Tractel Tractelift Type II User manual

Rev.: 10/13 – NA Installation and maintenance manual ® Page 1 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

™

*Patent N°: US12/718259

Rev.: 10/13 – NA Installation and maintenance manual ® Page 2 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

Page

3

3

4-5

6

7

4.1 Components 7

4.2 Required tools 8

5.1 Driver unit 9

5.2 Diverter unit 10 - 11

5.3 Welding the round belt 12 - 16

5.4 Testing the welded joint 16

5.5 Connecting the optional removeable control panel 17 - 18

5.6 Connecting the power supply and function control 18

5.7 Test and guiding device assembly 18 - 19

5.8 Reporting to the log-book 19

6.1 Driver unit 20

6.2 Diverter unit 20

6.3 Round belt and guiding devices 20 - 21

6.4 Rope grab and spring snap connector 21

6.5 Remote Control 22

22 - 23

Rev.: 10/13 – NA Installation and maintenance manual ® Page 3 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

Symbol Code Word Meaning Possible damage after noncompliance

Potentially

Potentially

Useful tips

for best operation none

Information for written Instruction to

(without code word)

8th edition: November, 2012

The manufacturer holds the copyright of this instal-

lation and maintenance manual.

51 Morgan Dr.

Norwood, MA 02062

USA

Telephone: (800) 421-0246

Fax: (781) 828-7600

internet: www.tractel.com

Rev.: 10/13 – NA Installation and maintenance manual ® Page 4 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

This warning is your share or duties for achieving safety.

YOUR DUTY TO UNDERSTAND AND COMPLY

1. It is the responsibilty of the operator and their

employer to strictly read and conform to the instruc-

tions in this manual.

2. It is imperative for safety and efciency of op-

erations that this manual be read and

by the operator before using

the Tractelift™ Type II.

contained herein must be carefully and strictly

, including applicable Tractel safety

guidelines.

A copy of this manual must be available to the op-

erators at all times. Manual is to be posted in each

location where the system is used.

3. Should you hand over a remote, under whatever

conditions, to any party operating out of your con-

trol, you must provide a clean copy of this manual

and draw the other party’s attention that strictly

following all the instructions therein is a matter of

life or death.

4. Use of the Tractelift™ Type II may be only carried

out by persons, who are trained with the equip-

ment, and whose weight is

5. User must have received instruction by an ap-

proved Tractel® trainer to perform this task.

6.

Harness with appropriate life line

fall arrester used on a fall protection system (ANSI

Z359, CSA Z259 and PPE directive 89/686/CEE).

9.

. It shall only be used for assisting

persons, when climbing or descending a vertical

ladder.

10. Users must be familiar with the local safety and

health regulations, as well as with the instructions

of all personal protection equipment in use, and

have received appropriate instructions.

11. If the task is performed by employees, the con-

tractor has to follow the requirements of the

relevant safety and health regulations.

12. Only one person allowed to be connected during

use! Before use, you must READ and fully

understand the complete operating instructions!

13. Never use a Tractelift™ Type II which has been

modied.

14. Tractel® carries no liability for damage due to

noncandidate use of the Tractelift™ Type II, or

due to retrots and alterations on the equipment

or where non-original spare parts are used that

the company has not approved in writing.

YOUR DUTY TO INSPECT AND MAINTAIN

15. Keep this manual available at all times for easy

reference whenever required. Extra copies are

available from Tractel.

16. Carefully take notice of all the labels and name-

plates afxed to the Tractelift™ Type II . Never

operate the Tractelift™ Type II if any label or

nameplate, normally xed on the Tractelift™ Type

II is obscured or missing. Tractel® will supply extra

labels and nameplates on customer’s request.

17. The Tractelift™ Type II has to be maintained/in-

spected by a competent person, either on demand,

or at the latest after 12 months. The result of the

annual inspection has to be led in the log-book.

18. A careful and regular inspection of the Tractelift™

Type II, is part of the safety requirements. If you

have any questions, call Tractel®. (see back cover)

19. Do not use a Tractelift™ Type II with, damaged

assist rope.

20. Do not attempt to lengthen or repair the assist

rope.

Rev.: 10/13 – NA Installation and maintenance manual ® Page 5 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

YOUR DUTY TO TRAIN AND CONTROL PEOPLE

21. An operator must not be assigned to a hosting job or to

rigging for the job, if the person is not:

a) mentally or physically t for that purpose

b) competent for the job to be performed

c) familiar with all application safety rules and require-

ments

d) trained for working under the above requirements

22. Never disassemble the Tractelift™ Type II by yourself or

by your staff. Except for the operations described in this

manual, the maintenance of the Tractelift™ Type II, as

well as disassembly and repair, must be exclusively done

by qualied repairers authorized in writing by Tractel®

Inc. for USA or Tractel® Ltd. for Canada. Tractelift™ Type

II spare parts in accordance with the serial number of

each machine must be exclusively utilized. No substitu-

tions are allowed.

23. Never let the Tractelift™ Type II and other equipment

of a system be managed or operated by a person other

than those authorized and assigned to the job.

24. Training operators must be set up by a competent

person, or of its technical consultant. According to the

working conditions, prior to putting the equipment into

operation, contact Tractel® Inc. for the USA or Tractel®

Ltd. for Canada. (see back cover)

25. Every job must be placed under the control of a per-

son having the required competence and the authority

for checking that all the instructions prescribed by this

manual be regularly and efciently carried out.

YOUR DUTY OF SAFETY BEYOND THE TRACTELIFT™

TYPE II

As being only one component of the system, the Tractelift™

Type II can contribute to the required SAFETY, IF:

26. It is tted on and with compatible equipment.

27. Other components meet the requirements of the ap-

plicable safety regulations and are of the proper quality,

and assembled to form a safe system.

28. Every support is stable, sufciently strong, according to

the load either static and dynamic.

29. Supporting structure provides the required resistance to

every load to be applied either static or dynamic, during

operating the equipment.

30. All the requirements in strength and resistance are ob-

tained with the necessary safety factor (see regulations

and professional standards).

