RLE Technologies LD1500 User manual

Leak Detection

User Guide

LD1500

Version 3.5

2 LD1500 User Guide 800.518.1519

Copyright and Trademark Notices

© Raymond & Lae Engineering, Inc. 2011. All rights reserved. RLE® is a registered trademark and

SeaHawk™, Falcon™, and Raptor™ are trademarks of Raymond & Lae Engineering, Inc. The

products sold by Raymond & Lae Engineering, Inc. are subject to the limited warranty, limited liability,

and other terms and conditions of sale set forth at http://rletech.com/RLE-Terms-and-Conditions.html.

Revision History

Note: As necessary, blank pages are added to make the page count even.

Rev. No. Date

2.0 June 2010

2.1 October 2010

2.2 February 2011

3.0 April 2013

Copyright and Trademark Notices

© Raymond & Lae Engineering, Inc. 2012. All rights reserved. RLE® is a registered trademark and

SeaHawk™, Falcon™, and Raptor™ are trademarks of Raymond & Lae Engineering, Inc. The

products sold by Raymond & Lae Engineering, Inc. are subject to the limited warranty, limited liability,

and other terms and conditions of sale set forth at http://www.rletech.com/.

Revision History

Rev. No. Date Rev. No. Date

2.0 June 2010 3.4 March 2018

2.1 October 2010 3.5 April 2019

2.2 February 2011

3.0 April 2013

3.1 August 2014

3.2 September 2015

3.3 December 2016

rletech.com LD1500 User Guide 3

Manufacturer’s Notes

This product is manufactured by RLE Technologies, 104 Racquette Drive, Fort Collins, CO, 80524. If

this product is used in any manner other than that specified by the manufacturer, the protection

provided by the equipment may be impaired.

Product Registration

Product registration helps RLE Technologies inform owners of:

• Product upgrades

• Firmware enhancements

• New products and technologies

• Special offers available only to registered users

Any information provided to RLE Technologies through the registration form will be regarded as

confidential. RLE will not sell or distribute any of the information to third parties.

Technical Support

Before you install an LD1500, refer to RLE Technologies’ website, www.rletech.com, to ensure you are

using the most recent version of all documentation.

Personal assistance is available Monday through Friday, from 8:00 a.m. to 5:00 p.m. MST.

A request for assistance may be sent to support@rletech.com

Otherwise, please call us directly at: 800.518.1519.

The following information is located on the bottom of each LD1500 unit. Please have this information

available whenever a technical support call is placed:

The LD1500 is not a field-serviceable item and must be sent back to RLE Technologies for mechanical

repair. Power must be disconnected (unplugged) from the LD1500 any time the unit is mechanically

serviced. Physically unplug power from the unit any time you are making wiring connections to or from

the LD1500.

RLE cannot accept an item for repair without a Return Materials Authorization number, which must be

provided by RLE.

Product Model Number

Product Serial Number

Product Manufacture Date

4 LD1500 User Guide 800.518.1519

RLE Product Warranty

Seller warrants to the Ultimate Purchaser (the purchaser who buys for use and not for resale) that all

products furnished under this order and which are manufactured by Seller will conform to final

specifications, drawings, samples and other written descriptions approved in writing by Seller, and will be

free from defects in materials and workmanship. These warranties shall remain in effect for RLE

Manufactured parts for a period of twenty four (24) months after shipment. These warranties shall remain in

effect for RLE distributor supplied parts for a period defined by the original manufacturer’s warranty after

shipment. All parts replaced or repaired in the warranty period shall carry the unexpired portion of the

original warranty. A unit placed with the purchaser on consignment and then later purchased will be

warranted for twenty four (24) months [original manufacturer’s warranty for RLE distributor supplied parts]

from the time the Seller receives notification of the Purchaser’s intent to purchase said consigned item.

Products are NOT life and safety certified. In no event shall the Seller be liable for loss, damage, or expense

directly or indirectly arising from the use of the units, or from any other cause, except as expressly stated in

this warranty. Seller makes no warranties, express or implied, including any warranty as to merchantability

or fitness for a particular purpose or use. Seller is not liable for and Purchaser waives any right of action it

has or may have against Seller for any consequential or special damages arising out of any breach of

warranty, and for any damages Purchaser may claim for damage to any property or injury or death to any

person arising out of its purchase or the use, operation, or maintenance of the product. Seller will not be

liable for any labor subcontracted or performed by Purchaser for preparation of warranted item for return to

Seller’s factory or for preparation work for field repair or replacement. Invoicing of Seller for labor either

performed or subcontracted by Purchaser will not be considered as a liability by the Seller.

