Tecumseh F31HC Installation and user guide

ENGLISH

Installation, Operation, Service

and

Maintenance Instructions

“UNIT COOLERS FOR COLD ROOMS”

Model Series

F31HC / F35HC

UNIT FOR USE WITH WALK-IN COOLER,

FREEZER OR REFRIGERATED WAREHOUSE

2

TABLE OF CONTENTS

INSTALLATION AND OPERATION MANUAL

SUBJECT PAGE #

Warning Symbols And Placards 3

General Safety Information 4

Product Warranty Statement 5

Receiving And Inspection 5

Uncrating And Rigging 5-6

Unit Mounting 6-8

Locating Equipment 7

Drain Line Piping 8-9

Refrigerant Piping 10

Refrigerant Piping (Distributor / TXV / Solenoid Valve) 11

Leak Testing, Evacuation And Charging 12

Evaporator Superheat 12

Refrigerant Blends / Temperature Glide 13

Field & Factory Wiring / Electrical Requirements 13

Typical Field Wiring Diagrams 14 - 22

Start Up 23

Service - Maintenance (Fan / Motor Assy) 24

Service - Maintenance (Coil Corrosion) 24

Service - Maintenance (Defrost Cycle / Heaters) 25

Remove / Replace Fan And Motor Assy 26

Remove / Replace Defrost Heaters 27

Start Up / Service / Maintenance Notes 28

Factory Contact Information 29

3

WARNING SYMBOLS AND THEIR MEANING

Check Guard

Ear Protection

Required

Eye Protection

Required

Hand Protection

Required

No Fire, Open

Flame or

Smoking

Sharp ElementOverhead LoadAutomatic StartHot Surfaces

Toxic Substan-

ces

Electricity

Hand Injury Pos-

sible

MANDATORY SIGNS AND THEIR MEANING

OTHER SIGNS AND THEIR MEANING

Protective Clo-

thing Reqd

Forklift Traffic

Connect To Earth

Ground

Use Safety

Footwear

Hard Hat Area

Activate Before

Work

This is only a “Right To Know”

law in the state of CA. It does

not mean that LU-VE products

contain any substance or

materials that may cause cancer

or reproductive harm

4

RISK OF PERSONAL INJURY OR DAMAGE TO MATERIALS OR PROPERTY MAY OCCUR

IN THE CASE OF A FAILURE TO FOLLOW THESE INSTRUCTIONS COMPLETELY!

Installation, maintenance and service are to be performed only by qualified personnel who are familiar with local codes and

applicable regulations. They should also have prior experience working with this type of equipment.

Avoid contact with sharp edges and coil surfaces as they are potentially hazardous. Wear appropriate personal protection equi-

pment (PPE) whenever necessary to avoid personal injury.

Read and observe all precautions and warnings on tags, labels, stickers and literature attached to or provided with equipment.

Employ authorized personnel only for operating any moving and lifting equipment (ex. forklifts, scissor lifts, cranes, etc.)

In order to avoid potential damage all equipment should be left in the original shipping container until just prior to installation.

When rigging and lifting units never work directly below suspended loads.

Always wear appropriate personal protection equipment (PPE) whenever handling, lifting, installing, servicing and performing

routine maintence on equipment.

Make sure that all power and control wiring to the equipment conforms to the requirements of all relevant local and national

codes and is in accordance with the data listed on the unit rating label.

All sources of power should be turned OFF, tagged and locked out before attempting any type of service, maintenance or re-

pairs. Failure to do so could result in damage to equipment, personal injury or death to servicing personnel.

All coil assemblies are shipped internally pressurized with dry air or nitrogen. Before attempting to remove caps or seals to

make any field connections to the coil reduce internal coil pressure to atmosphere.

Some traces of a transparent liquid may remain inside the coil circuit after the manufacturing process. This is evaporative oil

which is completely compatible with all refrigerants and refrigeration oils in current use. This oil can sometimes collect in small

quantities inside the coil header connections where it may be observed by installing personnel when removing the factory caps.

It can be easily verified that this is oil and not water due to the fact that it evaporates very quickly when touched. If a drop of it

is placed on a flat surface it widens out quickly like a stain and if exposed to flame it burns readily, giving off a white smoke.

When welding or brazing make sure the torch flame is directed away from any potentially flammable materials, sensitive equip-

ment surfaces and components. Provide adequate shielding, wet rags or thermal paste when necessary. If required, provide a

fire watch with an available means of fire suppressant and clearly post emegency exits in the event of evacuation.

Refrigerants used in cooling and freezing equipment can be hazardous to people as well as the environment and may even be

fatal in sufficient concentrations. Only personnel who are trained and certified to handle refrigerants should be allowed to do

so. Follow all applicable local and national codes which may apply to transporting, charging, reclaiming and disposing of these

chemicals.

After any service or routine maintenance is performed be sure to properly reinstall all access / cover panels, fan guards, drain

pans, electrical covers and their fasteners. Never operate equipment with any of these componenents missing or damaged.

EC fan and motor assemblies are not designed for replacement or servicing of individual parts. Replace only as a complete

assembly.

Tecumseh designed by LU-VE products are manufactured using the following primary materials;

- Plastic Material; Polyethylene, ABS, Rubber

- Ferrous Materials; Iron, Stainless Steel, Copper, Aluminum (possibly coated / treated for

corrosion protection)

Tecumseh designed by LU-VE products are manufactured to the following industry standards;

- UL412:2011 Ed.5+R:09 Jan 2017

- CSA C22.2#120 Issued: 01/03/2013 Ed

- 4 Refrigeration Equipment and NSF 7:2016

- PED 2014/68/EU

- Safety of Machinery EN 60204-1

- Directive 2014/30/EC and subsequent modifications

- Electromagnetic compatibility

- Low voltage - Reference Directive 2014/35/EC

GENERAL SAFETY INFORMATION AND PRECAUTIONS

5

PRODUCT WARRANTY STATEMENT

Subject to the limitations and disclaimers contained herein, Tecumseh Products Company (“Seller”) warrants to its original

equipment manufacturer customer (“OEM”), that any compressors, condensing units, unit coolers, component parts,

controllers, or other goods manufactured by Seller and sold by Seller to OEM (collectively, “Goods”) will be free from defects in

material and workmanship under normal use with regular service and maintenance for the greater of; (a) twenty (20) months from the

date of manufacture by Seller or, (b) eighteen (18) months from the date of invoice (the “Warranty Period”). Products sold by

Seller to Authorized Wholesale (collectively, “Goods”) will be free from defects in material and workmanship under normal use with

regular service and maintenance for a period of sixty (60) months from the date of manufacture by Seller or twelve (12) months

from the date of sale by Tecumseh’s authorized wholesaler, whichever occurs first (the “Warranty Period”).

This WARRANTY does not cover:

•Costs, expenses, or any other type of damage incurred by any other person concerning the repair or replacement of any Goods;

•Any Goods that become inoperative because of system processing, design or installation;

•An indication in the Goods that there is no defect in material or workmanship;

•Transportation costs other than the freight allowance expressly described herein;

•Any Goods where Seller’s serial number, code plate, or serial label is missing, rendered illegible,

tampered with and/or altered in any way; or;

•Goods sold through export unless agreed upon by Seller and Authorized Wholesaler or OEM

in a written service agreement duly executed by the parties authorized representatives.