31. All the calculations, design and subsequent work neces-

sary to the above requirements have been made by a

competent person on the basis of proper technical infor-

mation regarding the site.

32. Do not use the Tractelift™Type II or climb the ladder dur-

ing periods of severe weather or during electrical storms.

YOUR DUTY TO AVOID TAKING CHANCES

33. Tractelift™ Type II MUST NOT be used in explosive at-

mosphere. It has not been designed for such an applica-

tion.

AN ULTIMATE RECOMMENDATION

®

The companies of The Tractel

®

and their

appointed repairers will supply on request their

documentation regarding other Tractel

®

products

available: Lifting and pulling equipment and their

accessories, site and facade access equipment,

handling equipment, safety devices for load, per-

sonal fall protection equipment, load and tension

indicators, etc.

Go to

The Tractel

®

network can supply an after sales

and periodic inspection service.

Rev.: 10/13 – NA Installation and maintenance manual ® Page 6 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

The Tractelift

™

Type II al-

leviates persons climbing a

vertical ladder (Fig. 1) with

adjustable pulling force ap-

proximately 60% of the of

the person’s weight entered

on the remote control. Two

user remotes are available,

Blue rubber casing for users

between 102 - 160lbs. (51

- 80 kg) and a Red rubber

casing for users between

160 and 250lbs. (80 kg -

125 kg).

The drive comes with a re-

mote control that is directly

connected with a Carabi-

neer and a rope grab to the

pulley belt. The other end

of this remote is attached

to the climbers approved safety harness with another

Carabineer.

