer.

Only Authorized Dealers can provide original parts. They can assemble the parts and offer advice regarding the

assembly and use of these spare parts.

July-2015 10

– GENERAL INFORMATION –

WARRANTY

The start of the guarantee comes into effect on the day of commissioning, providing the

documents are received within 15 days at most.

In the event that these operation and maintenance precautions are not followed, Tecnoma will be

forced to waiver all guarantees or nancial consequences due to the failure to comply with these

recommendations.

2.7-APPENDIX

IMPORTANT

Please see the "APPENDIX" chapter at the end of this manual. Except where indicated to the

contrary, apply the recommendations indicated in this chapter, such as the type of grease to use,

torques to be applied. etc

JULY-2015 11

CHAPTER 3

3.1-FOREWORD

For safe usage, follow the instructions in this chapter and in the rest of this manual. You must also obey the

legislation applying to safety precautions, accident prevention, the labour code and the highway code.

Thorough knowledge and a good understanding of the safety rules are also necessary to use the machine

safely and properly.

3.2-USE OF AN AGRICULTURAL MACHINE.

Using an agricultural machine can incur risks for the user, third parties, the machine and even its environment.

To minimize these risks :

When using the machine, follow the safety instructions under "Risks connected to machine operation"

in chapter GENERAL SAFETY

of your machine manual.

Following these instructions helps ensure your safety.

•Only use the machine for its intended purpose as stated in GENERAL INFORMATION

.

•Always keep the machine in perfect working order and a safe condition.

•Regularly check the prescribed tightening torques.

•Regularly inspect the hydraulic circuit and check all connections.

•Before use, always activate the safety and protection systems that must be installed and operational.

•Always call on qualied personnel for the upkeep and maintenance of the machine.

•Clean the machine after use so that the safety labels remain legible and before any maintenance

operations.

•The use of a tractor with a safety cabin is recommended

•The machine should be driven by just one person, sitting in the tractor driving seat.

•Always keep children well clear of the machine.

•Leave remote controls in the places provided by the manufacturer.

•Stay well clear of moving parts..

•Do not wear loose clothing, jewellery or long hair which can be trapped or caught by moving parts.

•Make sure that no person, animal or obstacle is close to the machine before setting in motion.

•During boom manoeuvres: WATCH OUT for telephone and electricity lines.

•Do not loiter close to the moving machine.

•If you hear an unexpected noise or vibration, stop the machine and try to correct the cause of the noise

before resuming. Call your dealer if necessary

Remember that caution and care are the required to work in safety

3.3-USING CROP TREATMENT PRODUCTS

This crop sprayer was designed and built by our company to be used with the treatment products of your choosing.

To make sure that the sprayer functions correctly, please strictly follow the recommendations in the User Manual

provided .

As the user, you alone are responsible for following the recommendations given by the manufacturers of the

treatment products you use. The operator must also obtain an approved applicator's certicate and obey the

applicable legislation.

In particular, each user is advised to:

•check the pressure with clear water before incorporating products in the tank.

3 - GENERAL SAFETY

JULY-2015 12

– GENERAL SAFETY –

•Read carefully the treatment product manufacturer's label(s) and follow the instructions therein (dosage,

PPE, etc.);

•Avoid mixing the products unless their compatibility is specically recognised by the manufacturer of the

phytosanitary products;

•Prevent air from entering the sprayer tank when lling to avoid the formation of foam and problems due to

overow;

•Follow the precautions and warnings given by the manufacturer of the phytosanitary products, especially

for the storage of the treatment products, which should be kept in a locked room out of reach of children and

animals;

•Follow the precautions for recycling the packaging, in accordance with the recommendations of the

manufacturers of the phytosanitary products;

•Protect untreated areas;

•Contact the manufacturer of the phytosanitary product (or their representative) if you are in doubt, or if

information is missing.

After treatment, wash and change your clothes. Wash the tools that may have been contaminated.

3.4-CONVENTIONS RELATING TO SAFETY SYMBOLS

The terms DANGER, WARNING and CAUTION are used with the triangular safety symbol. This symbol

refers to the degree of importance of the risk incurred.

DANGER

Indicates an immediate and serious danger

Failure to follow the recommendations could lead to death or extremely serious injury (long-term

injury, memory loss).

WARNING

Indicates a potential moderate danger

Failure to follow the recommendations could, under certain conditions, lead to death or extremely

serious injury.