For more information please contact your local Tecumseh Sales representative or Corporate office at:

Tecumseh Products Company / 5683 Hines Drive / Ann Arbor, MI 48108 / Ph. 734.585.9500 / www.tecumseh.com

RECEIVING AND INSPECTION

When the equipment is initially received, a responsible individual acting on behalf of the equipment purchaser must be present to

check the quantity of cartons and crates being delivered against the bill of lading to confirm that all items listed therein are accounted

for. Inspect all shipping containers (boxes and crates) for any signs of visible damage. Report any damage or shortages to the

delivering freight company immediately. It is the customer's responsibility to file all claims with the freight company. Damaged

equipment may be refused but must not be returned to the manufacturer for any reason without prior authorization.

Installing personnel must exercise caution when removing equipment from crates and boxes to prevent physical injury to themselves

or the product. Always wear appropriate personal protection equipment (PPE) such as hard hats, gloves, safety glasses, safety shoes,

long sleeve shirts and pants, etc. to avoid physical injury. When lifting smaller units by hand always utilize proper lifting techniques to

avoid personal injury. Equipment should be left in the original shipping container whenever possible until just prior to installation. Do

not use piping connections, fan guards, drain pans or other such similar components as lifting points. On larger units which must be

removed from the shipping container or skid with lifting straps make sure to utilize a spreader bar to avoid damage to the units sheet

metal housing.

REMOVING EQUIPMENT FROM SHIPPING CONTAINERS / PACKAGING

If using a forklift roll the unit over onto a wooden pallet with the shipping skid “up” (Figure 1 - Steps 1 & 2 - Page 6).

Remove the banding which holds the cardboard box to the shipping skid, then using a razor knife, carefully cut the box down all (4)

corners and fold the cardboard down onto the pallet, leaving the unit resting on the original cardboard shipping blocks and carton top

flaps (Figure 2 - Step 3 - Page 6).

Remove the (4) nuts and bolts that secure the unit mounting brackets to the shipping skid and lay aside the skid (Figure 2 - Steps 4

& 5 - Page 6).

With the shipping container and skid removed, remove the two side access panels from the ends of the unit and check closely for any

concealed or hidden damage. If any damage is noted, report it to the manufacturer immediately before proceding with the equipment

installation. All units are shipped with approx. 25 PSIG of dry air or nitrogen holding charge in the coil. Use an accurate suction

service gauge to verify internal coil pressure prior to proceeding with the unit installation. Although the absence of pressure or a lower

than nor-mal pressure reading does not necessarily indicate a leak, if the reading is “low” a leak test must be performed before

contrinuing with the installation or requesting a return goods authorization from the distributor or manufacturer (Figure 3 - Step 6 -

Page 6).

6

RIGGING AND MOUNTING

The unit can now be lifted to it’s final mounting position by inserting the

lifting forks into the pallet (Figures 4 & 5 - Step 8) and raising the unit

into place (Figures 4 & 5 - Step 9). On longer units it is important to find

the center “balance point” of the unit and spread the lifting forks wide

enough to avoid tipping.

UNIT MOUNTING POINTS

F31HC

F35HC

16.4

16.4

F31HC

F35HC

16.3

19.2

0.39

0.59 14.8

3/4”MPT

1.33

1.73

5.285.28

F31HC

F35HC

18.7

19.1

Fig. 1

Fig. 2

(0.39

375 (14.8)

F31HC

375 (14.8)

0.39

F35HC 14.8

14.8

2

1

Fig. 3

7

Fig. 4

Fig. 5

9

9

DIMENSIONAL DATA

Check coil pressure with an

accurate service gauge. If

pressure is “low” or “0” the

unit must be checked for

leaks before installation.

(Figure 3 - Step 7).

Do not return the unit to the

distributor or manufacturer

without prior authorization!

UNIT MOUNTING POINTS

Fig. 2

Unit Model Series F31HC 115-4116-4125-4126-4135-4136-4146-4

F31HC 215-6216-6225-6226-6235-6236-6246-6

Number of Fans 12.4” Diam 1 1 2 2 3 3 4

Refrig Conn Liquid ½” ½” ½” ½” ½” ⅝” ⅝”

Refrig Conn Suction ⅝” ¾” ¾” ⅞” ⅞” 1-⅜” 1-⅜”

Dimension A30 30 47-5/8" 47-5/8" 65-3/8" 65-3/8" 83-1/16"

Dimension B19-3/8" 19-3/8" 37-1/8" 37-1/8" 54-13/16" 54-13/16" 72-1/2"

Unit Model Series F35HC 73-4106-4145-4215-4272-4323-4362-4430-4

F35HC 59-684-6117-6174-6218-6261-6290-6348-6

Number of Fans 13.8” Diam 1 1 2 2 3 3 4 4

Refrig Conn Liquid ½” ½” ½” ⅝” ⅝” ⅝” ⅝” ⅞”

Refrig Conn Suction 1-⅛” 1-⅛” 1-⅛” 1-⅛” 1-⅜” 1-⅜” 1-⅝” 1-⅝”

Dimension A34" 34" 56" 56" 77-3/4" 77-3/4" 99-5/8" 99-5/8"

Dimension B23-1/2" 23-1/2" 45-3/8" 45-3/8" 67-3/16" 67-3/16" 89-1/16" 89-1/16"

Dimension C--- --- --- --- --- --- 44-1/2" 44-1/2"