The liability of Seller hereunder is limited to replacing or repairing at Seller’s factory or on the job site at

Seller’s option, any part or parts which have been returned to the Seller and which are defective or do not

conform to such specifications, drawings or other written descriptions; provided that such part or parts are

returned by the Ultimate Purchaser within ninety (90) days after such defect is discovered. The Seller shall

have the sole right to determine if the parts are to be repaired at the job site or whether they are to be

returned to the factory for repair or replacement. All items returned to Seller for repair or replacement must

be sent freight, prepaid to its factory. Purchaser must obtain Seller’s Return Material Authorization prior to

returning items. The above conditions must be met if warranty is to be valid. Seller will not be liable for any

damage done by unauthorized repair work, unauthorized replacement parts, from any misapplication of the

item, or for damage due to accident, abuse, or act of God.

This warranty shall be exclusive of any and all other warranties express or implied and may be modified only

by writing signed by any officer of the Seller. This warranty shall extend to the Ultimate Purchaser but to no

one else. Accessories supplied by Seller but manufactured by others carry any warranty the manufacturers

have made to Seller and which can be passed on to the Ultimate Purchaser.

Seller makes no warranty with respect to whether the products sold hereunder infringe any patent, U.S. or

foreign, and Purchaser represents that any specially ordered products do not infringe any patent. Purchaser

agrees to indemnify and hold Seller harmless from any liability by virtue of any patent claims where

Purchaser has ordered a product conforming to Purchaser’s specifications, or conforming to Purchaser’s

specific design.

Purchaser has not relied and shall not rely on any oral representation regarding the Product sold hereunder

and any oral representation shall not bind Seller and shall not be part of any warranty.

Contents

rletech.com 5 970.484.6510

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mechanical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Reference Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Connections and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Connections and Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

P1: Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TB1: Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TB2: Cable Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

P2: RJ45 Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SW1.1: Ethernet Port Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SW1.2:EIA-485 Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TB3: EIA-485 Modbus Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

P4: EIA-232 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Installing the LD1500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting the Leak Detection Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Securing Cable to the Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Applying Power to the LD1500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Set the LD1500's IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Set the LD1500's IP Address Using a Web Browser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Set the LD1500’s IP Address using an EIA-232 Connection. . . . . . . . . . . . . . . . . . . . . . . . . 20

Calibrate Cable Resistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Home/Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Alarm Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Leak Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Web Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Network/IP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SNMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SNMP/Syslog Communities 1 & 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SNMP Trap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

EIA-485/Modbus/N2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

BACnet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

BACnet Register FD/BDT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

BACnet Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

System Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

970.484.6510 6 rletech.com

5 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Implementation Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Modes of Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Slave Address Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Function Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Data Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Error Check (Checksum) Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Exception Responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Packet Communications for the LD1500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Function 03: Read Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Function 04: Read Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Function 06: Preset Single Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Function 16: Preset Multiple Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

RTU Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

AFirmware Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Update the Flash Firmware Via Web Interface/TFTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Update the Firmware Via X-Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Update the Flash Firmware Via Bootloader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

B Preventive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

C Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

D Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figures

rletech.com 7 970.484.6510

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2 Connections and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 2.1 LD1500 Connections and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 3.1 SeaHawk Sensing Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 3.2 Cable Installation Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 4.1 Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 4.2 LD1500 Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 4.3 Alarm Log Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 4.4 Configuration Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 4.5 Leak Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 4.6 Web Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 4.7 Network/IP Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 4.8 SNMP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 4.9 SNMP/Syslog Communities Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 4.10 SNMP Trap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 4.11 Modbus/EIA-485 Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 4.12 BACnet Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 4.13 BACnet Register FD/BDT Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 4.14 BACnet Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 4.15 System Management Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

A Firmware Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

B Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

C Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

D Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

970.484.6510 8 rletech.com

Tables

rletech.com 9 970.484.6510

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 Connections and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Web Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 4.1 Leak Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 4.2 Web Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 4.3 Network/IP Configuration Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 4.4 SNMP Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 4.5 EIA-485/Modbus/N2 Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 4.6 BACnet Configuration Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 4.7 BACnet Alarm Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 4.8 System Management Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 5.1 Exception Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 5.2 Read Output Registers Packet Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 5.3 Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 5.4 Read Input Registers Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 5.5 Input Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 5.6 Status Flags (Register 30001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 5.7 Preset Single Register Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 5.8 Preset Multiple Registers Packet Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 5.9 Response Sample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A Firmware Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

B Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

C Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table C.1 Troubleshooting Problems with the LD1500 . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

D Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table D.1 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

970.484.6510 10 rletech.com

rletech.com LD1500 User Guide 11

CHAPTER

CHAPTER 0PRODUCT OVERVIEW

1.1. Description

The LD1500 is a complete monitoring system that detects and reports the presence of water

and other conductive liquids. The LD1500 couples SeaHawk Leak Detection Cable (sensing

cable) with an advanced control panel. Each LD1500 monitors up to 1,500 feet (457.2m) of

sensing cable. When a conductive liquid comes in contact with the sensing cable, an Alarm

LED is illuminated red on the front panel, the distance to the leak is shown on the LD1500’s

web page, and alarm notifications are distributed via user-configurable Modbus (EIA-485

RTU or TCP/IP), BACnet (EIA-485 MS/TP or IP), or SNMP.

1.2. Operation

When the LD1500's analog circuitry measures a current in excess of the user-defined leak

threshold, the unit's microprocessor computes the distance to the leak. The unit then

annunciates the leak and logs the alarm in its event log. The LD1500 provides a webpage

interface to allow users to get updates on the unit's conditions via the Internet or local area

network. The LD1500 also provides Modbus and BACnet outputs via EIA-485, twisted-pair

wire or TCP/IP.

Note The LD1500 produces an alarm in the following conditions:

♦ Leak detected

♦ Cable break (or cable fault)

♦ Cable contamination

♦ Loss of communications

The LD1500 is a supervised system; it continually monitors the cable for continuity. A cable

break or excess contamination of the cable causes an Alarm indication and notification.

12 LD1500 User Guide 800.518.1519

1 Product Overview

1.3. Mechanical Description

The LD1500 is built with one circuit board. The main board is mounted inside of the

enclosure.

1.4. Installation

The LD1500 is a wall mounted device. Before applying power to the unit, ensure that all

connections are correct and all screw terminals are secure. The LD1500 requires and isolated

power supply and is powered by 24 VAC or 24 VDC power. A power supply is not included

with the LD1500. Purchase an RLE power supply, either the PSWA-DC-24 (24VDC isolated

power) or the WA-AC-24 (24VAC isolated power). DO NOT connect 115/230 VAC to the

unit; damage will occur to the circuitry.

1.5. Reference Map

Users are advised to purchase a framed reference map (FM1114) for use with the LD1500 to

aid in locating any detected leaks along the sensing cable. Once all the sensing cable is

installed, compare this reference map with the actual cable installation. Note any discrepancies

and return the map to the original author for correction. Keep a copy for use until the map is

revised.

1.6. Web Interface

The LD1500's web page interface provides remote information updates via network

communications.

A more detailed description of the web page interface can be found in Chapter 4, “Web

Interface” on page 23.