CAUTION

Indicates a low level danger

Failure to follow the recommendations could lead to bodily injury and material damage on a reduced

or moderate scale.

JULY-2015 13

– GENERAL SAFETY –

IMPORTANT

Indicates an obligation

Failure to behave properly or to perform the actions described in the recommendations could lead to

accidents or malfunction.

REMARK

Indicates information or advice on use

This advice will enable you to operate your machine to the full.

3.5-RECOMMENDATIONS PRIOR TO USE

3.5.1 - THE USER INSTRUCTIONS

THE MANUAL

•Must always be accessible to users and maintenance personnel and should be kept where the

machine is used. It must also be understood.

3.5.2 - PERSON PROTECTION

Having a rst aid kit on hand is strongly recommended

WARNING

Phytosanitary products, oils,

anti-freeze, solvents and fuels.

Follow the manufacturers' instructions in order to

use these products in safety.

To avoid any contact with the skin, eyes and mouth,

provide the user with protective gear bearing

the label

Example of personal protection equipment:

•gloves and overalls that are resistant to

chemical agents

•waterproof safety footwear

•face protection

•protective goggles

•respiratoryg protection

•etc.

In the event of an incident, consult a doctor and bring the label of the product.

Via the mucosa (eyes)

• splashing

• rubbing of the eyes with

contaminated hands

via the respiratory system

• dust

• spray mist

• vapour

via the digestive system

• eating, drinking and smoking during

application or after treatment with

unwashed hands

• accidental ingestion

via the skin

• splashing

• contact with the treated cultures

Main pathways of contamination

JULY-2015 14

– GENERAL SAFETY –

3.6-WARNING PICTOGRAMS AND OTHER MARKINGS

IMPORTANT

Check that the warning pictograms are present and clean.

Replace illegible or missing pictograms by ordering them from your reseller (remember to

note the reference, e.g., 5319909)

You will nd the pictogram references used on your machine in chapter

MACHINE DESCRIPTION

.

