TECNOTER LQMP User manual

P

PERMANENT

ERMANENT H

HYDRAULIC

YDRAULIC M

MAGNET

AGNET

LQMP

LQMP

V

VER

ER. 102Q

. 102Q

User manual

Rev. 1.0

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 1/26 Rev: 2.0 – 02/08/2020

Index

0 INTRODUCTION.............................................................................................................................3

1 Scope of the manual......................................................................................................................3

2 How to read the manual................................................................................................................4

3 Preservation of the manual...........................................................................................................5

4 Update of the manual....................................................................................................................5

5 Addressees....................................................................................................................................5

1 GENERAL INFORMATION............................................................................................................6

1 Manufacturer data.........................................................................................................................6

2 Customer responsibilities..............................................................................................................6

3 Declarations and load limits.........................................................................................................7

Load limits..................................................................................................................................7

4 Safet ...........................................................................................................................................8

2 HANDLING, STORAGE, DECOMMISSIONING AND CONTENT...........................................10

1 Handling......................................................................................................................................10

2 Storage........................................................................................................................................11

3 Decommissioning.......................................................................................................................12

4 What is necessar to activate the s stem....................................................................................13

3 PARTS.............................................................................................................................................14

1 Parts identification......................................................................................................................14

4 INSTALLATION.............................................................................................................................16

1 S stem installation......................................................................................................................16

5 USE..................................................................................................................................................19

1 Operations...................................................................................................................................19

6 MAINTENANCE............................................................................................................................22

1 State of maintenance...................................................................................................................22

2 Machine insulation......................................................................................................................22

3 Cautions......................................................................................................................................22

4 Maintenance operations..............................................................................................................23

Lower shield..............................................................................................................................23

Chains and suspension bolts.....................................................................................................23

Storage......................................................................................................................................23

Scheduled maintenance.............................................................................................................23

7 SPARE PARTS................................................................................................................................24

1 Assistance ...................................................................................................................................24

2 Spare parts ..................................................................................................................................24

3 Limited warrant .........................................................................................................................24

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 2/26 Rev: 2.0 – 02/08/2020

0 INTRODUCTION

1 Scope of the manual

This instruction manual is part of the machine and it provides all the necessar information to:

•manipulation of the machine, packed and unpacked in safet conditions

•correct assembl of the machine

•thorough knowledge of its operation and its limits;

According to the current regulations, the responsible of the departments where this machine

will be assembled must read carefully the content of this instruction manual and make sure

that the employees read it.

Time spent for this purpose will be rewarded by the correct functioning of the machine and by

its use in safety conditions.

This document assumes that the plants where this machine will be set compl with the current

safet regulations and h giene conditions.

Instructions, drawings and documentation contained in this manual are reserved and intellectual

propert of the manufacturer, and the cannot be full or partiall reproduced.

If the manufacturer made an change in this manual, the customer must verif that onl updated

versions of it would be present in site where the machine is used.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 3/26 Rev: 2.0 – 02/08/2020

2 How to read the manual

Manual is divided into autonomous chapters, and it is addressed to assemblers with the necessar

skills to operate on the machine in safet conditions.

The instruction manual is composed b a cover, a table of contents and a series of chapters

(sections).

PAGE UMBERI G

Company Product ame Model Arrangement Page no. Revision no.

TABLES UMBERI G

Ever table is numbered progressivel

Numbering starts from “1” at ever section.

Numbering is composed as follows:

ABBREVIATIO S

Sect. = Section

Ch. = Chapter

Par. = Paragraph

Pag. = Page

Fig. = Figure

Tab. = Table

U IT OF MEASURE

Units from the International S stem of Units (SI)

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 4/26 Rev: 2.0 – 02/08/2020

Tecnoter AME MODEL ARRA G. 5/36 REV. - DATE

3 Preservation of the manual

Instruction manual should be carefull preserved and it has to accompan the machine in ever

change of ownership.

Preservation should be facilitated b a careful handling, with clean hands and it shouldn't be put on

dirt surfaces.

You don't have to eliminate, tear or change an part.

Manual has to be filed in an environment without humidit and heat and near the machine it refers

to.

Manufacturer can suppl further copies of the instruction manual on demand of the User.

4 Update of the manual

Manufacturer has the right to modif and make improvements to the machine without

communicating it to the customers, and without updating the manual alread in hands of the user.

Moreover, the manufactures has to send the updated manual for an agreed change of the machine

at the customer's site.

User is responsible for changing the old chapters, the cover and the table of contents with the new

ones in ever owned cop .

5 Addressees

This manual addresses to the operator, the assembler and the maintenance technicians.

OPERATOR: one or more people that assembl or do the maintenance of a machine;

QUALIFIED PERSO EL OR OPERATOR: people that attended specialization courses and

that have experience in assembl and maintenance of the machine.