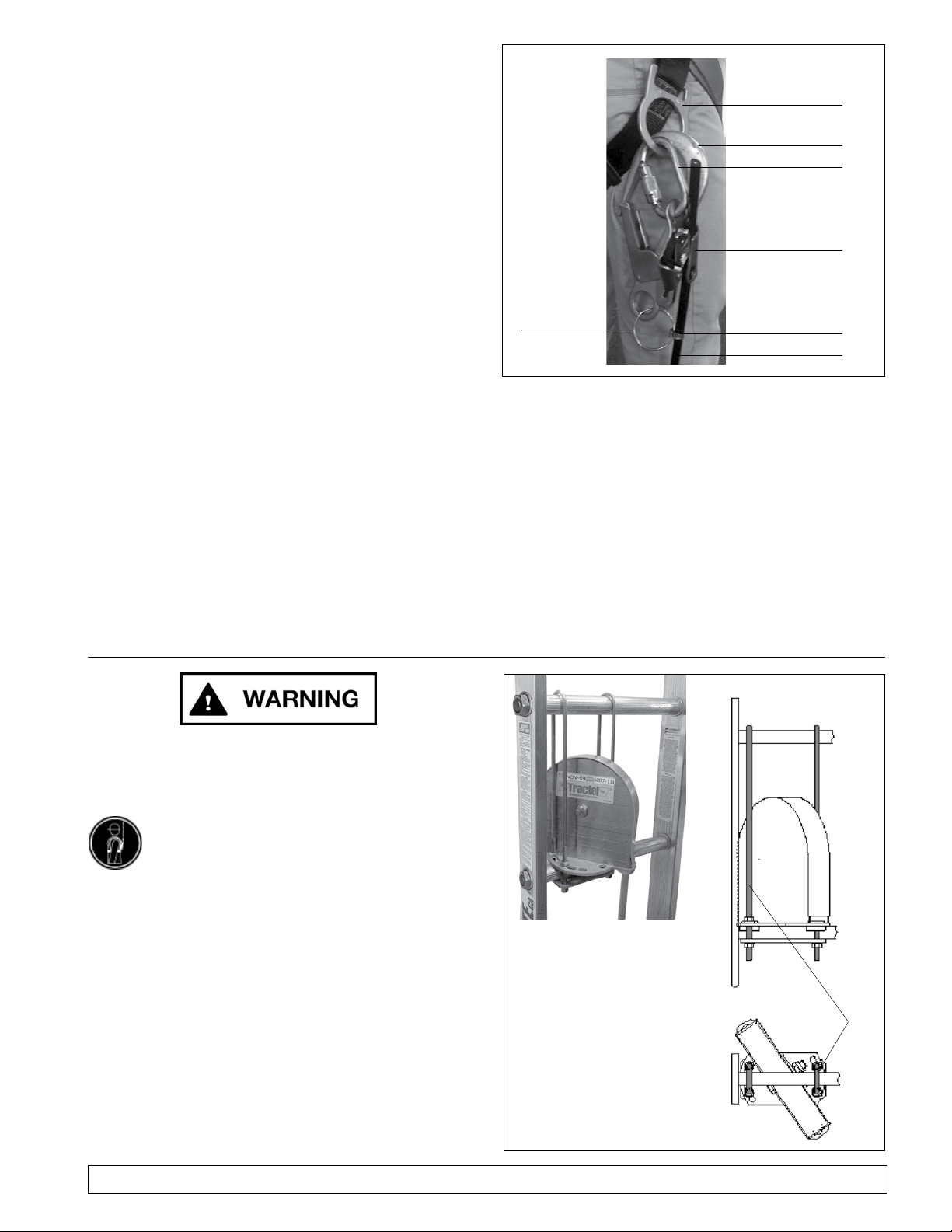

Fig. 2

Fig. 4

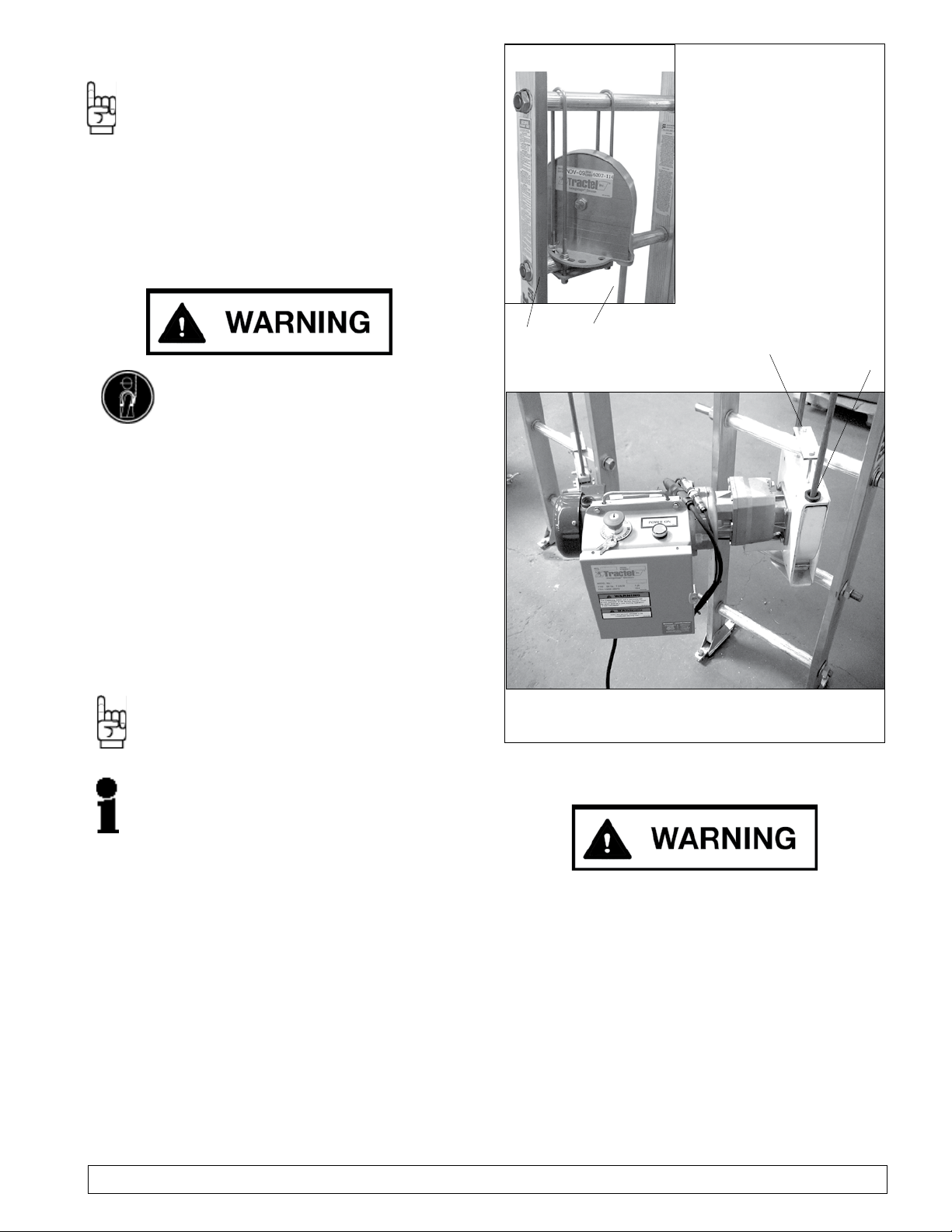

At the lower end of the ladder (Fig. 3), a motor with

that drives pretension endless round belt by means of

a driver pulley. Shown with and without the removable

control box in place.

The continuous welded round belt, made of special

synthetic material (Ø 1/2 inch / 12,5 mm) runs on the

driver pulley of the motor and a diverter pulley at the

upper end of the vertical ladder (Fig. 2).

The connection to the round belt is made by a belt grab,

xed to a locking carabiner, with the top of the remote

control attached, on the bottom side of the remote a

second carabiner is attached which attaches to the us-

ers safety harness. (Fig. 4).

Fig. 3

Round belt

Belt grab

Locking

carabiner

User

Remote

Locking

carabiner

This manual is valid for Tractelift™ Type II with remote

only.

Fig. 1

Rev.: 10/13 – NA Installation and maintenance manual ® Page 7 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

This can be, for example, a fall arrest system with fall

arrest device on the middle pole of the ladder, connected

to the anchor ring of the harness.

The is

, but a part of the vertical ladder.

The shown pictures/drawings shall be understood as

examples.

Fall arrest

system

Climbing

Aid

Fig. 5

Fig. 6

Adjustable

positioning lanyard

a) The

b) to

the ladder ,

before starting with an installation:

– Attach the lanyard to one of the D-rings at the

waist belt, guide it behind the ladder, and attach

the other end to the second D-ring.

– Lock both locking carabiners.

– Adjust the length of the lanyard to get sufcient

freedom of movement for executing the installa-

tion.

The use of the positioning lanyard will reduce the pos-

sibility of fall, when leaning around the edge of the ladder

to install belt guides or similar.

Check completeness:

a)

b)

For standard ladders with including

.

c) on drum has sufcient length.

d) Belt for

– the ladder, and

– of the ladder, if there are obstacles.

.

e) For aluminum ladders:

Two .

Rev.: 10/13 – NA Installation and maintenance manual ® Page 8 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

Check completeness

(Fig. 7)

1 Welding clamp with xing brackets

2 Welding iron

3 Special cutter

4 Cutter-knife

5 lever hoist 500lb. (250 kg)

with 10’ (3 m) of chain and manual

6 2 belt grabs with locking carabiner

7 ® dynamometer with 2 hooks

(440 lbs/200 kg1))

8 Thermometer

9 Pipe hook with key ring and hose clamp

10 Sling Ø 4.5 mm/ length 0.5 m

11 Tool box (not as shown)

a) 1 Set of socket wrenches 3/8” to 1 1/8” (10

to 30 mm) with extension

b) 1 Set of open end wrenches 3/8” to 1 1/8”

(10 / 13 / 19 / 30 mm)

c) 1 Socket spanner size 1/2” (10mm)

d) - Insulating tape

e) - Molycote® grease paste DX

f) 1 Walkie-talkies for communication

between the two installers. Walkie Talkies

must conform to local telecommunication

regulations.

Fig. 7

Rev.: 10/13 – NA Installation and maintenance manual ® Page 9 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

Step

reinforcement

Apply Molycote® on all

: To avoid electro-

chemical corrosion

at those

places, where they might get in contact

with stainless-steel-components (screws or

guiding devices)!