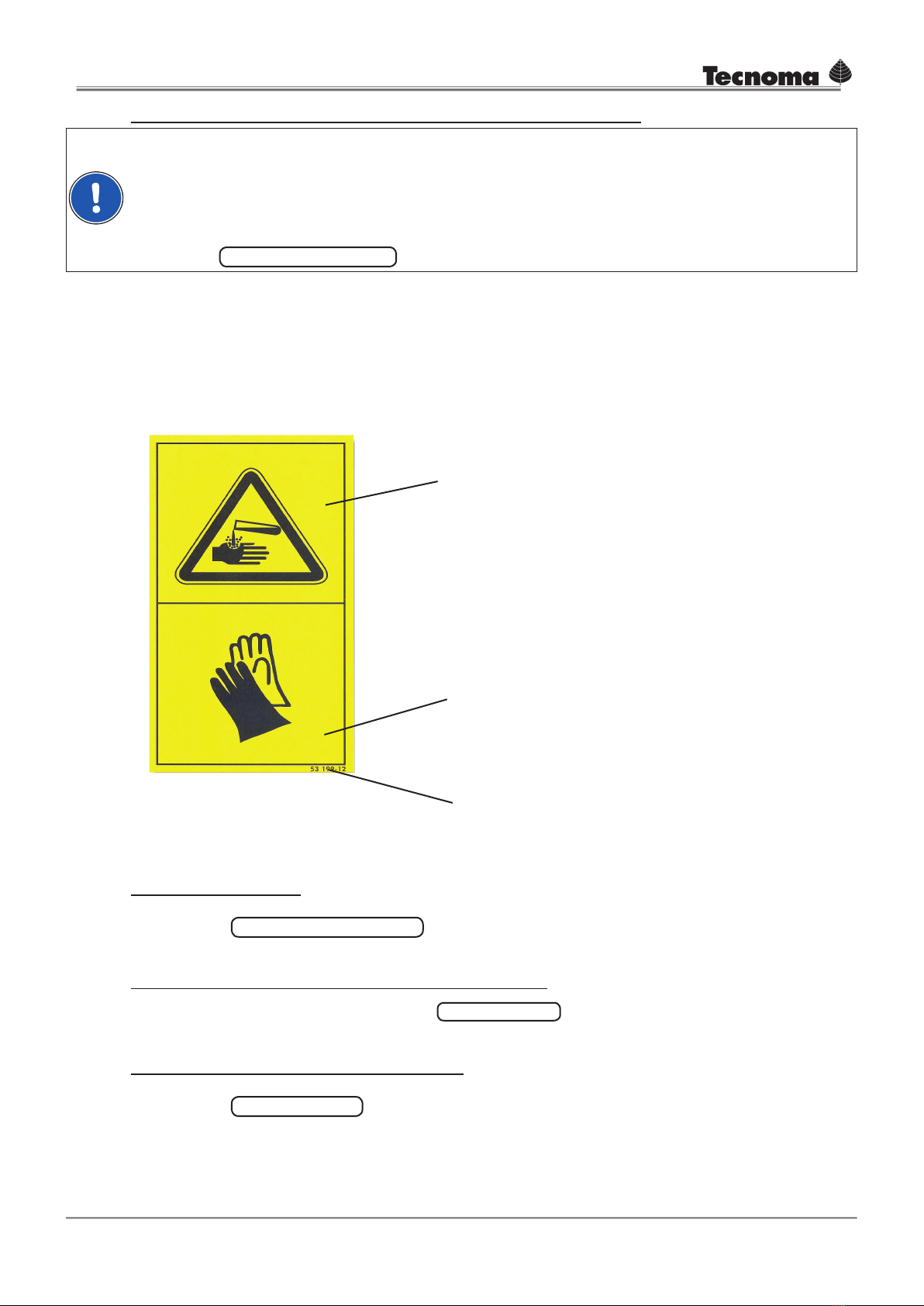

3.6.1 - DESCRIPTION OF WARNING PICTOGRAMS

A warning pictogram indicates an area of potential danger on an apparatus, as well as the risks incurred.

ZONE THAT DESCRIBES THE RISK INCURRED

IN THE FORM OF AN ILLUSTRATION FRAMED

WITHIN A SAFETY TRIANGLE

A warning pictogram has two sectiopns

A SECTION THAT DISPLAYS THE RECOM-

MENDATION WHICH ENABLES THE RISK

TO BE AVOIDED

reference to the pictogram

3.7-GENERIC RISKS

Please read chapter MACHINE MAINTENANCE

in your machine manual.

3.8-CLEANING, MAINTENANCE AND REPAIR

For general machine maintenance refer to chapter

MAINTENANCE of your machine manual

3.9-ENVIRONMENTAL PROTECTION

Please read chapter GENERAL SAFETY

in your machine manual.

JULY-2015 15

CHAPTER 4

4.1-GENERAL CHARACTERISTICS

Since Tecnoma regularly updates the specications of its machines, the following description is not binding.

4.1.1 - VITIFIX BOOM

•Frame tted on a slide on the column Its height can be adjusted by sliding it manually or using the

hydraulic option.

•The upper part of this frame has two horizontal manual slides allowing lateral adjustment of the position of

the guns

•The guns are tted in two manually or electrically adjustable positions in the Telesit option, at the end of

the slides.

•Distribution by two independent solenoid spray valves on each side, controlled by a joystick. Where the

Telesit option is tted or hydraulic lifting is tted, these are also joystick controlled.

•Where hydraulic lifting is tted. (option) requires a DE

•Planned for tting on Vinis, Duo and Vectis

•Standard pneumatic equipment:

◊ 4 hands, 4 guns

•Optional Pneumatic equipment:

◊ 2H/4F tted instead of standard

4H

◊ 2G-S22 tted instead of standard

4G-S17

◊ 4H/3F tted instead of standard

4H

◊ Lower hands behind the unit

(Standard on Vitivario)

◊ Upper 2F hands tted in reverse on arms for Vitix, Vitimobil and Vitivario

4.2-CONFORMITY

Your sprayer is tted with a riveted or glued on identication plate. Refer to chapter

DESCRIPTION OF THE MACHINE

in your sprayer's instruction manual.

4.2.1.1Useful contacts

Refer to chapter

IDENTIFICATION in this manual

4.3-EQUIPMENT FOR ROAD TRAVEL

NOTE

•Read the chapter

DESCRIPTION OF THE MACHINE

in the manual

for your machine.

•Equipment for road travel may:

◊ vary depending on the country.

◊ vary depending on the machine to which the

boom is tted

Fig.2

4 - DESCRIPTION OF THE BOOM

JULY-2015 16

– DESCRIPTION OF THE BOOM –

4.4-TECHNICAL CHARACTERISTICS

NOTE

•Weights and dimensions are given as examples and may change according to the equipment

on your boom.