Qualification of addressees

The machine is intended for industrial and therefore professional use, so its use is addressed to

qualified technicians that:

•are of age;

•are ph sicall and ps chicall apt to do technicall difficult jobs;

•have been properl instructed on use and maintenance of the machine;

•are judged b the emplo er as suitable to do the designed job;

•have the skill of assembl and operating the specific t pe of equipment;

•have familiarit with the specific regulations of the matter.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 5/26 Rev: 2.0 – 02/08/2020

1 GENERAL INFORMATION

1 Manufacturer data

Tecnoter srl

Via Carlo Alberto dalla Chiesa 6

20098 San Giuliano Milanese (MI)

P. Iva 13072070157

After sales service / spare parts

Via Carlo Alberto dalla Chiesa 6

20098 San Giuliano Milanese (MI)

Tel.: 02.9824.8180

Fax: 02.9824.7605

www.tecnotergroup.com

2 Customer responsi ilities

1. Make sure the work area is compliant with the safet requirements set forth in current

legislation in the countr where the magnet is used.

2. Check that all the work equipment made available to the operators compl with the

safet requirements established b the legislation in force in the countr where the

lifting s stem is installed and used.

3. Check the correctness of oil flow and pressure setting.

4. Make sure the operator has been adequatel instructed about safe use and hazardous

situations.

5. It is the user/customer's responsibilit to observe and carefull follow the instructions

contained in this manual.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 6/26 Rev: 2.0 – 02/08/2020

3 Declarations and load limits

The machine is manufactured in conformit with the corresponding EU Directives.

This manual, which includes also the instructions for use, does not replace the individual national

legislation as the Machiner Directive.

The machine is designed to handle iron plates and parts according to the limits and features

indicated in the next pages. For no reasons different applications can be considered using this

device.

This machine is designed to be h draulicall operated. H draulic connections and h draulic

parameters (flow, pressure, temperature, viscosit and oil t pe) have to be carefull controlled

before operate the s stem itself.

