212930 | A001

Contents

1 Overview........................................................................................................................................1

1.1 Type label..............................................................................................................................1

1.2 Warranty...............................................................................................................................1

1.3 Disposal and recycling ..............................................................................................................2

2 Important Safety Information..............................................................................................................2

2.1 Intended Use..........................................................................................................................2

2.2 Admonitions...........................................................................................................................2

2.3 Declaration of Conformity..........................................................................................................3

3 Technical Data .................................................................................................................................4

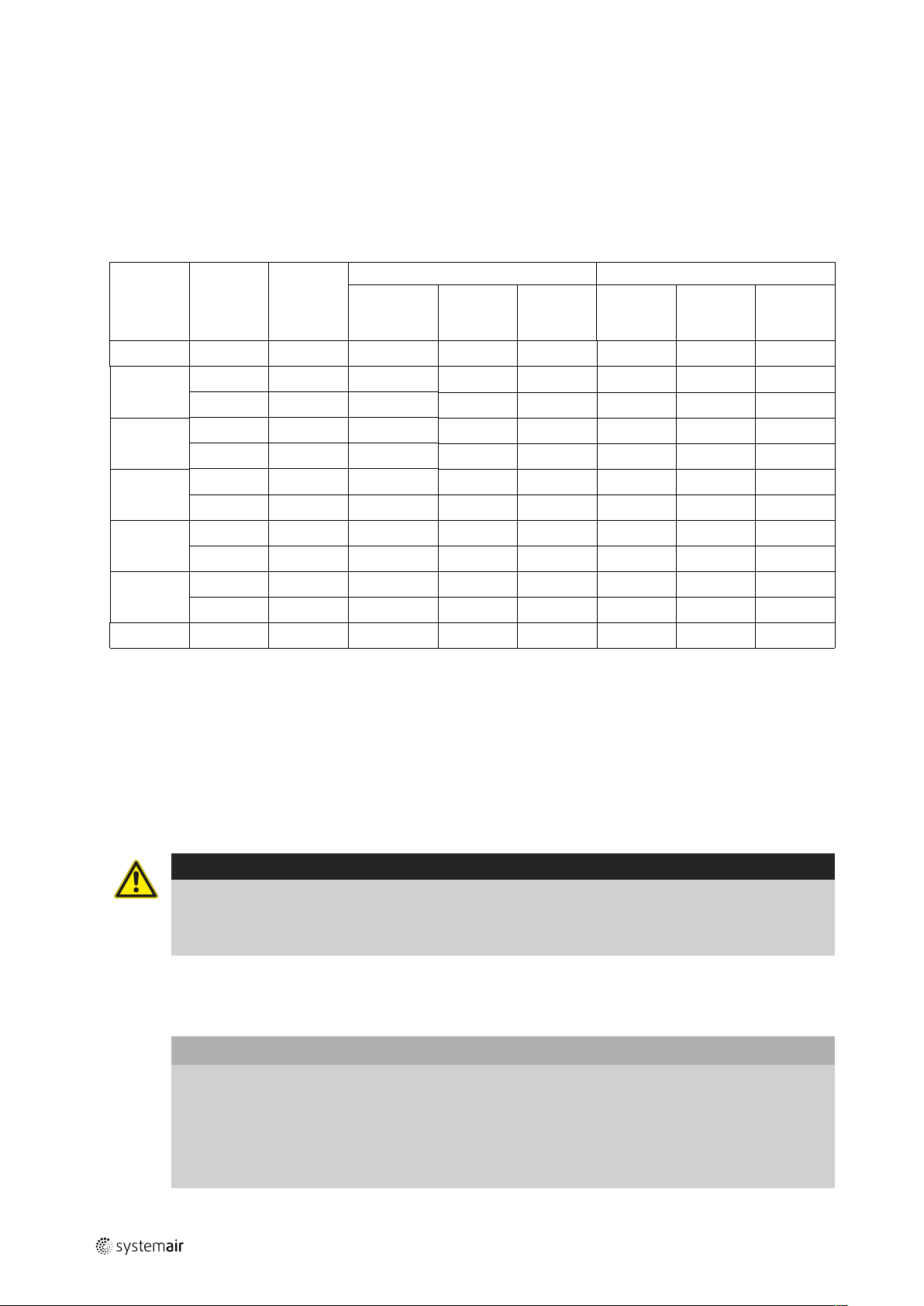

3.1 Unit size and Compressor(s).......................................................................................................4

3.2 Refrigerant.............................................................................................................................4