7

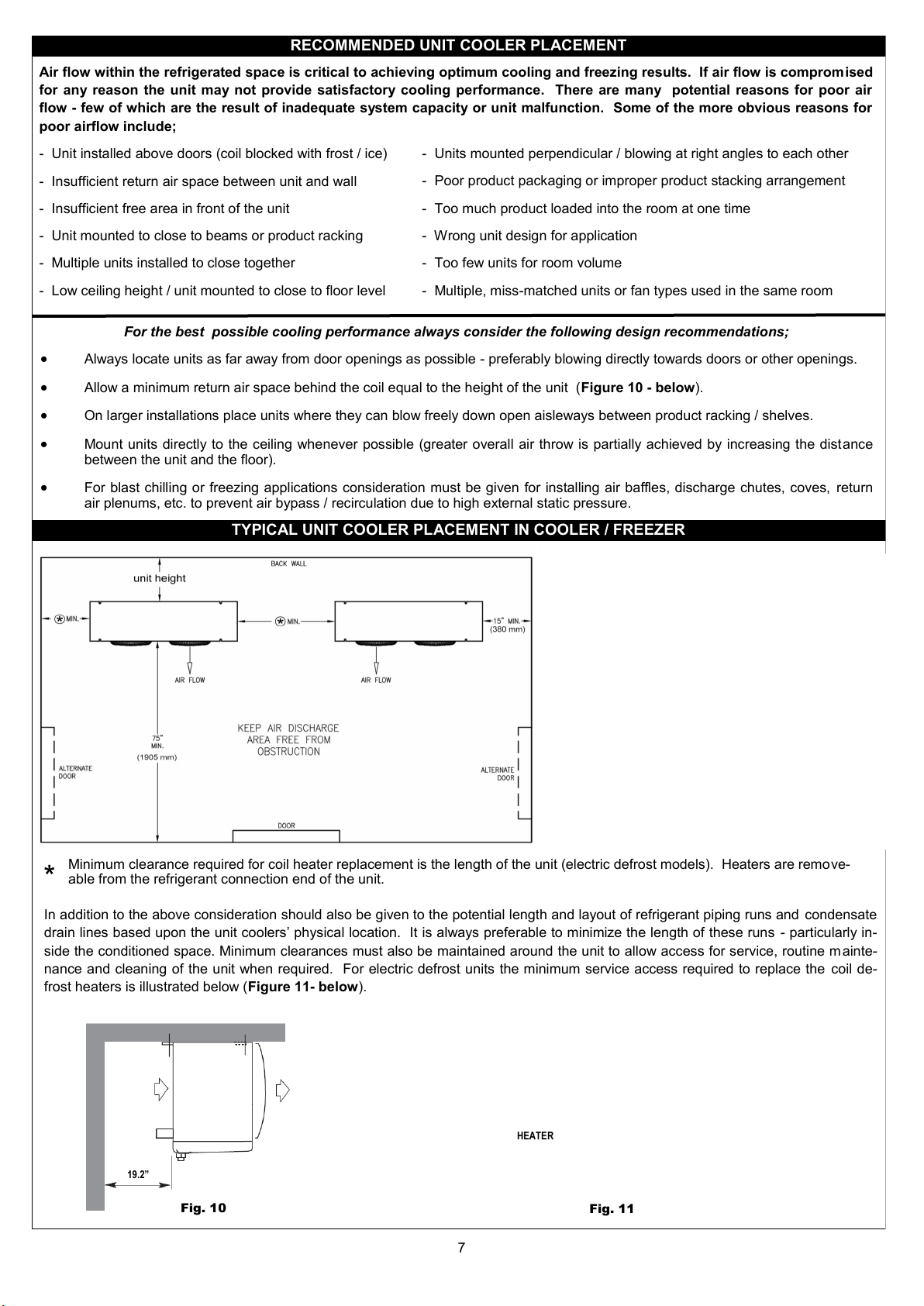

RECOMMENDED UNIT COOLER PLACEMENT

Air flow within the refrigerated space is critical to achieving optimum cooling and freezing results. If air flow is compromised

for any reason the unit may not provide satisfactory cooling performance. There are many potential reasons for poor air

flow - few of which are the result of inadequate system capacity or unit malfunction. Some of the more obvious reasons for

poor airflow include;

- Unit installed above doors (coil blocked with frost / ice)

- Insufficient return air space between unit and wall

- Insufficient free area in front of the unit

- Unit mounted to close to beams or product racking

- Multiple units installed to close together

- Low ceiling height / unit mounted to close to floor level

- Units mounted perpendicular / blowing at right angles to each other

- Poor product packaging or improper product stacking arrangement

- Too much product loaded into the room at one time

- Wrong unit design for application

- Too few units for room volume

- Multiple, miss-matched units or fan types used in the same room

For the best possible cooling performance always consider the following design recommendations;

Always locate units as far away from door openings as possible - preferably blowing directly towards doors or other openings.

Allow a minimum return air space behind the coil equal to the height of the unit (Figure 10 - below).

On larger installations place units where they can blow freely down open aisleways between product racking / shelves.

Mount units directly to the ceiling whenever possible (greater overall air throw is partially achieved by increasing the distance

between the unit and the floor).

For blast chilling or freezing applications consideration must be given for installing air baffles, discharge chutes, coves, return

air plenums, etc. to prevent air bypass / recirculation due to high external static pressure.

TYPICAL UNIT COOLER PLACEMENT IN COOLER / FREEZER

Minimum clearance required for coil heater replacement is the length of the unit (electric defrost models). Heaters are remove-

able from the refrigerant connection end of the unit.

In addition to the above consideration should also be given to the potential length and layout of refrigerant piping runs and condensate

drain lines based upon the unit coolers’ physical location. It is always preferable to minimize the length of these runs - particularly in-

side the conditioned space. Minimum clearances must also be maintained around the unit to allow access for service, routine mainte-

nance and cleaning of the unit when required. For electric defrost units the minimum service access required to replace the coil de-

frost heaters is illustrated below (Figure 11- below).

19.2”

Fig. 10

HEATER

Fig. 11

*

8

UNIT MOUNTING DETAIL

Units should be mounted flush to a level ceiling panel using 3/8” stainless steel bolts, hangar rods or lag screws.

There is no need to block or pitch the unit to ensure proper condensate drainage if the unit is mounted level.

NSF SANITATION

Seal the gap between the top of the unit and the ceiling with NSF approved sealant to prevent accumulation of dirt and foreign material.

CONDENSATE DRAIN PAN CONNECTION

Apply an approved pipe thread sealant to the threads of the drain pan

fitting before making the field piping connection.

Do not torque / over-tighten the field pipe fitting attached directly to the

drain pan connection! Use a backer wrench on the drain pan fitting and tighten

the attached pipe fitting no more than approx. 1/2 turn beyond hand tight.

9

CONDENSATE DRAIN LINES

CONDENSATE DRAIN LINE PIPING — SINGLE UNIT

It is the installers responsibility to ensure that all drain line piping is installed in accordance with local and national plumbing

codes.

Drain line piping runs should be kept as short as possible within the conditioned space whenever possible.

Pitch all field piping in the direction of flow a minimum of 1/4” per foot of pipe run.

Use an approved pipe thread sealant on the threads of the drain line fitting. DO NOT OVER-TIGHTEN THE FITTING

ATTACHED DIRECTLY TO THE DRAIN PAN CONNECTION!

Install a P-trap in all unit drain lines. Traps in freezer drain lines should be located outside the freezer whenever possible.

The use of plastic (PVC) pipe is acceptable only on cooler applications operating above freezing.

For all freezer applications (+32 degrees and lower) use copper pipe only.

Use an insertion type drain line heater on all freezer applications or wrap all piping and P-traps exposed to freezing temperatures

with self regulating type heat tape and insulate wherever practical. A minimum of 20 watts / foot of drain line is generally recom-

mended for freezers operating down to 0 degrees and 30 watts / foot of drain line for those operating from 0 down to -20 de-

grees.

Common drain lines serving multiple units (whether in the same space or different rooms) must be adequately sized to handle the

condensate flow from ALL connected evaporators. DO NOT REDUCE THE DRAIN LINE PIPE SIZE SMALLER THAN THE

CONNECTION ON THE DRAIN PAN! The branch lines from each individual evaporator must also be separately trapped.

All drain lines must terminate above an open floor drain or in an outdoor area where the condensate will not pose any personal

safety or environmental issues. Do not connect drain lines directly to the building sewer system.

Check the unit drain pan after an initial period of operation to ensure there is no standing water in the pan. Check unit for level or

correct field piping if necessary to eliminate standing water.

CONDENSATE DRAIN LINE PIPING — MULTIPLE UNITS ON A COMMON DRAIN LINE

P-Trap

Open Floor Drain

UNI T1UNI T2

P-Trap

UNI T3

Pitch In Direction Of Flow - 1/4" / Foot (MINIMUM))

P-Trap

Air Flow

P-Trap

Floor

COOLER (Above +32)

Open

Drain

FREEZER (Below +32)

Air Flow

P-Trap

Floor

COOLER (Above +32)

Drain

Open

Units which are located in different rooms but piped to a com-

mon drain line must be individually trapped.

Units operating near or below freezing should be trapped out-

side the room or adequately protected from freezing.

10

REFRIGERANT PIPING

CAUTION! UNIT IS PRESSURIZED

WITH DRY AIR OR INERT GAS

FOR SHIPPING

THIS HOLDING CHARGE MUST

BE VENTED AND THE SYSTEM

LEAK TESTED AND EVACUATED

BEFORE CHARGING WITH RE-

FRIGERANT

CHARGE SYSTEM WITH ONLY

PURE, VIRGIN REFRIGERANT

Use only clean, sealed ACR grade copper tubing for refrigerant duty. Unit warranty cover-

age may be voided if system is installed with any other type of tubing. All piping must be

installed according to local and national codes as well as accepted commercial refrigeration

industry standards and practices. All tubing should be cut using a wheel type tubing cutter

(no hacksaws) and all cut tubing must be de-burred. Clean all joints with sand cloth and

apply a small amount of high quality paste flux (being careful to avoid placing any flux near

the ends of the tubing) before firmly joining connections. When brazing, use only high tem-

perature, silver bearing solder on all joints while continuously flowing a regulated, low pres-

sure, inert gas through the inside of the piping to avoid the formation of scale and copper

oxides.