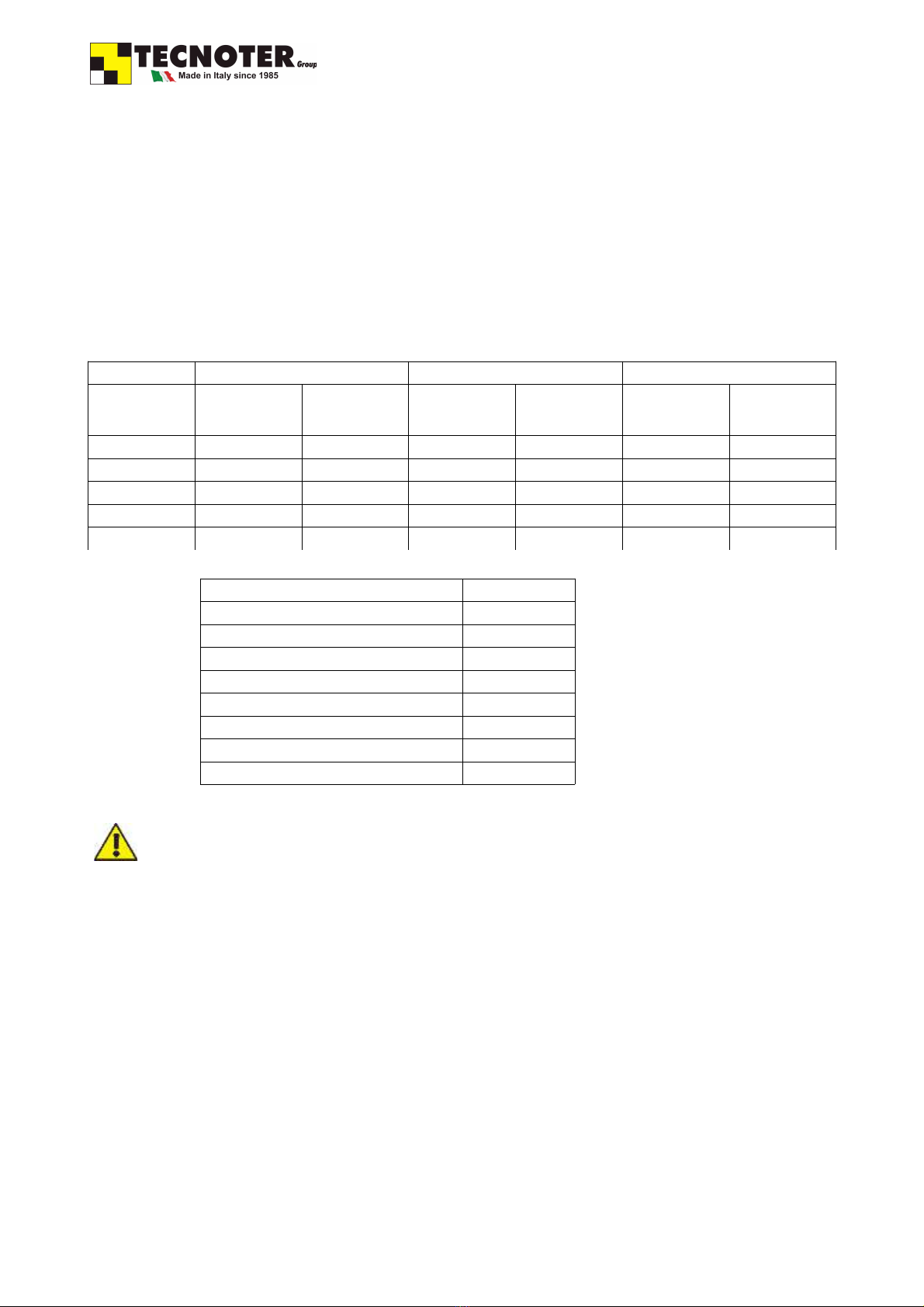

Load limits

Air gap < 0,3 mm Air gap 0,3 – 0,6 mm Air gap 0,7 – 0,8 mm

Material

thickmess

mm

Max load

Kg

Max

dimensions

mm

Max load

Kg

Max

dimensions

mm

Max load

Kg

Max

dimensions

mm

>= 10 700 220x1500 600 2200x1500 500 2200x1200

>= 15 1200 2500x1500 1000 2500x1500 900 2500x1200

>= 20 1800 3000x1500 1500 3000x1500 1300 3000x1200

>= 25 2000 3500x1500 1700 3000x1500 1500 3000x1200

Ø 100-450 1000 4500 800 4000 650 3000

Material Load power

Carbon Steel 0,1 - 0,3 % C ST37/52 100%

Carbon Steel 0,4 - 0,5 % C 90%

Allo Steel 2312/2379... 80% - 90%

Cast Iron GGG 70% - 80%

Cast Iron GG 45% - 60%

Allo Steel hardened at 55-60 HRc 40% - 50%

Stainless Steel No load

Brass, Aluminum, Copper No load

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 7/26 Rev: 2.0 – 02/08/2020

4 Safety

WARNING!

NEVER operate or maintenance this machine before the complete reading and perfect

understanding of this manual.

To operate the machine under an operating condition, including maintenance, it is not necessar

that more than one person be present.

Staff have to be instructed on the risks of accidents, on safet devices and on the general rules

concerning prevention and protection, as established b the European Communit Directives and b

the current legislation in the countr where the machine is installed.

The operator should be aware of the location and operation of all controls and of all the machine

features.

The operator should also have read the entire manual.

Onl skilled technicians should carr out maintenance jobs, after having dul prepared the machine.

Unauthorized tampering or replacement of an parts of the machine ma generate potential risks or

injuries as well as the use of not recommended items.

Hazardous areas have been considered during the engineering process and, therefore, all necessar

precautions have been taken to avoid risks to people and damage to the machine components.

The machine is equipped with fixed protections able to prevent access to moving parts and parts

under h draulic pressure.

Remaining residual risks can be eliminated or reduced adopting opportune precautions regarding

•Risk of bruises, tearing, cuts

•Risk of contamination b oil and/or oil high pressure

•Risk of magnetic fields

WAR I G!

•The operator shall use personal protection devices.

•Never use this device for unauthorized operations.

•Never operate the s stem if there is an possibilit of personal injur .

•Never operate the s stem out of the working parameters.

•Never remove the protections when the machine is running.

IMPORTA T!

To prevent an risk related to the use or storage of this s stem, strictl observe all the safet and

maintenance prescriptions.

Please don't hesitate to contact Tecnoter group for an detail or information.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 8/26 Rev: 2.0 – 02/08/2020

