TECSYSTEM T538 User manual

http://www.tecsystem.it

T538

Software rel. 3.1

INSTRUCTION MANUAL

TECSYSTEM S.r.l.

Via Cristoforo Colombo, 5/C

20094 Corsico (MI)

tel. +39 - 02 - 48601011 / 4581861

Fax: +39 - 02 – 48600783

T538 protection relays

TECSYSTEM S.r.l ®

R.6 17/09/03

T538

Software rel. 3.1

3

T538 protection relays

TECSYSTEM S.r.l ®

1) TECHNICAL SPECIFICATIONS

AUXILIARY POWER SUPPLY

Rated voltage 24-240 Vac-dc

Maximum ratings 20.270 Vac-dc

Vdc with reversible polarities

COMMUNICATION

Opt. Output RS232/485 Modbus® RTU

INPUTS

8 inputs RTD Pt100 sensors-3 wires

removable rear terminals

input channels protected against elec-

tromagnetic noises and spikes

sensors length cables compensation

up to 500 m (1mm²)

opt. 8 analog inputs 4-20 mA (range 0-

240°C)

OUTPUTS

2 alarm relays (ALARM-TRIP)

1 alarm relay for sensor fault or working

anomaly (FAULT)

output contacts capacity: 5A-250Vac

res.

Arranged for output relays test

ALARM & TRIP programming for Fail

Safe and NO Fail safe

Opt. Relay AUX.1 (FAN)

TESTS AND PERFORMANCES

Assembling in accordance with CE

rules

Protection against electrical and mag-

netic noises: CEI-EN50081-2/50082-2

Dielectric strength 2500 Vac for 1 min.

from relays to sensors, relays to power

supply, power supply to sensors

Accuracy: ± 1% full scale, ± 1 digit

Ambient operating temperature –20°C

to +60°C

Humidity 90% no-condensing

ABS self-extinguishing housing

NORYL 94VO

Burden 3VA

Data storage 10 years minimum

Digital linearity of sensors signal

Self-diagnostic circuit

Opt. Protection treatment of electronic

part

Opt frontal plastic protection

DISPLAYING AND DATA MANAGEMENT

1display 13mm high 3 digit with 3 digit

for displaying temperatures

8 LED for displaying reference channel

8 LED indicating alarm or trip

LED indicating fault

Temperature monitoring from 0°C to

240°C

2 alarm thresholds for each input

sensors diagnostic (Fcc-Foc-Fcd)

entering the programming by frontal

push button

automatic output from programming cy-

cle after 1 min. of no-operation

wrong programming automatic display

programmed data call out

possibility of setting manual channel

scanning or hottest channel

maximum temperatures storage

number of channels software program-

DIMENSIONS

96x96mm-DIN43700-Prof.150mm

(with rear terminals)

panel cutout 92x92mm

Rated voltage 24-240 Vac-dc

Rated voltage 24-240 Vac-dc

. Output RS232/485 Modbus® RTU

OUTPUTS

2 alarm relays (ALARM-TRIP)

2 alarm relays (ALARM-TRIP)

1 alarm relay for sensor fault or working

1 alarm relay for sensor fault or working

anomaly (FAULT)

anomaly (FAULT)

output contacts capacity: 5A-250Vac

output contacts capacity: 5A-250Vac

res.

Arranged for output relays test

Arranged for output relays test

ALARM & TRIP programming for Fail

ALARM & TRIP programming for Fail

Safe and NO Fail safe

opt. 8 analog inputs 4-20 mA (range 0-

opt. 8 analog inputs 4-20 mA (range 0-

240°C)

LED indicating fault

Temperature monitoring from 0°C to

Temperature monitoring from 0°C to

240°C

96x96mm-DIN43700-Prof.150mm

2 alarm thresholds for each input

4T538 protection relays

TECSYSTEM S.r.l ®

2) MOUNTING

Make a hole with the dimensions of 92x92 mm in the panel plate.

Fasten firmly the unit by the fixing blocks you are equipped with.

3) POWER SUPPLY

The T538 unit has an Universal Power Supply: it can be supplied indifferently from 24 to

240 Vac-dc without any respect of the polarities.

This particularity is obtained by the application of a tried power supplier which provides the

installer free from the worries concerning the correct Vac or Vdc power supply.

The ground cable must be fixed to the clamp 41.

When the unit is supplied directly from the secondary of the transformers to protect, it can

be fulminated by high intensity overvoltage.

This happens when the charge is connected with the locking of the master switch.

This is much more evident when the 220 Vac voltage is obtained directly from the bars of

the secondary of the transformers and there is a fixed phase adjustment condenser of the

same transformer.