On aluminum ladders, insert step reinforce-

ment to avoid deformation of the step, when

tensioning the round belt (Fig. 8a). The step

reinforcement should be on upper and lower

ladders rungs the upper and lower drive

pulleys are attached to.

Connect the driver pulley to the lowest possible

step (Fig. 8a - 8d).

Fig. 8a

Fig. 8b

Fig. 8c

The lower drive pulley should be attached to the

lowest possible step, by using the upper and lower

hardware (Fig. 8b-d). While attaching the lower

pulley the motor needs to be supported during

assembly. Sit the lower pulley on the lowest step

and tighten the two lower bolts through the lower

connector plate (Fig. 8c-d) into the pulley assem-

bly. Using the upper connector plate tighten the

two bolts into the top of the lower pulley assembly.

Tighten till the pulley is secure.

Fig. 8d

A

Rev.: 10/13 – NA Installation and maintenance manual ® Page 10 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

Fig. 9

Pipe hook

Key ring Hose clamp

Round belt

a) Material and equipment to be taken with on the

ascent:

– pre-assembled

c/w anchoring parts;

for ladders with round steps incl. the

–

– and :

Socket size 1/2” 10 mm,

wrench/ratchet size 3/8” to 1 1/8” (13 mm and

19mm),

screw driver for the hose clamp,

Molycote® grease paste DX,

insulating band (only for aluminum-ladders)

–

(only for aluminum-ladders)

–

b) Connect the round belt’s end by means of the hose

clamp to the key ring of the pipe hook . As a backup

also attach the belt grab and carabiner to the round

belt. This carabiner and the pipe hook are then at-

tached to the lower D ring of the harness (g. 9).

a) The 1st installer connects the pipe hook and the

carabiner with the round belt to one of the D-rings

of its harness, and takes the rest of the material.

b) He secures himself to the climbing protection system

and starts climbing.

c) The 2nd installer watches the proper un-coiling of

the round belt from the hasp.

d) After arriving on top,

– Safely lay down the material on the platform.

– Take the round belt off the harness and secure

to the ladder by means of the pipe hook.

Fig. 10a

Fig. 10b

a) Align the pulley with the bottom pulley

b)

Before mounting the diverter make sure no moving

parts of the nacelle will obstruct with it. Fix the di-

verter unit at the highest two steps possible, (Fig.

10a). On steps use anchor brackets () to avoid

the diverter unit from tilting (Fig. 10b).

Belt grab

Harness D ring

Carabiner

Rev.: 10/13 – NA Installation and maintenance manual ® Page 11 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

Fig. 11b

During the following steps, securely

hold the round belt to protect it against

falling down!

a) Open the hose clamp, take off the belt’s end, and

insert it at () in the entry bushing of the diverter

pulley, until it exits at () (Fig. 11a).

b) Fix the belt’s end again to the pipe hook.

c) Before starting with decent:

take off

of the , guide it

behind the ladder, and connect it in that way to a

free D-ring of the harness, that it will not interfere

during descent.

d) Guide the belt’s end

, and connect the pipe hook

to one of the D-rings of the harness – this makes

it easier to pull down the belt’s end.

e) The installer at ground level again watches the cor-

rect uncoiling of the round belt.

Fig. 11a

,

since it could be pulled upwards by the weight

of the belt hanging in front of the ladder.

f) At the places, where the ladder is connected to the

tower wall by brackets:

Unhook the rope grab from your harness, guide it

behind the bracket, and hook it up again to the har-

ness.

g) When reaching the ground, open the hose clamp

and remove the belt grab.

h) Introduce the belt’s end at () a n d

push it through between driver pulley

and guide cover, until it exits at ().

Pull the end out, until it is approx. 5 ft. (1.5 m) long.

In the next step, the Bravo™ lever hoist if

not used as directed may cause serious

injuries. You must read and understand

and follow all instructions in the manual

(included in the Installation Kit) before

beginning to weld the belt and using the

Bravo™ lever hoist

Rev.: 10/13 – NA Installation and maintenance manual ® Page 12 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

a) At the height () of the lower belt’s end (Fig. 12),

x the welding clamp with its xing bracket on a

ladder step (Fig. 13a).

b) Approx. 3 ft. (1 m) under the belt’s end, which comes

from the driver pulley, fasten a belt grab –

. (Fig. 12).

c) Approx. 10 ft. (3 m) above this clamp, fasten the

second belt grab to the round belt, which comes from

the top – (Fig.

12).

d) Anchor the chain hook of the Bravo™ lever hoist to

the locking carabiner of the upper rope grab, and

pull through by hand the chain as far as possible

(Fig. 13b). Check that the load chain has not become

twisted during installation. If twisted one of the links

could enter in the wrong position and damage the

hoist and the chain.

e) Anchor ® dynamometer between the top

hook of the lever hoist and the locking carabiner

of the lower belt grab (Fig. 13b).

Fig. 12

lower

belt grab

Fig. 13b

handifor®

bravo® lever

hoist

Fig. 13a

upper

belt grab

approx. 10 ft.

approx. 3 ft

Rev.: 10/13 – NA Installation and maintenance manual ® Page 13 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

a) Switch on the dynamometer and push the tare-button

to set the display to zero.

b) Check the surrounding temperature.

c) With the lever hoist, tension the round belt

– to approx. 220 lbf (100 daN)

for temperatures above 32° F (≥ 0° C),

– to the value of table 1

for temperatures less than 32° F (below 0° C).

Before welding the round belt, it must be

. This requires

some time:

d) , watch the dynamom-

eter’s display, and to approx.

220 lbf (100 daN) (respectively the above dened

value for minus grades), until it stays stable.

,

:

If necessary, adjust tension until it is stable.

Table 1

1) When assembling at these temperatures you must get a dynamometer

with a (100 daN),

ex. a DYNAFOR® with a capacity of 500 lbs (250 kg):

Model LLX: Accuracy ±0,2 % / smallest load 0.5 lb, or

Model LLZ: Accuracy ±0,8 % / smallest load 1 lb.