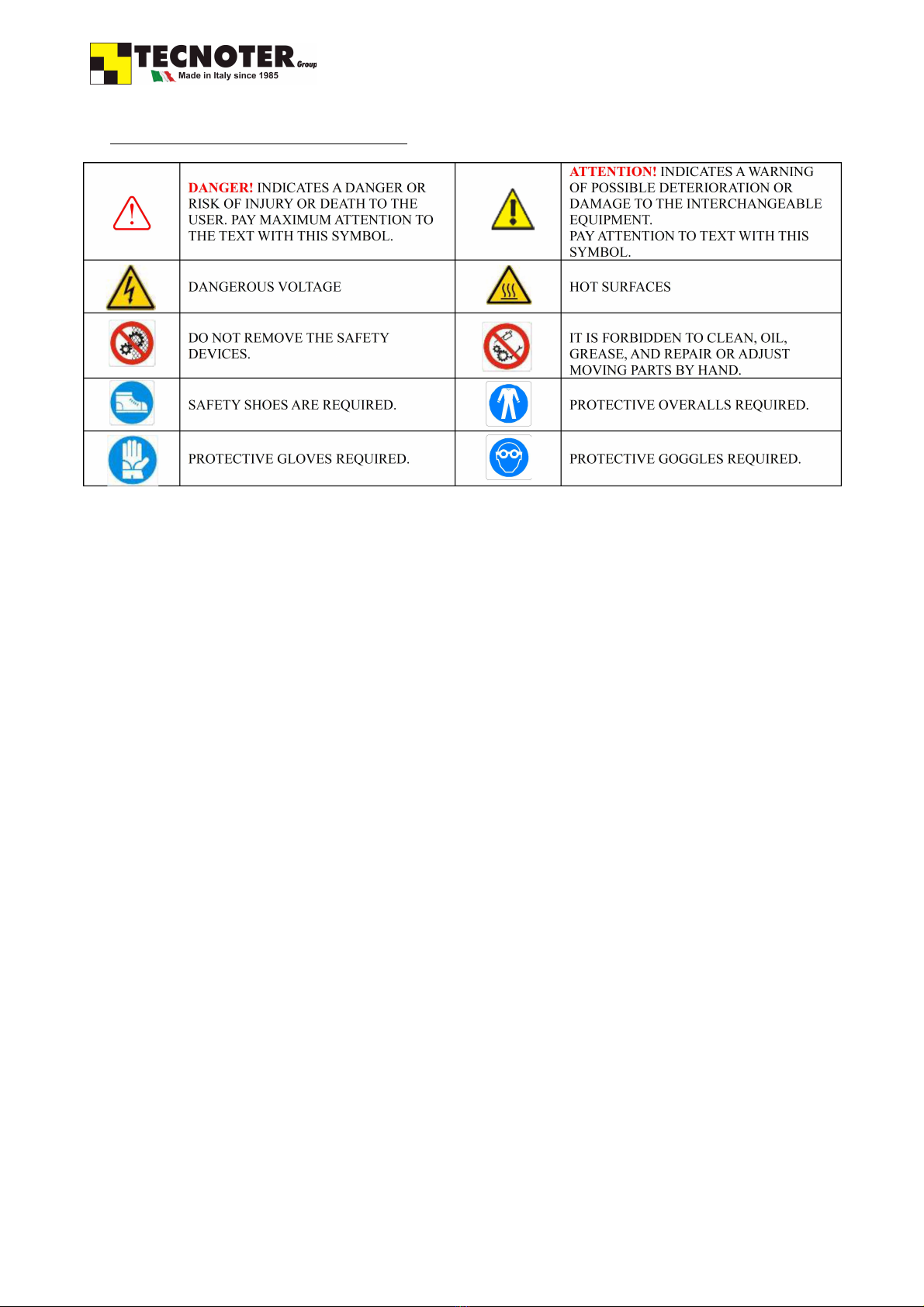

SYMBOLS RELATED TO SAFETY

THE SYMBOLS IN A TRIANGLE INDICATE A HAZARD.

THE SYMBOLS IN A CIRCLE INDICATE A REQUIREME T/PROHIBITIO .

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 9/26 Rev: 2.0 – 02/08/2020

2 HANDLING, TORAGE, DECOMMI IONING AND CONTENT

1 Handling

The s stem is stored on a pallet or crate. Upon receipt of the s stem, be sure to completel inspect

the machine for an signs of possible shipping damage. The carrier should be immediatel notified

of damage or missing parts.

Removal from Shipping Crate:

1. Open the crate top using the appropriate tool.

3. Remove the accessories (if an ) and store them in a appropriate location.

4. Carefull , lift the s stem carr ing it b the base or connecting appropriate cranes to the

lifting points.

WAR I G!

Maintain control over the movement of the s stem.

System Inspection

Inspect the s stem for visible signs of damage, evidence of oil leaks, and check the accessories, if

an . The carrier shall be immediatel notified of damages or missing parts.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 10/26 Rev: 2.0 – 02/08/2020