In order to protect the electronic apparatus, we suggest the application of the elec-

tronic discharges of the serie PT73 –220 which have been studied by Tecsystem Srl

for this specific purpose.

Alternately, we suggest the application of a power supply by 24 Vac or better 24 Vdc.

4) ALARMS ELECTRICAL CONNECTIONS

Carry out the electrical connections on the removable terminal board after having taken

them off from the apparatus (follow the Fig.1).

ALARM and TRIP relays energize only when the prefixed temperature limits are reached

(NO Fail Safe) or deenergize when the prefixed temperature limits are reached (Fail Safe).

The FAULT relay energizes always when the apparatus is powered and it de-energizes

when the Pt100 are damaged or when there is not any power supply voltage.

2) MOUNTING

The T538 unit has an Universal Power Supply: it can be supplied indifferently from 24 to

The T538 unit has an Universal Power Supply: it can be supplied indifferently from 24 to

240 Vac-dc without any respect of the polarities.

Make a hole with the dimensions of 92x92 mm in the panel plate.

Make a hole with the dimensions of 92x92 mm in the panel plate.

Fasten firmly the unit by the fixing blocks you are equipped with.

3) POWER SUPPLY

5

T538 protection relays

TECSYSTEM S.r.l ®

5) MEASURE SIGNALS TRANSPORT

All the transport cables of the Pt100 measure signals must absolutely:

be divided from the power ones

be realized with shielded cable with twisted conductors

have a section of min 0,5 mm²

be twisted if you have not any shield

be firmly fixed in the terminal board

have tinned or silvered conductors

All the serie “T” units have the sensors linearization with a max error of 0,5% v.f.s..

TECSYSTEM srl has realized a special cable for the measure signal transport with

all the protection requirements in accordance with CEI Normes: mod. CT-ES

6) WARRANTY

The serie “T” units are under warranty for 12 months from the delivery date signed on

the unit.

The warranty is recognised when the unit breaks down due to some production faults or

insufficient calibration.

The warranty is not valid when the unit is tampered with or when it has been damaged

for a wrong sensors connection or wrong power supply, out of the max working limits

(20÷270 Vac-dc). The warranty is not valid when the unit has been fulminated by exces-

sive transitory voltages. In this case TECSYSTEM Srl does not answer for damages

caused by faulted or defective units. All the delivery expenses (there and back) of the

unit must be paid by the Customer

In case of dispute, the qualified FORUM is the one in Milan.

The warranty is always F.CO our Company in Corsico.

7) PT100 EXTENSION CABLE: TECHNICAL SPECIFICATIONS

Cable 20xAWG 20/19 cu/stg

Section 0,55 mm²

Antiflame Insulation PVC105

In accordance with CEI 20.35 IEC 332.1

Max. working temperature: 105°C

Conformation : 4 terns of numbered conductors (1-1-1.........4-4-4)

RRW twisted and coloured conductors

Cu/stg Shield

PVC Antiflame protecting covering

External diameter 9,0 mm

Skeins of 100 m

All the transport cables of the Pt100 measure signals must absolutely:

5) MEASURE SIGNALS TRANSPORT

7) PT100 EXTENSION CABLE: TECHNICAL SPECIFICATIONS

6T538 protection relays

TECSYSTEM S.r.l ®

8) DISPLAY MODE

Pressing on DISPLAY MODE you establish the visualization ways of the display:

HOT : the unit visualizes automatically the hottest channel

MAN : manual reading of the channels temperature by !

!!

!and "

""

"push-buttons

T.MAX :the unit visualizes the max. temperature reached by the sensors and

the eventual alarms starting from last reset.

SCAN :channels are cyclically every 2 seconds

9) WORKING PROGRAM CONTROL

In order to control the programmed temperature values, you have to push shortly on PRG.

Pushing PRG repeatedly the values established previously appear on the display in se-

quence.

In order to end the visualization you have to push ENT.

10) RANGE

Pressing “SET” button when the unit is on AUTOMATIC working, the ALARM and TRIP

values appear on the display in sequence.

To have a more rapid channels scanning, you have to press many times the SET button.

At the end it is carried out the LAMP TEST

11) LAMP TEST

It is advisable to carry out regularly the LED test of the unit. For this operation you have to

push TEST.

If one of the LED does not work, please send us the unit in order to be repaired.

8) DISPLAY MODE

9) WORKING PROGRAM CONTROL

10) RANGE

11) LAMP TEST

It is advisable to carry out regularly the LED test of the unit. For this operation you have to

7

T538 protection relays

TECSYSTEM S.r.l ®

12) OVER TEMPERATURE ( AUTO and MAN WORKING )

When one or more Pt100 sensors survey higher temperatures than the prefixed ones

switch on:

the GREEN led/s referred to the channel/s

the led referred to ALARM is YELLOW

the led referred to TRIP is RED and the ALARM-TRIP relays commute

When the temperature is 1°C under the prefixed limit, the led switches off and the relay re-

sets.

