Tecnowind EAGLE User manual

Model:

EAGLE

SERVICE Manual

RANGE HOOD CONTENTS

• Safety precautions

• Distance from the hob

• Technical specications

• Technical data

• Parts supplied

• Non-return valve - parts supplied

• Aluminium panel / charcoal lter

• Installation

• Control drawing

• Touch control

• Bulbs

• Transformer

• Power board

• Electrical assembly

• Motor

• Condenser

• Wiring diagram

• Exploded view

• Spare parts list

• Troubleshooting

SUMMARY

1. Safety precautions.....................................................................................................................................................................4

2. Distance from the hob.........................................................................................................................................................7

3. Technical specifications.........................................................................................................................................................8

4. Technical data............................................................................................................................................................................9

5. Parts supplied .......................................................................................................................................................................10

6. Non-return valve - parts supplied .....................................................................................................................................11

7. Aluminium panel / charcoal filter .......................................................................................................................................12

7.1 replacing the aluminum panel

7.2 replacing the charcoal filter

8. Installation...................................................................................................................................................13

8.1 fixing the appliance to a wall

8.2 fixing the decorative telescopic flue

8.3 installing the charcoal filters and aluminum panels

9. Control drawing......................................................................................................................................................................19

9.1 configuration

9.2 technical drawing of control board

10. Touch control............................................................................................................................................................................21

10.1 replacing the touch control

11. Bulbs.............................................................................................................................................................................................23

11.1 replacing the halogen bulbs

11.2 replacing the halogen bulbs socket

12. Transformer................................................................................................................................................................................26

12.1 replacing the transformer

13. Power board...............................................................................................................................................................................29

13.1 replacing the power board

14. Electrical assembly.................................................................................................................................................................31

15. Motor.............................................................................................................................................................................................32

15.1 replacing the motor

16. Condenser...................................................................................................................................................................................37

16.1 replacing the condenser

17. Wiring diagram.........................................................................................................................................................................40

18. Exploded view...........................................................................................................................................................................41

19. Spare parts list.....................................................................................................................................................................42

20. Troubleshooting.......................................................................................................................................................................43

- 3 -

Safety precautions

- 4 -

Before connecting the model to the electricity

network:

- Control the data plate (positioned inside the appliance)

to ascertain that the voltage and power correspond to

the network and the socket is suitable. If in doubt ask

a qualied electrician.

- If the power supply cable is damaged, it must be re-

placed with another cable or a special assembly, which

may be obtained direct from the manufacturer or from

the Technical Assistance Centre.

- This device must be connected to the supply network

through either a plug fused 3A or hardwired to a 2 fase

spur protected by 3A fuse.

WARNING !

In certain circumstances electrical appliances may

be a danger hazard.

A) Do not check the status of the filters while the

cooker hood is operating

B) Do not touch bulbs or adjacent areas, during or

straight after prolonged use of the lighting instal-

lation.

C) Flambè (Flamed) cooking is prohibited under-

neath the cooker hood

D) Avoid free flame, as it is damaging for the filters

and a fire hazard

E) Constantly check food frying to avoid that the

overheated oil may become a fire hazard

F) Disconnect the electrical plug prior to any main-

tenance.

G) This appliance is not intended for use by young

children or infirm persons without supervision

H) Young children should be supervised to ensure

they do not play with the appliance

I) There shall be adequate ventilation of the room

when the rangehood is used at the same time as

appliances burning gas or other fuels

L) There is a risk of fire if cleaning is not carried out

in accordance with the instructions

M) Please use a private plug receptacle for power

plug.

: It might set a fire.

N) Please don’t operate the hood when taking fire

on the dishes or frying pan.

: It might set a fire.

O) Please don’t touch the product or operate the

switch with wet hands.

: You might get a shock of electricity.

P) Please don’t wipe off the hood with the chemi-

cals when cleaning.

This appliance conforms to the European Directive

EC/2002/96, Waste Electrical and Electronic Equip-

ment (WEEE). By making sure that this appliance is

disposed of in a suitable manner, the user is helping

to prevent potential damage to the environment or to

public health.

The symbol on the product or on the accompa-

nying paperwork indicates that the appliance

should not be treated as domestic waste, but

should be delivered to a suitable electric and elec-

tronic appliance recycling collection point. Follow lo-

cal guidelines when disposing of waste. For more in-

formation on the treatment, re-use and recycling of

this product, please contact your local authority, do-

mestic waste collection service or the shop where the

appliance was purchased.

Assembly and electrical connections must be car-

ried out by specialised personnel.

• Electric Connection

The appliance has been manufactured as a class II,

therefore no earth cable is necessary.

The connection to the mains is carried out as follows:

BROWN = L line

BLUE = N neutral

If not provided, connect a plug for the electrical load

indicated on the description label. Where a plug is

provided, the cooker hood must be installed in order

that the plug is easily accessible. An omnipolar switch

with a minimum opening of 3mm between contacts,

in line with the electrical load and local standards,

must be placed between the appliance and the net-

work in the case of direct connection to the electrical

network.

Before proceeding with the assembly operations, re-

move the anti-grease filter(s) so that the unit is easier

to handle. In the case of assembly of the appliance in

the suction version prepare the hole for evacuation of

the air.

• We recommend the use of an air exhaust tube which

has the same diameter as the air exhaust outlet hole.

If a pipe with a smaller diameter is used, the efficiency

of the product may be reduced and its operation may

become noisier.