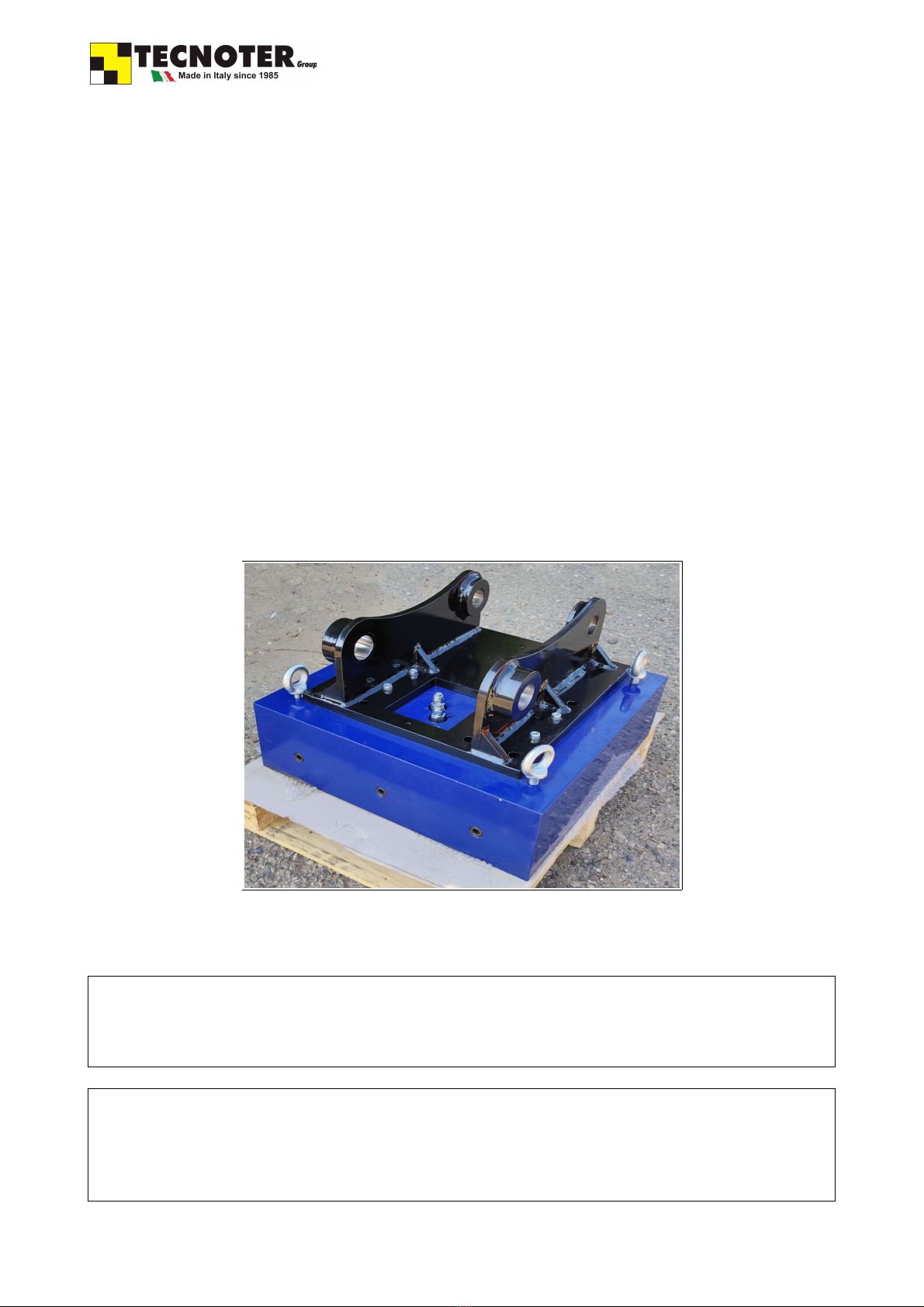

Machine la out

2 Storage

The s stem is protected against corrosion and deterioration for the shipment period and for a

relativel short period.

In an case it is suitable to keep the s stem in a dr place, protected against atmospheric agents.

In wet climates, to protect the electrical, h draulic and mechanic components the machine should be

kept in a heated room or closed in a barrier - bag with heaters or light bulbs.

WAR I G!

Plug the h draulic manifold's ports.

Using a plastic bag, seal the inlet and outlet cooling ports.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 11/26 Rev: 2.0 – 02/08/2020

3 Decommissioning

Decommissioning the machine does not involve an special precautions, onl collection of the oil

contained in the machine, h draulic valves and motor and components of the h draulic s stem.

WAR I G!

Both these elements and the oil should be collected and dumped in compliance with the current

regulations on the environment in order to avoid an pollution and danger of fire.

When the s stem has reached the end of its technical and operating life, it can be demolished, i.e.

decommissioned and put in such a condition so as not to be used an longer for the purposes it was

designed and built, with the possible rec cling of raw materials.

NOTE

Tecnoter group will not take an responsibilit for damage to people or objects that ma derive

from the rec cling of individual components of the machine, for operation or assembling situations

different that the original ones.

WAR I G!

The deactivation and dismantling of the machine should be carried out onl b dul trained and

equipped staff and strictl following the applicable laws and the up-to-dated technical solutions.

Act as follows to deactivate the machine permanentl :

•Set the s stem in UNLOAD condition

•Discharge oil pressure

•Drain all oils

•Disconnect the s stem from the host machine

•Lift and manage the s stem as indicated in the specific section

•Disassemble the s stem main components and clean them

•Block all the s stem moving parts

•Take all s stem machine components in supervised dumps

Residual risks after deactivation

After deactivating the machine, there are no residual risk if all moving parts have been dul blocked

and cleaned.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 12/26 Rev: 2.0 – 02/08/2020

4 What is necessary to activate the system

The s stem is designed to be used in several different applications and to be connected to several

different host machines.

The s stem shall be completed with:

–Specific support for the host machine

–Connecting hoses

WAR I G:

an incorrect support ma damage the s stem and the host machine.

–Medium pressure two wa s line must be present aboard the host machine

Ideal hydraulic setting: 5 l/min at 40 bar

Acceptable h draulic range

Oil flow: 5 to 30 l/min

Oil pressure: 40 to 100 bar

WAR I G:

overflow and/or over pressure may damage the system and causes injuries

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 13/26 Rev: 2.0 – 02/08/2020