•Refer to the chapter DESCRIPTION OF THE MACHINE

in the manual for your machine to

obtain the weights and dimensions for the sprayer with the boom tted.

4.4.1 - DIMENSIONS AND WEIGHT OF THE BOOM

BOOM DIMENSIONS ONLY

CONFIGURATION:

4 HANDS 4 GUNS

DIMENSIONS

→ IN METRES

WWIDTH

MINIMUM 1.5

MAXIMUM 2.0

HHEIGHT (b)

MINIMUM 2.30

MAXIMUM 2.90

W

H

Fig.3

WEIGHT OF BOOMS ONLY → in kg

CONFIGURATION

STANDARD EQUIPMENT

BOOM

SHORT

2 HANDS 4 FINGERS,

2 HANDS 2 FINGERS,

4 GUNS, DIAMETER 120 S17

(a)

(a): Value not available at the time this manual went to press

(b): Important, take the height of the hitch into consideration

JULY-2015 17

CHAPTER 5

5 - COMMISIONING

Your Tecnoma authorised distributor is responsible for adaptation to the tractor, installing your machine

and starting it up for the rst time.

5.1-DELIVERY OF THE MACHINE

Refer to the manual for your sprayer

5.1.1 - DELIVERY INSPECTION

Check that the machine delivered is consistent with what was ordered.

5.2-COMMISSIONING

5.1.2 - OPERATOR QUALIFICATION

The person preparing the machine must be qualied to carry out the operations covered in chapter

COMMISIONING

Before the machine is commissioned,

the user must have read and understood the manual.

5.1.3 - CHECK ON THE REQUIRED TRACTOR CHARACTERISTICS

Refer to the manual for your sprayer

5.3-ADDITIONAL DOCUMENTATION

Refer to the manual for your sprayer

5.4-PREPARATION

• The sprayer must be lubricated (see "Maintenance" chapter).

• The sprayer must be hitched to the tractor.

• the boom must be set up on a at surface.

• The boom must be unfolded.

• Depending on which boom you have, the cant corrector or the GVs must be in the neutral position.

• The boom must be set up with the hydraulic circuit de-pressurised.

5.5-ELECTRICAL CONNECTION

Refer to the manual for your sprayer.

JULY-2015 18

– COMMISIONING –

5.6-ADJUSTING THE BOOM

NOTE

Depending on your crops, you may need to adjust the position of the guns, hands or Precijet.Refer to

"POSITIONING THE SPRAYER PARTS" in chapter USE .

NOTE

If the hydraulic lifting option is not tted, the boom height may be adjusted manually.