The over temperature alarm signal is intentionally delayed in order to avoid false alarms

caused by temperature transistors.

The max. temperatures are any way memorized even if their performance time is not

enough long to cause any alarm.

IMPORTANT NOTICE

Before making the insulation test on the electrical panel on which the unit is installed, you

must take it off from the power supply in order to keep it out of damage.

13) FAULT

The T538 monitoring unit is provided with a self-diagnostic program with alarm relay and

visualization of the kind of fault of the sensors.

An additional program allows to distinguish a high temperature signal given by an eventual

defective sensor. In this case the FAULT relays commutes and on the display appears Fcd

with the relative defective sensor.

This particular program avoids the signalization of accidental alarms due to defective sen-

sors which indicate wrong temperature values.

14) DATA STORED DIAGNOSTIC

If the internal memory is corrupted, at the start up on display it appears the message Ech

with the FAULT alarm. In this case the unit uploads the default parameters; press RESET

to delete the FAULT alarm and the Ech message; start a new programming cycle with the

desired parameters.Turn off and turn on the unit to check if memory work properly. If it is

damaged or broken, on display it appears Ech message again. In this case, send the unit

to Tecsystem for reparation.

15) THERMOMETRIC SENSORS DIAGNOSTIC

In the event one of the thermometric sensors installed on the machine to protect is dam-

aged, the FAULT relay energizes immediately, the ALARM and TRIP LED’s of the dam-

aged channel (Chn) lighten and the FAULT LED is lightening.

The screen will automatically display a message showing the fault condition:

· Fcc sensor is short circuited

· Foc sensor is open

· Fcd sensor is fault

12) OVER TEMPERATURE ( AUTO and MAN WORKING )