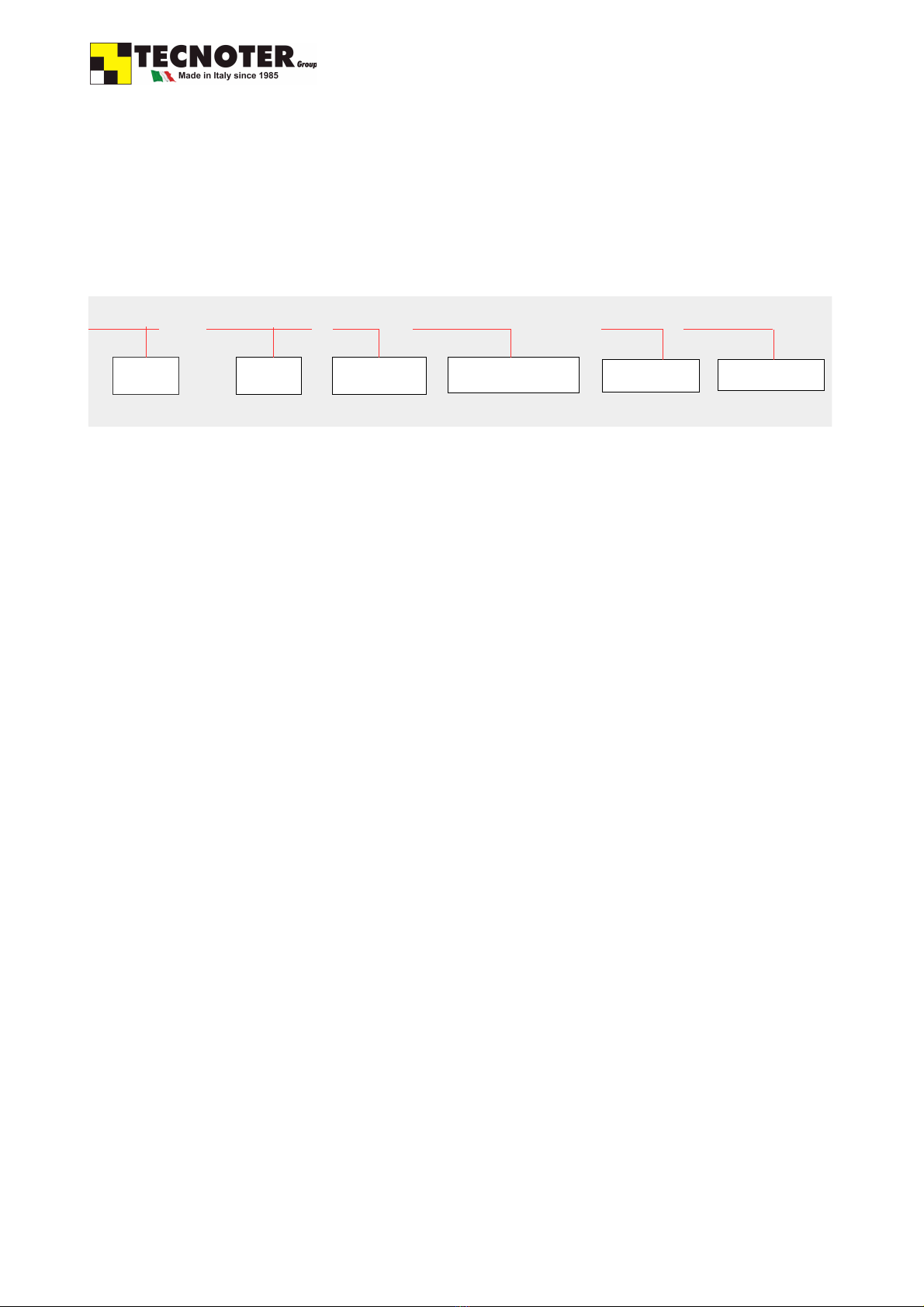

3 PART

1 Parts identification

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 14/26 Rev: 2.0 – 02/08/2020