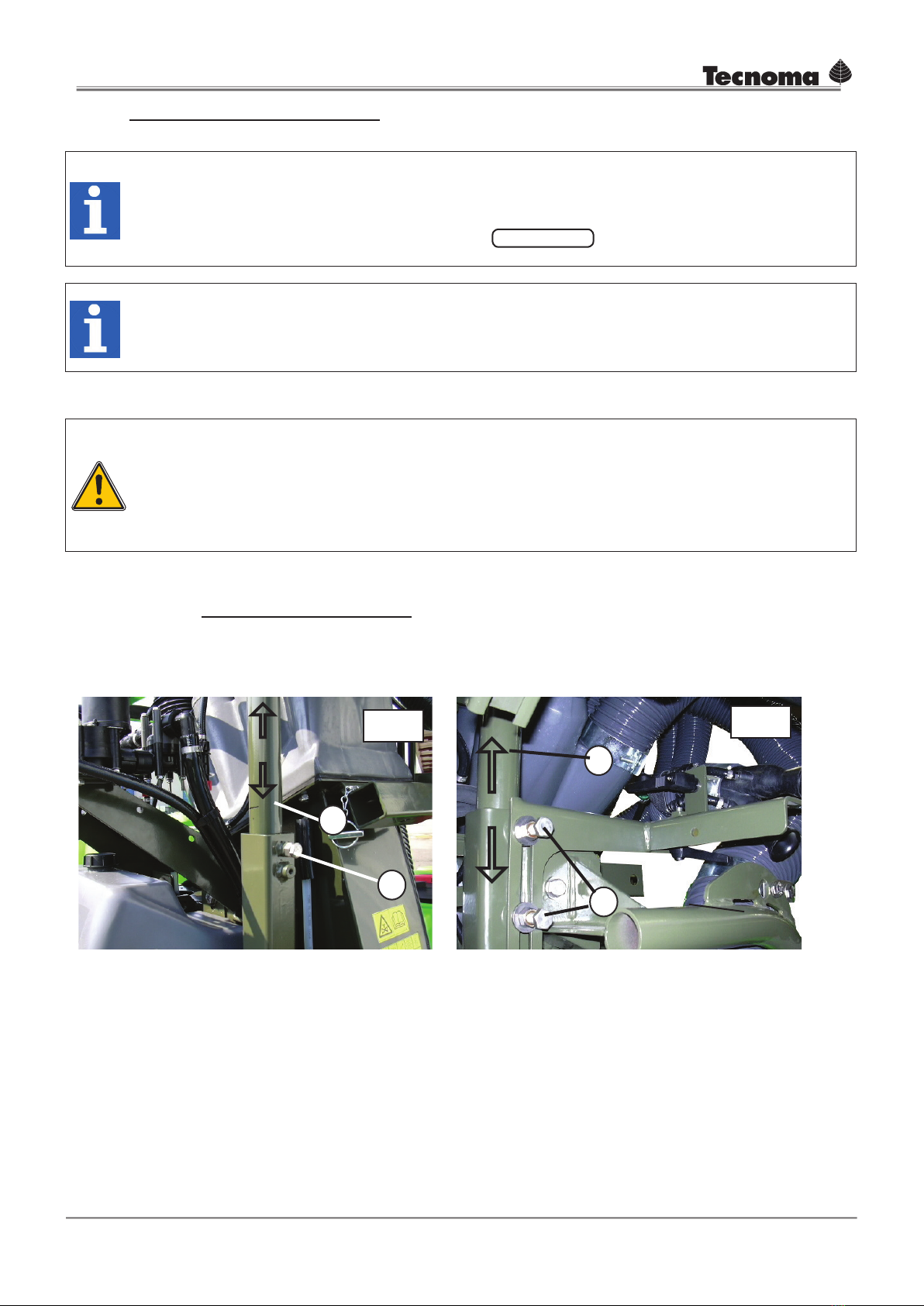

5.1.4 - MANUALLY SETTING THE HEIGHT OF THE FRAME

WARNING

There is the risk of accidents when adjusting the boom height manually.

•Any person not involved in making the adjustment should be kept at a distance.

•Secure the boom using a hoist.

5.6.0.1 Raising or lowering the frame,

1. Loosen the two tubes on the frame (B) bolts (A)

2. Lift the frame (B) to the desired height.

3. Tighten the bolts (A)

Fig.4

A

B

VINIS - DUO

Fig.5

B

A

VECTIS

JULY-2015 19

CHAPTER 6

6 - USE

6.1-RECOMMENDATIONS PRIOR TO USE

DANGER

Risk of electrocution from electrical contact with the boom

Refer to the safety instructions and do not forget the machine's maximum height. See

Sprayer dimensions in section DESCRIPTION OF THE MACHINE

IMPORTANT

Risk of damage to the boom!

• Adopt a forward speed suitable for the terrain and do not make any sudden movements. This will

prolong the life of the boom.

• Check regularly that the boom is correctly adjusted.

• Follow the recommendations with regard to maintenance and greasing moving parts.

IMPORTANT

Risk from poor handling!

Check regularly that nozzles are clean;

check their ow rates.

IMPORTANT

• When using the machine, follow the safety instructions in the "Risks associated with use of the

machine" paragraph in section GENERAL SAFETY

• following these instructions will contribute to your safety.

IMPORTANT

To ensure that the machine operates correctly, the specications in the "TECHNICAL FEATURES"

paragraph in chapter DESCRIPTION OF THE MACHINE

and the structures and functions descri-

bed in the paragraph should be checked regularly by a Tecnoma authorised dealer.

JULY-2015 20

– USE –

NOTE

For any problems in use

Contact your nearest Tecnoma authorised dealer.

Its staff have been trained on Tecnoma equipment and are fully qualied to assist your in obtaining

maximum efciency from your sprayer.

6.2-POSITIONING THE BOOM

6.2.1 - ADJUSTING THE HEIGHT

NOTE

If you do not have the hydraulic lifting option, the boom may be raised manually.