Safety precautions

- 5 -

• We recommend that the cooker hood is switched on

before any food is cooked. We also recommend that

the appliance is left running for 15 minutes after the

food is cooked, in order to thoroughly eliminate all

contaminated air.

The effective performance of the cooker hood de-

pends on constant maintenance; the anti-grease filter

and the active carbon filter both require special atten-

tion.

• The anti-grease filter is used to trap any grease parti-

cles suspended in the air, therefore is subject to satu-

ration (the time it takes for the filter to become satu-

rated depends on the way in which the appliance is

used).

-Topreventpotentialrehazards,theanti-grease lters

should be washed a minimum of every 2 months (it is

possible to use the dishwasher for this task).

-Afterafewwashes,thecolouroftheltersmaychange.

This does not mean they have to be replaced.

If the replacement and washing instructions are not fol-

lowed, the anti-grease lters may present a re hazard.

• The acrylic filter, which is found resting on the grille,

should be replaced when the text, visible through the

grille, changes colour and the ink spreads; the new fil-

ter should be fitted in such a way that the text can be

seen through the grille from outside the cooker hood.

• If the filters do not have any text on them, or if metal

filters or aluminium panel filters are used, they should

be washed every 2 months in order to prevent the risk

of fire.

To wash the filters, proceed as follows:

- Remove the filter from the grille and wash it using a

solution of water and neutral liquid detergent, leaving

the dirt to soften.

- Rinse thoroughly with warm water and leave to dry.

• The active carbon filters are used to purify the air

which is released back into the room. The filters are

not washable or re-usable and must be replaced at

least once every four months. The active carbon filter

saturation level depends on the frequency with which

the appliance is used, the type of cooking performed

and the regularity with which the anti-grease filters

are cleaned.

• Remove build-up from the fan and other surfaces

of the cooker hood regularly using a cloth moistened

with denatured alcohol or non-abrasive neutral liquid

detergent.

CAUTION!

Wear gloves during the installation of the product oth-

erwise injury at ngers could happen by sharp edges.

Safety precautions

WARNING !

• Take care when the cooker hood is operating simultaneously with an open fireplace or burner that depend

on the air in the environment and are supplied by other than electrical energy, as the cooker hood removes

the air from the environment which a burner or fireplace need for combustion. The negative pressure in the

environment must not exceed 4Pa (4x10-5 bar). Provide adequate ventilation in the environment for a safe

operation of the cooker hood. Follow the local laws applicable for external air evacuation.

- 6 -

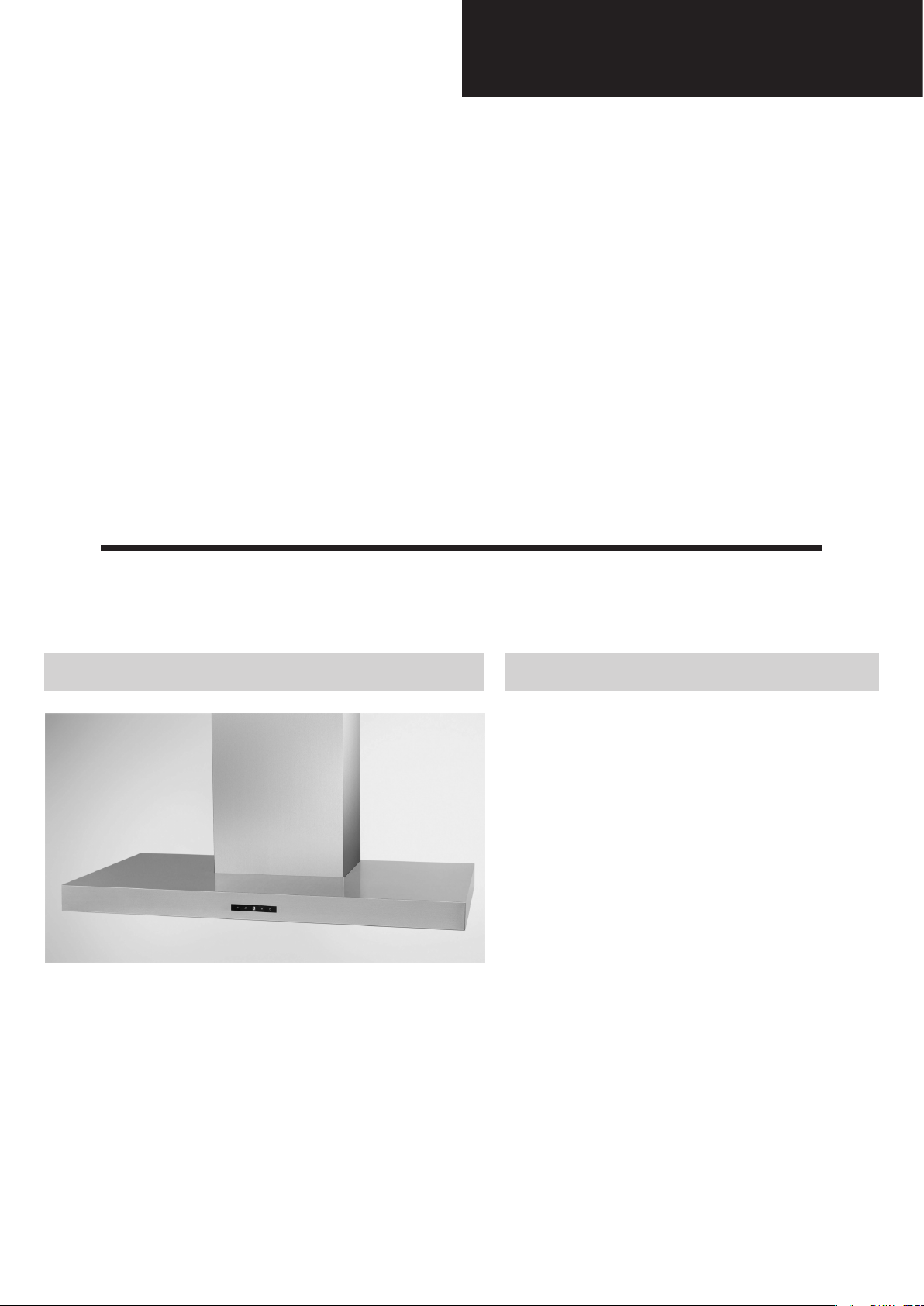

Distance from the hob

• The minimum distance between the support surfaces of the cooking pots on the cooker top and the lowest part

of the cooker hood must be at least 650 mm.

If a connection tube composed of two parts is used, the upper part must be placed outside the lower part.

Do not connect the cooker hood exhaust to the same conductor used to circulate hot air or for evacuating fumes

from other appliances generated by other than an electrical source.

- 7 -

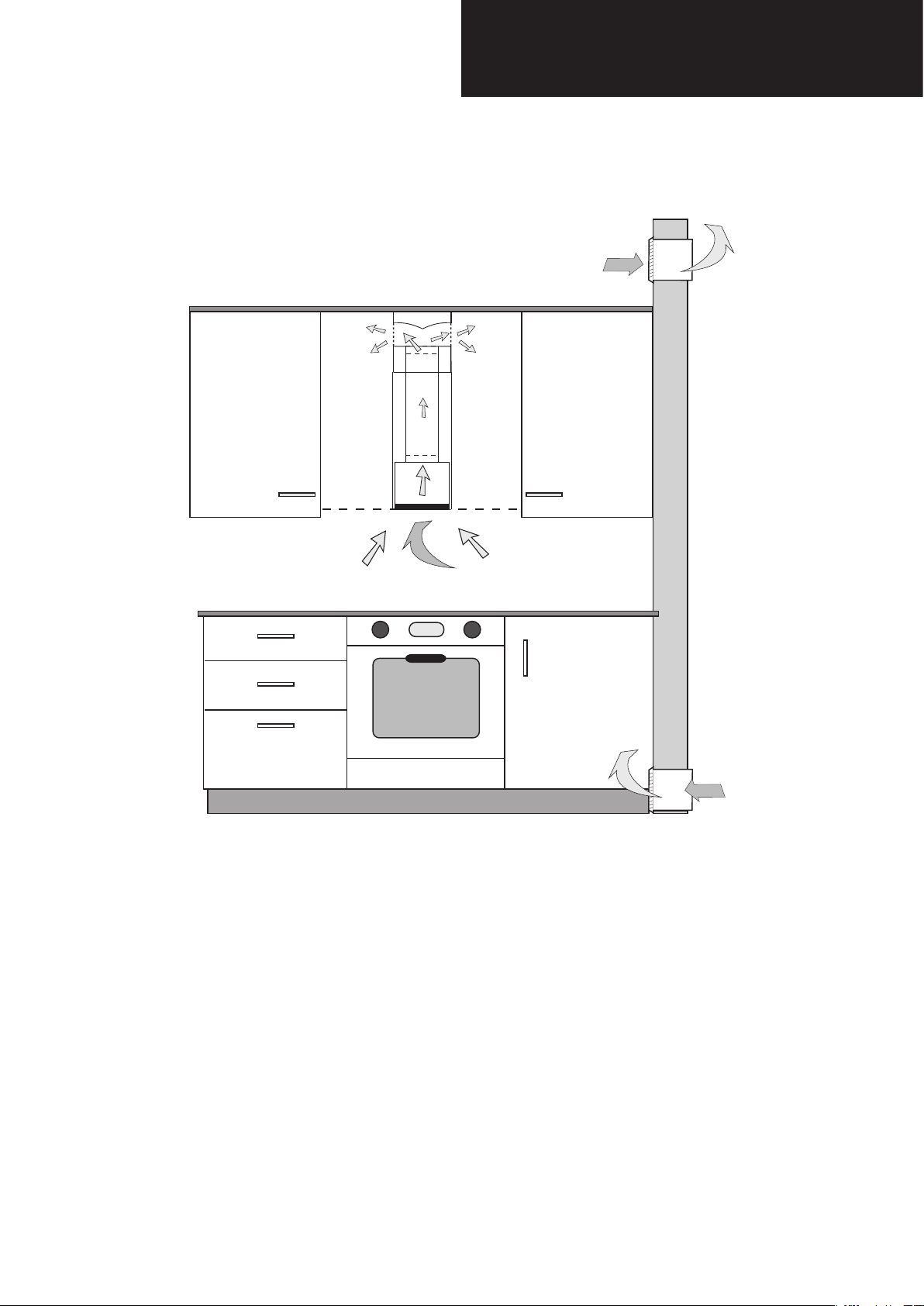

Technical specications

CONTROLS

ALUMINIUM PANELS

LIGHT

MODEL EAGLE

Size 600-900 mm

Finish St.steel A430

Motor JC2

Extracting power (m³/h) 500

Voltage 220-240V ~ 50/60Hz

Motor power consumption 1 x 130 W

Product certication CE - NEMKO

Product class II

Type model TYPE TOP..... MODEL:1J2HE

Air outlet diameter (mm) 150

Controls Touch Control

Speeds 3+1

Version Recycling

Filters Aluminium panels

Charcoal Filters 2 Circular lters

Bulbs 2 x 20 W Halogen lamps

Weight Gross 13,6 - 16 Kg

- 8 -

DUCTS

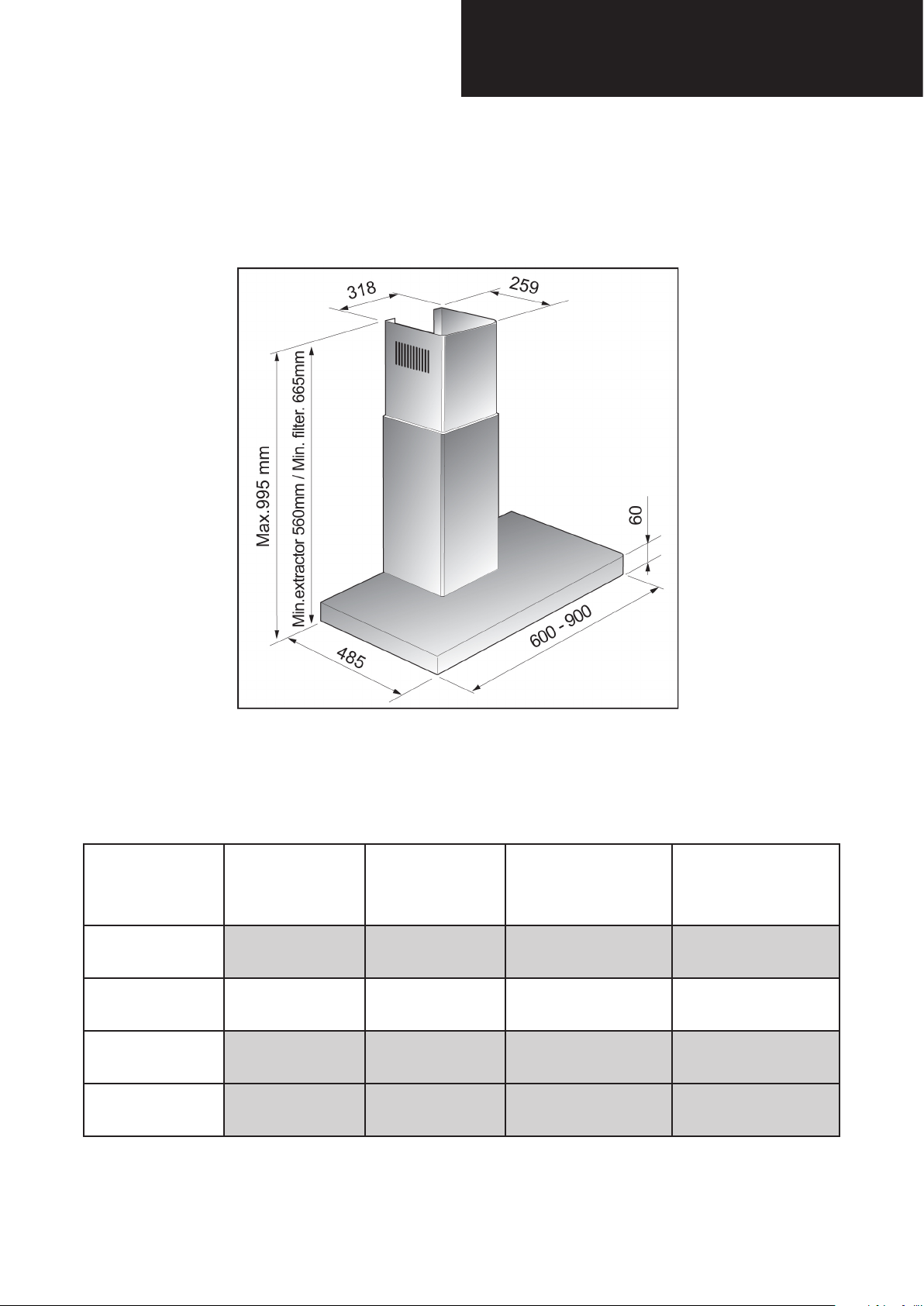

Technical data

- 9 -

motor power consumption 130 W

Speed Suction

(m³/h)

Pressure

(Pa)

Noise Level

(sound pressure)

dBA

Noise Level

(sound power)

dBA

1 172 135 34 44

2 279 213 44 54

3 380 257 52 62

4 500 286 57 67

Parts supplied

- 10 -

NON RETURN VALVE

MOUNTING SCREWS

AIR DEVIATOR

CHIMNEY BRACKET

2 CHARCOAL FILTERS

TYPE INSERT

3,2x13 self-tapping screw Pz 2

3,5x6 self-tapping screw Pz 2

Non-return valve

parts supplied

- 11 -

The non-return valve is recommended when the ap-

pliance is installed in the extracting version, to prevent

cold air blowing back in from outside.

The valve is made up of two parts which must be fixed

to the air outlet flange on the motor assembly

If the appliance is installed in the filtering version, the

non-return valve is not necessary.

- 12 -

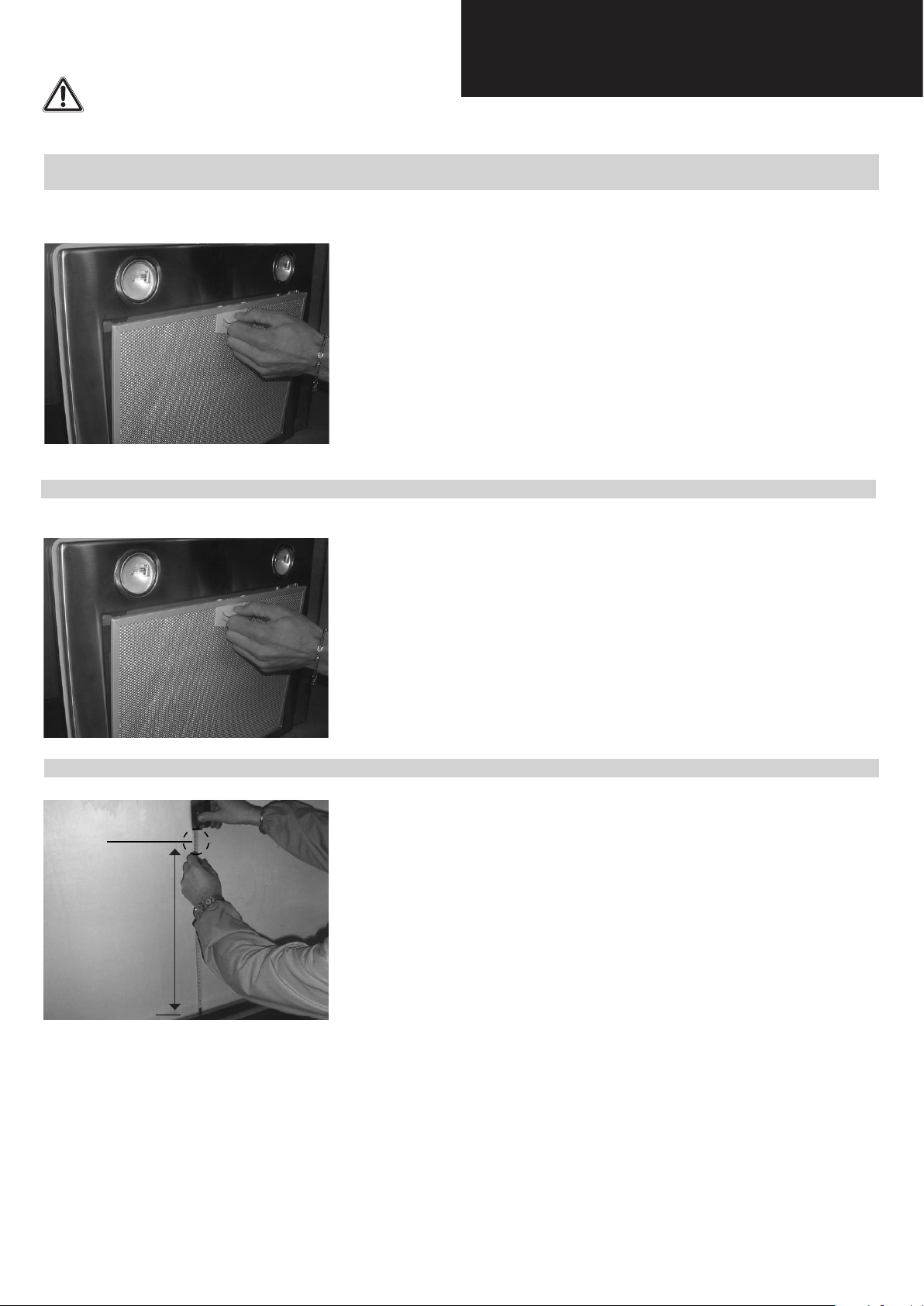

Aluminium panel

Charcoal lter

The metal filters and/or aluminium panel are also dishwasher

safe. If the filters are made using aluminium, or if an aluminium

panel is used, after a few washes the colour may change. This

does not mean they have to be replaced.

If the replacement and washing instructions are not followed, the

anti-grease filters may present a fire hazard.

To replace the aluminium panels, simply operate the handle (a)

provided for the purpose, as illustrated in the drawing.

The active carbon filters are used to purify the air which is relea-

sed back into the room. The filters are not washable or re-usable

and must be replaced at least once every four months. The acti-

ve carbon filter saturation level depends on the frequency with

which the appliance is used, the type of cooking performed and

the regularity with which the anti-grease filters are cleaned.

To replace the active charcoal filters, simply operate the handle

provided for the purpose, as illustrated in the drawing.

Replacing the aluminium panel (a) 7.1

Replacing the charcoal lter (b) 7.2

a

b

- 13 -

Installation

Fixing the appliance to a wall 8.1

Phase 1

Phase 2

Before starting to fix the hood, disconnect the anti-grease

filter for easier appliance handing. Before this operation, perform

the following steps:

Phase 1

- Pull handle as shown in the picture and remove the anti-grease

filter.

Phase 2

- Check the distance between the surface which carries the co-

oking utensils on the cooking device and the bottom surface of

the cooker hood, which must be not less than 650 mm. Mark the

position of the lower side of the hood on the wall.

650 mm

CAUTION!

Wear gloves during the installation of the product otherwise injury at ngers could happen by sharp edges.

- 14 -

Installation

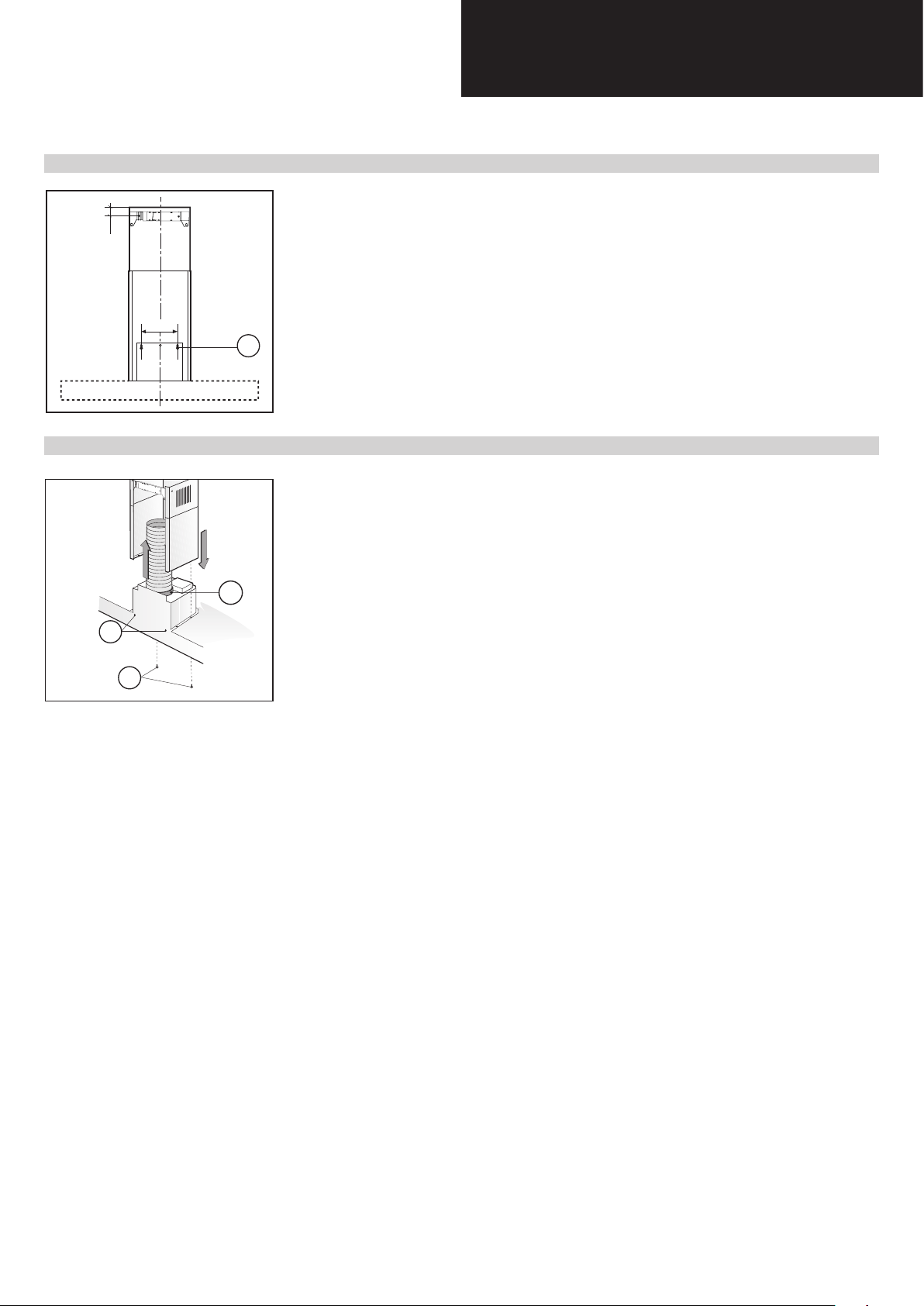

Phase 3

Phase 4

Phase 3

- Drill the holes A respecting the distances indicated. Fix the appli-

ance to the wall and align it in horizontal position to the wall units.

Phase 4

- When the appliance has been adjusted, definitely fix the hood

using the screws A. For the various installations use screws and

screw anchors suited to the type of wall (e.g. reinforced concrete,

plasterboard, etc.). If the screws and screw anchors are provided

with the product, check that they are suitable for the type of wall

on which the hood is to be fixed.

The hood is now fixed to the wall.

- 15 -

Fixing the decorative telescopic ue 8.2

Installation

Phase 2

Phase 1

- Arrange the electrical power supply within the dimensions of

the decorative ue. If your appliance is to be installed in the duct-

ing version or in the version with external motor, prepare the air

exhaust opening.

- Adjust the width of the support bracket of the upper ue.

- Then x it to the ceiling using the screws A in such a way that it is

in line with your hood and respecting the distance from the ceiling.

Phase 2

- Cut the air deviator D with a cutter, following carefully the first

pre-cut starting from the outer edge on both sides, as indicated

in the picture.

Air deviator D

Phase 1

A

B

- 16 -

Installation

D

C

C

D

Phase 3

- Take the air deviator D and make two holes as shown in the pho-

tographs.

- Secure the duct fixing bracket to the air deviator D as shown in

the photograph.

Phase 4

- Carry out final fixing of the air deflector D to the wall with a

fixing screw as shown in the photograph.

Phase 4

D

Phase 3

Ø 6

- 17 -

Phase 7

Phase 7

- Extend the upper decorative duct as far as bracket C and fix it in

place using screws X.

Installation

C

Phase 5

D

F

G

Phase 6

Phase 5

- Connect the flexible pipe (not supplied) to the deviator D.

- Fix the flexible pipe onto the connector flange G.

Phase 6

- Take care not to scratch the duct; wear gloves when removing

the protective lm.

- 18 -

Installation

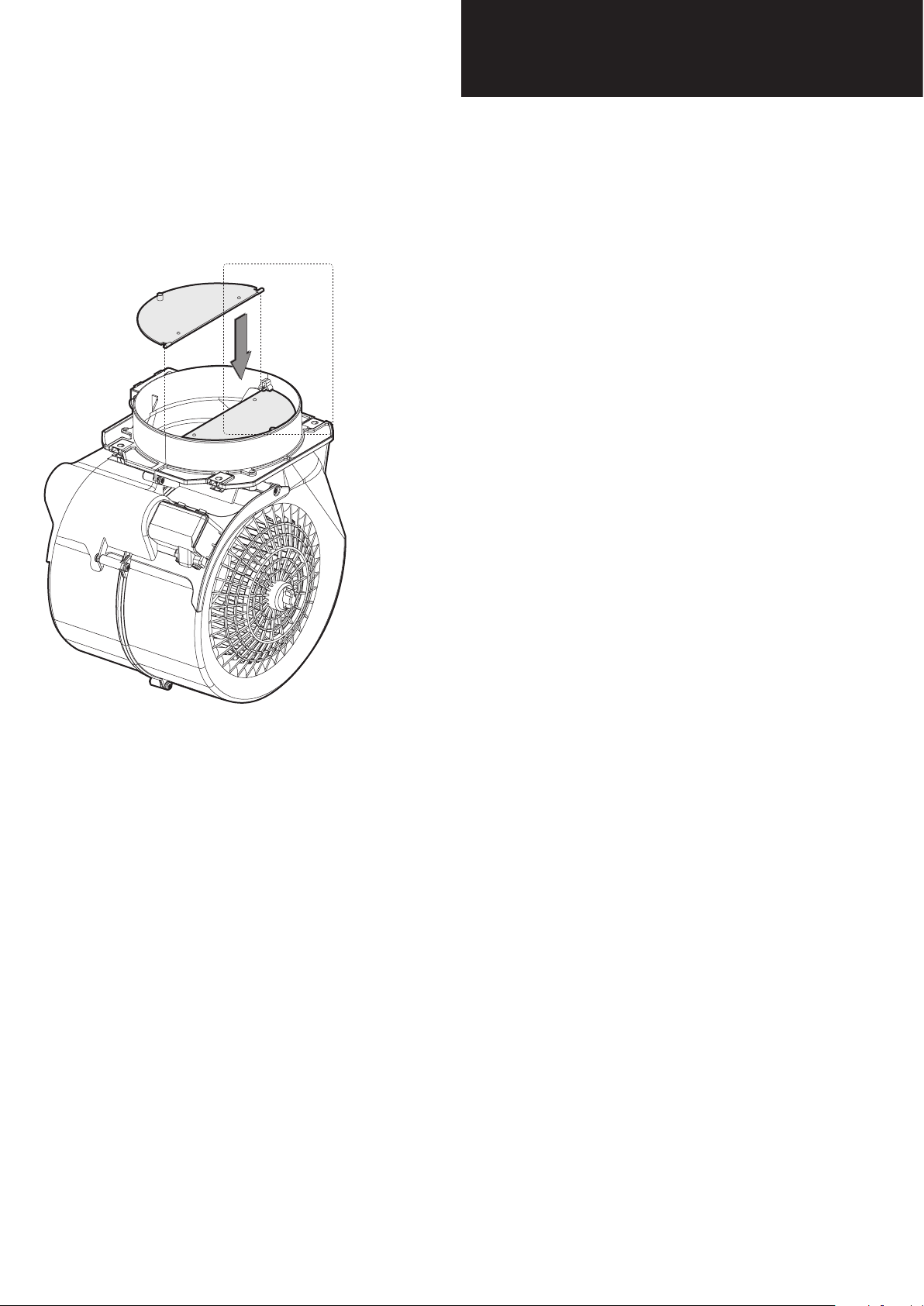

Installing the charcoal lters and aluminum panels 8.3

Phase 1

Phase 2

Phase 1

- Take the active charcoal filters and position them in their hou-

sings.

Phase 2

- Take the aluminum panels and position them in their housings.

- 19 -

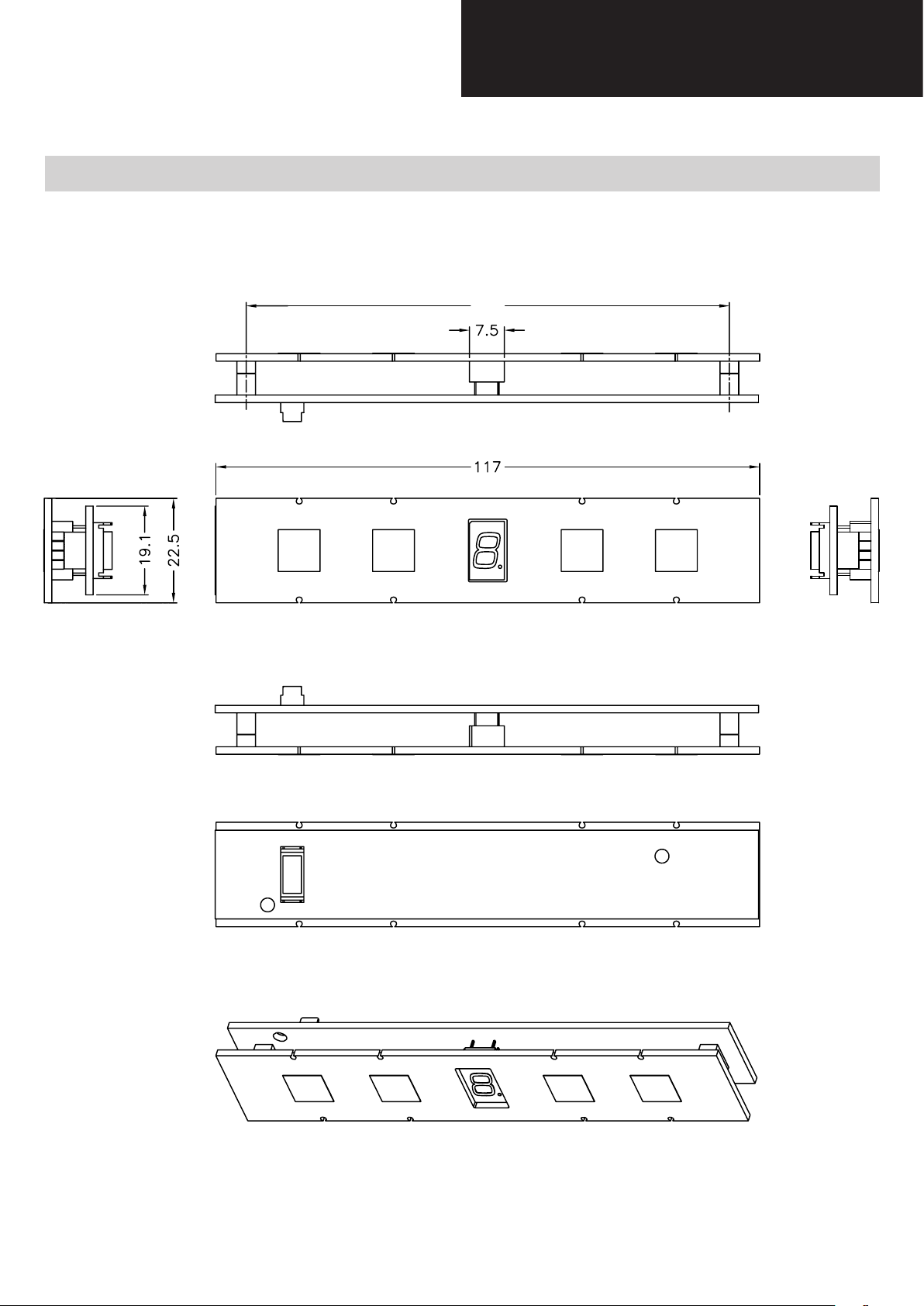

Control drawing

Conguration 9.1

A = on/o lights switch

B = on/o cooker hood switch

C = indicates the motor speed level selected

D = switches on the cooker hood. Increases the motor speed

E = timer

- 20 -

Control drawing

Technical drawing of control board 9.2

Table of contents

Other Tecnowind Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Sirius Satellite Radio

Sirius Satellite Radio SLTC 111 Installation, Use and Maintenance Instruction

Whirlpool

Whirlpool HE36W Health & safety, use & care and installation guide

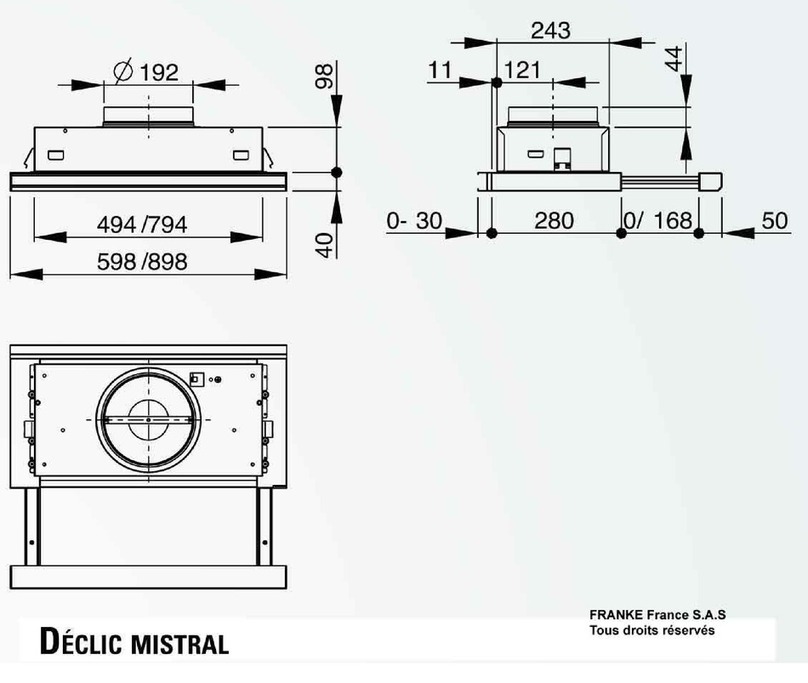

ROBLIN

ROBLIN DECLIC MISTRAL Dimensions

Vallox

Vallox X-Line KTX manual

FALMEC

FALMEC Lumen isola 175 Instruction booklet

KRONAsteel

KRONAsteel RUT 600 inox 3P-S Application Sheet

Electrolux

Electrolux EFC 635 X user manual

Miele

Miele DA 5990 W EXT Installation diagram

Baumatic

Baumatic BT120 Instructions for installation, use and maintenance

Lamona

Lamona LAM2877 user manual

Panasonic

Panasonic FV70HQU1 operating instructions

BKI

BKI Rotisserie Ventless Hood VGH-Series Installation and operation manual