IMPORTANT NOTICE

13) FAULT

14) DATA STORED DIAGNOSTIC

15) THERMOMETRIC SENSORS DIAGNOSTIC

8T538 protection relays

TECSYSTEM S.r.l ®

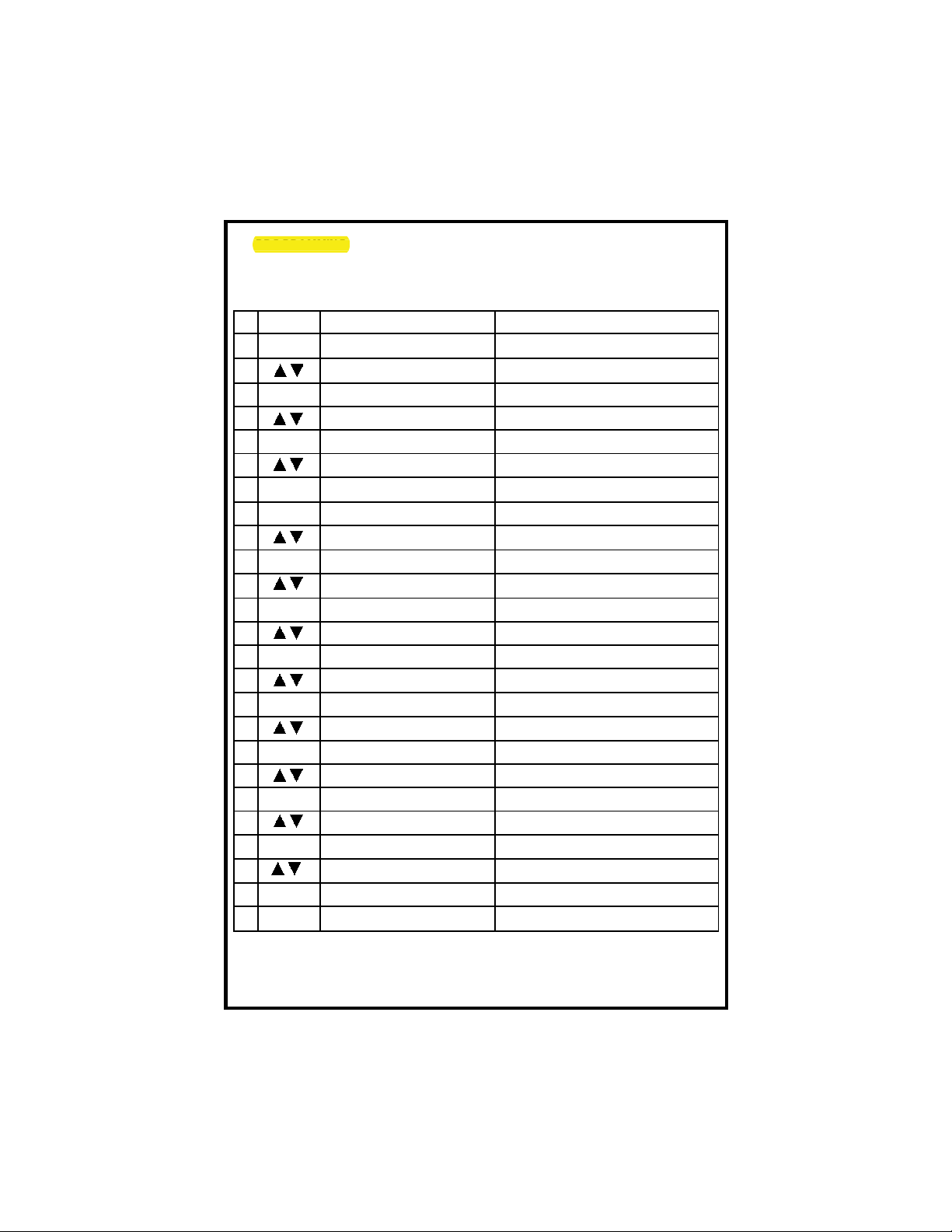

16) PROGRAMMING:

LED PROGRAM SWITCH OFF: VISUALIZATION OF THE PROGRAM

LED PROGRAM ON: INPUT TO THE PROGRAM

N° KEY DISPLAY NOTES

1PRG/SET start programming appears nCH

00n Keep pressed the push button PRG/SET for 7”

until stops to lighten to enter the program.

2set up the number n° of the desired

channels from CH1 to CH8

3PRG/SET set T° of ALARM of CH1 appears

4set up the desired limit Set 000 to disable ALARM relay

5PRG/SET Set T° of TRIP of CH1 appears

6set up the desired limit Set 000 to disable TRIP relay

7PRG/SET Repeat same procedure starting

from “2”

8PRG/SET on display Fcd appears

9set up Fcd YES or NO Fcd YES= control of damaged Pt100 con-

nected

10 PRG/SET ONLY IF opt. RS232/RS485

11 set up the Baud rate (E:parity

Even, n:parity None) Baud rate: E1.2 - E2.4 - E9.6 - E19.2

n1.2 - n2.4 - n9.6 - n19.2

12 PRG/SET ONLY IF OPZ. RS485

13 set up address for opt. RS485 from 0 to 32 max

14 PRG/SET on display appears Prg

15 set up Prg YES or no Prg NO= the programming is blocked

16 PRG/SET set up the function of the ALARM

relay

17 function for ALARM Fail Safe YES - Fail Safe NO

18 PRG/SET set up the function of the TRIP relay

19 function for TRIP Fail Safe YES - Fail Safe NO

20 PRG/SET on display appears HLd

21 set up HLd YES or no with HLd YES function HOLD established

22 PRG/SET The message 4.20 appears on

display (only with option 4.20 mA)

23 1-8,HOT Select the channel for 4.20 mA output

24 PRG/SET out of the programming lamp test

25 ENT/

RESET return to step 1

In case exist the option AUX.1 relay, It have to be set the values of FAN OFF and FAN ON, accord-

ing to the programming procedure, starting from point 2.

16) PROGRAMMING:

9

T538 protection relays

TECSYSTEM S.r.l ®

17) HOLD FUNCTION

If you set up by programming HLD-YES, ALARM and TRIP relays will be energized until

the manual reset when the temperatur falls down below the set alarm thresholds. If you do

not want this function you have to establish HLD-NO by !

!!

!and "

""

"push-buttons.

18) PROGRAMMING REHABILITATION IN CASE OF BLOCK (Prg no)

If the programming has been blocked, in order to enter again the programming of the unit,

it is necessary to carry out the following unblocking procedure :

enter the program vision way pushing PRG

keep TEST pushed until PRG stops to lighten. ( LED PROGRAM alight )

During the blocking, pushing PRG for more than two seconds, on the display it appears

“noP” to indicate the impossibility to program the data.

19) ALARM RELAYS TEST

This function allows to test the relays working without any additional instrument.

To carry out the test you have to push TEST for 5 seconds: all the LED will switch on and

on the display will appear tSt lightening.

Release it when the RELAY TEST LED will be alight.

The first relay to test will be indicated by the display and the respective LED will be alight.

The relays to test will be indicated on the display by:

“Fan” : fan relay (if the option is present)

“Flt” : Pt100 fault relay

“Alr” : alarm relay

“TrP” : trip relay

Select the relay to test by !

!!

!and "

""

"push-buttons. Energize it pushing SET and de-

energize it pushing RESET.