Note: The line sizing required for the system is not necessarily the same size as the factory

pipe connections supplied on the unit. We strongly recommend that you work directly with

an experienced consulting engineer to properly size and design system piping however as a

convenience to our customers (and with no liability for services provided as gratis) we can

supply the installer with line sizing charts which may be used to select the field line sizing

based upon the calculated, overall equivalent feet of tubing (lineal feet plus allowances for

fittings), refrigerant type, unit capacity and SST.

Refer to ASHRAE REFRIGERATION HANDBOOK for detailed system piping design information!

Always consider the overall length of field piping runs when locating unit coolers and matching condensing units. Excessively

long piping runs should be avoided whenever possible.

Select the optimum pipe size which minimizes total system pressure drop while maintaining sufficient internal gas velocities to

ensure continuous oil return back to the compressor. Often times pipe selection is a compromise between operating efficiency

over the lifetime of the system and initial, installed cost.

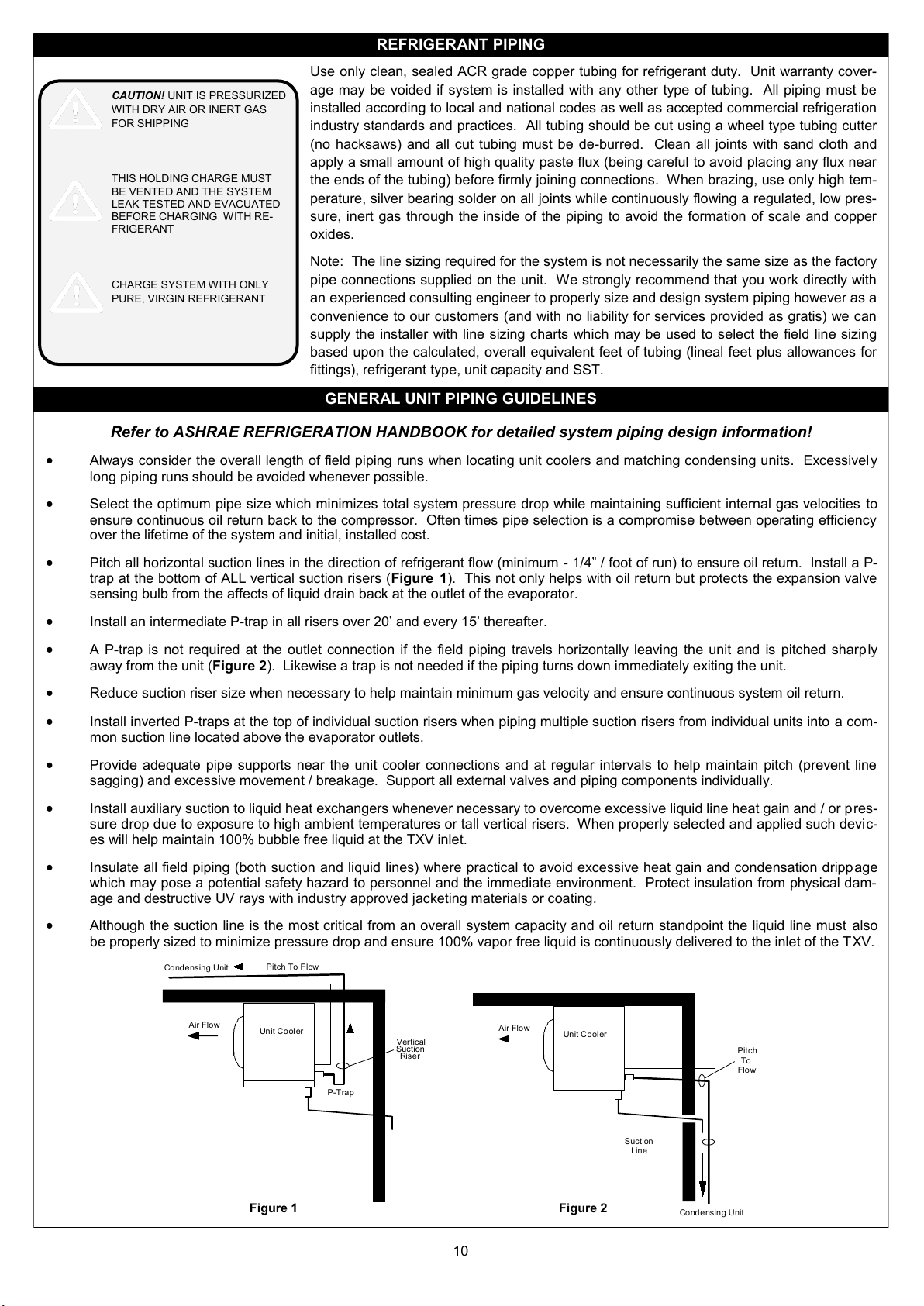

Pitch all horizontal suction lines in the direction of refrigerant flow (minimum - 1/4” / foot of run) to ensure oil return. Install a P-

trap at the bottom of ALL vertical suction risers (Figure 1). This not only helps with oil return but protects the expansion valve

sensing bulb from the affects of liquid drain back at the outlet of the evaporator.

Install an intermediate P-trap in all risers over 20’ and every 15’ thereafter.

A P-trap is not required at the outlet connection if the field piping travels horizontally leaving the unit and is pitched sharply

away from the unit (Figure 2). Likewise a trap is not needed if the piping turns down immediately exiting the unit.

Reduce suction riser size when necessary to help maintain minimum gas velocity and ensure continuous system oil return.

Install inverted P-traps at the top of individual suction risers when piping multiple suction risers from individual units into a com-

mon suction line located above the evaporator outlets.

Provide adequate pipe supports near the unit cooler connections and at regular intervals to help maintain pitch (prevent line

sagging) and excessive movement / breakage. Support all external valves and piping components individually.

Install auxiliary suction to liquid heat exchangers whenever necessary to overcome excessive liquid line heat gain and / or pres-

sure drop due to exposure to high ambient temperatures or tall vertical risers. When properly selected and applied such devic-

es will help maintain 100% bubble free liquid at the TXV inlet.

Insulate all field piping (both suction and liquid lines) where practical to avoid excessive heat gain and condensation drippage

which may pose a potential safety hazard to personnel and the immediate environment. Protect insulation from physical dam-

age and destructive UV rays with industry approved jacketing materials or coating.

Although the suction line is the most critical from an overall system capacity and oil return standpoint the liquid line must also

be properly sized to minimize pressure drop and ensure 100% vapor free liquid is continuously delivered to the inlet of the TXV.

GENERAL UNIT PIPING GUIDELINES

Condensing Unit

Pitch

Suction

Line

Air Flow Unit Cooler

Pitch To Flow

To

Flow

Suction

P-Trap

Air Flow

Vertical

Riser

Condensing Unit

Unit Cooler

Figure 2Figure 1

11

REFRIGERANT PIPING — CONTINUED

All F31HC and F35HC model series unit coolers are equipped with a venturi-flo refrigerant distributor

which ensures maximum efficiency of the coil under most all operating conditions. There is no orifice

or nozzle plate to select / install in the distributor inlet. For optimum coil performance the TXV should

be mounted within the end compartment of the unit and as short a distance as possible from the dis-

tributor inlet. Do not install any elbows between the outlet of the TXV and the inlet of the distributor!

A 1/4” O.D. equalizer tube is supplied on all units. Never cap this line - use only externally equalized

valves. See Figures 4, 5 & 6 (below) for location and mounting of the TXV sensing bulb.