Fig. 14a

Welding iron

a) Put the welding iron in a safe place, so it will not

interfere with the following preparation procedures

(Fig. 14a).

b) Connect the welding iron to power supply

and switch it on.

the welding iron

has reached 425º F or above the iron is at

.

(Fig. 14a).

Rev.: 10/13 – NA Installation and maintenance manual ® Page 14 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

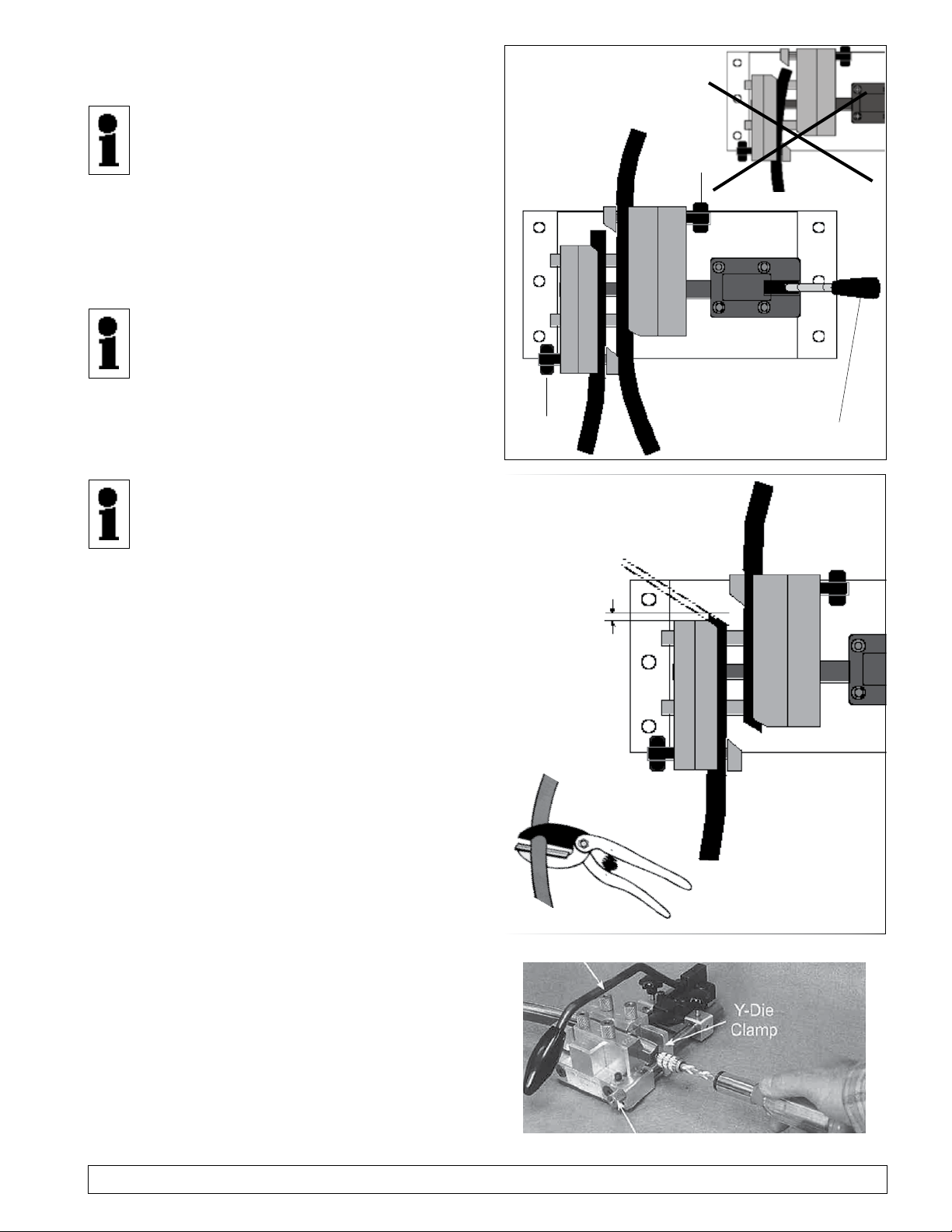

Cam lever

Clamping

screw

Fig. 15a

Special cutter

Fig. 15b

(Fig. 15a) – this

gets them lying parallel to the welding jaws

after xing them with the clamping screws.

a) With the cam lever completely open the welding

clamp, and if necessary, untwist the clamping screws,

until the belt can be inserted.

b) Insert the belt’s end coming from the driver unit into

the left clamp (Fig.15a).

If the belt’s end does not project over

welding clamp for at least 1/4 to 1/2 inch

(5 to 10 mm), push the complete pre-tensioned

belt upwards for the required distance.

c) Insert the belt coming from the top into the right

clamp, and tightly x both belts by means of the

clamping screws.

d)

Push the cam lever to the right, until the belts

get into contact, for two reasons:

1. To check, that the lever is not obstructed

during the welding procedure, and

2. to get practice – in particular on side rail

ladders – how to turn the cranked (off-set)

cam lever for quickly closing the welding

clamp, after the welding iron will be taken

off.

Completely re-open the welding clamp.

a) Using the special cutter, cut both belt ends according

to Fig. 15b:

– , and

– with .

This provides for a most complete contact to the

welding iron.

b) With the belt secure drill the core of each end with

a 1/32” drill bit to a depth of at least 3/16” (5mm)

(Fig. 16).

c)

Clamping

screw

Fig. 16

Rev.: 10/13 – NA Installation and maintenance manual ® Page 15 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

a) ,put and hold the hot welding

iron between the belts’ ends (Fig. 17).

b) ,rmly push the cam lever

backwards and to the right to

(Fig. 18).

c) Making the weld joint

During this procedure, a lot of liqueed plastic

emerges from the clamp – , since

half of the material from both belts over the weld-

ing length has to be displaced

The index must be on the at

the right end of the coloured scale – it’s not until

then, that the welding clamp is completely locked

for the cooling down.

d) Safely lay down the welding iron for cooling down.

(See next page for cleaning the welding iron.)