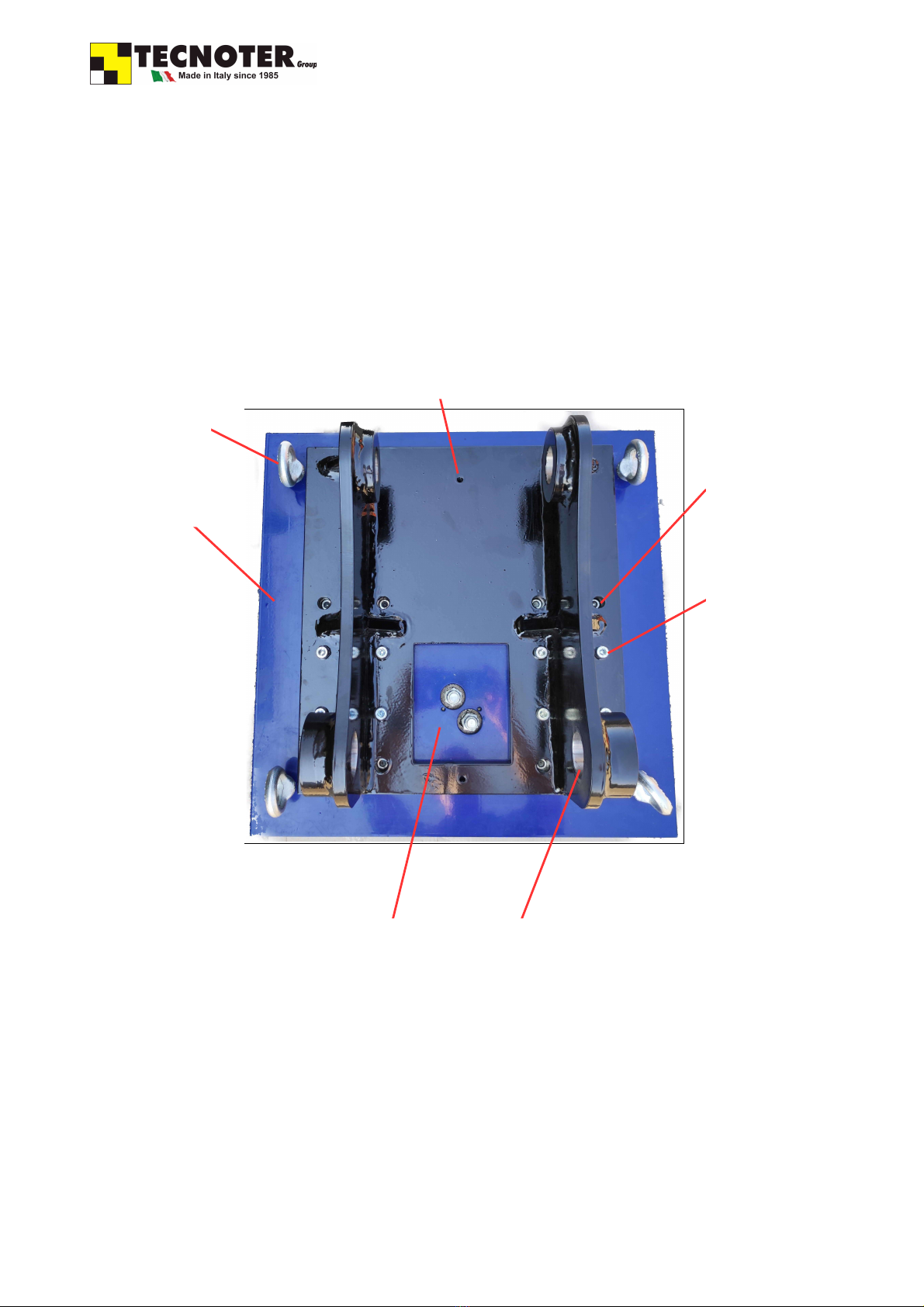

Lifting e es(*)

Chassis

Hoses fixing holes - two

H draulic ports Bracket(*)

(*) = option

Internal bolts

8 units

Bracket bolts(*)

10 units

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 15/26 Rev: 2.0 – 02/08/2020

Magnetic units

Shield

4 IN TALLATION

1 System installation

Prepare an opportune area considering the size of equipment and host machine.

The installation area must be large enough for:

•Operating space

•Passage (forklifts, etc.)

•Escape routes

Warning:

•Suitable lifting equipment have to be available

•Make sure personnel are equipped with PPE for the activit and in compliance with

current legislation in the countr where the magnet is installed/used.

•As much as possible, the operational area must be free of material that can impede or limit

vision, create obstructions or danger.

•Access to the area involved in the operation must be inhibited using protective barriers

(road barriers).

ATTE TIO !

It is the customer's responsibilit to make sure the floor supports the static/d namic load

of the magnet and host machine

DA GER!

Before operating the s stem, make sure that the fixed guards and safety devices on

the host machine are correctl installed.

DA GER!

Before operating the s stem, cordon off the area and verif the presence of signs

alerting persons with pacemakers.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 16/26 Rev: 2.0 – 02/08/2020

!

!

CO ECTIO S

To operate the h draulic magnet, the host machine must be equipped with an adequate h draulic

s stem as below indicated.

Required h draulic s stem t pe:

two ways (double action), closed center

Recommended features:

Flow: 5 l/min

Pressure: 40 bar

Oil type: Hydraulic from SAE 10 to SAE 46

Oil temperature: < 70 °C

Acceptable range:

Oil flow: 3 to 30 l/min

Oil pressure: 40 to 100 bar

DA GER!

Incorrect oil setting ma permanentl damage the s stem

Attention! It is the responsibilit of the user to ensure that the machine complies with the

following conditions:

Upon switching off of the machine, all the h draulic flows to and from the magnet must

terminate.

An residual pressure present in the h draulic circuit (depressurization) must be safel

eliminated before an activities of installation, maintenance or adjustment can be performed

on the magnet.

DA GER ! Temperature and toxicity of hydraulic oil

H draulic oil can reach ver high temperatures.

Before carr ing out an operation that involves the possibilit of coming into

contact with h draulic oil, it is necessar to wait until it cools. H draulic oil is toxic and

can cause injur to persons if it is in contact with the skin and e es. See also the instructions

displa ed on the machine.

Connection operations:

1. Strictl following the instructions indicated in the section “Handling” of this manual,

carefull lift the s stem set and fit it in the installation place

2. Using an appropriate bracket or four-branches-chain, connect the magnet to the host

machine

3. Connect A and B h draulic ports to the oil suppl lines

The s stem is now read for use

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 17/26 Rev: 2.0 – 02/08/2020

The following actions are strictly forbidden:

1. To pass, stand, operate, or manoeuvre underneath the hanging load

2. To allow the s stem to be used b non-qualified personnel

3. To use the s stem if not in suitable mental and ph sical condition

4. To put hands on the chain or hook during the tensioning phase

5. To leave the hanging load unsupervised

6. To engage loads heavier or wider than the nominal capacit

7. To let the load swing during movement

8. To use the s stem for pulling, dragging or tensioning other items

9. To bang the structure of the building or other machines and s stems with the load

10. To use the s stem in unforeseen environmental conditions

11. To perform temporar repairs or operations not set forth in the instructions

12. To use non-original replacement parts or those not recommended b the manufacturer

13. To use the magnet as a hammer or mallet

14. To use the magnet on hot materials

15. To lift "guided" loads.

These prescriptions MUST be followed:

1. Strictl follow safet regulations in force in the countr where used

2. Follow all danger and safet precautions

3. Onl use the s stem in areas free from persons, animals and dangerous items

Attention The s stem is a powerful magnetic field generator. It is absolutel forbidden

for individuals with pacemakers or artificial cardiac stimulators to be near it.