If not supplied with the unit, the expansion valve must be selected according to the design characteris-

tics of the particular system - taking into consideration the following criteria; Refrigerant type, design

room temperature, system TD or design saturated suction temperature (SST), liquid temperature

(subcooling) and the minimum operating head pressure (SCT) of the system. LU-VE can provide a

separate valve selection table of suggested expansion valves for the most common refrigerants, oper-

ating temperatures and system TD’s however we strongly recommend that you consult with your sup-

plier or valve manufacturer for selection assistance - especially for any unusual or non-standard appli-

cations.

If a liquid line solenoid valve is to be installed in the system we recommend placing it in the field piping reasonably close to the unit

cooler. Do not select valves based only on the physical connection size - the valve you install may be much to large for the application

which can result in operational problems with the valve and possibly even damage to the connected unit cooler or system piping. Re-

fer to the valve manufacturers capacity charts or selection software or consult with your local valve supplier for assistance. Always be

sure to provide adequate pipe clamps and supports for external piping and components - never allow the unit coil connections to sup-

port the weight or unrestricted movement of any field installed piping components. Any damage to the coil which is determined to be

caused by improper field piping design / installation will void the product warranty coverage.

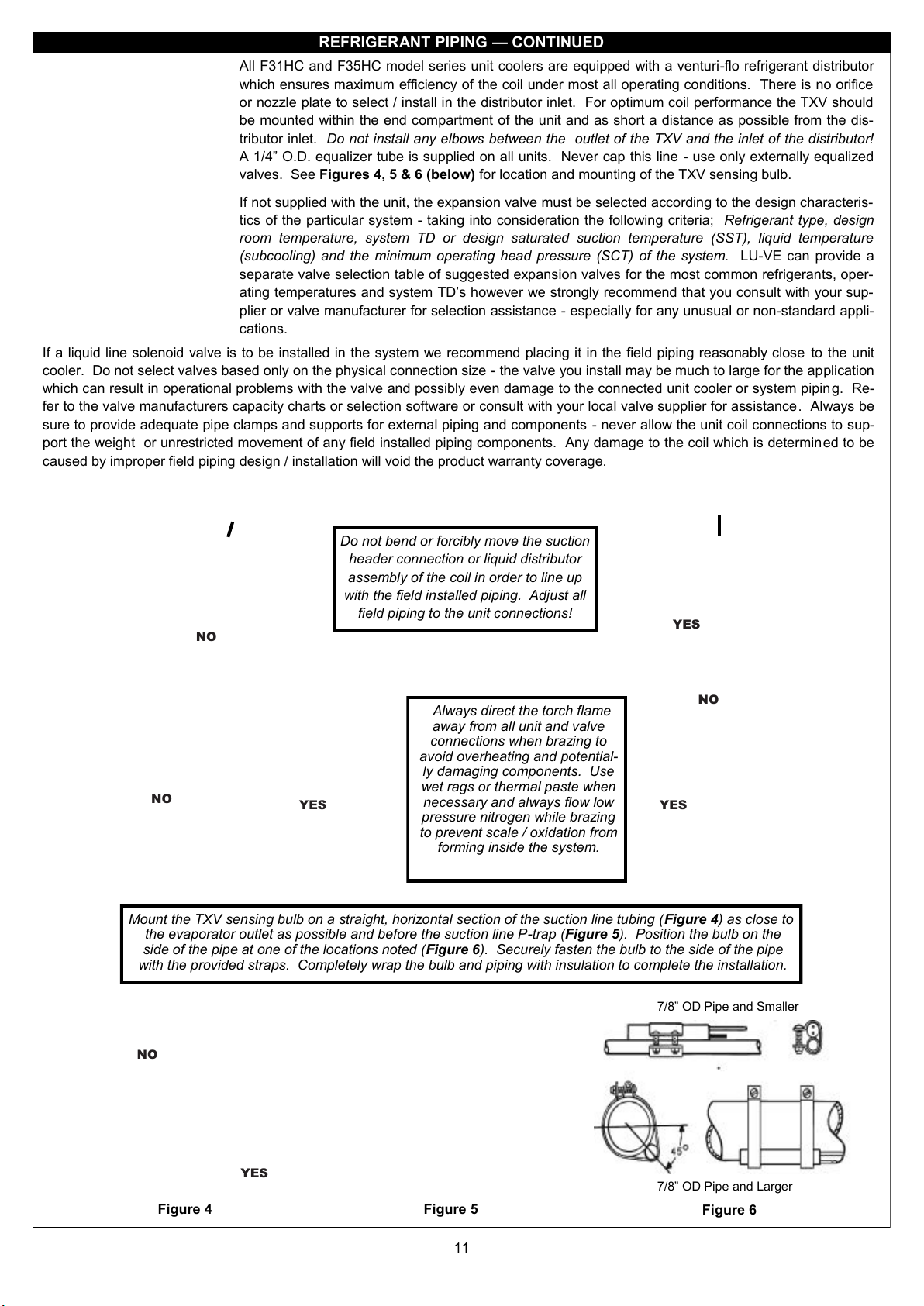

Do not bend or forcibly move the suction

header connection or liquid distributor

assembly of the coil in order to line up

with the field installed piping. Adjust all

field piping to the unit connections!

NO

YES

NO YES

Always direct the torch flame

away from all unit and valve

connections when brazing to

avoid overheating and potential-

ly damaging components. Use

wet rags or thermal paste when

necessary and always flow low

pressure nitrogen while brazing

to prevent scale / oxidation from

forming inside the system.

NO

YES

Mount the TXV sensing bulb on a straight, horizontal section of the suction line tubing (Figure 4) as close to

the evaporator outlet as possible and before the suction line P-trap (Figure 5). Position the bulb on the

side of the pipe at one of the locations noted (Figure 6). Securely fasten the bulb to the side of the pipe

with the provided straps. Completely wrap the bulb and piping with insulation to complete the installation.

Figure 5

NO

YES

Figure 6

Figure 4

7/8” OD Pipe and Smaller

7/8” OD Pipe and Larger

12

LEAK TESTING

Once all field piping connections have been made and the braze joints visually inspected for any obvious voids or gaps introduce a

trace amount of the system refrigerant through a service gauge manifold to achieve an equalized, static pressure of 25 to 30 PSIG.

Make sure that all service and shut off valves are in the open position and slowly introduce a regulated, inert gas such as nitrogen to

increase the static system pressure to approx. 150 PSIG.

Note: Always verify the MAXIMUM system test pressure allowed for all other components in the system before pressurizing

to this level!

Allow sufficient time for the entire sealed system to achieve an equalized test pressure before physically checking all braze joints and

installed system components (both field and factory) with an electronic leak detector. Be sure to turn off the fans of any units operating

nearby or block all air movement with tarps or baffles during testing. If any leaks are indicated double check the suspected area using

soap bubbles, a strong light and an inspection mirror (if necessary). Note the location of any leaks found, reduce the system pressure

to atmosphere, repair the leak(s) (being sure to again flow low pressure nitrogen inside the system while brazing), then repeat the pre-

viously used test procedure to confirm all leaks have been satisfactorily repaired. Allow the system to stand at test pressure overnight

if possible (or several hours at a minimum), and confirm that there has been no discernable pressure decay during that time.