rletech.com LD1500 User Guide 13

CHAPTER

CHAPTER 0CONNECTIONS AND INDICATORS

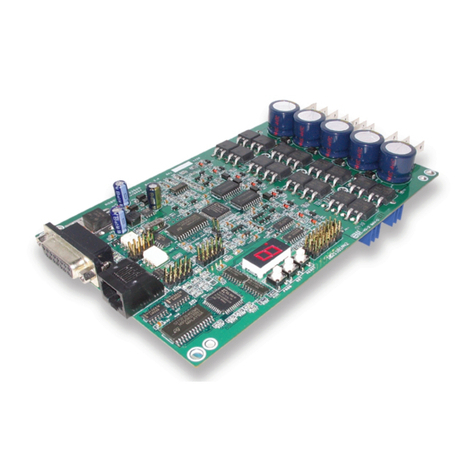

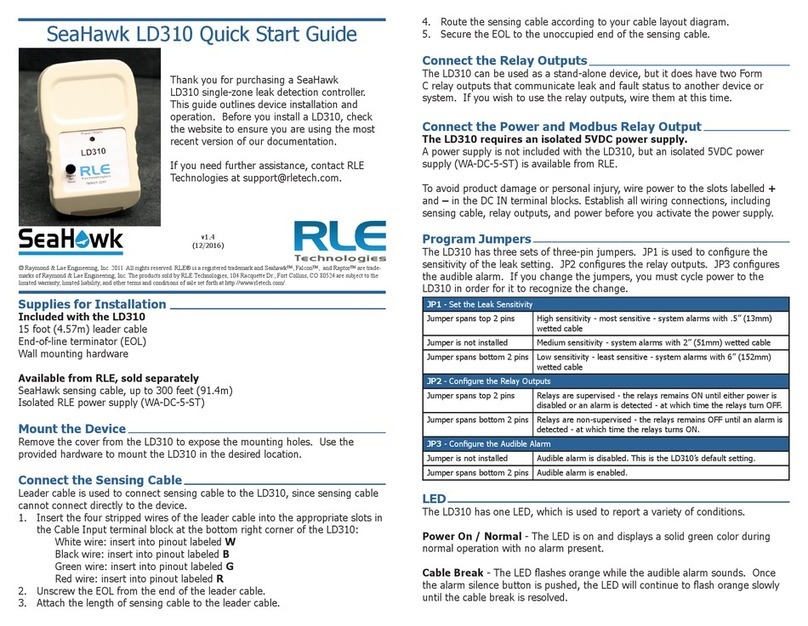

The LD1500 contains one circuit board. All connections are accessible when the unit is inside

of its enclosure. The connectors on the main board, found at the bottom of the following

photograph, are labeled TB1 through TB3 and P1 through P4.

Figure 2.1

LD1500 Connections and Indicators

Status LED

14 LD1500 User Guide 800.518.1519

2 Connections and Indicators

2.1. Connections and Default Settings

2.1.1 P1: Input Power

This is an optional barrel connection for input power (as you may also use TB1 for input

power) with the following connection:

Inside positive (+)

Outside negative (-)

The LD1500 requires an isolated power supply. Power supplies are available from RLE and

are not included with the LD1500. Contact RLE directly to purchase either RLE part number

PSWA-DC-24 (24VDC isloated power supply) or WA-AC-24 (24VAC isolated power supply.

2.1.2 TB1: Input Power

This is an optional two position connector (as you may also use P1 for input power) with the

following connections:

TB1-1 24VDC positive (+)

TB1-2 24VDC negative (-)

The LD1500 requires an isolated power supply. If you have purchased a PSWA-DC-24 or

WA-AC-24 from RLE Technologies, you may need to snip off the barrel connector and strip

the ends of the wires so they can be placed into TB1.

Polarity suggestions are optional, as the LD1500 power inputs are connected directly to an

internal bridge rectifier. 24VAC uses the same power connector as 24VDC.

2.1.3 TB2: Cable Interface

SeaHawk Sensing Cable connects to TB2. Since sensing cable cannot connect directly to a

controller, a15 foot (4.57m) non-sensing leader cable is required (included in a leader cable

kit: part #LC-KIT). Connect the leader cable wires to TB2 as follows, and connect the sensing

cable to the leader cable.

TB2-1 White wire

TB2-2 Black wire

TB2-3 Green wire

TB2-4 Red wire

2.1.4 P2: RJ45 Network

A 10/100 Ethernet connection is available to connect the LD1500 on a local area network. Use

a crossover cable for initial connection and configuration. The default settings are as follows:

IP Address: 10.0.0.188

Subnet Mask: 255.255.255.0

rletech.com LD1500 User Guide 15

2 Connections and Indicators

2.1.5 SW1.1: Ethernet Port Configuration

Switch SW1.1, when switched DOWN, enables 10/100BASE-T Auto Negotiate. When

switched UP, it locks the Ethernet port in 100BASE-T. Auto Negotiate does not work with

some gigabit switches; therefore, the LD1500 ships with switch SW1.1 in the UP, 100BASE-

T locked, position.

2.1.6 SW1.2:EIA-485 Termination

Switch SW1.2, when switched ON (DOWN), places a termination resistor across the + and -

terminals of the EIA-485 port. This is used when the LD1500 is the last unit on an EIA-485

network.

2.1.7 TB3: EIA-485 Modbus Port

TB4 connects to an EIA-485 network. A grounded shield contact is provided for connection to

shielded cable. If the shield contact is used, verify the power connector is properly grounded

and there is no voltage potential between units on the network. The EIA-485 port is set to 8

data bits, no parity, and 1 stop bit (8, N, 1). Connect the EIA-485 wires to TB4 as follows:

TB3-1 A (+)

TB3-2 B (-)

TB3-3 Shield

2.1.8 P4: EIA-232 Connector

The EIA-232 uses a baud rate of 9600. The EIA-232 port is set to 8 data bits, no parity, and 1

stop bit (8, N, 1). A straight through cable should be used to connect a terminal or PC to the

LD1500. This connection should only be used for Setting of the IP address, advanced

diagnostics, firmware uploading, and troubleshooting only.Connections and Default Settings

2.2. Indicators

2.2.1 Status LED

The front panel of the LD1500 features a status LED. This LED blinks once every two seconds

to indicate the firmware on the LD1500 is running and active.

16 LD1500 User Guide 800.518.1519

2 Connections and Indicators

rletech.com LD1500 User Guide 17

CHAPTER

CHAPTER 0INSTALLATION

3.1. Installing the LD1500

The LD1500 is a wall mounted device. There are four mounting holes on the sides of the unit

spaced 6.6 inches (.167m) apart. Use drywall anchors if securing the unit to drywall.

3.2. Connecting the Leak Detection Cable

The LD1500 is shipped with a 15-foot (4.57m) leader cable. One end of this leader cable

connects to the LD1500 controller, and the other end connects to the SeaHawk sensing cable.

Connect each end of the leader cable as follows:

1With the screws of the terminal block connector on the LD1500 facing up, connect the four

stripped, bare wires of the leader cable to the terminals in this order, from left to right:

white, black, green, red. Tighten the screws to secure the ends of the leader cable, and plug

the connector into TB2. Make sure the wires, from left to right, are in the white-black-

green-red order.

Note If the terminal connector is removed from the end of the cable, make sure the wires are in

white-black-green-red order when the connector is reapplied.

2Unscrew the end-of-line (EOL) terminator from the other end of the leader cable.

3Attach the first length of leak detection cable (sensing cable) to the leader cable.

Figure 3.1

SeaHawk Sensing Cable

18 LD1500 User Guide 800.518.1519

3 Installation

4Route the sensing cable according to a cable layout diagram, if provided.

5Secure the EOL terminator on the unoccupied end of the sensing cable.

Note It is important to finish the end of the SeaHawk Water Leak Detection Cable (sensing cable)

with the end terminator (EOL). If the EOL terminator is not present, a cable fault will register.

Note any variances between the cable layout diagram and the actual cable installation.

3.2.1 Securing Cable to the Floor

Secure the sensing cable to the floor with either J-clips, or one of the other approved methods

shown in Figure 3.2. J-clips, available from RLE and designed specifically for use with

sensing cable, are the manufacturer's recommended installation method and can be installed as

follows:

♦ Place one J-clip every 5 to 6 feet (1.52 to 1.83m) along the length of the sensing cable and

one at each turn of the cable. Use more J-clips if a “tighter” configuration is required.

♦ If the cable is installed over an obstruction, place a J-clip on the cable on both sides, as

close to the obstruction as possible.

Do not install the cable directly in front of an air conditioner. Allow a minimum of 4

to 6 feet (1.22 to 1.83m) between the unit and the cable. If the cable is too close to

the air conditioning unit’s air stream, the moisture from the humidifier may cause

false leak readings. If the cable must be installed in front of an air conditioning

unit, place the J-clips 12 to 18 inches (.305 to .457m) apart.

Figure 3.2

Cable Installation Methods

WARNING

rletech.com LD1500 User Guide 19

3 Installation

3.3. Applying Power to the LD1500

Once the SeaHawk sensing cable is connected to the unit, power can be applied. The LD1500

requires an isolated power supply. A power supply is not included with the LD1500. If you

wish to use 24VDC power, the LD1500 requires RLE power supply PSWA-DC-24 (not

included - purchase separately from RLE). If you wish to use AC power, the LD1500 requires

RLE power supply WA-AC-24 (not included - purchase separately from RLE).

Run an isolated power supply to the location of the unit.

Before applying power to the unit, ensure all cable and communication connections are

complete. The LD1500 begins booting once power is applied. Wait approximately one minute.

No alarm should be present.

On the web page interface, the cable length is displayed. If this reading varies by more than

±5% of the actual length of cable installed, verify the installation. The LD1500 should not

require any calibration. If any calibration is required, verify that the cable current is 0 (zero)

before calibrating or false and inaccurate readings will occur.

3.4. Communication

The LD1500 will not communicate over a user's network the first time it is connected to the

network. The manufacturer programs the LD1500 with a default IP address: 10.0.0.188,

subnet: 255.255.255.0 and gateway (Def Route): 10.0.0.1. These settings must be changed to

IP addresses that correspond with the user's network before the LD1500 can communicate

over the network.

3.4.1 Set the LD1500's IP Address

♦ Via the Web browser

♦ Via the EIA-232 interface

3.4.1.1 Set the LD1500's IP Address Using a Web Browser

1Plug a crossover network cable into the laptop or workstation that will be used to configure

the LD1500. This cable is not intended to be connected to a network hub.

2Write down the computer's IP address and Subnet Mask. Then change the IP address and

Subnet Mask of the computer from its existing address to one that will allow it to

communicate with the LD1500, such as 10.0.0.190. It may be beneficial to set the IP

address to one that is one number different from the Falcon's IP address. Consult the

computer's manual or your IT Department before attempting this.

3Connect the other end of the network cable to the Ethernet port on the LD1500. Access the

LD1500 through a Web browser by typing the IP address into the location bar. Enter the

LD1500 user name and password when prompted.

Note The default user name is “

ld1500

” (use all lowercase, as user name is case sensitive).

There is no default password — leave the password field empty.

4Select the Configuration Menu link, then select the Network Settings link. Change the IP

address, Subnet Mask, and Def Route to ones provided by the network administrator. Press

the Submit Changes button. The LD1500 will save the new IP address and reboot. You

20 LD1500 User Guide 800.518.1519

3 Installation

must now use the new IP address and reset your computer to its original IP address and

Subnet Mask.

5Change the IP address of your computer back to its original IP address. If the computer was

configured as DHCP (the network domain controller assigns an IP address) return it to this

state. This may require assistance from your IT Department, or you may need to consult the

computer's manual

6The computer and the LD1500 are now both configured to communicate on the network.

Both should be accessible via the network. Connect the PC and the LD1500 to the network.

From the PC Web browser, type in the IP address of the LD1500. Enter the user name and

password as stated above to verify network access to the LD1500.

3.4.1.2 Set the LD1500’s IP Address using an EIA-232 Connection

To use the EIA-232 interface:

1Connect the EIA-232 port (P4) on the LD1500 to a terminal or PC running terminal

emulation software (such as HyperTerminal) with a 9-pin male-female straight through

serial cable.

2Set the appropriate communication port to 9600 baud, 8 data bits, no parity, 1 stop bit

(9600/N/8/1), and no software or hardware flow command.

3Once the terminal emulation software starts, type ? and press ENTER on the keyboard and

the Main Menu should appear. If the Main Menu does not appear, check the communication

settings and make sure the unit is powered on.

4From the Main Menu type “netcfg” to select the Network Configuration Menu.

5Enter the new IP address for the LD1500 by typing ip xxx.xxx.xxx.xxx where

xxx.xxx.xxx.xxx is the new IP address of the unit. Separate each field with a decimal point

— for example, type ip 10.0.0.50 <enter>.

6The LD1500 will erase a memory block and copy data to Flash memory before rebooting.

7The LD1500 IP address is now set and the LD1500 can be accessed through a Web browser

using the new IP address.

8Repeat steps 4-7 to change the Subnet Mask and Def Route, if needed, using the commands

nm xxx.xxx.xxx.xxx to change the Subnet Mask and dg xxx.xxx.xxx.xxx to change the

default gateway.

Table of contents

Other RLE Technologies Controllers manuals

RLE Technologies

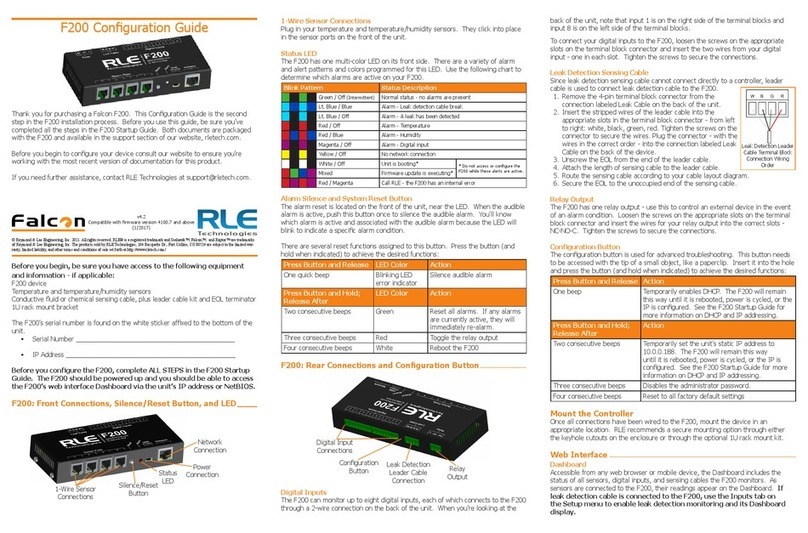

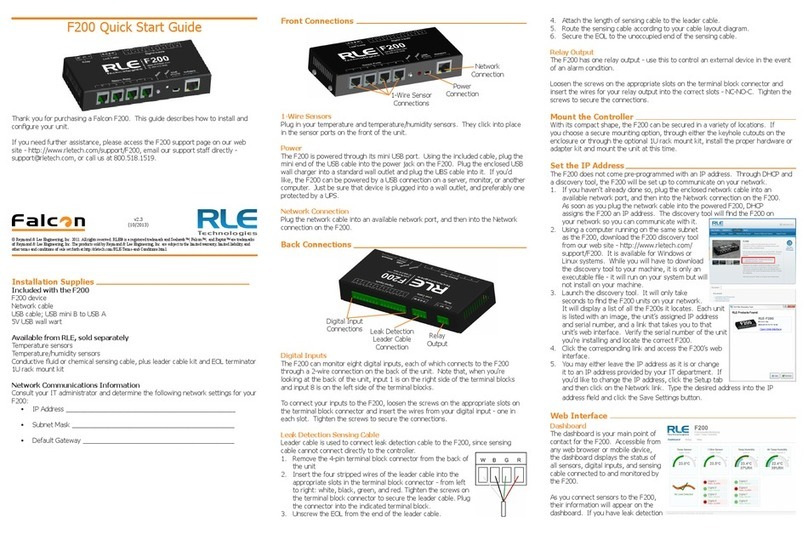

RLE Technologies Falcon F200 User manual

RLE Technologies

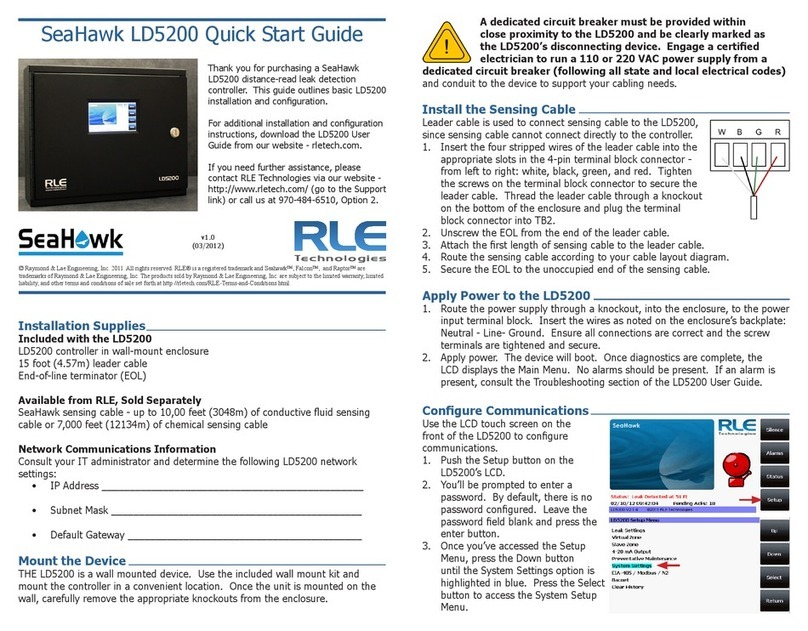

RLE Technologies SeaHawk LD5200 User manual

RLE Technologies

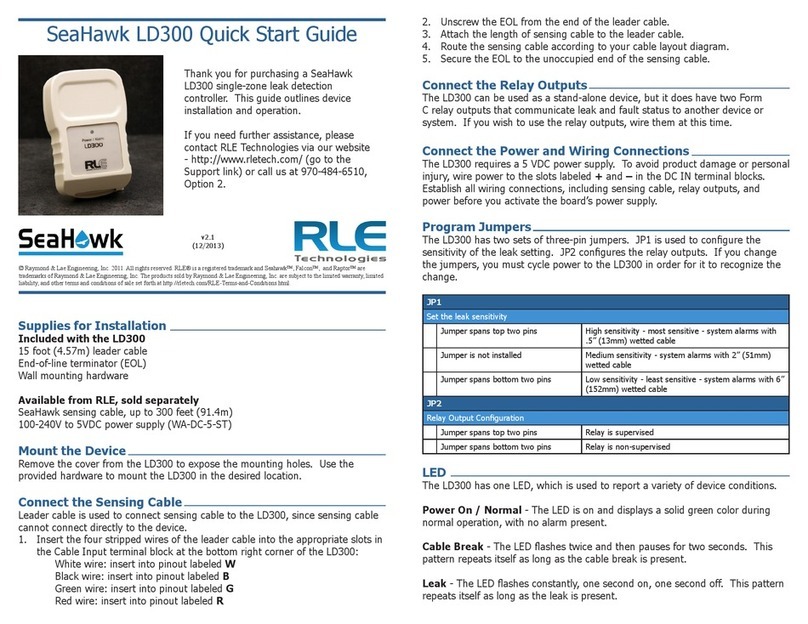

RLE Technologies SeaHawk LD300 User manual

RLE Technologies

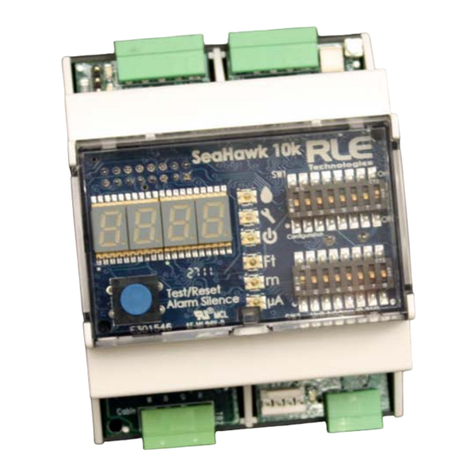

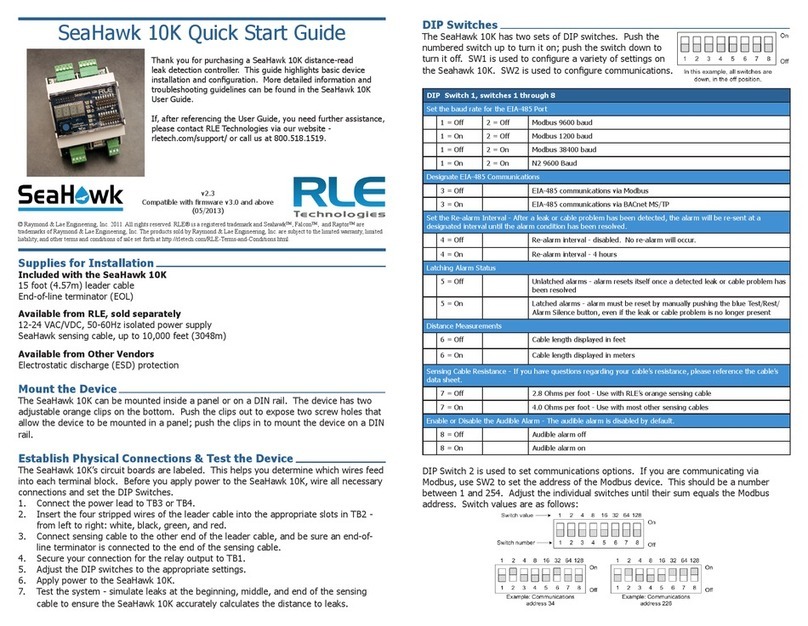

RLE Technologies SeaHawk 10K User manual

RLE Technologies

RLE Technologies SeaHawk 10K User manual

RLE Technologies

RLE Technologies Falcon F200 Operating and maintenance instructions

RLE Technologies

RLE Technologies SeaHawk LD5200 User manual

RLE Technologies

RLE Technologies SeaHawk LD310 User manual