Intense magnetic field (E 12198)

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 18/26 Rev: 2.0 – 02/08/2020

5 U E

1 Operations

Permitted load:

The loads must consist of ferromagnetic plates and parts.

Strictl follow the indications contained in the below tables.

Air gap < 0,3 mm Air gap 0,3 – 0,6 mm Air gap 0,7 – 0,8 mm

Material

thickmess

mm

Max load

Kg

Max

dimensions

mm

Max load

Kg

Max

dimensions

mm

Max load

Kg

Max

dimensions

mm

>= 10 700 220x1500 600 2200x1500 500 2200x1200

>= 15 1200 2500x1500 1000 2500x1500 900 2500x1200

>= 20 1800 3000x1500 1500 3000x1500 1300 3000x1200

>= 25 2000 3500x1500 1700 3000x1500 1500 3000x1200

Ø 100-450 1000 4500 800 4000 650 3000

Material Load power

Carbon Steel 0,1 - 0,3 % C ST37/52 100%

Carbon Steel 0,4 - 0,5 % C 90%

Allo Steel 2312/2379... 80% - 90%

Cast Iron GGG 70% - 80%

Cast Iron GG 45% - 60%

Allo Steel hardened at 55-60 HRc 40% - 50%

Stainless Steel No load

Brass, Aluminum, Copper No load

ATTE TIO

To lift loads exceeding the maximum defined in the technical data sheet is strictl

not permitted.

If the magnet is connected to the host machine through a rigid bracket, do not shake it

violently.

Environmental conditions

The s stem doesn't require particular environmental conditions.

Allowed temperatures from -10° to 50° C, with humidit not higher than 50% at 40° C or, not

higher than 70% at 20° C.

WARNING: the machine is not suitable for use in environment with explosive or corrosive

atmosphere or with excessive presence of dust.

The underwater use of this equipment is strictly not allowed.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 19/26 Rev: 2.0 – 02/08/2020

MAG ET ACTIVATIO

1. Make sure the area has been cordoned off, danger signs are well visible and no people,

animals or objects are present in the host machine working

2. Put the magnet in direct contact with the surface to be load

3. Deliver oil trough the port A for a few seconds to activate the magnet

4. Carefull lift the load and verif its stabilit

5. Deliver oil trough the port B for a few seconds to release the load

In order to optimize lifting of the load, the following factors must be taken into consideration:

Con t

act s ur f

ace

Parts to be lift shall be in direct contact with the magnet.

The greater the surface area with which the magnet comes into contact with the piece to be lifted,

the greater the force with which the piece itself is lifted.

S u pe

r fi

c i

al f i

n i

s h

A good surface of contact with the magnetic lifter considerabl diminishes the gaps (the empt

spaces between the magnet and materials) thus obtaining a consistent force of magnetic anchorage.

M

a te

r i

al

The lifting material must be a magnetic conductor. Material with the highest conductivit is mild

steel (ferromagnetic), while the worst is aluminum (diamagnetic).

THE HYDRAULIC MAGNET MUST OT BE USED FOR ANYTHING OTHER THAN

THOSE SET FOR and therefore IT IS FORBIDDE to use it in conditions other than those

mentioned and in particular:

•In explosive or corrosive atmospheres or atmospheres with a high concentration of dust or

oil substances suspended in the air.

•With safet devices excluded or not operating.

•With h draulic supplies that are different than what indicated.

•In conditions with a low level of safet for the operator or other individuals;

•In the event of tampering;

•If a visual inspection shows damage to the magnet or a malfunction;

•For lifting and moving loads other than those deriving from the effect of magnetization;

•B operators who are not qualified or who have not read, understood and learnt the contents

of the manual;

IT IS ALSO FORBIDDEN:

•To use the magnet without periodic maintenance having been performed

•To use the magnet with lack of concentration or carelessl . This conduct can lead to serious

accidents.

Tecnoter group

Div. Tecnoter srl

H draulic

permanent magnet

ILQMP Ver 102Q Page 20/26 Rev: 2.0 – 02/08/2020

Table of contents

Popular Construction Equipment manuals by other brands

Yamato

Yamato Betoniera HCM 650 instruction manual

Yale

Yale SHAW-BOX YK Series Assembly & instruction manual

Greenlee

Greenlee 555C instruction manual

Komatsu

Komatsu PC3000-6 Operation & maintenance manual

Atlas Copco

Atlas Copco HB Series Safety and operating instructions

Kato Imer

Kato Imer CARRY 105 ELECTRIC POWER operating instructions

CMT ORANGE TOOLS

CMT ORANGE TOOLS CMT7E manual

Dynapac

Dynapac SD2500W Operation & maintenance manual

Farmi Forest Corporation

Farmi Forest Corporation 4670 OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

HYVA

HYVA Amco Veba 825 WARNING, OPERATING AND MAINTENANCE MANUAL

Terex

Terex CBR 24 PLUS quick start guide

Tractel

Tractel Tractelift Type II Installation and maintenance instructions