Refer to paragraph "RÉGLAGE MANUELLE DE LA HAUTEUR DU PORTIQUE", page 18

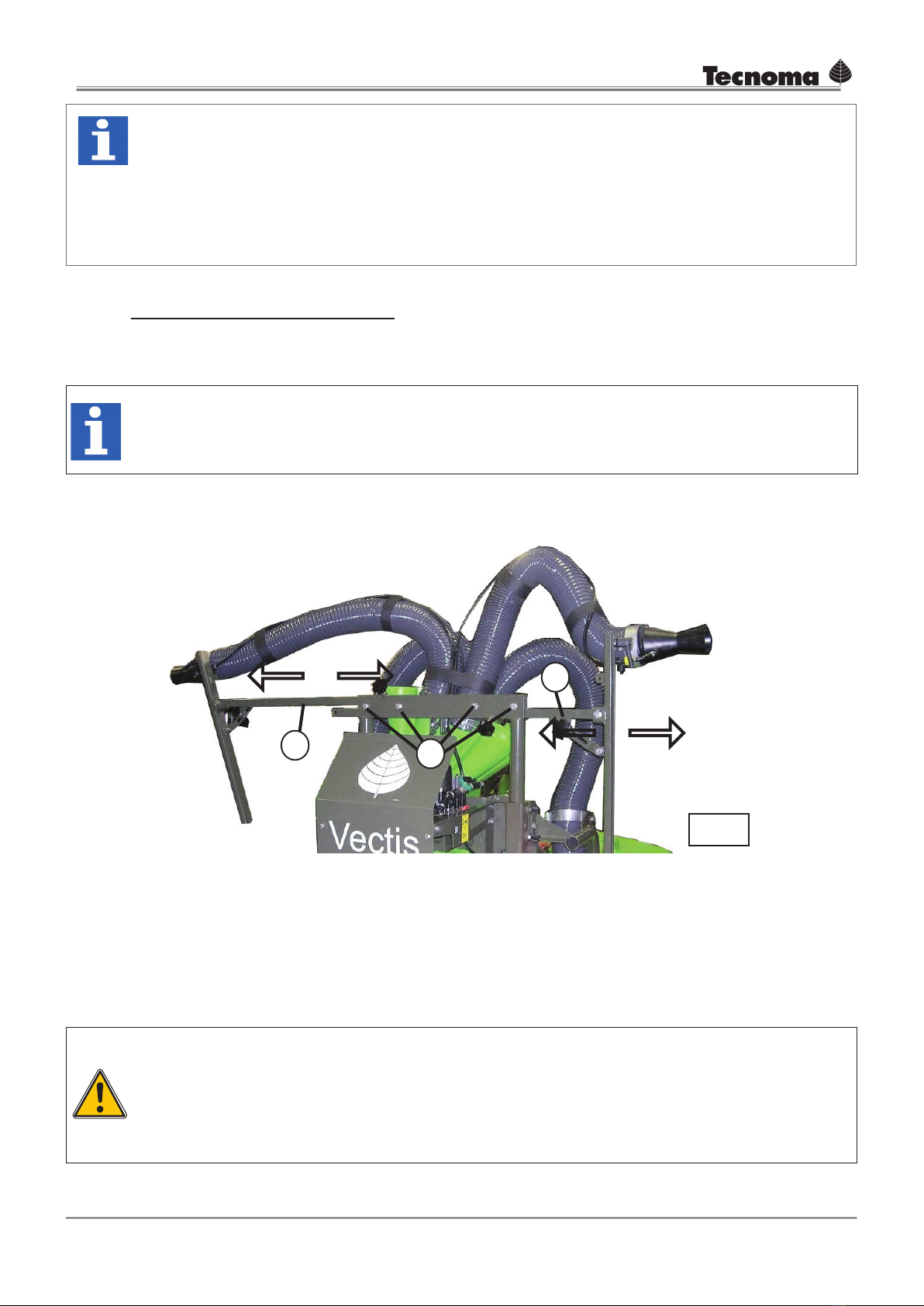

6.2.2 - ADJUSTING THE WIDTH OF THE BOOM

Fig.6

1

2

2

To modify the width of the boom, as necessary, slide the arms in or out:

•To slide the arms:

1. Loosen the locking screws (1),

2. slide the arms (2) to the desired position,

3. re-tighten the locking screws.

6.2.3 - BOOM POSITION FOR TRANSPORT

WARNING

Risk of accidents from tipping, attaching the boom to the transport without folding the arms!

When work has been completed, always retract the arms before any transport operation.

To retract the arms, refer to paragraph "Adjusting the width of the boom", page 20

Table of contents