P/N: C11746308 REV. AB June 2022

2

TABLE OF CONTENTS

1) SAFETY PRECAUTIONS .......................................................................................................................4

IMPORTANT INFORMATION AND WARNINGS......................................................................................... 5

2) FABRICATION OF GIRDER(S) FOR BRIDGE BEAM WITH CAPPING CHANNEL .............................8

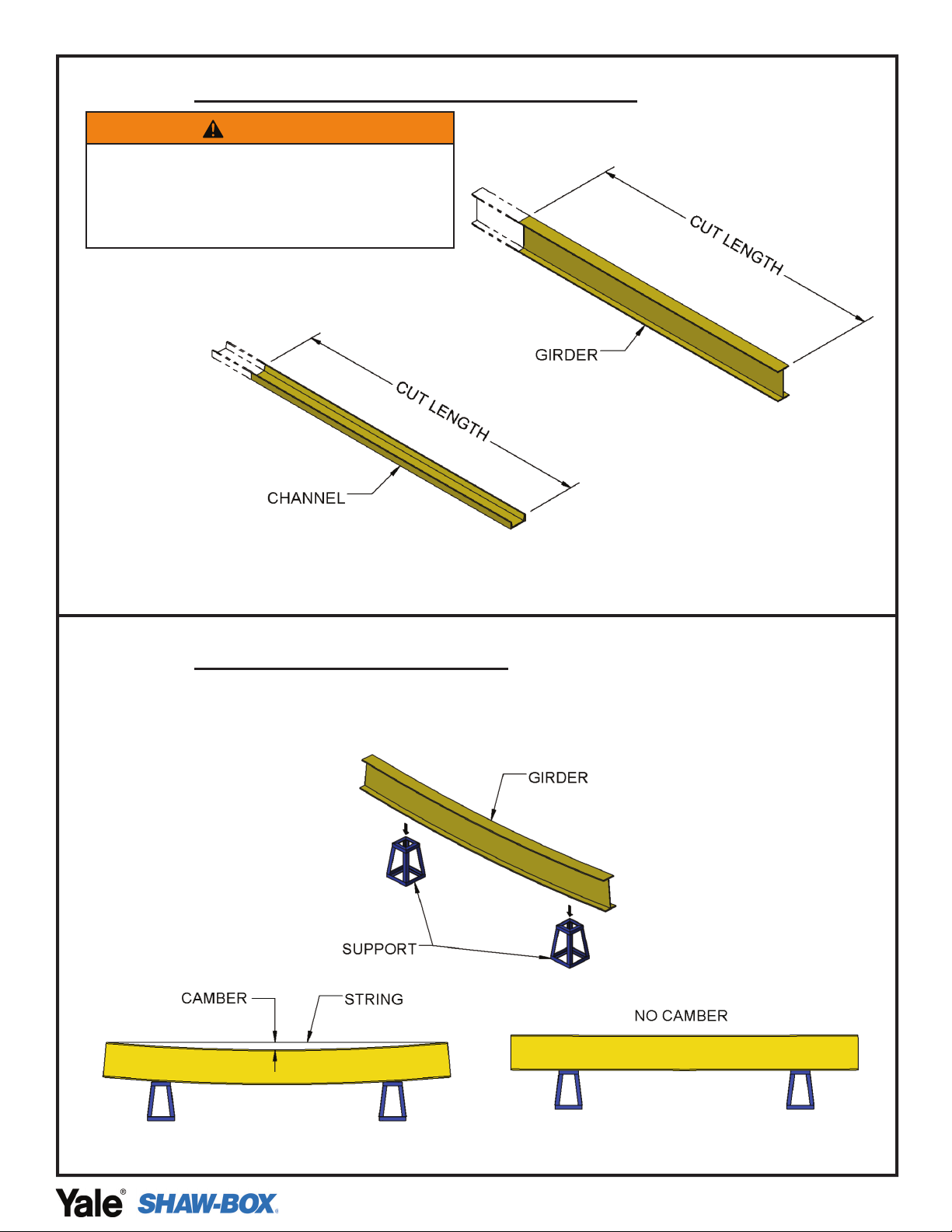

STEP 1: CUT GIRDER AND C-CHANNEL (AS REQUIRED)..................................................................... 9

STEP 2: CHECK CAMBER (AS REQUIRED).............................................................................................. 9