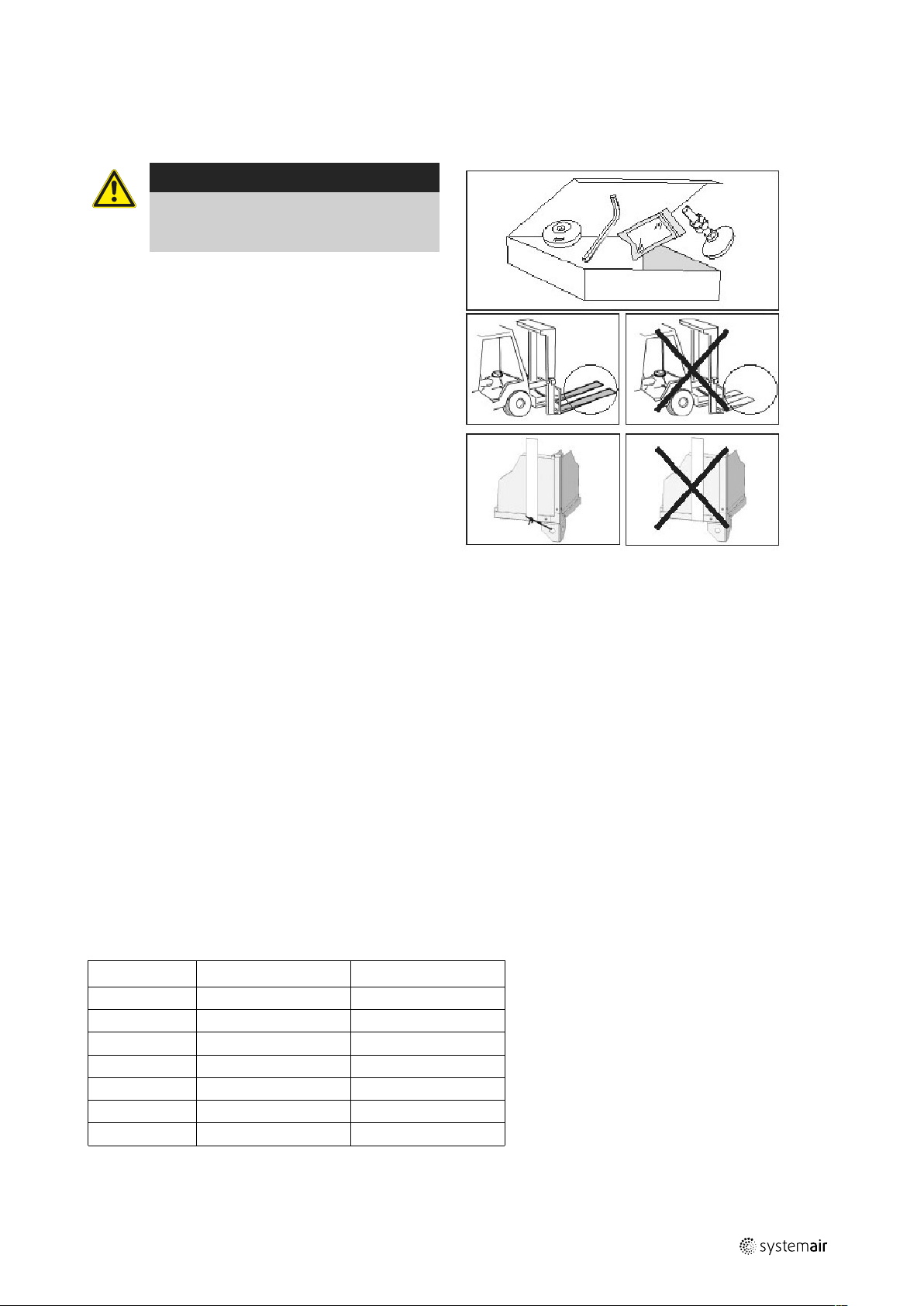

4 Delivery, Transport, Storage................................................................................................................4

4.1 Transport and storage ..............................................................................................................4

4.2 Delivery/Unloading..................................................................................................................5

5 Prerequisites for Installation................................................................................................................5

5.1 Location and Space Requirements . ....................... ..... .. .................. ..... .. .................. ... .. ................5