In order to stop this procedure, you have to push again TEST and all the relays will be re-

stored to the starting configuration.

After 5 minutes of inactivity of the keyboard, the TEST RELAY procedure will be automati-

cally interrupted.

20) ALARM RELAY EXCLUSION

If you want to exclude the alarm signal, you have to push RESET: the relay de-energizes

and the respective LED, which was alight, starts to lighten. If the transformer temperatures

is still rising, the ALARM relay will energize again until to have a temperature value of 5°C

less than TRIP threshold. In this moment the user can exclude again the ALARM, but in

this case, it will not appear any other indication as regards ALARM relay.

The exclusion system will be automatically disconnected when the temperature falls down

the ALARM threshold.

17) HOLD FUNCTION

18) PROGRAMMING REHABILITATION IN CASE OF BLOCK (Prg no)

19) ALARM RELAYS TEST

20) ALARM RELAY EXCLUSION

10 T538 protection relays

TECSYSTEM S.r.l ®

FAULTS DIAGNOSTIC CAUSES AND REMEDIES

The unit doesn’t switch on even if there is volt-

age to the terminals Connector not well fit in its place.

Connection wires not well closed in the clamp Burnt

power supplier.

Take away and give again voltage.

The sensor is damaged The FAULT relay closes and the FAULT LED

switches on. The RED LED of the relative channel is

lightening. It is indicated on the display the kind of

damage of the sensors:

FOC= sensor open

FCC= sensor in short circuit

One of the eight channels is in FAULT for FOC/

FCC Check the Pt100 sensors connection.

Probable damaged sensor.

Replace the damaged sensor

During the main switch manoeuvre ON-OFF, the

ALARM and TRIP relays energize Strong electrical noises on the power supply line.

Plug in the PT73.

Check if the shield of the signal transport cable is

connected to the ground in the side of the panel.

If you have not any shielded cable, You have to put

it. (Mod. CT-ES).

If it is not at your disposal, twist the three connecting

wires of the sensors.

All the Pt100 sensors are in FCC. Wrong connection of the sensors. Upside-down ter-

minal board.

Check the connections and the terminal board

The temperature indicated by 1 or more chan-

nels is wrong. Pt100 Sensor/s defective.

Check the sensor resistance by an Ohm meter.

Unit with input circuit unrated.

Send the unit to TECSYSTEM S.r.l. for reparation.

With power supply at 24 Vdc, the unit switches

off and , after a tension drop, it doesn’t switch on

again.

Take off the voltage to the unit and check that the

value of the Vdc is from 20 up to 24V.

Give again voltage.

If the unit does not switch on , send the unit back to

TECSYSTEM S.r.l.

Sudden release of the main switch with a normal

temperature level.

An only channel caused the unhooking.

Pt100 sensor defective (Fcd).

Replace the sensor.Check the measure signal ter-

minal board.

