Spraying Systems AutoJet 1000+ User manual

Other Spraying Systems Paint Sprayer manuals

Spraying Systems

Spraying Systems GunJet 60 User manual

Spraying Systems

Spraying Systems CW1500A Series User manual

Spraying Systems

Spraying Systems 1550+ AutoJet User manual

Spraying Systems

Spraying Systems AutoJet 1000+ User manual

Spraying Systems

Spraying Systems GunJet CU150A User manual

Spraying Systems

Spraying Systems AutoJet 1750+ User manual

Spraying Systems

Spraying Systems PulsaJet 10000AUH-03-Z1 User manual

Spraying Systems

Spraying Systems GunJet PW4000A User manual

Spraying Systems

Spraying Systems PulsaJet 10000AUH-03-Z1-EPFC User manual

Spraying Systems

Spraying Systems GunJet AA27H User manual

Spraying Systems

Spraying Systems GunJet 80 User manual

Spraying Systems

Spraying Systems GunJet 60-21580 User manual

Spraying Systems

Spraying Systems Teejet 845-AB User manual

Spraying Systems

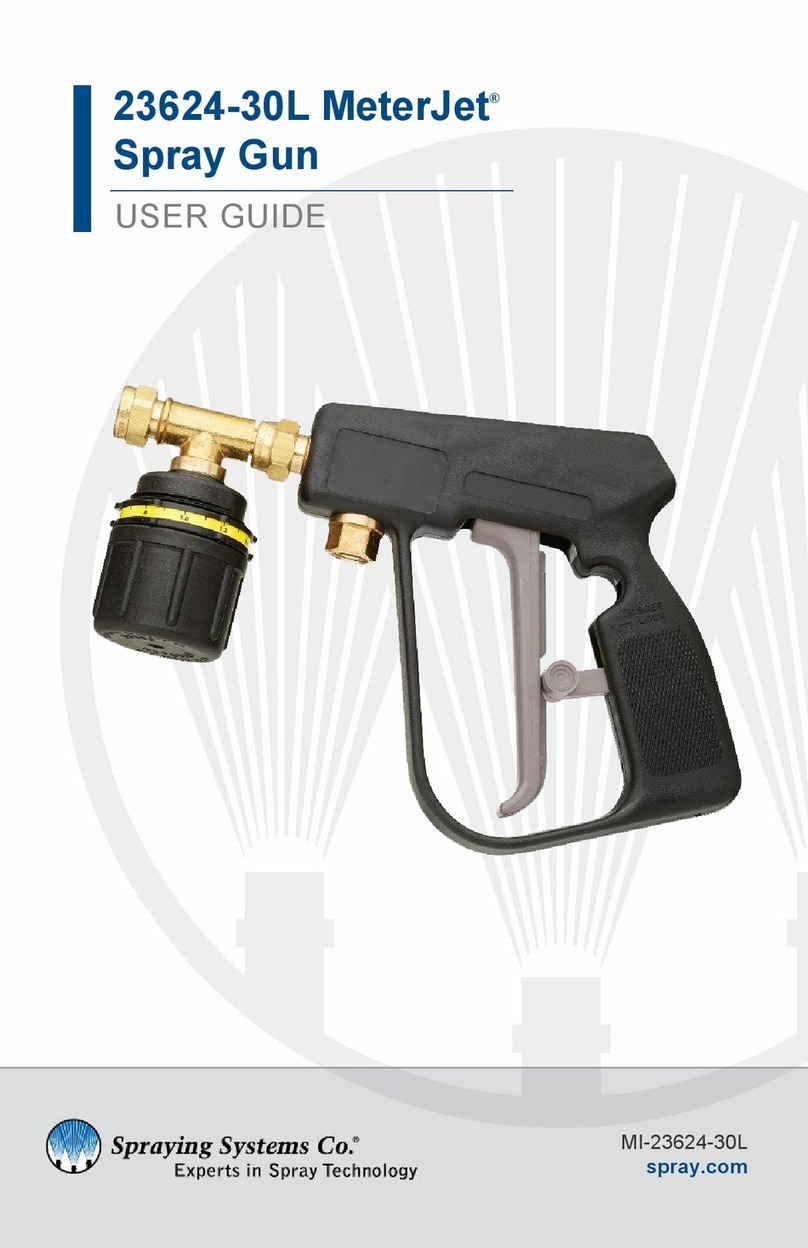

Spraying Systems MeterJet User manual

Spraying Systems

Spraying Systems TeeJet TECHNOLOGIES BoomPilot User manual

Spraying Systems

Spraying Systems TeeJet TECHNOLOGIES BoomPilot User manual

Spraying Systems

Spraying Systems TeeJet TECHNOLOGIES BoomPilot User manual

Spraying Systems

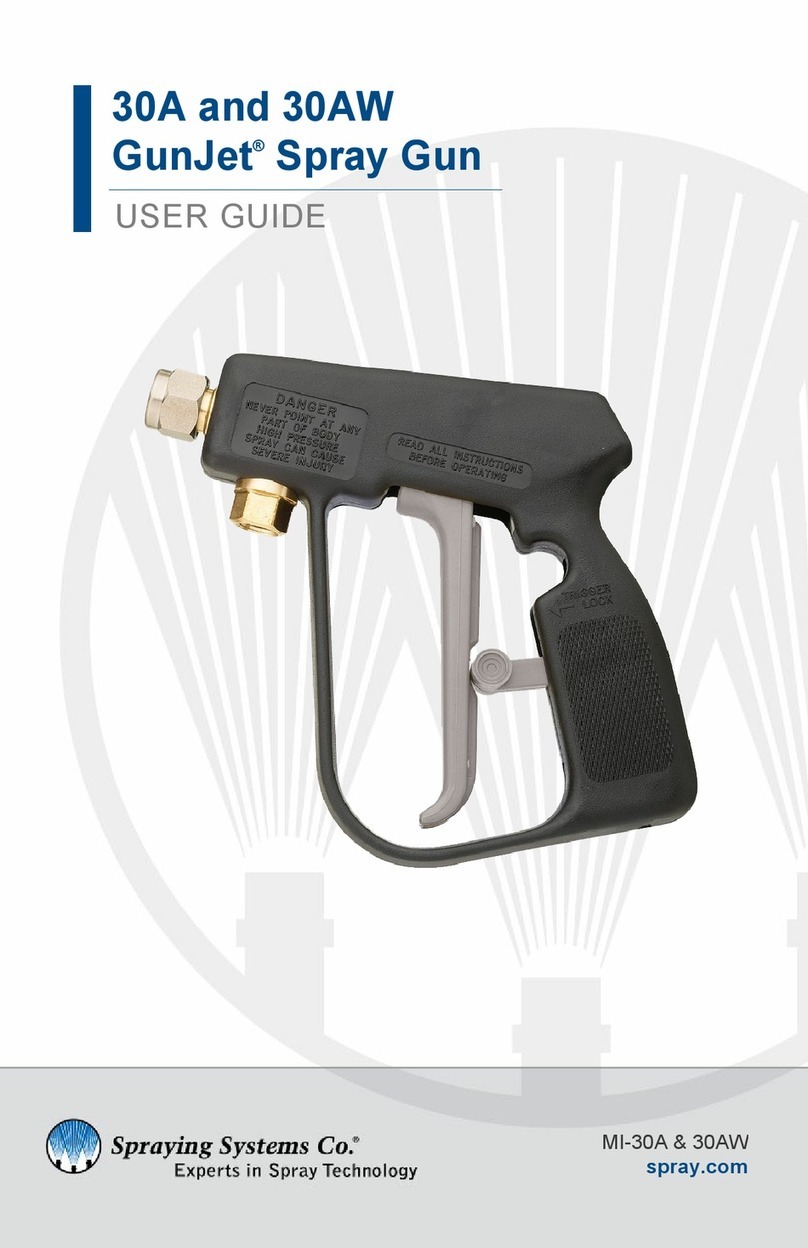

Spraying Systems GunJet 30A User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual