TEI FDC-3 User manual

••

FDC·3

li-

CARD USER'S GUIDE

..

Et

FDC-3

FLOPPY-DISK

CONTROLLER

USER

MANUAL

CON

TEN

T

IIKTRODUCTION

1.1

General

1.2

Physical

Description

II

INSTALLATION

III

THEORY

OF

OPERATION

3.1

Address

Decoder

3.2

Drive-Select

Latch

3.3

Function-Select

Logic

3.4

Bidirectional

Bus

Buffers

3.5

Read/Write

Clock

Generation

3.6

1791

Controller

3.7

Miscellaneous

Logic

3.8

Jumper

Selection

of

Various

Functions

IV

SOFTWARE

CONSIDERATIONS

4.1

FDC-3

Card

4.2

1791

Device

V

HARDWARE

CONSIDERATIO~S

5.1

Drive

Configuration

5.2

Signal-Cable

Connections

VI

USER

REPAIR GUIDE

1-1

1-1

2-1

3-1

3-1

3-1

3-1

3-3

3-5

3-7

3-9

4-1

4-1

5-1

5-1

6-1

A

TEl,

A.l

A.2

A.3

INC.

T/DOS DISKETTE READ/WRITE

ERROR

INDICATIONS

General

Commands

Error-Recovery

Procedures

FIG

U

RES

A-I

A-I

P.-4

1-1

TEl,

Inc.

FDC-3

Floppy-Disk

Controller

3-1

FDC-3

Card

Block

Diagram

3-2

1791

Device

Block

Diagram

3-3

FDC-3

Card

Address

Jumper

Selection

3-4

Drive-Ready

Delay

Jumper

Selection

6-1

Card

Ejector,

Left

SidE

TAB

L E S

5-1

Regular

Drive

Signal

Connections

5-2

Miniature

Drive

Signal

Connections

A-I

Type

ICommand

Codes

A-2

Type

II

Command

Codes

A-3

Type

III

Command

Codes

1-0

3-0

3-4

3-8

3-10

6-0

5-2

5-3

A-I

A~2

A-2

i

..

"

g

•

..

-

,

-

•

..

-

-

•

•

..

-

~

,

c

••

•

..

o

g

..

•

o

-

-

Q

•

SECTION

I

INTRODUCTION

1.1

GENERAL

The

TEl,

Inc.

FDC-3

Floppy-Disk

Controller

combines

the

1791

LSI

floppy-disk

controller

device

and

supporting

logic

to

control

up

to

eight

standard

drives

and

up

to

three

mini

drives

-

single

or

double-

sided,

single

or

double

density.

The

1791

device

allows

software

selection

of

both

density

and

number

of

sides

for

ease

in

changing

system

conf

iguration.

The

FDC-3

Floppy-Disk

compatible

formats;

automatic

track-seek

detection.

Controller

also

effers

such

features

as

IBM-

buffered

control,

data,

and

status

lines,

with

verification;

and

CRC

generation

and

The

TEl,

Inc.

FDC-3

Floppy-Disk

Controller

was

specifically

designed

to

operate

reliably

in

a

TEl,

Inc.

ComFuter

System

using

TEl,

Inc.

system

components.

Although

the

FDC-3

Floppy-Disk

Controller

may work

properly

in

another

manufacturer's

computer,

or

with

another

manufacturer's

components,

TEl,

Inc.

cannot

guarantee

that

it

will

do

so.

1.2

PHYSICAL

DESCRIPTION

The

FDC-3

Controller

card

(Figure

1-1)

consists

of

31

integratec

circuits,

plus

supporting

components;

50-pin

socket

for

standard

(8")

diskette-drive

signal

cable;

and

a

34-pin

socket

for

miniature

(5.25")

drive

signal

cable;

all

mounted

on

a

5"

x

10"

(127-mm

x254-mill)

fiberglass

double-sided

etched-circuit

board

complete

with

a

standard

S-IOO

bus

connector

that

has

gold-plated

contacts

for

reliability

and

long

life.

1-1

SECTION

II

INSTALLATIOK

1)

Turn

System

power

off.

CAUTION!

NEVER

INSTALL

OR

REMOVE

ACIRCUIT

CARD

WITH

POWER

ON!

2)

Install

card

in

any

card

slot.

If

the

FDC-3

card

replaces

an

FDC-

2

card,

install

in

same

slot

to

avoid

having

to

move

cables.

Note

that

the

edge-connector

location

prevents

plugging

the

card

in

backwards.

3)

Plug

signal

cable(s)

into

FDC-3

card.

Cable

from

standard

(8")

drive(s)

plugs

into

large

connector.

Cable

from

miniature

(5.25")

drive(s)

plugs

into

small

connector.

Be

sure

connector

(s)

firmly

seated.

4)

Turn

System

on,

with

all

drive

doors

open.

If

T/DOS

Version

1.44

(or

lower)

information

appears

(after

CRT

warmup)

with

drive

doors

open,

FDC-3

card

will

not

work

properly.

5)

Place

System

diskette(l)

in

drive

A(2),

close

drive

door,

wait

for

memory-size

prompt,

then

enter

size

(in

K)

for

desired

program,

or

press

RETURN

to

load

maximum

size

automatically.

6)

Check

CRT

Display.

If

T/DOS

Version

2.0

(or

higher)

installed,

System

is

ready

for

operation.

(1)

Consult

local

documentation,

Supervisor,

or

Dealer

for

correct

diskette

insertion

method

on

your

System.

Diskette

should

not

be

Wr

i

te-Protected,

if

recording

on

disk

et

te

requi

red.

(2)TEI,

Inc.

Systems

with

eight

function

keys

on

keyboard,

can

load

T/DOS

Version

2.0

(or

higher)

from

drives

B,

C,

or

D,

if

desired.

Press

key

8

to

load

from

drive

B,

key

7

to

load

from

drive

C,

keys

7

and

8

to

load

from

drive

D.

2-1

DRIVE

a

Dr

ive

#

/Datil

Reset

....

i'

Read/Write

Drive-Select

~

,-

1791

v

Clk

Clock

Raw

Dat

Latch

i'

Generator

v

Rd

Clk

i'

Earlv

-

~

..

Lat0

-

Do

Bid

i

rectional

/

Dal

....

Write

Data

....

DI

Buss

Driver

......

,-

::.

Write

Gate

Di

rect

ion

~

"

Step

....

Head

Load

"

'/

Head

Loadedl

Delay

1

......

Address

"

A2-A7

---

,

Write

Fault

~

Decoder

A2

'/

F

I'

-----0

I . /

Write

Protect

MatrIx

G

Index

Pulse

AD.

Al

.....

......

".

1/

Ready

I

......

I

Delav

SINP

R/W

.....

SOUT

Function

".

1/

Track.

0

PD

BIN

Select

PWR

Logic

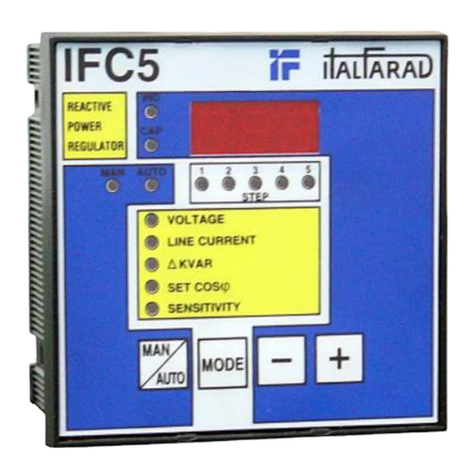

Figure

3-1

FDC-3

Floppy-Disk

Controller

Card

Block

Diagram

SECTION

III

THEORY

OF

OPERATION

The

TEl,

Inc.

FDC-3

Floppy-Disk

Controller

Card

(Figure

3-1)

contains

an

Address

Decoder,

Drive-Select

Latch,

Function-Select

Latch,

Bidirectional

Bus

Buffers,

crystal-controlled

Read/Write

Clock

Generator

with

Digital

phase-Locked

loop,

type

1791

MOS

LSI

controller,

and

miscellaneous

logic.

3.1

ADDRESS

DECODER

The

basic

FDC-3

address

is

XXOY

to

XXFY

(hex)

where

xx

is

"don't-care"

(high-order

address

byte

not

decoded

on

FDC-3

card),

0

to

F

is

jumper-

selected

on

the

FDC-3

card,

and

Y

is

partly

jumpered

and

partly

software-controlled

to

direct

the

accompa~ying

data

byte

to

the

proper

card

or

1791

device

register

(Section

3.6).

Comparator

Z26

and

gates

in

Z24

and

Z25

form

the

FDC-3

address

decoder.

The

three-row

by

five-column

matrix

between

Z26

and

the

card

edge

enables

the

jumper

selection

described

above

(and

in

Section

3.8)

•

When

the

CPU

sends

date.

to

the

address

Lelected

by

the

jumpers,

the

Address

Decoder

enables

the

card

to

receive

or

transmit

data.

3.2

DRIVE-SELECT

LATCH

Z30

and

gates

in

Z24

and

Z25

form

an

eight-bit

latch

for

the

selected

drive

numbers,

type

(mini

or

standard),

side

number,

density,

and

reset.

Data

on

the

data

bus

(low

order

byte

with

TEl,

Inc.

CPU-85

card)

enters

the

latch

when

the

operating

system

executes

an

OUT

instruction

to

the

FDC-3

address,

with

address

bit

A2

high.

Bits

Al

and

AO

are

ignored.

3.3

FUNCTION-SELECT LOGIC

Ga

tes

in

Z

9,

Z24

and

Z25

decode

CPU

commands

to

the

FDC-3

to

steer

or

condition

onboard

logic

to

receive

or

transmit

the

proper

data.

3.4

BIDIRECTIONAL

BUS

BUFFERS

Z28

and

Z29

are

four-bic

bidirectional

bus

driver/receivers.

3-1

3.5

READ/WRITE

CLOCK

GENERATION

The

Read/Write

Clock

Generator

performs

the

dual

function

of

(1)

Accurately

separating

incoming

data

and

clocks

in

either

FM

mode

(single

density)

or

MFH

mode

(double

density);

and

(2)

Supplying

write

clocks

for

either

recording

mode.

This

logic

consists

of

a

crystal-controlled

Oscillator,

Dividers,

Write-Data

Delay

Generator,

multiplexer-controlled

Buffers,

and

Digital

Phase-Locked

Loop.

3.5.1

OSCILLATOR

R24,

R25,

Xl,

and

two

sections

of

Z16

form

a

16-~Hz

oscillator.

The

oscillator

output

clocks

the

Divider

log~c.

3.5.2

DIVIDERS

AND

MULTIPLEXED

BUFFER

Z12

divides

the

16-MHz

oscillator

signal

to

generate

2,

4

and

8

MHz.

Z14

enables

cne

of

the

four

buffers

in

Z13,

steered

by

density

ana

drive

signals.

The

selected

buffer

passe~

the

selected

frequency

--2,

4,

8,

or

16

MHz--

to

the

Digital

Phase-Lc'cked

Loop.

3.5.3

WRITE-DA'I'A

DELAY

GENERATOR

AND

BUFFER

Z5

delays

the

Write

Data

signal

one,

three

or

five

16-MHz

clock

times

as

required

for

write

precompensation.

Z14

enables

one

of

the

four

buffers

in

Z6,

steered

by

Early

and

Late

outputs

from

the

1791

device.

3.5.4

DIGITAL

PHASE-LOCKED

LOOP

Zl,

Z2,

Z4,

ZlO,

211

and

Z16

form

a

Digital

Phase-Locked

loop.

This

circuit

receives

combined

data

and

clock

transitions

from

the

drive

electronics

and

accurately

separates

the

clock

pulses

from

the

data

pulses.

ZIA

and

Z2A

clock.

Z2B

transition.

Clock.

synchronize

incoming

signal

transitions

with

the

FDC-3

and

gates

in

Z10

output

short

pulses

for

each

input

These

pulses

clock

Zll

and

Z4

which

output

the

Read

ZlB,

Z2B,

and

buffers

in

Z16

and

Z17

sel~ct

the

1791

device

clock.

3-3

~----,-----t

+

0.,.

...

OUT

ttuHERS

-,

t+r1

It•1•

DATA

,-,r)-"'~'A·~('

r

SECiOA

~I

r-

TRACt(

K-

$TATUS

MEG

FlE(~

REG REG REG

•iI

,

d;

I

.::;

......

i

L--

MAW

READ

51.11'

r

__

EG

:

:IAcU

W~~EO~S~T"

4-

!

1-1--

I,

..

~

OPEC'OR

:,

ReL.IC.

i

rl,---C_""

'_0uc_ll---·

-----J

~':'.Q---r-----I

-_

....

_----

--~._--

--~--

__

we

__

--~':.._-

--~-

ro,

N1;:"u'i'4

·,,"'ftlFACf

(O",,"'F:lO

..

P,

•

WG

r043

;;mo

-

WP

"

-

r.3a

O'$IC.

REAO'"

I",TEAF·CT

CO""TIlIO~

STEP

DIllie

EARLY

LoAT!,

MG

",0

'"

T

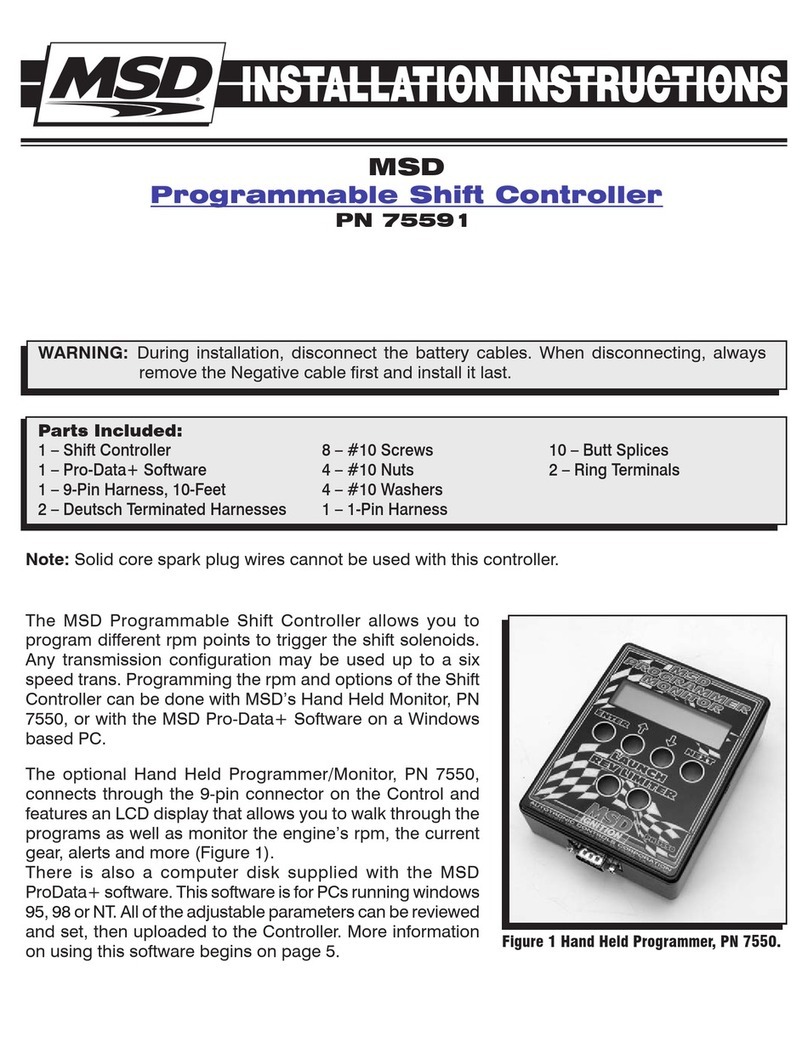

FD1791 BLOCK DIAGRAM

Figure

3-2

1791

Device

Block

Diagraffi

~-4

3.6

1791

CONTROLLER

The

1791

Controller

is

an

r~os

LSI

device

that

contains

logic

to

select

a

disk

track,

then

reco!o

data

on

that

track

or

read

data

already

recorded.

The

1791

device

(Figure

3-2)

consists

cf

a

buffered

Data

Register,

Data

Shift

Register,

Sector

Register,

Command

Register,

Track-Number

Register,

Status

Register,

CRC

Logic,

Address-Detect

Logic

Arithmetic/Logic

Unit

(ALU),

Computer-Interface

Logic,

and

Drive-

Interface

Logic.

3.6.1

DATA

REGISTER

This

bidirectional

register

receives

data

or

commands

from

the

CPU

and

transmits

data

to

the

CPU.

3.6.2

DATA

SHIF7

REGISTER

This

register

receives

eignt

bits

of

serial

data

from

the

drive,

then

outputs

it

as

one

byte

to

the

Dcta

Regis~er;

or

receives

a

byte

from

the

Data

Register

and

transmits

it

as

serial

data

to

the

drive.

3.6.3

SECTOR

REGISTER

This

eight-bit

register

holes

the

address

of

the

desired

sector.

3.6.4

COMMAND

REGISTER

This

eight-bit

register

holds

the

command

currently

being

executed

by

the

1791

device.

The

device

has

11

cOffiffiands

of

four

types

(Section

IV)

•

3.6.5

TRACK-NUMBER

REGISTER

This

eight-bit

register

holds

the

number

of

the

track

over

which

the

Read/Write

head

is

currently

positioned.

Step

and

Direction

commands

from

the

Drive-Interface

logic

increment

or

decrement

the

register.

3.6.6

STA?US

REGISTER

This

eight-bit

register

holds

drive

status

such

as

ready,

write-

protected,

etc.;

and

coremand-result

status.

Refer

to

Appendix

A.

3-5

3.6.7

CRC

LOGIC

Thi~

logic

generates

a

unique

16-bi

t

chec.(-word

for

each

data

transfer

[rolil

the: CPU,

and

records

that

word

along

with

the

data.

When

the

date..

is

read

out,

it

again

passes

through

the

CRC

logic.

If

the

check-word

generated

during

the

read

operation

does

not

match

the

recorded

check-

word,

the

1791

device

enters

a

CRC

error

bit

in

its

Status

register

and

stops

the

Read

operation.

3.6.8

ADDRESS-DETECT

LOGIC

This

logic

detects

ID,

dat~,

or

index

marks

during

operation.

3.6.9

ARITHNETIC/LOGIC

UNIT

The

ALU

increments

or

decrements

registers

as

required.

3.6.10

COMPUTER-INTERFACE

AND

;)RIVE-INT::RFACE

LOGIC

The

Computer-Interface

logic

rec2ives

all

control

signals

from

the

CPU

and

selects

register

data

flow

accordingly.

The

Drive-Interface

logic

processEs

status

signals

f~om

the

disk

drive

and

control

signals

from

the

Computer-Interface

logic

to

control

data

transfer

to

and

from

the

drive.

A

Prograremed

Logic

Array

(PLN

stores

the

program

that

controls

both

the

Computer-Interfac~

and

Drive-Interface

logic

blocks.

3.7

3.7.1

MISCELLANEOUS

LOGIC

HEAD-LOAD

DELAY

Z21

generates

a

noninal

40-millisecond

delay

pulse,

timed

by

C18

a,.c.

R5,

each

time

the

1791

device

generates

the

Head-Load

signal.

This

pulse

applied

to

the

1791

device's

HLT

input

prevents

any

transfer

until

the

drive

head

settles

on

the

diskette

surface.

3.7.2

DRIVE-READY

LOGIC

3.7.2.1

Miniature

Drive

Z20

counts

index

pulses

generated

by

the

drive

electronics

each

time

the

diskette

index-hole

passes

a

sensor

in

the

drive.

Upon

reaching

the

desired

number

(Section

1.<;);

Z20

outputs

a

RDY

signal

for

the

1791

device.

3-7

3.7.2.2

Regular

Drive

The

drive

electronics

generates

RDY/ or.

interface

connector

pin

22

upon

detection

of

the

second

index

pulse

after

drive

door

closed.

Z26-4

A3

*

Z26-6

A4

*

Z26-10

AS

*

Z26-12

A6

*

Z26-14

A7

*

Ground

+5

VDC

\

1 I I 1 I

*-----------*-----------*-----------*-----------*

I

1

I

*-----------*-----------*-----------*-----------*/

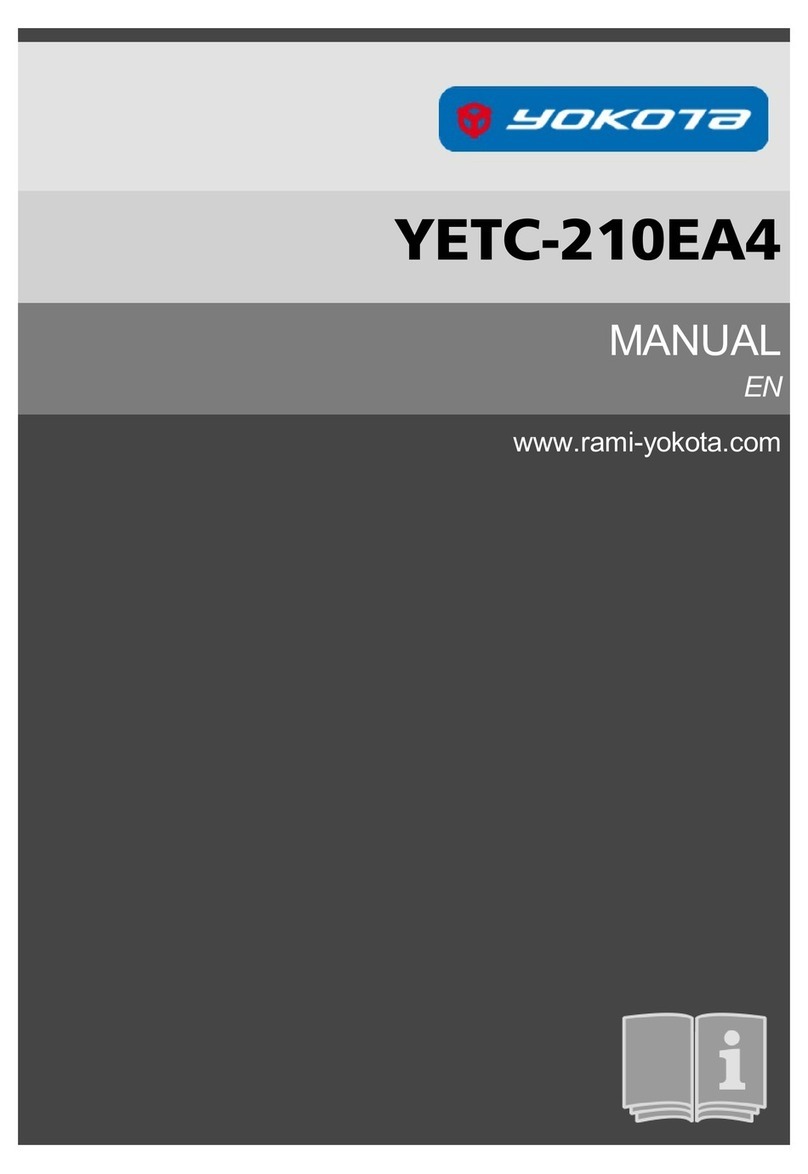

Figure

3-3

FDC-3

Card

Address

Jumpering,

Wiring

Side

of

Card

Up

TABLE

3-2

FDC-3

ADDRESS

JUMPER SELECTION

===================================

I I

A7

I

A6

I

AS

1

A4

I

1-----1------1------1------1------1

o

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

o

c

o

o

o

o

o

o

1

1

1

1

1

1

1

1

o

o

o

o

1

1

1

1

o

o

o

o

1

1

1

1

J

o

1

1

a

)

1

1

oJ

o

1

1

o

a

1

1

o

1

a

1

a

1

o

1

o

1

a

1

o

1

a

1

===================================

*If

A3

strapped

high,

the

low

order

address

byte

varies

from

8

to

F;

if

low,

from

0-7.

3-8

3.8

JUMPER

SELECTION

OF

VARIOUS

FUNCTIONS

The

FDC-3

card

has

jumper

selection

for

address,

interrupts,

drive-

ready

delay,

and

Write

Fault.

The FDC-3

card

leaves

the

factory

with

etched

jumpers

selecting

these

functions

for

proper

operation

with

the

TEl,

Inc.

Disk

Operating

System

(T/DOS).

Changing

any

of

these

jumpers

may

result

in

improper

T/DOS

operation.

3.8.1

FDC-3

ADDRESS

Recall

from

SectiCin

3.1

that

the

basic

FDC-3

address

is

XXOY

to

XXFY

(hex).

Jumpers

insE::rted

in

the

matrix

between

Z26

and

the

card

edge

connector

(Figure

3-3)

and

the

System

software

determine

the

specific

FDC-3

address,

OY

to

FY.

The

card

leaves

the

factory

wtl

A7

conn

~cted

to

+5

VDC

<logic

1>

and

A6-A3

connected

to

ground

(logic

0).

This

forms

address

8X,

where

X

consists

of

A3

at

logic

0

and

A2

-

AO

software-selected

from

0-7,

which

results

in

a

final

address

of

80

to

87.

To

select

a

different

address,

refer

~o

Table

3-2,

determine

the

address

connection,

c~refully

cut

the

factory

jumpers

to

Z26

(as

required),

then

solder

jumpers

from

thE

+5VDC

or

ground

rows

to

the

226

inputs.

3.8.2

END-OF-COMMAND

INTERRUPT

with

the

etched

jumper

just

above

5-100

bus

pin

9

intact,

the

1791

device

generates

a

VISI

interrupt

signal

~t

the

end

of

each

command.

3.8.3

DATA

REQUEST

INTERRUPT

With

the

etched

jumper

just

above

pin

10

intact,

the

1791

devicE::

generates

aVI61

(Data

Request)

interrupt

signal

if

(1)

Data

Register

full

during

Read,

or

(2)

Data

Register

enpty

during

vlrite.

3.8.4

WRI'::'E

FAUL'I'

If

thE::

user's

drive

supplies

a

Write-Fault

signal

(WF/),

connecting

a

jumper

between

points

"H"

and

"F"

below

the

large

signal-cable

connector

causes

the

1791

device

to

stop

the

Write

operation

and

set

the

Write-Fault

status

bit

upon

detectio~

of

the

Fault

signal.

3-9

3.8.5

DRIVE-READY

DELAY

SELECTION

with

the

etched

jumper

(on

back

side

of

board)

connected

to

Z20,

pin

11

(Figure

3-4),

the

1791

device

receives

a

Ready

signal

after

the

sixth

diskette

rotation

(sixth

index

pulse

received).

To

select

the

fifth,

seventh,

or

eighth

rotation

instead,

turn

the

board

wiring

side

up,

locate

the

group

of

empty

holes

shown

in

detail

(as

asterisks)

in

Figure

3-4

(approximately

3n

(7.5

cm)

straight

down

from

left

edge

of

large

signal

connector),

cut

the

etched

jumper,

then

solder

a

jumper

from

the

single

hole

to

the

hole

above

pin

10

for

selection

of

the

fifth

rotation,

to

the

hole

above

pin

12

for

selection

of

the

seventh

rotation,

or

to

the

hole

above

pin

13

for

selection

of

the

eighth

rotation.

o0

Z20

o0

*

/

/

-------Etched

jumper

****

IIII

0000 0

10 11

12

13

0000 0

Figure

3-4

Drive-Ready

Delay

Jumper

Selection,

Wiring

Side

3-10

SECTION

IV

SOFTWARE

CONSIDERATIONS

4.1

FDC-3

CARD

The

FDC-3

card

requires

three

programming

steps:

Drive

Selection,

Drive

Initialization,

and

Data

Transfer.

The

TEl,

Inc.

Operating

System,

T/DOS

Version

2.0

(or

higher),

performs

these

functions

as

required

for

program

operation.

Note

that

T/DOS

Versions

2.0

-

2.XX

support

amaximum

of

four

diskette

drives.

4.2

1791

DEVICE

The

1791

LSI

device

responds

to

11

commands

of

four

types.

Type

I

cowmands

cause

hea.d

anG/or

stepper

motor

action.

Type

II

commands

read

or

write

data

fromlto

a

selected

sector.

Type

III

commands

read

an

address

or

data

fron,

i:l.

track

or

write

data

onto

a

trock.

The

single

Type

IV command

controls

the

device's

interrupt

capabilities.

As

stated

for

the

FDC-3

card,

T/DOS

supplies

these

commands

as

needed

for

program

operation.

Refer

to

Appenaix

A

for

a

discussion

oE

1791

device

commonds

ana

stc:.tus

codes.

4-1

SECTION V

HARDWARE

CONSIDERATIONS

5.1

DRIVE

CONFIGURATION

Each

drive

in

a

TEl,

Inc.

Computer

System

must

be

physically

configured

according

to

its

System

designation.

Configuration

occurs

during

System

checkout.

Drive

selection

during

program

operation

is

software-controlled.

5.2

5.2.]

SIGNAL-CABLE

CONNECTIONS

REGULJl.R

DRIVES

Table

5-1

sho\Vs

signal

connections

tor

regular

drives

<large

connector).

5.2.2

MINIATURE

DRIVES

Table

5-2

sr,ows

signal

connee

tions

f(

r

miniaL.

re

driveE

(small

connector).

5-1

TABLE

5-1

REGULAR

DRIVE

SIGNAL

CO~NECTIONS

==========================================================

I

Pin

I

FUNCTION

I

Pin

I

FUNCTION

I

1-------1--------------

1-------1------------------------1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

I

Ground

I

Spare

1

Ground

I

Write

Fault

I

Ground

I

Track

44-76

1

Ground

I

Spare

1

Ground

I

Spare

1

Ground

INot Used

I

Ground

I

Side

Select

I

Ground

I

In

Use*

I

Ground

IHead Load

I

Ground

I

Index

I

Ground

I

Ready

1

Ground

I

Spare

I

Ground

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Enable

Drive

Select

11

Ground

I

Drive

Select

2 1

Ground

I

Drive

Select

3 I

Ground

I

Drive

Select

4 1

Ground

I

Direction

1

Ground

I

St2P

I

Ground

I

Write

Data

I

Ground

I

Write

Gate

I

Ground

I

Spare

I

Ground

I

Write

Protect

I

Ground

I

Raw

Data

I

Ground

I

Separated

Data

I

Ground

j

Se?arated

Clock

I

5-2

==============================================~=======

=====

*Door

Light

TABLE

5-2

XINIATURE

DRIVE

SIGNAL

'::ONNECTION

===================================:=====================

Pin

1

FUNCTION

I I

Pin

1

FUNCTION

I

-------1----------------1

1-------1--------------------1

1

IGrouna

I I

18

I

Direction

2

ISpare

1I

19

I

Ground

3IGround II

20

I

Step

4

ISpare

I I

21

I

Ground

5IGround I

22

I

write

Data

6

ISpare

1

23

I

Ground

7IGround I

24

1

Write

Gate

8

IInd~x

1

25

I

Ground

9IGround I

26

1

Track

0

10

IDr i

ve

1

Select

I27 1

Ground

11

IGround I

28

1

vir

i

te

Protect

12

IDrive

2

Select

I

29

I

Ground

13

IGrounCi I

30

I

Raw

Data

14

IDrive

3

Select

I

31

I

Ground

15

IGrounci I

32

I

Side

Select

16

IHotor

On

I

33

IGround

17

IGroun(; I

34

I

=======~===;======.===~=;=============================

===

5-3

SECTION

VI

USER

REPAIR

GUIDE

TEl,

Inc.

designed

and

built

your

FDC-3

Floppy-Disk

Controller

Card

for

extreme

reliability.

Before

returning

the

card

for

repair,

please

check

the

following

items:

1) Does

power-supply

fan

run

and

memory-size

prompt

appear

on

screen

when

System

turned

on

and

Operating

System

diskette

loaded

into

crive?

If

not,

check

computer

AC

connection

and

fuse.

TURN

POWER

OFF

AND

UNPLUG

LINE

CORD

FIRST.

2)

Is

card

seated

properly?

Turn

power

off,

pull

up

Of.

ins10e

edg~

of

both

card

ejectors

(Figure

6-1)

·simultaneously

to

unseat

card,

then

press

firmly

back

into

socket.

If

card

still

does

not

function

properly,

unplug

signal

cable(s),

unseat

card

as

described

above,

remove

unseated

card

carefLllly

from

Computer,

then

place

card

on

a

clean,

firnl

surface

and

GENTLY

burnish

each

contact

on

both

sides

of

the

S-IOO

bus

edge

connector

with

a

pencil

eraser.

Do

not

use

a

power

eraser

or

an

art

gum

eraser.

Replace

card

in

Computer,

then

reconnect

signal

cable(s).

Be

sure

to

seat

both

card

and

co~nector(s)

firmly.

3)

Is

each

diske~te-drive

signal

cable

seated

properly?

Turn

power

off,

press

firmly

in

on

cable

connector.

4)

Does

problem

exist

for

one

diskette

only?

If

so,

copy

as

much

material

as

possible

from

defective

diskette

to

good

diskette

and

discar6

bad

diskette.

5)

In

multidrive

Syste~s,

does

problem

exist

for

one

drive

only?

Check

that

motor

in

problem

drive

turns

by

looking

into

drive

wi~h

door

open.

If

all

above

items

check

and

FDC-3

card

still

aoes

not

function

correctly,

please

contact:

Custom~r

Support

Coordinator

TEl,

Inc.

5075

South

Loop

East

HOLlston,

TX

77033

USA

(713)

738-2300

Tv~:

910-881-3639

6-1

Table of contents