FAULTS DIAGNOSTIC

CAUSES AND REMEDIES

11

T538 protection relays

TECSYSTEM S.r.l ®

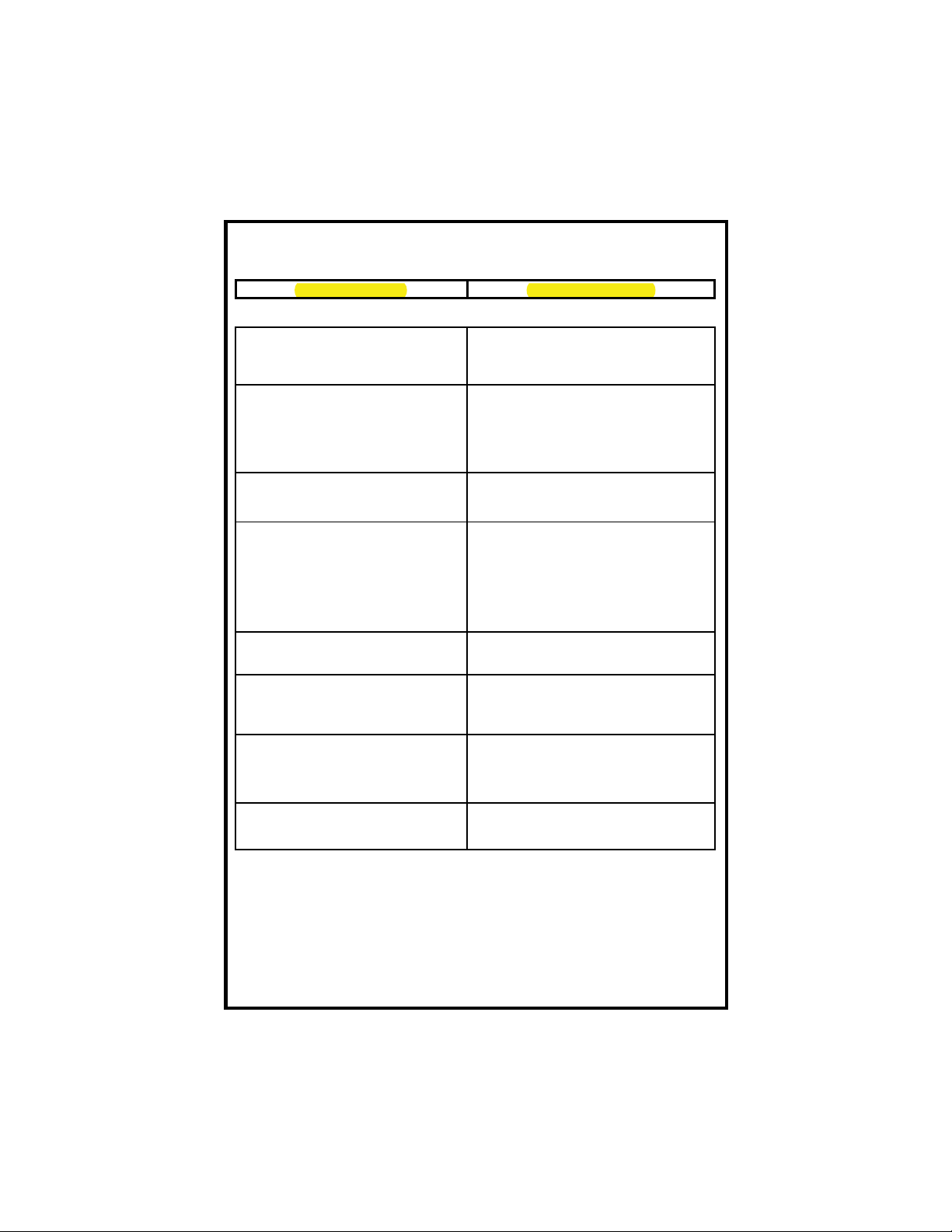

ELECTRICAL CONNECTIONS

OUTPUT ALARM RELAY WITH FAIL SAFE

60 61 62

RS 232 GND TX RX

RS 485 GND - +

40

41

42 POWER SUPPLY

24-240 VCA-VCC

WHITE

RED

RED

Pt100

13 14 15 19 20 21 25 26 27 31 32 33

CH 1 CH 3 CH 5 CH 7

INPUT Pt100

16 17 18 22 23 24 28 29 30 34 35 36

CH 2 CH 4 CH 6 CH 8

1 2 3

ALARM

4 5 6

TRIP

7 8 9

FAULT

10 11

FAN

1 2 3

ALARM

4 5 6

TRIP

7 8 9

FAULT

10 11

FAN

OUTPUT ALARM RELAY WITH FAIL SAFE ON