Fig. 19

Fig. 18

Fig. 17

Index

Welding iron

Cam lever

Welding iron

2nd black marking

Welding burr

and excess material

Rev.: 10/13 – NA Installation and maintenance manual ® Page 16 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

After cooling down of the weld joint:

a) Completely release the clamping screws, and

open the welding clamp by means of the cam

lever, so that the belt is free.

b) Release the lever hoist, take off the ®, switch

it off and store it in the sheath.

c) Take off the lever hoist, the welding clamp, and the

two belt grabs. Check that the load chain has not

become twisted during installation. If twisted one of

the links could enter in the wrong position and dam-

age the hoist and the chain.

d) If necessary, clean all tools, and store them in the

tool box.

e) Then,

, ex. with a cotton cloth, or once cooled it

can be removed by using one’s ngernails –

f) Store the welding iron in the tools box.

Risk of cuts use approved safety gloves

a) Cut off larger material remaining with the special

cutter, always cutting away from the body.

b) Using the cutter-knife trim the welding burr to get an

even round surface of the belt.

Warning of serious injuries if the welded joint

breaks when under load.

– Perform visual inspection and stress test in ac-

cordance with these instructions.

The welded joint must be tested after welding the

circular belt and deburring the welding seam:

If the following defects are visible to the naked eye

then the welded joint must be renewed:

• Excessive number of air inclusions

• Interruptions to the welding seam / seam not

completely closed

The edges of the fused belt must be cleanly weld-

ed closed along the entire length of the fused area.

See Fig. 20)

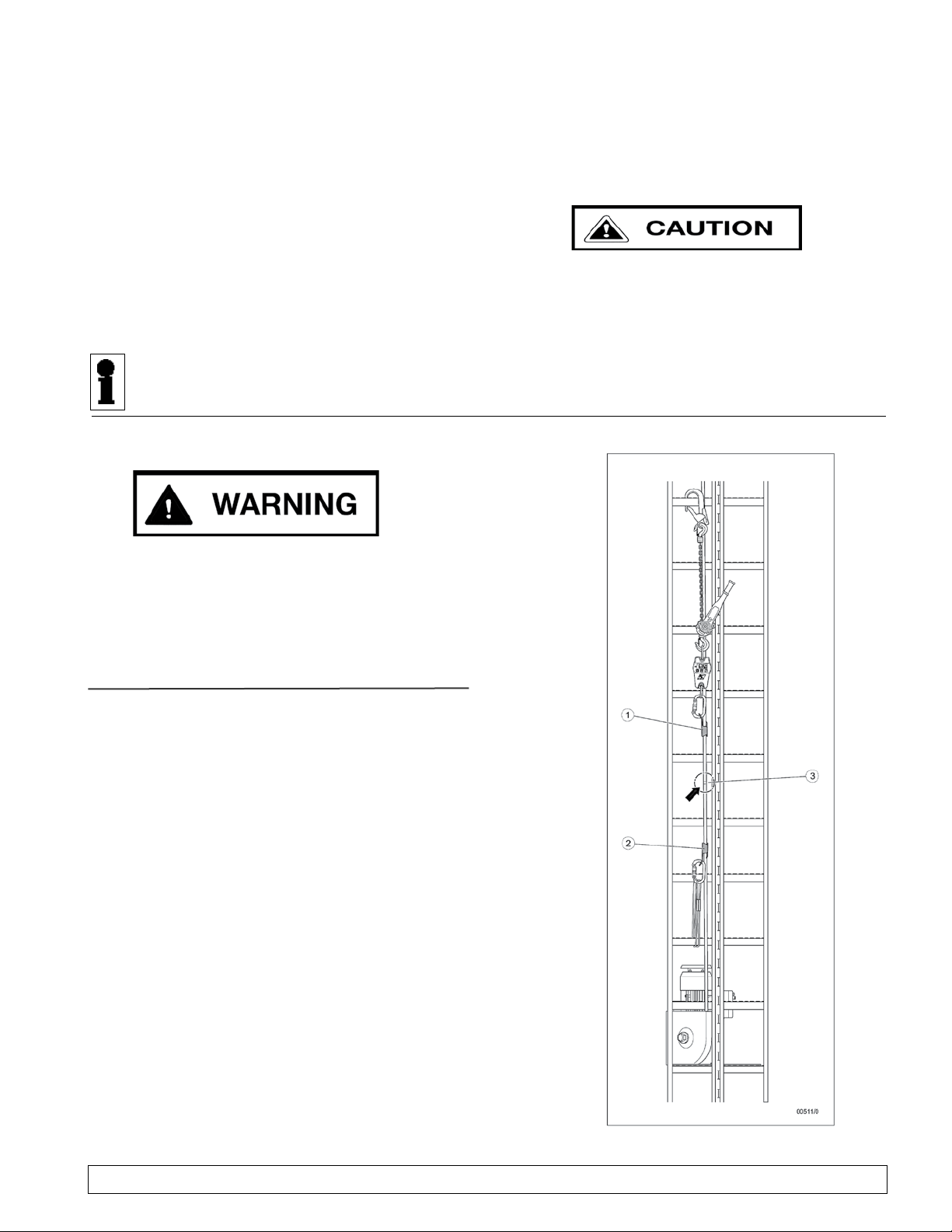

• Arrange the rope clamps (1) and (2) in such

a way that the welded joint (3) is positioned in

between them, as centrally as possible.

• Apply a tension of 100 daN (kg) to the welded

joint.

• The tension must be maintained for at least 5

minutes. Tensioning must not result in lateral

contraction of the welded joint.

• Repeat visual inspection.

Fig. 20

Rev.: 10/13 – NA Installation and maintenance manual ® Page 17 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

d) Once the control panel is in place, lock the panel

pin in place by twisting the pin. (Fig. 23 & 24).