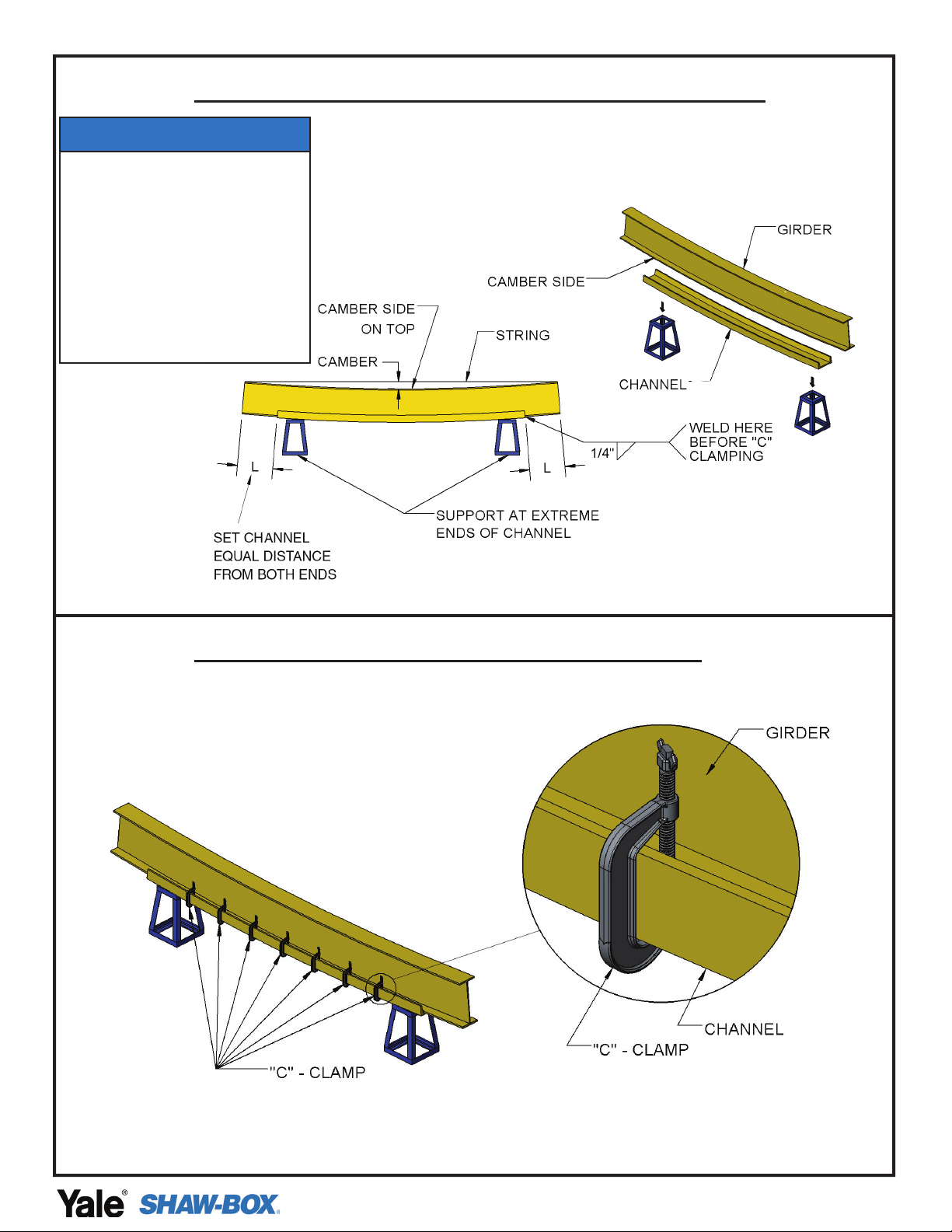

STEP 3: GIRDER AND C-CHANNEL WELDING AT END (AS REQUIRED)............................................. 10

STEP 4: CLAMPING GIRDER AND C-CHANNEL (AS REQUIRED)......................................................... 10

STEP 5: GIRDER AND C-CHANNEL WELDING (AS REQUIRED)........................................................... 11

STEP 6: CHECK CAMBER AFTER WELDING (AS REQUIRED).............................................................. 11

3) ASSEMBLING BRIDGE GIRDER TO END TRUCKS (SINGLE GIRDER).............................................12

3.A) TRSG END TRUCK TYPES.................................................................................................................. 13

3.B) INTEGRAL-AXLE TUBE-FRAME END TRUCK .................................................................................. 14

3.C) FIXED AXLE END TRUCK.................................................................................................................... 15

3.D) CHANNEL TYPE END TRUCK............................................................................................................. 16

3.E) ROTATING AXLE TOP RUNNING END TRUCK................................................................................. 17

STEP 1: NOTCHING GIRDER AT ENDS (AS REQUIRED) ....................................................................... 18

STEP 2: MOUNTING GIRDER ON SUPPORT (AS REQUIRED).............................................................. 18

STEP 3: LOCATE & ALIGN END TRUCKS.................................................................................................. 19

STEP 4: POSITION END TRUCKS.............................................................................................................. 19

STEP 5: CHECK SQUARENESS BETWEEN END TRUCKS.................................................................... 20

STEP 6: CHECK SPAN DISTANCE BETWEEN END TRUCKS ................................................................ 20

STEP 7: WELDING END TRUCKS WITH GIRDER.................................................................................... 21

STEP 8: TRIA METRIC END TRUCK DRIVE INSTALLATION .................................................................. 22

STEP 8A: TRFA END TRUCK A4 DRIVE INSTALLATION ......................................................................... 23

STEP 8B: TRFC END TRUCK DRIVE INSTALLATION.............................................................................. 24

STEP 8C: TRRA END TRUCK DRIVE INSTALLATION.............................................................................. 25

STEP 9: BRIDGE BOLTED PLATE END CONNECTION SINGLE GIRDER ............................................ 26

4) END STOPS & TROLLEY STOPS..........................................................................................................27

4.A) END STOP ASSEMBLY......................................................................................................................... 28

4.B TROLLEY STOPS SUPPLIED BY CUSTOMER................................................................................... 28

5) MOUNTING HOIST ON GIRDER............................................................................................................29

YK/SK HOIST INSTALLATION ..................................................................................................................... 30

STEP 1: PREPARATION FOR MOUNTING HOIST ON GIRDER ............................................................. 30

STEP 2: MOUNTING HOIST ON GIRDER .................................................................................................. 31

Y80/800 HOIST INSTALLATION................................................................................................................... 32

STEP 1: PREPARATION FOR MOUNTING HOIST ON GIRDER ............................................................. 32

STEP 2: MOUNTING HOIST ON GIRDER .................................................................................................. 33