70 71 72 73

+ - Vcc Gnd

OUT 4-20 mA

ELECTRICAL CONNECTIONS

41

OUTPUT ALARM RELAY WITH FAIL SAFE

40

60 61 62

RS 232 GND TX RX

RS 485 GND - +

RS 485 GND - +

12 T538 protection relays

TECSYSTEM S.r.l ®

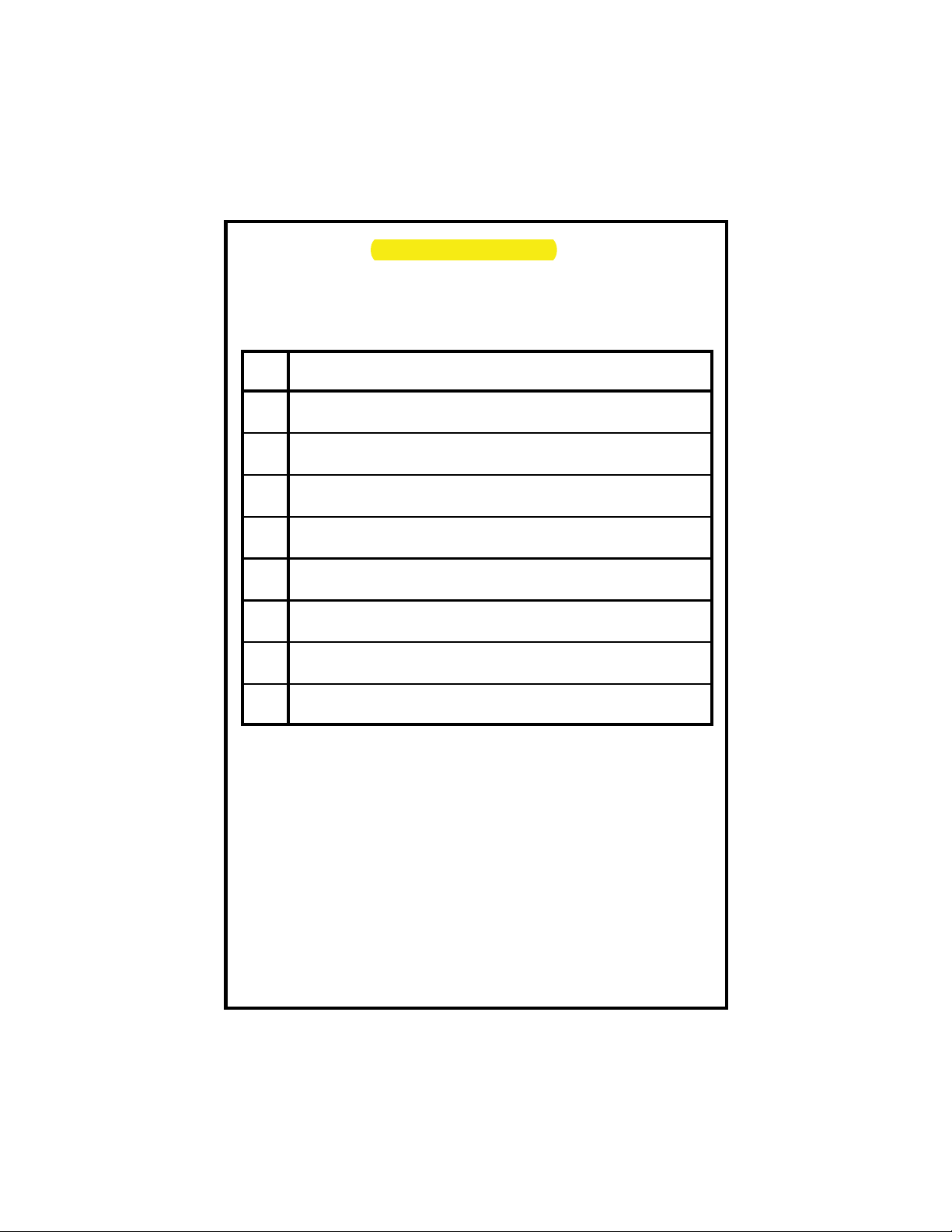

T538 TEST DESCRIPTION

Date of shipment:

N° Description

1 PC board test

2 Input test

3 Test of relay contacts and outputs

4 Key test

5 Lamp test

6 Calibration at 100 and 200°C (Range 0 - 240°C)

7 Software test

8 Burn-in minimum 24h

The unit was submitted to the following tests during production:

T538 TEST DESCRIPTION

This manual suits for next models

3

Table of contents

Other TECSYSTEM Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

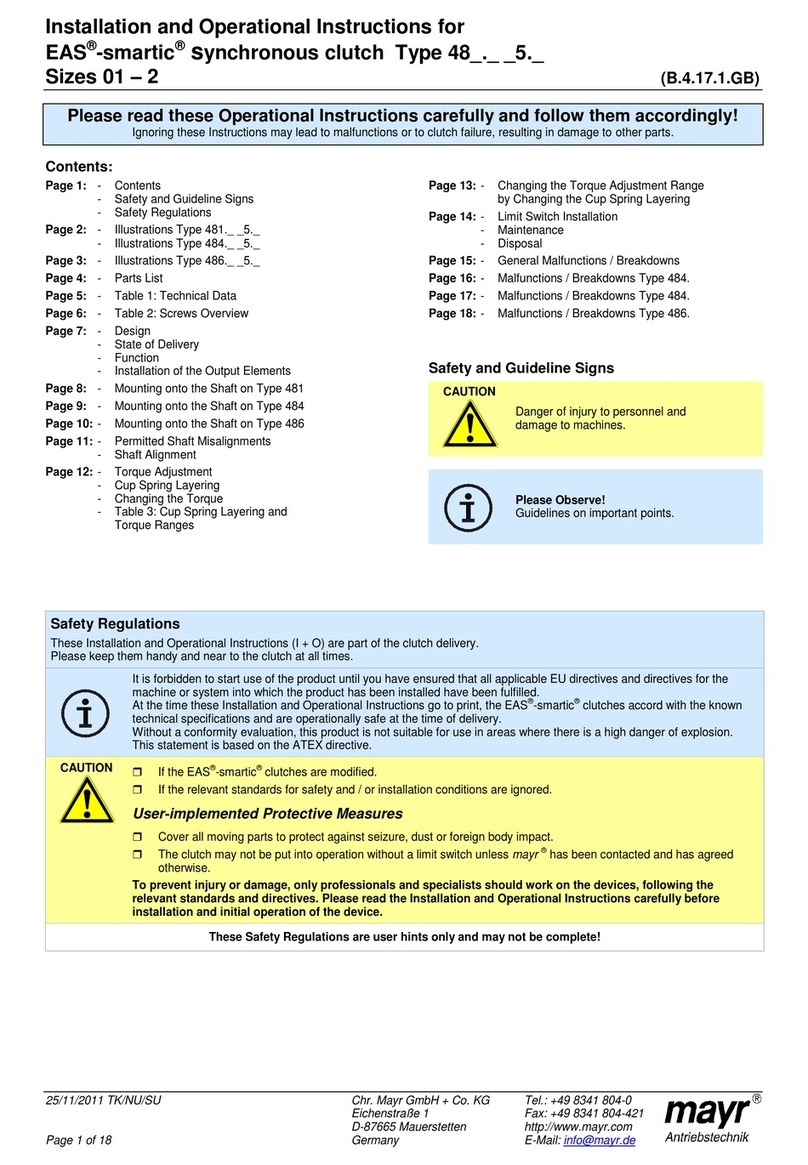

Mayr

Mayr EAS-smartic 484.XX5 Series Installation and operational instructions

Jet

Jet 190918 operating instructions

JMA Wireless

JMA Wireless Weather Protection System WPS-DM-14S installation instructions

Mark 7

Mark 7 APEX 10 user manual

ABB

ABB HT843539 Operation manual

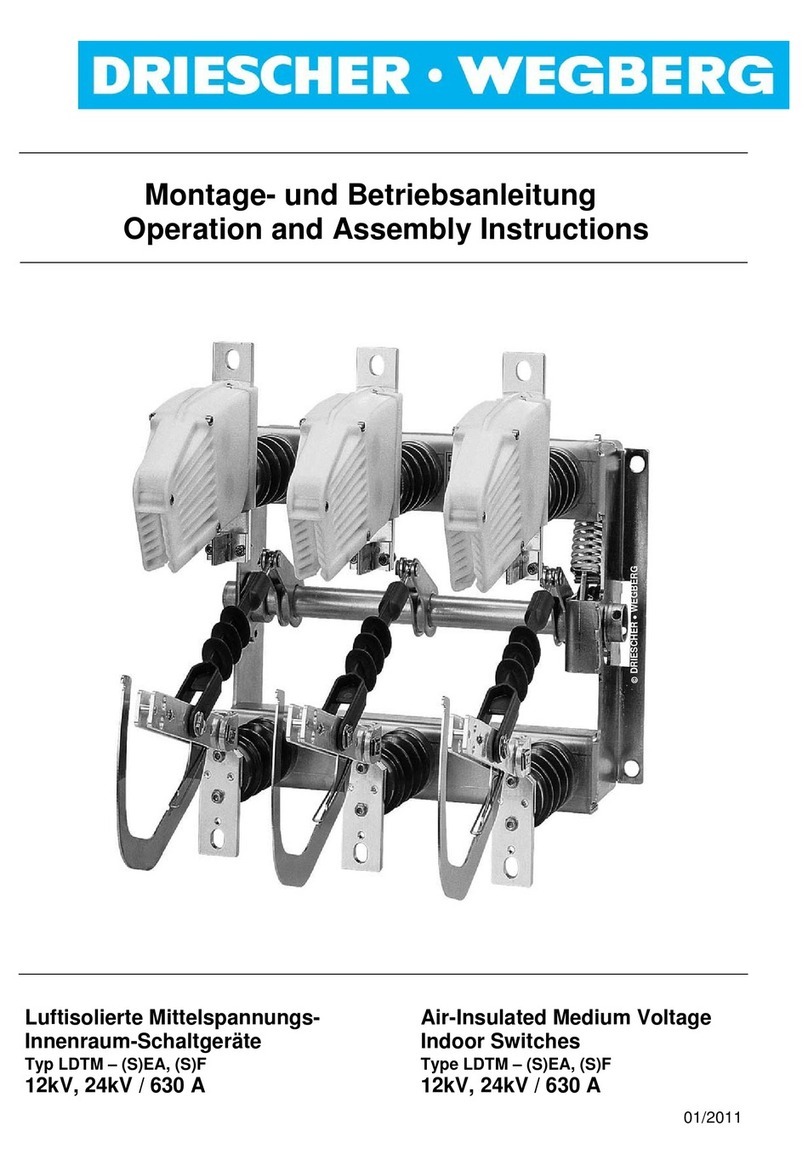

DRIESCHER-WEGBERG

DRIESCHER-WEGBERG LDTM 12/630 F-E EA-E Operation and assembly instructions