EVACUATION AND CHARGING

All refrigeration systems must be properly evacuated prior to charging with refrigerant. Simply purging the system with refrigerant or

skipping this important step entirely will result in system operational problems, shortened equipment life and voiding the product war-

ranty coverage. Use a deep vacuum pump which has been properly maintained and the oil recently changed. Connect the pump

(along with an electronic micron gauge) using a service gauge manifold with large bore hoses or tubing. Operate the vacuum pump

continuously during the entire evacuation process (larger volume systems may take several hours and multiple pump oil changes to

achieve a satisfactory vacuum level). Monitor the micron gauge during this time and when a minimum reading of 400 microns is

achieved, blank off the gauge, shut off the pump and observe the gauge for 10-15 minutes. At this point, if the system is tight and dry,

there should be no observed decay of the vacuum gauge reading. Break the vacuum with the correct system refrigerant and charge

as per the system design requirements.

Note: Always refer to the manufacturers charging data for the system condensing unit as the unit cooler operating charge

represents only a very small portion of the total, year round operating charge required for the entire system. Be sure

to charge any refrigerant blend as a liquid (not vapor) in order to avoid fractionization.

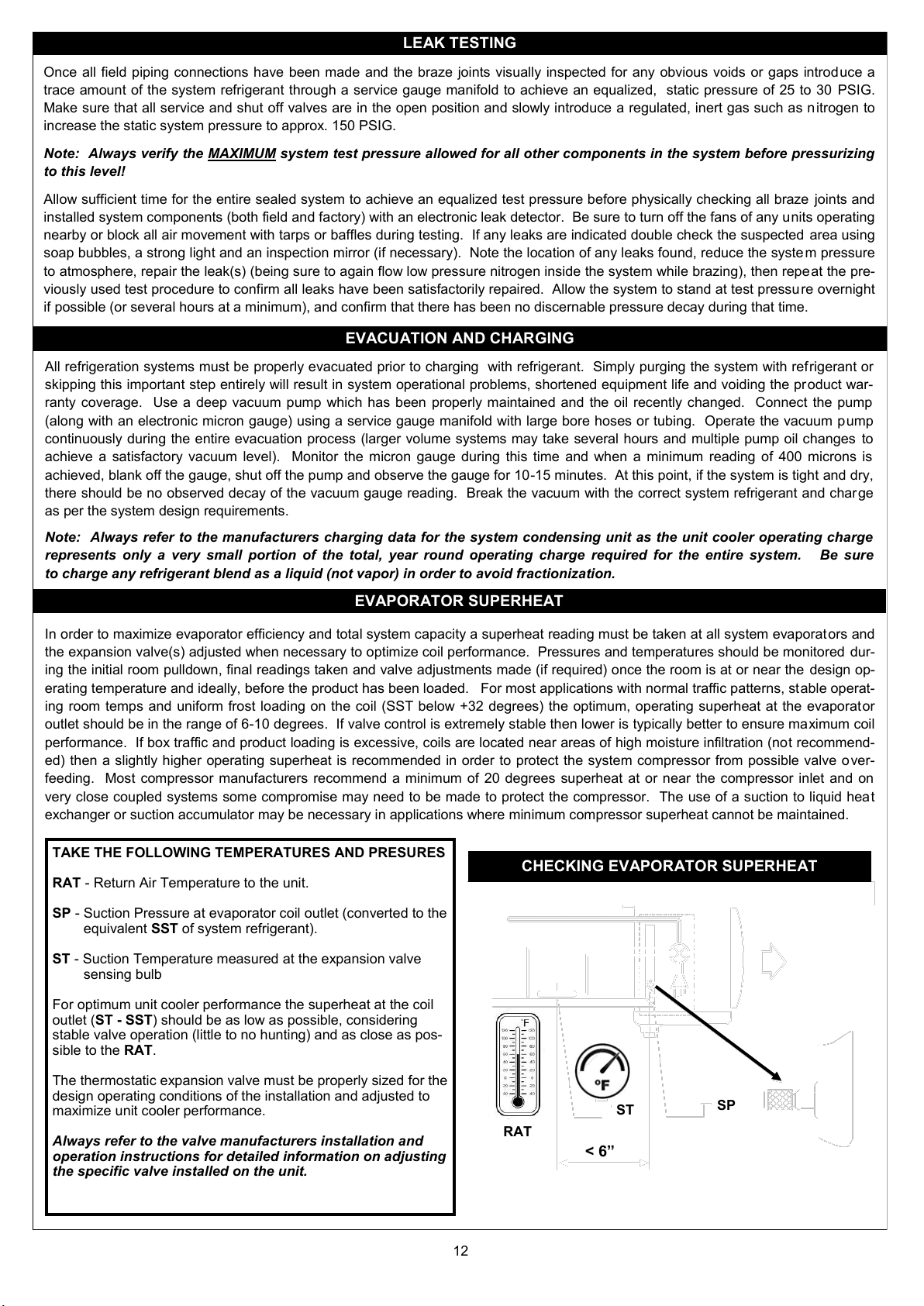

EVAPORATOR SUPERHEAT

In order to maximize evaporator efficiency and total system capacity a superheat reading must be taken at all system evaporators and

the expansion valve(s) adjusted when necessary to optimize coil performance. Pressures and temperatures should be monitored dur-

ing the initial room pulldown, final readings taken and valve adjustments made (if required) once the room is at or near the design op-

erating temperature and ideally, before the product has been loaded. For most applications with normal traffic patterns, stable operat-

ing room temps and uniform frost loading on the coil (SST below +32 degrees) the optimum, operating superheat at the evaporator

outlet should be in the range of 6-10 degrees. If valve control is extremely stable then lower is typically better to ensure maximum coil

performance. If box traffic and product loading is excessive, coils are located near areas of high moisture infiltration (not recommend-

ed) then a slightly higher operating superheat is recommended in order to protect the system compressor from possible valve over-

feeding. Most compressor manufacturers recommend a minimum of 20 degrees superheat at or near the compressor inlet and on

very close coupled systems some compromise may need to be made to protect the compressor. The use of a suction to liquid heat

exchanger or suction accumulator may be necessary in applications where minimum compressor superheat cannot be maintained.

TAKE THE FOLLOWING TEMPERATURES AND PRESURES

RAT - Return Air Temperature to the unit.

SP - Suction Pressure at evaporator coil outlet (converted to the

equivalent SST of system refrigerant).

ST - Suction Temperature measured at the expansion valve

sensing bulb

For optimum unit cooler performance the superheat at the coil

outlet (ST - SST) should be as low as possible, considering

stable valve operation (little to no hunting) and as close as pos-

sible to the RAT.

The thermostatic expansion valve must be properly sized for the

design operating conditions of the installation and adjusted to

maximize unit cooler performance.

Always refer to the valve manufacturers installation and

operation instructions for detailed information on adjusting

the specific valve installed on the unit.

CHECKING EVAPORATOR SUPERHEAT

SP

ST

RAT

< 6”

13

REFRIGERANT BLENDS — TEMPERATURE GLIDE

The majority of HFC refrigerants in use today are referred to as refrigerant “blends” (composed of two or more different refrigerants).

As such, each component within this “blend” evaporates (or condenses) at different temperatures. The temperature range within which

each of these different refrigerants completely changes state from a liquid to a gas (or vice versa) is referred to as “temperature glide”.

Essentially this means that the traditional way we measure superheat and liquid sub-cooling must be adjusted to account for this tem-

perature “glide”. Depending upon which one of these refrigerant is used in the system the temperature glide could range from as low

as 6 to perhaps as high as 12 degrees. Technically R-404A is also a blend but since it’s temperature glide is only around 1 degree it is

typically treated as an azeotrope (a refrigerant whose components boil and evaporate at the same temperature).