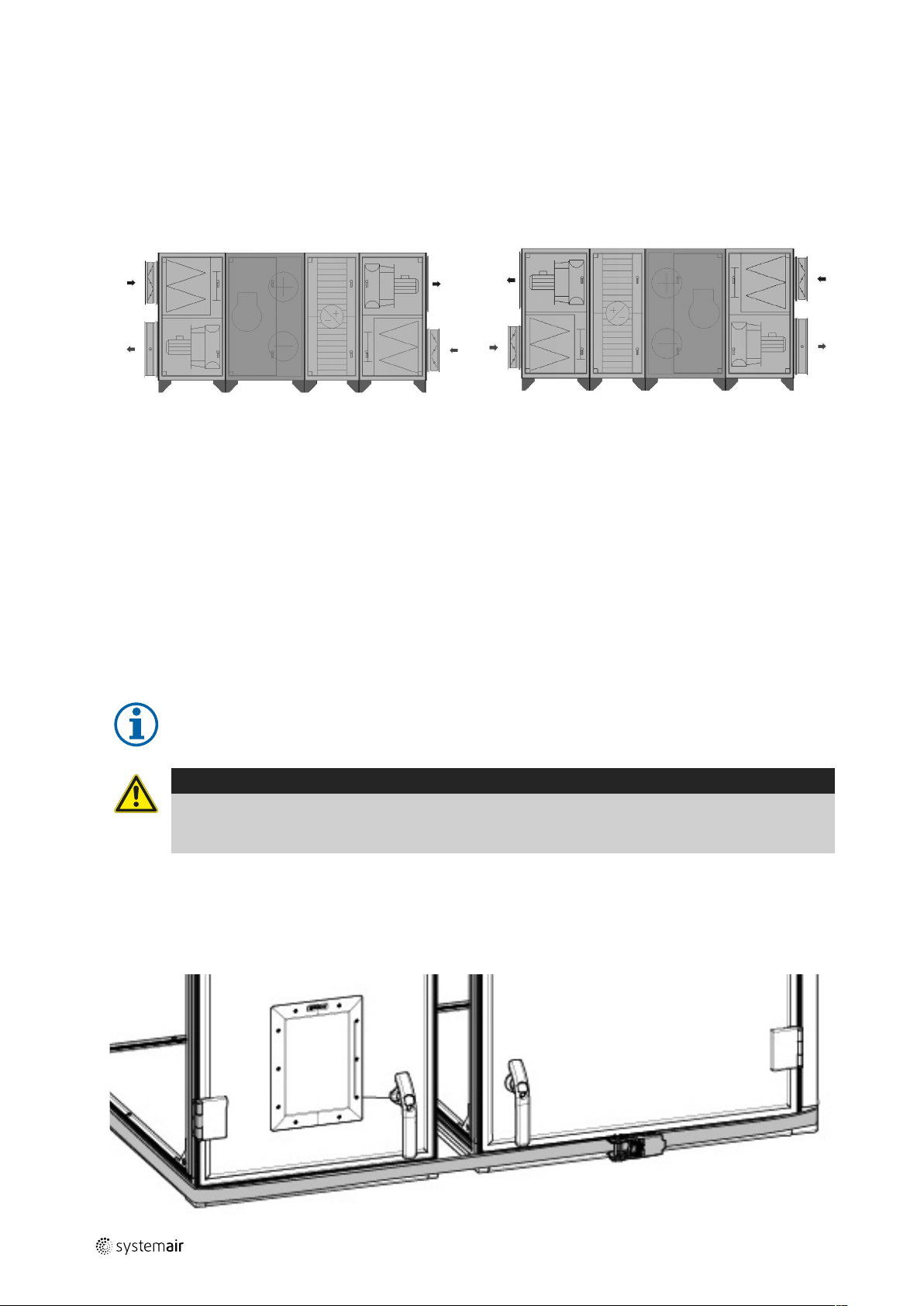

5.2 Positions and Placement ...........................................................................................................6

5.2.1 Positioning of compressors ............................................................................................6

5.3 Access to Power Supply............................................................................................................6

6 Installation......................................................................................................................................6

6.1 Electrical Connection ................................................................................................................7

6.1.1 Rotational direction of compressor(s)...............................................................................7

7 Commissioning ................................................................................................................................7

7.1 Before start-up .......................................................................................................................7

7.2 Control of Geniox Softcooler ......................................................................................................7

7.2.1 Power control.............................................................................................................8

7.2.2 Power limitation..........................................................................................................8

8 Service and maintenance ...................................................................................................................8

8.1 Cooling-technical maintenance...................................................................................................8

8.2 Electronic expansion valve.........................................................................................................8

8.3 Other maintenance..................................................................................................................9

9 Concluding Routines..........................................................................................................................9

10 Troubleshooting...............................................................................................................................9

10.1 Diagrams...............................................................................................................................9

10.2 Settings.................................................................................................................................9

10.2.1 High exhaust temperature or insufficient air volumes ..........................................................9

10.3 Electrical faults......................................................................................................................10

10.4 Faults in cooling technology .............. ..... ...... ..... ......... ..... ...... ..... ......... ..... ...... ..... ......... ............ 10

11 Description of Geniox Softcooler ........................................................................................................ 10

11.1 Geniox Softcooler Cooling section ............................................................................................. 10