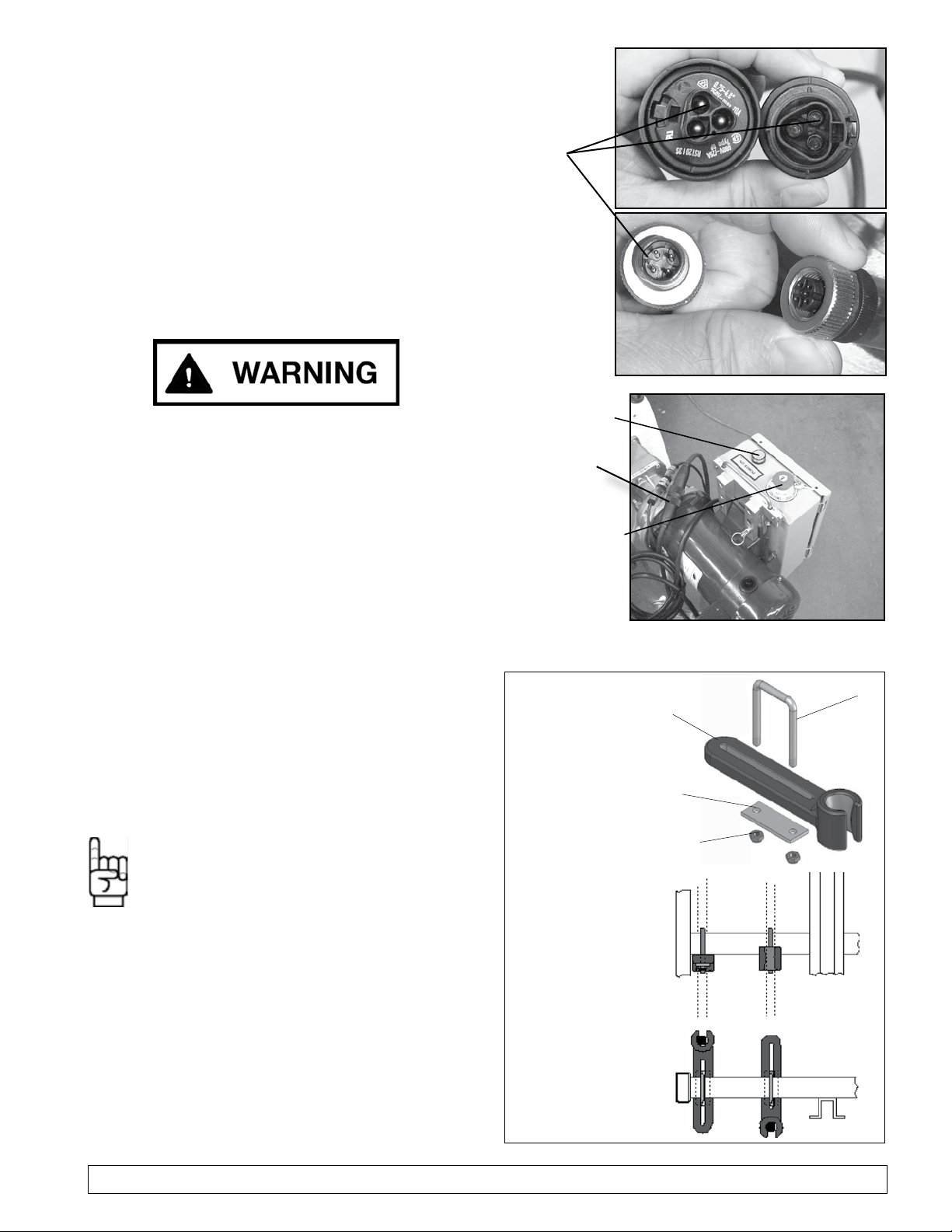

e) Connect the two control cables together,

connection is by male and female connectors.

Both connectors have a positive tting (D)

connections and can only be connected in one

alignment only

(Fig. 25 & 26)

. The connector

should tighten completely.

(Fig. 28 item E)

a) Disconnect the power supply and the control cables

b) Disengage the panel pin and slide the control box

up off the mounting plate.

c) Place the control panel back into the carrying con-

tainer

Fig. 24 - LOCKEDFig. 23 - OPEN

a) With the lower pulley and motor installed the unit is

ready for the removable control panel (Fig. 20)

b) Remove the control panel from the container (Fig. 21)

c) Slide the control panel (A) onto the mounting plate

(B) (Fig. 20, 21 & 22).

Fig. 20

Fig. 21

Fig. 22

Rev.: 10/13 – NA Installation and maintenance manual ® Page 18 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

a) If the round belt is not free-running on its total length,

guiding devices have to be mounted at the relevant

places. This can be necessary at

– intermediate platforms or

– other obstacles.

, the belt must be

also guided at those places, where it is not

obstructed during idle-running – but a person

using the Climbing Aid pulls it away from the

ladder, which may cause the belt to contact an

obstacle!

b) According to the local conditions, carry with you

the adequate number of (),

(), () and

M 6 () (Fig. 28).

c) and :

– Pole strap

– Socket spanner size 10

– Molycote® grease paste DX

– Insulating tape (only for Aluminum-ladders)

a. Make sure the power being supplied is the same

as the Tractelift Type II provided either 110 V - 1

PH, 50/60 Hz, (15 amp) (UL/CSA) or 220 V - 1

PH, 50/60 Hz, (10 amp) (EU - 2006/42/EC) and

plug in the control box to the approved power

supply (by qualied person only).

b. Turn the key of the (Fig. 27) to the

right – the comes

out, the signal lamp illuminates green.

.

Fig. 26

D

Fig. 28 (Principle sketches)

Service Switch

and

Signal lamp

E

Fig. 25

Fig. 27

Rev.: 10/13 – NA Installation and maintenance manual ® Page 19 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

:

– Push the –

the signal lamp goes off.

– Take off the key and store it to its intended place.

– On :

If requested, take off the motor unit, and store it

at a safe place.

After nishing assembly and checks the

responsible installer reports the “Inspection

before Initial Operation” to the log-book in-

cluded in the operation manual.

The result of these inspections have to be

written down in the log-book at the back of the operation

manual. The manual and the logbook should be located

in the lower section of the tower beside the ladder.

: To avoid electro-

chemical corrosion

, where the guiding

devices are mounted!

Apply Loctite® on all

guiding devices, ex. in the area of platform

hatches:

under the step

(Fig. 28), and .

guiding device, ex. in the area of anchor brack-

ets of the ladder:

Put the on the belt and con-

nect it under the step (Fig. 28).