When measuring superheat at the evaporator outlet of a system utilzing any of these high glide rfrigerants you must always refer to the

refrigerants’ “Dew Point” which is the point at which the last droplet of liquid refrigerant has vaporized. These values are all listed for

easy reference on all current temperature pressure charts, mechanical and electronic service gauge manifolds and apps commonly

used by todays field service technicians. If in doubt about the values you’ve measured always refer to published data supplied by the

various refrigerant manufacturers to confirm your field measurements. Regardless of which type of refrigerant is used in the system

the service technicians goal is still the same - to maximize the evaporator performance while ensuring both adequate compressor motor

cooling and the prevention of liquid floodback.

The diagram on the right graphically illustrates the relationship

or “glide” of two different components making up a single refrig-

erant blend as they pass through the evaporator coil. The

number on the left of the / mark represents the percentage of

refrigerant “A” and the number to the right of the / mark repre-

sents the percentage of refrigerant “B” which is present at each

location (1, 2 & 3) in the evaporator coil.

Note that the mixture is only equal (50/50) at the inlet

(100% liquid) and at the outlet (100% vapor) of the evapo-

rator coil.

FIELD WIRING — ELECTRICAL REQUIREMENTS

The electrical characteristics of each unit are clearly marked on the unit rating label located on the front facing, left hand end cover of

the unit (as viewed facing the fans). This label lists the operating voltage, phase and amp draw of the fan motors and defrost heaters

(when equipped). It also lists the MINIMUM CIRCUIT AMPACITY (MCA) and MAXIMUM OVER CURRENT PROTECTION DEVICE

(MOPD) which should be used in order to determine the minimum wire gauge size required to supply power to the unit and the largest

circuit breaker / fuse size it should be fed from. These values apply only to the main power supply to the unit - there may be separate,

field control circuit wiring required which can be ran in smaller gauge wiring, but must still be suitable for the applied voltage.

All field wiring must be ran using copper conductors only and in total compliance with the National Electrical Code (NEC) as well as

any local or state codes. There are multiple knockouts supplied on the electrical end of the unit (opposite the refrigerant connection

end) to accommodate field installed wiring / conduit connections. Field wiring must be landed on the factory supplied terminal block

located inside the electrical end panel. Refer to the unit wiring diagram located on the inside of the electrical end cover panel for the

specific terminals to connect to. When making the field wiring connections it is always advisable to double check the factory wiring

connections to be sure that none have loosened in shipment or are otherwise dislodged from their terminals. The unit must al so be

properly grounded which may require that a dedicated ground wire be ran to the unit (depending upon local code requirements and

the type of conduit utilized in the installation).

The fan motors for all air defrost units are factory

wired to the terminal block. On electric defrost units

all fan motors, defrost heaters, heater safety and fan

delay / defrost termination controls are factory wired.

If not provided as a factory mounted option it is the

installing contractors responsibility to install and wire

a room thermostat, liquid line solenoid valve and de-

frost timer (when required). The typical wiring dia-

grams supplied on the following pages will assist with

the field wiring of these controls - as well as wiring for

multiple units on a single system when required.

MOTORS

K

J

N P

Fig. 5

Heater Safety Field Power Wiring

Defrost Termination

Fan Delay Control

Factory Mounted

Junction Box /

Terminal Block

FACTORY WIRING

14

AIR DEFROST — 115/1/60 OR 208/230/1/60 UNIT COOLER

FIELD WIRING DIAGRAMS — TYPICAL

IMPORTANT WIRING NOTES - INSTALLER PLEASE READ CAREFULLY!

Sub-circuit fusing or service disconnect switches are not shown but may be required as per the NEC and / or local codes.

It is the responsibility of the installing contractor to interpret and comply with all applicable electrical codes.

Field install an 18 GA jumper wire between terminals 3 & 4 on terminal block TB2 for continuous low speed fan operation (950

RPM). Fan motors will operate continuously on high speed without jumper wire installed (F31 Models Units - 1300 RPM / F35

model units - 1450 RPM). See page 21 for optional two speed fan relay control wiring if required.

An air defrost time clock may be supplied as an option (either field installed or factory mounted on the system condensing unit).

The room thermostat and liquid line solenoid valve are shown as field installed but may be factory mounted in the unit cooler.

Make sure the solenoid holding coil is wired for the correct control voltage (115 or 230).

*

+

<

**

15

FIELD WIRING DIAGRAMS — TYPICAL

ELECTRIC DEFROST — 208/230/1/60 — (1) UNIT COOLER (TIMER ONLY)

IIMPORTANT WIRING NOTES - INSTALLER PLEASE READ CAREFULLY!

Sub-circuit fusing or service disconnect switches are not shown but may be required as per the NEC and / or local codes.

It is the responsibility of the installing contractor to interpret and comply with all applicable electrical codes.

Field install an 18 GA jumper wire between terminals 3 & 4 on terminal block TB2 for continuous low speed fan operation (950

RPM). Fan motors will operate continuously on high speed without jumper wire installed (F31 Models Units - 1300 RPM / F35

model units - 1450 RPM). See page 21 for optional two speed fan relay control wiring if required.

The defrost time clock and block out relay are typically located in the system condensing unit. All unit cooler power should

feed from this unit. Make sure that the heater amp draw does not exceed the defrost timer contact rating (typically 40 resistive

amps for an 8145-20 or equivalent timer). Also be sure the wire gauge size is adequate to carry the total amp load required.

Factory installed jumper — remove if using a heater contactor.

The room thermostat and liquid line solenoid valve are shown as field installed but may be factory mounted in the unit cooler.

Make sure the solenoid holding coil is wired for the correct control voltage (115 or 230).

#

<

+

*

**

16

FIELD WIRING DIAGRAMS — TYPICAL

ELECTRIC DEFROST — 208/230/1/60 — (1) UNIT COOLER WITH HEATER CONTACTOR

IMPORTANT WIRING NOTES - INSTALLER PLEASE READ CAREFULLY!

Sub-circuit fusing or service disconnect switches are not shown but may be required as per the NEC and / or local codes.

It is the responsibility of the installing contractor to interpret and comply with all applicable electrical codes.

Field install an 18 GA jumper wire between terminals 3 & 4 on terminal block TB2 for continuous low speed fan operation (950

RPM). Fan motors will operate continuously on high speed without jumper wire installed (F31 Models Units - 1300 RPM / F35

model units - 1450 RPM). See page 21 for optional two speed fan relay control wiring if required.

The defrost time clock, block out relay / auxiliary switch and heater contactor are typically located in the system condensing

unit. All unit cooler power should feed from this unit. Make sure the total heater amp draw does not exceed the resistive rating

of the contactor. Also be sure the wire gauge size is adequate to carry the total amp load required.

When using a heater contactor with unit cooler defrost heaters factory wired for single phase remove factory installed jumper

between terminals 2 & 3 on TB1 and wire directly to heater contactor as shown above.

The room thermostat and liquid line solenoid valve are shown as field installed but may be factory mounted in the unit cooler.

Make sure the solenoid holding coil is wired for the correct control voltage (115 or 230).

**

+

#

<

*

17

ELECTRIC DEFROST — 208/230/1/60 — (2) UNIT COOLERS / TIMER ONLY

IMPORTANT WIRING NOTES - INSTALLER PLEASE READ CAREFULLY!

Sub-circuit fusing or service disconnect switches are not shown but may be required as per the NEC and / or local codes.

It is the responsibility of the installing contractor to interpret and comply with all applicable electrical codes.

Field install an 18 GA jumper wire between terminals 3 & 4 on terminal block TB2 for continuous low speed fan operation (950

RPM). Fan motors will operate continuously on high speed without jumper wire installed (F31 Models Units - 1300 RPM / F35

model units - 1450 RPM). See page 21 for optional two speed fan relay control wiring if required.

The defrost time clock and block out relay are typically located in the system condensing unit. All unit cooler power should

feed from this unit. When connecting multiple unit cooler defrost heaters to (1) defrost time clock make sure the total heater

amp draw does not exceed the defrost timer contact rating (typically 40 resistive amps for an 8145-20 or equivalent timer),

Also be sure the wire gauge size is adequate to carry the total amp load required.. If the combined heater amp draw exceeds

the defrost timer rating a heater contactor must be installed (see alternate wiring diagram for 1 or 2 heater contactor wiring

arrangement).

When connecting (2) electric defrost unit coolers to (1) defrost timer remove the black wire from the defrost termination / fan

delay control which is factory wired to terminal 2 - TB2 on unit cooler #2 and cap the wire. This will allow the fan delay on

unit cooler #1 to control the fans on both unit coolers.

When connecting (2) electric defrost unit coolers to (1) defrost timer remove the red wire from the defrost termination / fan

delay control which is factory wired to terminal 4 - TB1 on unit cooler #2 and hard wire to a field wire connected to terminal 1

- TB2 on unit cooler #1. This will place the (2) defrost termination controls in series so that both units must reach temperature

in order to terminate the defrost cycle.

When using a heater contactor with unit cooler defrost heaters factory wired for single phase remove factory installed jumper

between terminals 2 & 3 on TB1 and wire directly to heater contactor.

The room thermostat and liquid line solenoid valve are shown as field installed but may be factory mounted in the unit cooler.

Make sure the solenoid holding coil is wired for the correct control voltage (115 or 230).

<

+

*

**

!

^

FIELD WIRING DIAGRAMS — TYPICAL

#

18

FIELD WIRING DIAGRAMS — TYPICAL

ELECTRIC DEFROST — 208/230/1/60 — (2) UNIT COOLERS / (1) HEATER CONTACTOR

IMPORTANT WIRING NOTES - INSTALLER PLEASE READ CAREFULLY!

Sub-circuit fusing or service disconnect switches are not shown but may be required as per the NEC and / or local codes.

It is the responsibility of the installing contractor to interpret and comply with all applicable electrical codes.

Field install an 18 GA jumper wire between terminals 3 & 4 on terminal block TB2 for continuous low speed fan operation (950

RPM). Fan motors will operate continuously on high speed without jumper wire installed (F31 Models Units - 1300 RPM / F35

model units - 1450 RPM). See page 21 for optional two speed fan relay control wiring if required.

The defrost time clock, block out relay / auxiliary switch and heater contactor are all typically located in the system condensing

unit. All unit cooler power should feed from this unit. When connecting multiple unit cooler defrost heaters to (1) heater con-

tactor make sure the total heater amp draw does not exceed the resistive amp rating of the contactor. Also be sure the wire

gauge size is adequate to carry the total amp load required.

When using a heater contactor with unit cooler defrost heaters factory wired for single phase remove factory installed jumper

between terminals 2 & 3 on TB1 and wire directly to heater contactor as shown above.

When connecting (2) electric defrost unit coolers to (1) defrost timer remove the black wire from the defrost termination / fan

delay control which is factory wired to terminal 2 - TB2 on unit cooler #2 and cap the wire. This will allow the fan delay on unit

cooler #1 to control the fans on both unit coolers.

When connecting (2) electric defrost unit coolers to (1) defrost timer remove the red wire from the defrost termination / fan de-

lay control which is factory wired to terminal 4 - TB1 on unit cooler #2 and hard wire to a field wire connected to terminal 1 -

TB2 on unit cooler #1. This will place the (2) defrost termination controls in series so that both units must reach temperature in

order to terminate the defrost cycle.

The room thermostat and liquid line solenoid valve are shown as field installed but may be factory mounted in the unit cooler.

Make sure the solenoid holding coil is wired for the correct control voltage (115 or 230).

**

*

+

!

^

<

#

19

FIELD WIRING DIAGRAMS — TYPICAL

ELECTRIC DEFROST — 208/230/3/60 — (1) UNIT COOLER WITH HEATER CONTACTOR

IMPORTANT WIRING NOTES - INSTALLER PLEASE READ CAREFULLY!

Sub-circuit fusing or service disconnect switches are not shown but may be required as per the NEC and / or local codes.

It is the responsibility of the installing contractor to interpret and comply with all applicable electrical codes.

Field install an 18 GA jumper wire between terminals 3 & 4 on terminal block TB2 for continuous low speed fan operation (950

RPM). Fan motors will operate continuously on high speed without jumper wire installed (F31 Models Units - 1300 RPM / F35

model units - 1450 RPM). See page 21 for optional two speed fan relay control wiring if required.

The defrost time clock, block out relay / auxiliary switch and heater contactor are typically located in the system condensing

unit. All unit cooler power should feed from this unit. Make sure the total heater amp draw does not exceed the resistive rating

of the contactor. Also be sure the wire gauge size is adequate to carry the total amp load required.

When using a heater contactor with unit cooler defrost heaters factory wired for single phase remove factory installed jumper

between terminals 2 & 3 on TB1 and wire directly to heater contactor as shown above.

The room thermostat and liquid line solenoid valve are shown as field installed but may be factory mounted in the unit cooler.

Make sure the solenoid holding coil is wired for the correct control voltage (115 or 230).

**

+

#

<

*

20

FIELD WIRING DIAGRAMS — TYPICAL

ELECTRIC DEFROST — 208/230/3/60 — (2) UNIT COOLERS / (1) HEATER CONTACTOR

IMPORTANT WIRING NOTES - INSTALLER PLEASE READ CAREFULLY!

Sub-circuit fusing or service disconnect switches are not shown but may be required as per the NEC and / or local codes. It is

the responsibility of the installing contractor to interpret and comply with all applicable electrical codes.

Field install an 18 GA jumper wire between terminals 3 & 4 on terminal block TB2 for continuous low speed fan operation (950

RPM). Fan motors will operate continuously on high speed without jumper wire installed (F31 Models Units - 1300 RPM / F35

model units - 1450 RPM). See page 21 for optional two speed fan relay control wiring if required.

The defrost time clock, block out relay / auxiliary switch and heater contactor are all typically located in the system condensing

unit. All unit cooler power should feed from this unit. Make sure the total heater amp draw per unit cooler does not exceed the

resistive amp rating of the contactor. Also be sure the wire gauge size is adequate to carry the total amp load required.

When connecting (2) electric defrost unit coolers to (1) defrost timer remove the black wire from the defrost termination / fan

delay control which is factory wired to terminal 2 - TB2 on unit cooler #2 and cap the wire. This will allow the fan delay on unit

cooler #1 to control the fans on both unit coolers.

When connecting (2) electric defrost unit coolers to (1) defrost timer remove the red wire from the defrost termination / fan

delay control which is factory wired to terminal 4 - TB1 on unit cooler #2 and hard wire to a field wire connected to terminal 1 -

TB2 on unit cooler #1. This will place the (2) defrost termination controls in series so that both units must reach temperature in

order to terminate the defrost cycle.

The room thermostat and liquid line solenoid valve are shown as field installed but may be factory mounted in the unit cooler.

Make sure the solenoid holding coil is wired for the correct control voltage (115 or 230).

**

*

+

<

^

!

This manual suits for next models

1

Table of contents

Other Tecumseh Accessories manuals

Popular Accessories manuals by other brands

Heath Zenith

Heath Zenith Notifi elite owner's manual

Chef's Choice

Chef's Choice Sportsman Diamond Hone 4635 user manual

System air

System air Geniox Softcooler 12 Installation and service

C.P. Electronics

C.P. Electronics MWS5 Product guide

Baicells

Baicells Nova-227 installation guide

Simply Shade

Simply Shade SS-SERENATA instruction manual