To protect the belt from contact with the obstacle:

Mount the belt guide sideways offset.

a) Check the round belt’s course, and at every place,

where it touches an obstacle, stop the round belt,

and mount a guiding device.

Rev.: 10/13 – NA Installation and maintenance manual ® Page 20 of 24

Copyright 2013, Tractel® P4795 NA all rights reserved.

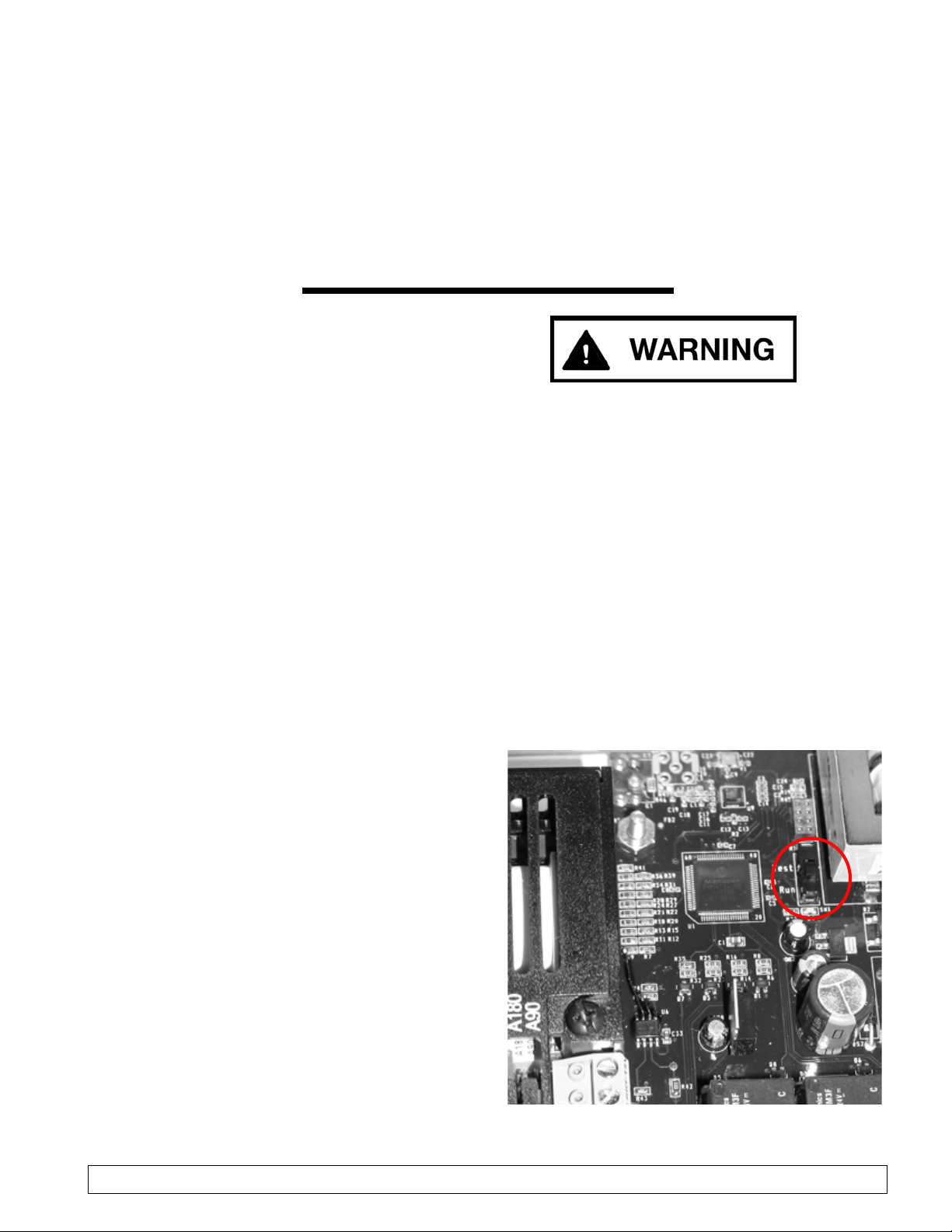

Visual control for damage, wear, or oil contamination.

To aid in visual maintenance the drive can be placed in

“pulse mode” which will activate the unit and start the

rotation of the round belt for inspection. The unit will

start on and off to provide time to inspect the belt as

it travels the system. To activate the pulse inspection

system, you must open the control panel and toggle

the black switch inside to the position (Fig. 30).

Once the inspection of the belt is complete return to

the position.

Fig. 30

The Tractelift™ Type II has to be maintained/inspected

by a competent person, either on demand, or at the latest

after 12 months. The result of the annual inspection

has to be led in the log-book, included in the operation

manual.

are on principle main-

tenance-free.

a)

– for damage, oil loss, corrosion, dirt, in the con-

trolbox inltraded water, or impurities,

– of correct anchoring of bracket, xing plates, and

driver disk guard plate.

b)

regarding vibration and abnormal noise.

Stop the motor.

c) If the motor is , it should be cleaned to

ensure an effective air ow.

a)

– for damage, oil loss, corrosion, or dirt,

– of correct anchoring of bracket, xing plates, and

diverter disk guard plate.

b)

regarding vibration and abnormal noise.

Stop the motor.

The Climbing Aid is on principle maintenance-free.

During the annual safety inspection

resp. during intermediate service,

ex. in the course of “trouble-shooting”,

a competent person should check the installation according to

the following instructions

see chapter 4.2 on page 8.

Other manuals for Tractelift Type II

1

Table of contents

Other Tractel Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Wacker Neuson

Wacker Neuson RD24 instruction manual

MULTILIFT

MULTILIFT Ultima S Flex User and maintenance manual

Doka

Doka Framax stripping corner I Series Original operating instructions

Hercules

Hercules G210 owner's manual

Marcegaglia Buildtech

Marcegaglia Buildtech N2BL-MARC2013 installation manual

Bomag

Bomag BW 900-2 operating instructions